Professional Documents

Culture Documents

PS40 Pressure Switches

PS40 Pressure Switches

Uploaded by

nvhoang0185Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PS40 Pressure Switches

PS40 Pressure Switches

Uploaded by

nvhoang0185Copyright:

Available Formats

MODEL PS40

PRESSURE SWITCH

(UL, cUL, and CSFM Listed, FM and LPC Approved, NYMEA

Accepted, CE Marked Pending)

Dimensions: 3.78" (9,6cm)W x 3.20" (8,1cm)D x 4.22" (10,7cm)H

Conduit Entrance: Two knockouts provided for 1/2" conduit. Individual

switch compartments and ground screw suitable for

dissimilar voltages

Enclosure: Cover- Die-cast with textured red powdercoat finish, single

cover screw and rain lip.

Base- Die-cast

Pressure Connection: Nylon 1/2" NPT male

Factory Adjustment: PS40-1 operates on decrease at 30 PSI (2,1 BAR)

PS40-2 operates in increase at 50 PSI (3,5 BAR)

and on decrease at 30 PSI (2,1 BAR)

Pressure Range: 10-60 PSI (,7 - 4,1 BAR)

Maximum Differential: Approximately 1 lb. at 10 PSI (,07 at ,7 BAR)

4 lbs at 60 PSI (,28 at 4,1 BAR)

Maximum System Pressure: 250 PSI (17,2 BAR)

Switch Contacts: SPDT (Form C)

10.1 Amps at 125/250VAC, 2.0 Amps at 30VDC

One SPDT in PS40-1, Two SPDT in PS40-2

Environmental Specifications:

NEMA 4/IP55 Rated Enclosure - indoor or outdoor when used

with NEMA 4 conduit fittings.

Temperature range: -40°F to 140°F (-40°C to 60°C)

Tamper: Cover incorporates tamper resistant fastener that requires a

special key for removal. One key is supplied with each device.

Ordering Information For optional cover tamper switch kit, order Stock No. 0090200.

Model Description Stock No. See bulletin #5401200 PSCTSK.

PS40-1 Pressure switch with one set SPDT contacts 1340403 Service Use:

PS40-2 Pressure switch with two sets SPDT contacts 1340404 Automatic Sprinkler NFPA-13

Hex Key 5250062 One or two family dwelling NFPA-13D

Cover Tamper Switch Kit 0090200 Residential Occupancy up to four stories NFPA-13R

BVL Bleeder valve 1000018 National Fire Alarm Code NFPA-72

Installation

The Potter PS40 Series Pressure Actuated Switches are designed primarily to 4. Connect the wires to the appropriate terminal connections for the

detect an increase and/or decrease from normal system pressure in automatic service intended. See Figures 2,4,5,6, and 8

fire sprinkler systems. Typical applications are: Dry pipe system, pre-action

Adjustment And Testing

air/nitrogen supervision, pressure tanks, air supplies, and water supplies.

The operation of the pressure supervisory switch should be tested upon

The PS40 switch is factory set for 40 PSI (2,8 BAR) normal system pressure.

completion of installation and periodically thereafter in accordance with

The switch marked with the word LOW is set to operate at a pressure decrease

the applicable NFPA codes and standards and/or the authority having

of 10 PSI (,7 BAR) at 30 PSI (2,1 BAR). The switch marked with the word

jurisdiction (manufacturer recommends quarterly or more frequently).

HIGH is set to operate at a pressure increase of 10 PSI (,7 BAR) at 50 PSI

Note: Testing the PS40 may activate other system connected devices.

(3,5 BAR). See section heading Adjustments and Testing if other than

The use of a Potter BVL (see product bulletin 8900067 for details) is

factory set point is required.

recommended to facilitate setting and testing of the PS40 pressure switch.

1. Connect the PS40 to the system side of any shutoff or check valve.

When a BVL (bleeder valve) is used, the pressure to the switch can be

2. Apply Teflon tape to the threaded male connection on the device.

isolated and bled from the exhaust port on the BVL without effecting the

(Do not use pipe dope)

supervisory pressure of the entire system. See Fig. 3

3. Device should be mounted in the upright position.

The operation point of the PS40 Pressure Switch can be adjusted to any

(Threaded connection down)

point between 10 and 60 PSI (0,7 - 4,11 BAR) by turning the adjustment

4. Tighten the device using a wrench on the flats on the device.

knob(s) clockwise to raise the actuation point and counter clockwise to

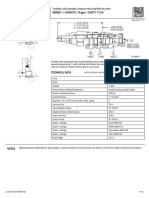

Wiring Instructions lower the actuation point. In the case of the PS40-2, both switches operate

1. Remove the tamper resistant screw with the special key provided. independent of each other. Each switch may be independently adjusted to

2. Carefully place a screwdriver on the edge of the knockout and sharply actuate at any point acrosss the switch adjustment range. Initial adjustment

apply a force sufficient to dislodge the knockout plug. See Fig. 9 can be made with a visual reference from the top of the adjustment knob

3. Run wires through an approved conduit connector and affix the across to the printed scale on the switch bracket. Final adjustments should

connector to the device. A NEMA-4 rated conduit fitting is be verified with a pressure gauge.

required for outdoor use.

Potter Electric Signal Company • 2081 Craig Road, St. Louis, MO, 63146-4161 • Phone: 800-325-3936/Canada 888-882-1833 • www.pottersignal.com

PRINTED IN USA MFG. #5400930 - 9/07 PAGE 1 OF 3

REV C

MODEL PS40

PRESSURE SWITCH

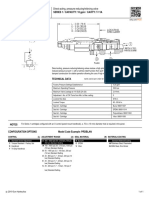

Dimensions Switch Clamping Plate Terminal

Fig. 1 Fig. 2

GROUND

NG

SCREWS MI

2.87 CO

IN

[72.97]

ADJUSTMENT

KNOB 4.22

[107.19]

NG

1/2" NPT OI DWG# 923-3

TG

OU

2.48 1.60

[62.87] [40.64]

3.78 3.20

[95.89] [81.28]

NOTE: To prevent leakage, apply teflon tape sealant to male threads only.

An uninsulated section of a single conductor

should not be looped around the terminal and

serve as two separate connections. The wire

must be severed, thereby providing supervision

of the connection in the event that the wire

becomes dislodged from under the terminal.

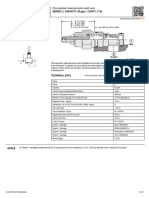

Typical Sprinkler Applications

Fig. 3

PS40

AIR LINE

SHUT-OFF PS10 Closing of any shutoff valves between the

VALVE BLEEDER ALARM

TEST PRESSURE alarm check valve and the PS10 will render

CHECK VALVE SWITCH the PS10 inoperative. To comply with NFPA-

VALVE BVL

WATER 72 any such valve shall be electrically

MOTOR

GONG supervised with a supervisory switch such as

CHECK RBVS

DRY PIPE VALVE Potter Model RBVS.

VALVE

WATER

DWG. #924-1A BY-PASS

OS & Y

TEST

VALVE

VALVE

Typical Connections

Fig. 4

WITH NORMAL SYSTEM PRESSURE PS40-1 PS40-2

APPLIED LOW -TERMINAL 2

CLOSES ON PRESSURE DROP.

TO FIRE

ALARM

PANEL HIGH

AIR

COM 1 2

2 1 COM

COM 1 2

WITH NORMAL SYSTEM

LOW PRESSURE APPLIED HIGH

TO FIRE EOLR AIR - TERMINAL 1 WILL CLOSE

ALARM ON PRESSURE INCREASE.

PANEL

EOLR

PRINTED IN USA MFG. #5400930 - 9/07 PAGE 2 OF 3

REV C

MODEL PS40

PRESSURE SWITCH

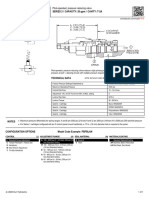

Low Pressure Signal Connection High Pressure Signal Connection One Conduit Wiring

Fig. 5 Fig. 6 Fig. 7

Break out thin section of divider to provide path for wires

TO FIRE ALARM PANEL TO FIRE ALARM PANEL

when wiring both switches from one conduit entrance.

EOLR EOLR

Changing Pressure Removing Knockouts

(With normal system pressure) Fig. 9

Fig. 8

LOW PRESSURE SWITCH

NC

For low pressure

C

use: Com and

Terminal 1 NO

C 1 2

HIGH PRESSURE SWITCH

NC

For waterflow

use: Com and C

Terminal 2 NO

C 1 2

Engineer/Architect Specifications Pressure Type Waterflow Switch

Pressure type supervisory switches; shall be a Model PS40 as manufactured by

Potter Electric Signal Company, St. Louis, MO., and shall be installed on the fire

•Installation must be performed by qualified personnel and in accordance with all

sprinkler system as shown and or specified herein.

national and local codes and ordinances.

Switches shall be provided with a 1/2" NPT male pressure connection to be •Shock hazard. Disconnect power source before servicing. Serious injury or death

connected into the air supply line on the system side of any shut-off valve. A could result.

Model BVL bleeder valve as supplied by Potter Electric Signal Company of St. •Read all instructions carefully and understand them before starting installation.

Louis, MO., or equivalent shall be connected in line with the PS40 to provide a Save instructions for future use. Failure to read and understand instructions could

means of testing the operation of the supervisory switch. (See Fig. 3) result in improper operation of device resulting in serious injury or death.

•Risk of explosion. Not for use is hazardous locations. Serious injury or death could result.

The switch unit shall contain SPDT (Form C) switch(es). One switch shall be

set to operate at a pressure decrease of 10 PSI (0,7 BAR) from normal. If two

switches are provided, the second switch shall be set to operate at a pressure

increase of 10 PSI (0,7 BAR) from normal.

Switch contacts shall be rated at 10.1 Amps at 125/250VAC and 2.0 Amps at

30VDC. The units shall have a maximum pressure rating of 250 PSI (17,2 BAR) •Do not tighten by grasping the switch enclosure. Use wrenching flats on the bushing

only. Failure to install properly could damage the switch and cause improper operation

and shall be adjustable from 10 to 60 PSI (0,7 to 4,1 BAR). resulting in damage to equipment and property.

Pressure switches shall have two conduit entrances, one for each individual switch •To seal threads, apply Teflon tape to male threads only. Using joint compounds or

compartment to facilitate the use of dissimilar voltages for each individual switch. cement can obstruct the pressure port inlet and result in improper device operation and

The cover of the pressure switch shall be zinc die-cast with rain lip and shall attach damage to equipment.

with one tamper resistant screw. The pressure switch shall be suitable for indoor or •Do not over tighten the device, standard piping practices apply.

outdoor service with a NEMA-4/IP55 rating.

The pressure switch shall be UL, ULC, and CSFM listed, FM and LPC approved

and NYMEA accepted.

PRINTED IN USA MFG. #5400930 - 9/07 PAGE 3 OF 3

REV C

You might also like

- ITP For Installation & Leakage Test For HVAC Ducts and AccessoriesDocument1 pageITP For Installation & Leakage Test For HVAC Ducts and AccessoriesDong VanraNo ratings yet

- Inspection and Test Plan Piping Work ActivitiesDocument2 pagesInspection and Test Plan Piping Work ActivitiesAbram Berkat100% (2)

- Indoor Olympic ArenaDocument40 pagesIndoor Olympic ArenaBelal AlmokdadNo ratings yet

- PS40Document3 pagesPS40LeoNo ratings yet

- PS40VDSEngGermanDocument8 pagesPS40VDSEngGermanRafael TrianaNo ratings yet

- PS120Document4 pagesPS120ErickNo ratings yet

- Potter Pressure SwitchDocument2 pagesPotter Pressure SwitchK SubramaniNo ratings yet

- Pressure SwitchDocument2 pagesPressure Switchmuhammad ismailNo ratings yet

- Model Ps10: Pressure SwitchDocument6 pagesModel Ps10: Pressure SwitchNatasha HickmanNo ratings yet

- PS25 para Altas Variaciones de PresionDocument8 pagesPS25 para Altas Variaciones de PresionHIDRUCOL SASNo ratings yet

- Ps10 Series: Pressure SwitchDocument3 pagesPs10 Series: Pressure SwitchCarlos Correa SalasNo ratings yet

- PS10Document3 pagesPS10LeoNo ratings yet

- Wet Alarm Pressure Switch PS10Document4 pagesWet Alarm Pressure Switch PS10asimnaqvi2008No ratings yet

- System Sensor Pressure Switch Model EPS40-2Document2 pagesSystem Sensor Pressure Switch Model EPS40-2Brandon TrocNo ratings yet

- PotterDocument4 pagesPotterCamilo AyalaNo ratings yet

- 3-Pressure Switch 10 A ManualDocument2 pages3-Pressure Switch 10 A Manualnasir khanNo ratings yet

- RPEI en Us A4Document1 pageRPEI en Us A4Rafael GoulartNo ratings yet

- Relife Valve Rpeclnn - Pilot OperatedDocument2 pagesRelife Valve Rpeclnn - Pilot OperatedHassan KhattabNo ratings yet

- PS3 SerieDocument10 pagesPS3 SerieMadmomNo ratings yet

- Relief Valve VENTABLE RVCALAN - T11A RV1Document1 pageRelief Valve VENTABLE RVCALAN - T11A RV1Hassan KhattabNo ratings yet

- Modelo Pilot-Operated, Reductor de Presión Válvula: Series 1 / Capacidad: 40 L/Min. / Cavidad: T-11ADocument2 pagesModelo Pilot-Operated, Reductor de Presión Válvula: Series 1 / Capacidad: 40 L/Min. / Cavidad: T-11AVictor CMNo ratings yet

- Modelo Pilot-Operated, Reductor/alivio de Presión Válvula: Series 1 / Capacidad: 40 L/Min. / Cavidad: T-11ADocument1 pageModelo Pilot-Operated, Reductor/alivio de Presión Válvula: Series 1 / Capacidad: 40 L/Min. / Cavidad: T-11AJonathanDavidDeLosSantosAdornoNo ratings yet

- Model Direct-Acting, Pressure Reducing/relieving Valve With Drain To Port 4Document1 pageModel Direct-Acting, Pressure Reducing/relieving Valve With Drain To Port 4mhasansharifiNo ratings yet

- Model Direct-Acting, Pressure Reducing/relieving Valve: Series 2 / Capacity: 20 GPM / Cavity: T-2ADocument1 pageModel Direct-Acting, Pressure Reducing/relieving Valve: Series 2 / Capacity: 20 GPM / Cavity: T-2AleosignareNo ratings yet

- PPDB en Us A4Document1 pagePPDB en Us A4Felipe DiazNo ratings yet

- Model Ventable, Pilot Operated, Balanced Piston Relief ValveDocument2 pagesModel Ventable, Pilot Operated, Balanced Piston Relief ValveErasmo LimaNo ratings yet

- Model Direct-Acting, Pressure Reducing/relieving Valve: Series 1 / Capacity: 10 GPM / Cavity: T-11ADocument1 pageModel Direct-Acting, Pressure Reducing/relieving Valve: Series 1 / Capacity: 10 GPM / Cavity: T-11AmhasansharifiNo ratings yet

- PRDBOEN Full en Us LetterDocument3 pagesPRDBOEN Full en Us LetterPartagon PowNo ratings yet

- P499 Series Electronic Pressure Transducers: DescriptionDocument3 pagesP499 Series Electronic Pressure Transducers: Descriptionahmed saberNo ratings yet

- A05 0939Document2 pagesA05 0939Argile-assholeNo ratings yet

- DRBCLBN Full Es Us A4Document2 pagesDRBCLBN Full Es Us A4Erasmo LimaNo ratings yet

- Model Anti-Shock, Pilot-Operated, Balanced Poppet Relief ValveDocument2 pagesModel Anti-Shock, Pilot-Operated, Balanced Poppet Relief ValveJustinNo ratings yet

- RPGC Full en Us A4Document2 pagesRPGC Full en Us A4zapchasty29No ratings yet

- Modelo 3-Vías, Acción-Directa, Direccional Válvula Con Drenaje Interno Al Puerto 3 (1 Bloqueado, 2 A 3 Abierto)Document1 pageModelo 3-Vías, Acción-Directa, Direccional Válvula Con Drenaje Interno Al Puerto 3 (1 Bloqueado, 2 A 3 Abierto)Erasmo LimaNo ratings yet

- Model 3-Way, Direct-Acting, Directional Valve With Internal Drain To Port 3 (1 Blocked, 2 To 3 Open)Document2 pagesModel 3-Way, Direct-Acting, Directional Valve With Internal Drain To Port 3 (1 Blocked, 2 To 3 Open)Erasmo LimaNo ratings yet

- PPDBLAN Es Metric LetterDocument1 pagePPDBLAN Es Metric Lettersebastian.vegaNo ratings yet

- 1.fisa Tehnica Detector Curgere PDFDocument10 pages1.fisa Tehnica Detector Curgere PDFHeart StoneNo ratings yet

- PX409 UsbDocument3 pagesPX409 UsbLaszlo MolnarNo ratings yet

- 30-30 Pulse Width Modulation ValvesDocument8 pages30-30 Pulse Width Modulation ValvesMechanical PowerNo ratings yet

- RDDALDN Full en Us A4Document3 pagesRDDALDN Full en Us A4clark jonesNo ratings yet

- Model Direct-Acting Relief Valve: CAPACITY: 12 GPM / CAVITY: T-162ADocument1 pageModel Direct-Acting Relief Valve: CAPACITY: 12 GPM / CAVITY: T-162AmhasansharifiNo ratings yet

- PRDC Sun ValveDocument3 pagesPRDC Sun ValvekhairulanuarjunNo ratings yet

- FT2 Flow Temperature Thermal Mass TransmitterDocument4 pagesFT2 Flow Temperature Thermal Mass TransmitterJulian GaleanoNo ratings yet

- RVCALCN Full en Us A4Document2 pagesRVCALCN Full en Us A4Felipe DiazNo ratings yet

- VS - SPDocument2 pagesVS - SPmc isipNo ratings yet

- VSR - Eu: Vane Type Waterflow Alarm Switch With RetardDocument10 pagesVSR - Eu: Vane Type Waterflow Alarm Switch With RetardGrafakos StavrosNo ratings yet

- PBFB en Us A4Document1 pagePBFB en Us A4operacion hydratekNo ratings yet

- Waterflow Switch VSR - Potter ElectricDocument8 pagesWaterflow Switch VSR - Potter ElectricXioNo ratings yet

- SUN RPGC-JCN (Relief Valve)Document3 pagesSUN RPGC-JCN (Relief Valve)ful islamNo ratings yet

- Parker 07f31ac DimensionesDocument7 pagesParker 07f31ac DimensionesJair Mata CuencaNo ratings yet

- PVDB Full en Us LetterDocument2 pagesPVDB Full en Us LetterIsrael RuizNo ratings yet

- Honeywell-Sensing-Switch-5000 Series-Productsheet PDFDocument2 pagesHoneywell-Sensing-Switch-5000 Series-Productsheet PDFshahrukhNo ratings yet

- Swith74380 PDFDocument2 pagesSwith74380 PDFLe DungNo ratings yet

- SUN RPGC-LAN (Relief Valve)Document3 pagesSUN RPGC-LAN (Relief Valve)ful islamNo ratings yet

- Model Ventable, Pilot-Operated, Balanced Piston Relief ValveDocument2 pagesModel Ventable, Pilot-Operated, Balanced Piston Relief ValveGamal El Deen KamalNo ratings yet

- Model Direct-Acting Relief Valve: Series 2 / Capacity: 50 GPM / Cavity: T-3ADocument2 pagesModel Direct-Acting Relief Valve: Series 2 / Capacity: 50 GPM / Cavity: T-3AJustinNo ratings yet

- Model Direct-Acting Relief Valve: SERIES 3 / CAPACITY: 380 L/min. / CAVITY: T-16ADocument1 pageModel Direct-Acting Relief Valve: SERIES 3 / CAPACITY: 380 L/min. / CAVITY: T-16APRASHANT KANTENo ratings yet

- Valvula Reguladora Continental PBFB-LAVDocument1 pageValvula Reguladora Continental PBFB-LAVsalesparts.norvateNo ratings yet

- Pressure Reducing - Relieving Valve PRFBDocument3 pagesPressure Reducing - Relieving Valve PRFBkocho79No ratings yet

- Series 1950 Explosion-Proof Differential Pressure Switches: Specifications - Installation and Operating InstructionsDocument2 pagesSeries 1950 Explosion-Proof Differential Pressure Switches: Specifications - Installation and Operating InstructionsJavi MosqueraNo ratings yet

- 2D51 Duct Smoke Detector For Special ApplicationsDocument4 pages2D51 Duct Smoke Detector For Special ApplicationsmotaNo ratings yet

- Radio Shack TRS-80 Expansion Interface: Operator's Manual: Catalog Numbers: 26-1140, 26-1141, 26-1142From EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual: Catalog Numbers: 26-1140, 26-1141, 26-1142No ratings yet

- Code No. 22 23Document1 pageCode No. 22 23nvhoang0185No ratings yet

- Air DistributionDocument84 pagesAir Distributionnvhoang0185No ratings yet

- COVNA WCB Wedge Gate Valve SpecificationDocument1 pageCOVNA WCB Wedge Gate Valve Specificationnvhoang0185No ratings yet

- Ty Trong Cua Khi - YOSHITAKEDocument3 pagesTy Trong Cua Khi - YOSHITAKEnvhoang0185No ratings yet

- 34 A48y Safety Relief ValveDocument1 page34 A48y Safety Relief Valvenvhoang0185No ratings yet

- COVNA Swing Type Check Valve SpecificationDocument1 pageCOVNA Swing Type Check Valve Specificationnvhoang0185No ratings yet

- COVNA Brass ProductsDocument35 pagesCOVNA Brass Productsnvhoang0185No ratings yet

- OrganoVN Brochure 2017Document8 pagesOrganoVN Brochure 2017nvhoang0185No ratings yet

- Neumax CatalogDocument5 pagesNeumax Catalognvhoang0185No ratings yet

- Part Submission Warrant: Organization Manufacturing Information Customer Submittal InformationDocument1 pagePart Submission Warrant: Organization Manufacturing Information Customer Submittal InformationJuan HernandezNo ratings yet

- Meadow Burke Lifting Tilt Up Panels Technical Notes 430701 PDFDocument6 pagesMeadow Burke Lifting Tilt Up Panels Technical Notes 430701 PDFKantishNo ratings yet

- Method of Statement: Grouting Under Steel BracketsDocument12 pagesMethod of Statement: Grouting Under Steel Bracketsfaisal nadeemNo ratings yet

- Question PaperDocument30 pagesQuestion Papervaishnavi mathapatiNo ratings yet

- Abrasion Test of AggregatesDocument9 pagesAbrasion Test of AggregatesDakshraj RathodNo ratings yet

- Asphalt Emulsions STP1079-EB.30067 PDFDocument117 pagesAsphalt Emulsions STP1079-EB.30067 PDFSri RamyaNo ratings yet

- COP-WFP-CHK-02-2013-v1 Cable Tray InstallationDocument3 pagesCOP-WFP-CHK-02-2013-v1 Cable Tray InstallationAbdul AzizNo ratings yet

- SASO 335 GS 78 Industrial Safety and Health Regulations Electrical Part 4: IlluminationDocument4 pagesSASO 335 GS 78 Industrial Safety and Health Regulations Electrical Part 4: IlluminationMohamed AbdinNo ratings yet

- ISO 17025 Accreditation - Thomas Bell Wright 4439 Testing-MultipleDocument8 pagesISO 17025 Accreditation - Thomas Bell Wright 4439 Testing-MultipleAmr EwisNo ratings yet

- Precast Cladding PanelsDocument12 pagesPrecast Cladding PanelsShreenidhi JoshiNo ratings yet

- High Voltage Live Work Procedures Distribution Insulated Stick 2015 05Document144 pagesHigh Voltage Live Work Procedures Distribution Insulated Stick 2015 05Pedro SarmientoNo ratings yet

- Plus+heat (Kai)Document4 pagesPlus+heat (Kai)Thanh Trung Nguyen PhanNo ratings yet

- Shivam Synopsis - SHIVAM PHADATAREDocument2 pagesShivam Synopsis - SHIVAM PHADATARENishantNo ratings yet

- Organic Architecture of Japan: Nina KonovalovaDocument7 pagesOrganic Architecture of Japan: Nina Konovalovaariel daffaNo ratings yet

- List of Construction Material Prices in The Philippines 2018 - PHILCON PRICESDocument16 pagesList of Construction Material Prices in The Philippines 2018 - PHILCON PRICESHamza82% (11)

- Technical - Emx-120 Quickmaster With ConveyorDocument14 pagesTechnical - Emx-120 Quickmaster With ConveyorJenriel CatulingNo ratings yet

- 1600 SQ FTDocument19 pages1600 SQ FTGeoDith MaganaNo ratings yet

- Saflok 700Document2 pagesSaflok 700Gireesh Krishna KadimiNo ratings yet

- Aloft Overside Work PDFDocument5 pagesAloft Overside Work PDFDank100% (1)

- Building Construction and Technology IV: Forth Semester, B.ArchDocument14 pagesBuilding Construction and Technology IV: Forth Semester, B.ArchRAVATNo ratings yet

- f32 - Information For Ready-Mixed Concrete CertificationDocument2 pagesf32 - Information For Ready-Mixed Concrete Certificationyun yen wongNo ratings yet

- Formwork Failure Study CaseDocument7 pagesFormwork Failure Study CaseElio SaldañaNo ratings yet

- CatalogueDEMCO GENERAL - BRO - V4Document2 pagesCatalogueDEMCO GENERAL - BRO - V4olympia sajuNo ratings yet

- AmpacityDocument3 pagesAmpacityjkNo ratings yet

- Office Space Interior B.O.Q. (Egypt)Document44 pagesOffice Space Interior B.O.Q. (Egypt)Moustapha AlgoharyNo ratings yet

- EIL Vendors ListDocument12 pagesEIL Vendors ListMohan Babu0% (1)

- Arvind Kumar Sahani: I.T.M. School of Architecture & Town Planing Lucknow-UpDocument25 pagesArvind Kumar Sahani: I.T.M. School of Architecture & Town Planing Lucknow-UpARVIND SAHANINo ratings yet