Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

9 viewsID Purge

ID Purge

Uploaded by

gtechkarthickThe document provides tables with guidelines for purge rates and pressures for tube welding using different tube sizes and wall thicknesses. It lists the minimum recommended purge rates in standard cubic feet per hour or liters per minute for each size, as well as the corresponding pressure ranges in inches of water column, mm of water column, or torr. It also provides recommended restrictor sizes to achieve the proper purge rates.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Acf Remover G 450 PDFDocument2 pagesAcf Remover G 450 PDFYoutube For EducationNo ratings yet

- Weld Cheat SheetDocument1 pageWeld Cheat SheetBruce BrownNo ratings yet

- Electromagnetic Flowmeter User Manual Combined KFL DCDocument35 pagesElectromagnetic Flowmeter User Manual Combined KFL DCSaravanan Mathi100% (1)

- Tank Cleaning GuideDocument53 pagesTank Cleaning Guideschjhdfi38100% (1)

- Soldering electronic circuits: Beginner's guideFrom EverandSoldering electronic circuits: Beginner's guideRating: 4.5 out of 5 stars4.5/5 (9)

- Welding Technology Two MarksDocument20 pagesWelding Technology Two Markssai100% (1)

- Section 25.: World Centre For Materials Joining TechnologyDocument36 pagesSection 25.: World Centre For Materials Joining Technologyjar_2100% (1)

- Sonicom NozzleDocument2 pagesSonicom NozzleRicardoNo ratings yet

- DY-LDG Manual - ENGDocument12 pagesDY-LDG Manual - ENGmerantinb.arifpeNo ratings yet

- KAFLON - Magnetic Flow Meter-CompressedDocument5 pagesKAFLON - Magnetic Flow Meter-CompressedDicky LeonardoNo ratings yet

- Alia AMF601 Electromagnetic FlowmeterDocument4 pagesAlia AMF601 Electromagnetic FlowmeterRexCrazyMindNo ratings yet

- B&C Minibrochure 2020 A4 ING LowDocument8 pagesB&C Minibrochure 2020 A4 ING LowGordon HarrisNo ratings yet

- Snap Action Switch: FeaturesDocument3 pagesSnap Action Switch: FeaturesAnita IonelaNo ratings yet

- HN10 / HN12 / HN15: Owner'S ManualDocument4 pagesHN10 / HN12 / HN15: Owner'S Manualchristopher ng'ang'a kamauNo ratings yet

- 274 en - US FactSheet - Main 01Document2 pages274 en - US FactSheet - Main 01Luisa FernandaNo ratings yet

- Process Engineering DesignDocument4 pagesProcess Engineering Designshakib nazmusNo ratings yet

- Transport PhenomenaDocument4 pagesTransport PhenomenaDynamix SolverNo ratings yet

- Starting Equipment RequiredDocument17 pagesStarting Equipment RequiredPortik RubenNo ratings yet

- OK Autrod 2209: Typical Tensile PropertiesDocument1 pageOK Autrod 2209: Typical Tensile PropertiesjavadmohammadiNo ratings yet

- Vacuum GVD 3-5 Datasheet NocropDocument2 pagesVacuum GVD 3-5 Datasheet NocropJohn KingNo ratings yet

- Flow SensorDocument8 pagesFlow SensorAchmad Nuriel AnwarNo ratings yet

- Estimates - Bill of QuantitiesDocument9 pagesEstimates - Bill of QuantitiesRoland CepedaNo ratings yet

- Caudalimetro Magnetico Heinrichs EpxDocument11 pagesCaudalimetro Magnetico Heinrichs EpxBase SistemasNo ratings yet

- Filter Press Mass Balance TemplateDocument11 pagesFilter Press Mass Balance TemplatesalesNo ratings yet

- Micro Bent Coriolis Flow Meter 1563792142Document5 pagesMicro Bent Coriolis Flow Meter 1563792142FREDDY YAJAMINNo ratings yet

- Snap Action Switch: FeaturesDocument3 pagesSnap Action Switch: Featuresdavid salazarNo ratings yet

- DIM Aaaa BBB EST ALV NNN ARR V01Document3 pagesDIM Aaaa BBB EST ALV NNN ARR V01Matheus AlvesNo ratings yet

- Thong S6 Ky Thuat: Hexagon NippleDocument2 pagesThong S6 Ky Thuat: Hexagon NippleNguyễn Trọng ThắngNo ratings yet

- en - US FactSheet - Main 01Document1 pageen - US FactSheet - Main 01Ganesh HileNo ratings yet

- EPX Data SheetDocument16 pagesEPX Data Sheetsaroat moongwattanaNo ratings yet

- Covered (Stick) Electrodes (SMAW)Document5 pagesCovered (Stick) Electrodes (SMAW)Hanny Dewi SaragihNo ratings yet

- Chufang Agri Spray Drone Catalogue & - PriceDocument1 pageChufang Agri Spray Drone Catalogue & - PriceHad AnzhrNo ratings yet

- Dibujo Industrial II Ing. Elkin PaduaDocument6 pagesDibujo Industrial II Ing. Elkin PaduaElkinNo ratings yet

- Ventstar-Oxylog-Pi-9102363-En-Master 4Document1 pageVentstar-Oxylog-Pi-9102363-En-Master 4Quyet PhungNo ratings yet

- Y Strainers-Floid EngineeringDocument16 pagesY Strainers-Floid EngineeringkobyrtaczNo ratings yet

- Transducer Specification Sheet Ultrasound 2009Document1 pageTransducer Specification Sheet Ultrasound 2009DiegoThomazSampaioNo ratings yet

- Maximum Flow in A Water Pipe For A Speed of 1.5 M/S: PipesDocument1 pageMaximum Flow in A Water Pipe For A Speed of 1.5 M/S: PipesSashini GaneshNo ratings yet

- Valori FiziologiceDocument2 pagesValori FiziologiceAndreea VicicăNo ratings yet

- Losa Aligerada 20Cm: Vu1 Vu2Document2 pagesLosa Aligerada 20Cm: Vu1 Vu2bryan carrascoNo ratings yet

- 11 - LZT - SPEC-RotametersWaterDocument3 pages11 - LZT - SPEC-RotametersWaterHeinium DannemannNo ratings yet

- Plant Capacity: 15 MGD Technology: Moving Bed Biological Reactor (MBBR)Document12 pagesPlant Capacity: 15 MGD Technology: Moving Bed Biological Reactor (MBBR)Dev Kumar DwivediNo ratings yet

- Schlumberger Case Hole Logging PSP - RevDocument15 pagesSchlumberger Case Hole Logging PSP - RevAung Htet LingNo ratings yet

- Ventilador Resu, Fisher & Paykel, Neopuff RD900, Manual Técnico, InglésDocument14 pagesVentilador Resu, Fisher & Paykel, Neopuff RD900, Manual Técnico, InglésDiegoNo ratings yet

- Universal Spray Nozzles Product ComparisonDocument3 pagesUniversal Spray Nozzles Product ComparisonNordson Adhesive Dispensing SystemsNo ratings yet

- 4286-01 2Document28 pages4286-01 2rp801113717No ratings yet

- Solenoid Valve CatalogDocument21 pagesSolenoid Valve CatalogDeepikaNo ratings yet

- Rivulis F6150 English Metric 20190909 WebDocument6 pagesRivulis F6150 English Metric 20190909 WebMehdi BassouNo ratings yet

- Ri-F&p NeopuffDocument14 pagesRi-F&p NeopuffXimena PrietoNo ratings yet

- File PageDocument1 pageFile PageZhaahirRaafiQafilNo ratings yet

- Rivulis F7050 English Metric 20201224 WebDocument6 pagesRivulis F7050 English Metric 20201224 WebMehdi BassouNo ratings yet

- DownloadDocument2 pagesDownloadAHMED KAMESHNo ratings yet

- Sdf600 & Scf600 - Flow Chart-Fill Volume ChartDocument1 pageSdf600 & Scf600 - Flow Chart-Fill Volume ChartRamesh PeddagoudNo ratings yet

- Ds Thomas Picolino Vte-Dte Rotary VaneDocument12 pagesDs Thomas Picolino Vte-Dte Rotary Vanesemih KokNo ratings yet

- Maximum Operating TemperatureDocument3 pagesMaximum Operating TemperatureMuhammad UmairNo ratings yet

- Fiber To Yarn Spinning Process of Polyester FiberDocument12 pagesFiber To Yarn Spinning Process of Polyester FiberVinod Kumar100% (1)

- TOKAFlex Metric Imperial Spec Sheet Gecko Robotics 2021Document1 pageTOKAFlex Metric Imperial Spec Sheet Gecko Robotics 2021gorkembaytenNo ratings yet

- 9211-A01u-01 - 05 03 2017Document2 pages9211-A01u-01 - 05 03 2017spazzastura showNo ratings yet

- Torque Wrench Catalogue and Usage InstructionsDocument4 pagesTorque Wrench Catalogue and Usage InstructionsRamesh SinghNo ratings yet

- Type BSDType CSD Self Drilling ScrewsDocument2 pagesType BSDType CSD Self Drilling Screwscheow jongNo ratings yet

- Neopuff Technical ManualDocument14 pagesNeopuff Technical ManualCarlos CortesNo ratings yet

- 2.2.4 Elgard Mixed Metal Oxide Ribbon Mesh Rev.0 July 2020Document2 pages2.2.4 Elgard Mixed Metal Oxide Ribbon Mesh Rev.0 July 2020newdelhyNo ratings yet

- TREADMILLDocument2 pagesTREADMILLmaxor4242No ratings yet

- Losa Maciza en Una DireccionDocument1 pageLosa Maciza en Una Direccionbryan carrascoNo ratings yet

- Welding Processes: Production Technology EDPT 201 A. Prof. Dr. Yasser FouadDocument37 pagesWelding Processes: Production Technology EDPT 201 A. Prof. Dr. Yasser FouadAhmad OmarNo ratings yet

- Performance Analysis of A New Hybrid Cooling-Drying System: A B A BDocument21 pagesPerformance Analysis of A New Hybrid Cooling-Drying System: A B A BNuraini Abdul AzizNo ratings yet

- Gas Metal Arc Welding (GMAW) : University of Kuala Lumpur - Malaysia France InstituteDocument16 pagesGas Metal Arc Welding (GMAW) : University of Kuala Lumpur - Malaysia France InstituteKamarul Nizam100% (1)

- Jadual Kursus Cswip 3.1Document3 pagesJadual Kursus Cswip 3.1Wong Chung MengNo ratings yet

- Weld Tracking Spreadsheet WeldNoteDocument5 pagesWeld Tracking Spreadsheet WeldNotejorgekarlosprNo ratings yet

- Electric Duct Heater: Specification and Installation InstructionsDocument8 pagesElectric Duct Heater: Specification and Installation InstructionsDonald VelosoNo ratings yet

- Case Study (Albaum Et Al., 2016)Document2 pagesCase Study (Albaum Et Al., 2016)AdrianaAlquichireArzuzaNo ratings yet

- Weldhelp MatrixDocument1 pageWeldhelp MatrixJoel BrasilBorgesNo ratings yet

- ESAB Catalogo-Equipamentos ENDocument88 pagesESAB Catalogo-Equipamentos ENEdilsn CruzNo ratings yet

- 1 RWMA - Resistance-Welding-Literature-1Document3 pages1 RWMA - Resistance-Welding-Literature-1dneprmtNo ratings yet

- Overzicht en Iso 3834 Editie 2017 - Engels PDFDocument1 pageOverzicht en Iso 3834 Editie 2017 - Engels PDFrohit mathankerNo ratings yet

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Ramadhan AdityaNo ratings yet

- Rooftop Packaged Air Conditioners: CatalogDocument212 pagesRooftop Packaged Air Conditioners: CatalogRicardo Molina SánchezNo ratings yet

- API 650 Part 2Document20 pagesAPI 650 Part 2Naveen RajNo ratings yet

- Mig Mag Saw CswipDocument35 pagesMig Mag Saw CswipHamza DhariwalNo ratings yet

- Overview Fusion Welding StandardsDocument1 pageOverview Fusion Welding StandardspedroNo ratings yet

- Welding Visual Inspection FormatDocument2 pagesWelding Visual Inspection Formatgst ajah100% (3)

- Eiga Cryogenic Vaporisation SystemsDocument29 pagesEiga Cryogenic Vaporisation Systemseaang55No ratings yet

- Laporan Welding ProsmanDocument20 pagesLaporan Welding Prosmannadia frizaNo ratings yet

- Presentation Induction Heater Plant in Moscow Russia 2020Document21 pagesPresentation Induction Heater Plant in Moscow Russia 2020HIRENNo ratings yet

- Aircondition With PicturesDocument37 pagesAircondition With PicturesSaikat BiswasNo ratings yet

- E9018 G Welding ElectrodeDocument1 pageE9018 G Welding ElectrodeSai PrasathNo ratings yet

- Welding StandardsDocument14 pagesWelding Standardsnikidragon4u100% (1)

- 3-Actual Exams Last Edition (ASME IX)Document6 pages3-Actual Exams Last Edition (ASME IX)Hares SlalNo ratings yet

- Welding Guide For Hensley Products - Adapters NosesDocument48 pagesWelding Guide For Hensley Products - Adapters NosesMilorad ZelenovicNo ratings yet

- Welding: Engr. Dheylvin Roy P. BuenaventuraDocument8 pagesWelding: Engr. Dheylvin Roy P. BuenaventuraEarl Justin EnriqueNo ratings yet

- WeldingDocument16 pagesWeldingKhuda BukshNo ratings yet

ID Purge

ID Purge

Uploaded by

gtechkarthick0 ratings0% found this document useful (0 votes)

9 views1 pageThe document provides tables with guidelines for purge rates and pressures for tube welding using different tube sizes and wall thicknesses. It lists the minimum recommended purge rates in standard cubic feet per hour or liters per minute for each size, as well as the corresponding pressure ranges in inches of water column, mm of water column, or torr. It also provides recommended restrictor sizes to achieve the proper purge rates.

Original Description:

ID purge for tube FOR ORBITAL WELDING

Original Title

ID purge

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides tables with guidelines for purge rates and pressures for tube welding using different tube sizes and wall thicknesses. It lists the minimum recommended purge rates in standard cubic feet per hour or liters per minute for each size, as well as the corresponding pressure ranges in inches of water column, mm of water column, or torr. It also provides recommended restrictor sizes to achieve the proper purge rates.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

9 views1 pageID Purge

ID Purge

Uploaded by

gtechkarthickThe document provides tables with guidelines for purge rates and pressures for tube welding using different tube sizes and wall thicknesses. It lists the minimum recommended purge rates in standard cubic feet per hour or liters per minute for each size, as well as the corresponding pressure ranges in inches of water column, mm of water column, or torr. It also provides recommended restrictor sizes to achieve the proper purge rates.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

M100 Power Supply

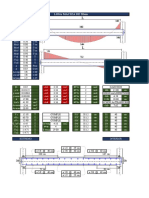

Table 5 Purge Rate and Pressure Tables

Wall Minimum ID Swagelok Weld Head

Tube Size Pressure①② Restrictor Size⑤

Thickness Purge Rate Purge Rates③④

13 to 16.8 torr

1/16 in. 0.015 in. 0.2 std ft3/hr 7 to 9 iwc 10 to 20 std ft3/hr n/a

n/a n/a 0.1 L/min 175 to 230 mmwc 5 to 10 std L/min

17.4 to 22.4 mb

9.3 to 16.8 torr

1/8 in. 0.028 in. 1 std ft3/hr 5 to 9 iwc 10 to 20 std ft3/hr 1/16 in.

3 mm 0.8 mm 0.5 L/min 130 to 230 mmwc 5 to 10 std L/min

12.4 to 22.4 mb

5.2 to 6.3 torr

1/4 in. 0.035 in. 6 std ft3/hr 2.8 to 3.4 iwc 10 to 20 std ft3/hr 1/8 in.

6 mm 1 mm 3 std L/min 71 to 86 mmwc 5 to 10 std L/min 3 mm

7.0 to 8.5 mb

2.8 to 4.7 torr

3/8 in. 0.035 in. 10 std ft3/hr 1.5 to 2.5 iwc 10 to 20 std ft3/hr 1/8 in.

10 mm 1 mm 5 L/min 38 to 64 mmwc 5 to 10 std L/min 3 mm

3.7 to 6.2 mb

1.9 to 2.8 torr

1/2 in. 0.049 in. 15 std ft3/hr 1.0 to 1.5 iwc 10 to 40 std ft3/hr 1/4 in.

12 mm 1 mm 7 std L/min 25 to 38 mmwc 5 to 12 std L/min 6 mm

2.5 to 3.7 mb

1 to 2 torr

3/4 in. 0.065 in. 20 std ft3/hr 0.5 to 1.1 iwc 15 to 40 std ft3/hr 1/4 in.

20 mm 1.5 mm 10 std L/min 13 to 28 mmwc 7 to 14 std L/min 6 mm

1.2 to 2.7 mb

1 to 1.3 torr

1 in. 0.065 in. 40 std ft3/hr 0.5 to 0.7 iwc 15 to 40 std ft3/hr 1/4 in.

25 mm 1.5 mm 20 std L/min 13 to 18 mmwc 7 to 14 std L/min 6 mm

1.2 to 2.5 mb

1 to 1.3 torr

1 1/2 in. 0.065 in. 90 std ft3/hr 0.5 to 0.7 iwc 15 to 50 std ft3/hr 1/4 in.

38 mm 1.5 mm 43 L/min 13 to 18 mmwc 7 to 12 std L/min 6 mm

1.2 to 1.7 mb

0.7 to 1.3 torr

2 in. 0.065 in. 170 std ft3/hr 0.4 to 0.7 iwc 15 to 50 std ft3/hr 3/8 in.

50 mm 1.5 mm 80 L/min 13 to 18 mmwc 7 to 12 std L/min 10 mm

1.0 to 1.7 mb

0.4 to 0.9 torr

3 in. 0.065 in. 400 std ft3/hr 0.2 to 0.5 iwc 30 to 50 std ft3/hr 1/2 in.

75 mm 1.5 mm 190 L/min 5 to 13 mmwc 12 mm

0.5 to 1.2 mb

0.4 to 0.7 torr

4 in. 0.083 in. 720 std ft3/hr 0.2 to 0.4 iwc 30 to 50 std ft3/hr 3/4 in.

100 mm 2 mm 340 L/min 5 to 13 mmwc 20 mm

0.5 to 1.0 mb

0.4 to 0.9 torr

3

6 in 0.083 in. 1670 std ft /hr 0.2 to 0.5 iwc 1 in.

150 mm 2 mm 790 L/min 5 to 13 mmwc 25 mm

0.5 to 1.2 mb

Note:

These weld tables are for use on butt welds only. If Weld Head Purge Rates exceed Swagelok

recommendations, be cautious of arc wander. For best results, use constant weld head purge between

welding cycles.

① ATW welds and Weld Ring welds typically will require approximately 15 % more purge pressure.

② Pressures must be adjusted for ID encroachment of 0 to +10 % of wall thickness at the bottom of the weld.

③ Indicated purge rates are for minimum color line.

④ ID purge rates shall be adjusted to the desired ID color line.

⑤ Restrictor sizes are approximate; purge rate and pressure are critical parameters.

© 2005 Swagelok Company, all rights reserved 75

September 2005

You might also like

- Acf Remover G 450 PDFDocument2 pagesAcf Remover G 450 PDFYoutube For EducationNo ratings yet

- Weld Cheat SheetDocument1 pageWeld Cheat SheetBruce BrownNo ratings yet

- Electromagnetic Flowmeter User Manual Combined KFL DCDocument35 pagesElectromagnetic Flowmeter User Manual Combined KFL DCSaravanan Mathi100% (1)

- Tank Cleaning GuideDocument53 pagesTank Cleaning Guideschjhdfi38100% (1)

- Soldering electronic circuits: Beginner's guideFrom EverandSoldering electronic circuits: Beginner's guideRating: 4.5 out of 5 stars4.5/5 (9)

- Welding Technology Two MarksDocument20 pagesWelding Technology Two Markssai100% (1)

- Section 25.: World Centre For Materials Joining TechnologyDocument36 pagesSection 25.: World Centre For Materials Joining Technologyjar_2100% (1)

- Sonicom NozzleDocument2 pagesSonicom NozzleRicardoNo ratings yet

- DY-LDG Manual - ENGDocument12 pagesDY-LDG Manual - ENGmerantinb.arifpeNo ratings yet

- KAFLON - Magnetic Flow Meter-CompressedDocument5 pagesKAFLON - Magnetic Flow Meter-CompressedDicky LeonardoNo ratings yet

- Alia AMF601 Electromagnetic FlowmeterDocument4 pagesAlia AMF601 Electromagnetic FlowmeterRexCrazyMindNo ratings yet

- B&C Minibrochure 2020 A4 ING LowDocument8 pagesB&C Minibrochure 2020 A4 ING LowGordon HarrisNo ratings yet

- Snap Action Switch: FeaturesDocument3 pagesSnap Action Switch: FeaturesAnita IonelaNo ratings yet

- HN10 / HN12 / HN15: Owner'S ManualDocument4 pagesHN10 / HN12 / HN15: Owner'S Manualchristopher ng'ang'a kamauNo ratings yet

- 274 en - US FactSheet - Main 01Document2 pages274 en - US FactSheet - Main 01Luisa FernandaNo ratings yet

- Process Engineering DesignDocument4 pagesProcess Engineering Designshakib nazmusNo ratings yet

- Transport PhenomenaDocument4 pagesTransport PhenomenaDynamix SolverNo ratings yet

- Starting Equipment RequiredDocument17 pagesStarting Equipment RequiredPortik RubenNo ratings yet

- OK Autrod 2209: Typical Tensile PropertiesDocument1 pageOK Autrod 2209: Typical Tensile PropertiesjavadmohammadiNo ratings yet

- Vacuum GVD 3-5 Datasheet NocropDocument2 pagesVacuum GVD 3-5 Datasheet NocropJohn KingNo ratings yet

- Flow SensorDocument8 pagesFlow SensorAchmad Nuriel AnwarNo ratings yet

- Estimates - Bill of QuantitiesDocument9 pagesEstimates - Bill of QuantitiesRoland CepedaNo ratings yet

- Caudalimetro Magnetico Heinrichs EpxDocument11 pagesCaudalimetro Magnetico Heinrichs EpxBase SistemasNo ratings yet

- Filter Press Mass Balance TemplateDocument11 pagesFilter Press Mass Balance TemplatesalesNo ratings yet

- Micro Bent Coriolis Flow Meter 1563792142Document5 pagesMicro Bent Coriolis Flow Meter 1563792142FREDDY YAJAMINNo ratings yet

- Snap Action Switch: FeaturesDocument3 pagesSnap Action Switch: Featuresdavid salazarNo ratings yet

- DIM Aaaa BBB EST ALV NNN ARR V01Document3 pagesDIM Aaaa BBB EST ALV NNN ARR V01Matheus AlvesNo ratings yet

- Thong S6 Ky Thuat: Hexagon NippleDocument2 pagesThong S6 Ky Thuat: Hexagon NippleNguyễn Trọng ThắngNo ratings yet

- en - US FactSheet - Main 01Document1 pageen - US FactSheet - Main 01Ganesh HileNo ratings yet

- EPX Data SheetDocument16 pagesEPX Data Sheetsaroat moongwattanaNo ratings yet

- Covered (Stick) Electrodes (SMAW)Document5 pagesCovered (Stick) Electrodes (SMAW)Hanny Dewi SaragihNo ratings yet

- Chufang Agri Spray Drone Catalogue & - PriceDocument1 pageChufang Agri Spray Drone Catalogue & - PriceHad AnzhrNo ratings yet

- Dibujo Industrial II Ing. Elkin PaduaDocument6 pagesDibujo Industrial II Ing. Elkin PaduaElkinNo ratings yet

- Ventstar-Oxylog-Pi-9102363-En-Master 4Document1 pageVentstar-Oxylog-Pi-9102363-En-Master 4Quyet PhungNo ratings yet

- Y Strainers-Floid EngineeringDocument16 pagesY Strainers-Floid EngineeringkobyrtaczNo ratings yet

- Transducer Specification Sheet Ultrasound 2009Document1 pageTransducer Specification Sheet Ultrasound 2009DiegoThomazSampaioNo ratings yet

- Maximum Flow in A Water Pipe For A Speed of 1.5 M/S: PipesDocument1 pageMaximum Flow in A Water Pipe For A Speed of 1.5 M/S: PipesSashini GaneshNo ratings yet

- Valori FiziologiceDocument2 pagesValori FiziologiceAndreea VicicăNo ratings yet

- Losa Aligerada 20Cm: Vu1 Vu2Document2 pagesLosa Aligerada 20Cm: Vu1 Vu2bryan carrascoNo ratings yet

- 11 - LZT - SPEC-RotametersWaterDocument3 pages11 - LZT - SPEC-RotametersWaterHeinium DannemannNo ratings yet

- Plant Capacity: 15 MGD Technology: Moving Bed Biological Reactor (MBBR)Document12 pagesPlant Capacity: 15 MGD Technology: Moving Bed Biological Reactor (MBBR)Dev Kumar DwivediNo ratings yet

- Schlumberger Case Hole Logging PSP - RevDocument15 pagesSchlumberger Case Hole Logging PSP - RevAung Htet LingNo ratings yet

- Ventilador Resu, Fisher & Paykel, Neopuff RD900, Manual Técnico, InglésDocument14 pagesVentilador Resu, Fisher & Paykel, Neopuff RD900, Manual Técnico, InglésDiegoNo ratings yet

- Universal Spray Nozzles Product ComparisonDocument3 pagesUniversal Spray Nozzles Product ComparisonNordson Adhesive Dispensing SystemsNo ratings yet

- 4286-01 2Document28 pages4286-01 2rp801113717No ratings yet

- Solenoid Valve CatalogDocument21 pagesSolenoid Valve CatalogDeepikaNo ratings yet

- Rivulis F6150 English Metric 20190909 WebDocument6 pagesRivulis F6150 English Metric 20190909 WebMehdi BassouNo ratings yet

- Ri-F&p NeopuffDocument14 pagesRi-F&p NeopuffXimena PrietoNo ratings yet

- File PageDocument1 pageFile PageZhaahirRaafiQafilNo ratings yet

- Rivulis F7050 English Metric 20201224 WebDocument6 pagesRivulis F7050 English Metric 20201224 WebMehdi BassouNo ratings yet

- DownloadDocument2 pagesDownloadAHMED KAMESHNo ratings yet

- Sdf600 & Scf600 - Flow Chart-Fill Volume ChartDocument1 pageSdf600 & Scf600 - Flow Chart-Fill Volume ChartRamesh PeddagoudNo ratings yet

- Ds Thomas Picolino Vte-Dte Rotary VaneDocument12 pagesDs Thomas Picolino Vte-Dte Rotary Vanesemih KokNo ratings yet

- Maximum Operating TemperatureDocument3 pagesMaximum Operating TemperatureMuhammad UmairNo ratings yet

- Fiber To Yarn Spinning Process of Polyester FiberDocument12 pagesFiber To Yarn Spinning Process of Polyester FiberVinod Kumar100% (1)

- TOKAFlex Metric Imperial Spec Sheet Gecko Robotics 2021Document1 pageTOKAFlex Metric Imperial Spec Sheet Gecko Robotics 2021gorkembaytenNo ratings yet

- 9211-A01u-01 - 05 03 2017Document2 pages9211-A01u-01 - 05 03 2017spazzastura showNo ratings yet

- Torque Wrench Catalogue and Usage InstructionsDocument4 pagesTorque Wrench Catalogue and Usage InstructionsRamesh SinghNo ratings yet

- Type BSDType CSD Self Drilling ScrewsDocument2 pagesType BSDType CSD Self Drilling Screwscheow jongNo ratings yet

- Neopuff Technical ManualDocument14 pagesNeopuff Technical ManualCarlos CortesNo ratings yet

- 2.2.4 Elgard Mixed Metal Oxide Ribbon Mesh Rev.0 July 2020Document2 pages2.2.4 Elgard Mixed Metal Oxide Ribbon Mesh Rev.0 July 2020newdelhyNo ratings yet

- TREADMILLDocument2 pagesTREADMILLmaxor4242No ratings yet

- Losa Maciza en Una DireccionDocument1 pageLosa Maciza en Una Direccionbryan carrascoNo ratings yet

- Welding Processes: Production Technology EDPT 201 A. Prof. Dr. Yasser FouadDocument37 pagesWelding Processes: Production Technology EDPT 201 A. Prof. Dr. Yasser FouadAhmad OmarNo ratings yet

- Performance Analysis of A New Hybrid Cooling-Drying System: A B A BDocument21 pagesPerformance Analysis of A New Hybrid Cooling-Drying System: A B A BNuraini Abdul AzizNo ratings yet

- Gas Metal Arc Welding (GMAW) : University of Kuala Lumpur - Malaysia France InstituteDocument16 pagesGas Metal Arc Welding (GMAW) : University of Kuala Lumpur - Malaysia France InstituteKamarul Nizam100% (1)

- Jadual Kursus Cswip 3.1Document3 pagesJadual Kursus Cswip 3.1Wong Chung MengNo ratings yet

- Weld Tracking Spreadsheet WeldNoteDocument5 pagesWeld Tracking Spreadsheet WeldNotejorgekarlosprNo ratings yet

- Electric Duct Heater: Specification and Installation InstructionsDocument8 pagesElectric Duct Heater: Specification and Installation InstructionsDonald VelosoNo ratings yet

- Case Study (Albaum Et Al., 2016)Document2 pagesCase Study (Albaum Et Al., 2016)AdrianaAlquichireArzuzaNo ratings yet

- Weldhelp MatrixDocument1 pageWeldhelp MatrixJoel BrasilBorgesNo ratings yet

- ESAB Catalogo-Equipamentos ENDocument88 pagesESAB Catalogo-Equipamentos ENEdilsn CruzNo ratings yet

- 1 RWMA - Resistance-Welding-Literature-1Document3 pages1 RWMA - Resistance-Welding-Literature-1dneprmtNo ratings yet

- Overzicht en Iso 3834 Editie 2017 - Engels PDFDocument1 pageOverzicht en Iso 3834 Editie 2017 - Engels PDFrohit mathankerNo ratings yet

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Ramadhan AdityaNo ratings yet

- Rooftop Packaged Air Conditioners: CatalogDocument212 pagesRooftop Packaged Air Conditioners: CatalogRicardo Molina SánchezNo ratings yet

- API 650 Part 2Document20 pagesAPI 650 Part 2Naveen RajNo ratings yet

- Mig Mag Saw CswipDocument35 pagesMig Mag Saw CswipHamza DhariwalNo ratings yet

- Overview Fusion Welding StandardsDocument1 pageOverview Fusion Welding StandardspedroNo ratings yet

- Welding Visual Inspection FormatDocument2 pagesWelding Visual Inspection Formatgst ajah100% (3)

- Eiga Cryogenic Vaporisation SystemsDocument29 pagesEiga Cryogenic Vaporisation Systemseaang55No ratings yet

- Laporan Welding ProsmanDocument20 pagesLaporan Welding Prosmannadia frizaNo ratings yet

- Presentation Induction Heater Plant in Moscow Russia 2020Document21 pagesPresentation Induction Heater Plant in Moscow Russia 2020HIRENNo ratings yet

- Aircondition With PicturesDocument37 pagesAircondition With PicturesSaikat BiswasNo ratings yet

- E9018 G Welding ElectrodeDocument1 pageE9018 G Welding ElectrodeSai PrasathNo ratings yet

- Welding StandardsDocument14 pagesWelding Standardsnikidragon4u100% (1)

- 3-Actual Exams Last Edition (ASME IX)Document6 pages3-Actual Exams Last Edition (ASME IX)Hares SlalNo ratings yet

- Welding Guide For Hensley Products - Adapters NosesDocument48 pagesWelding Guide For Hensley Products - Adapters NosesMilorad ZelenovicNo ratings yet

- Welding: Engr. Dheylvin Roy P. BuenaventuraDocument8 pagesWelding: Engr. Dheylvin Roy P. BuenaventuraEarl Justin EnriqueNo ratings yet

- WeldingDocument16 pagesWeldingKhuda BukshNo ratings yet