Professional Documents

Culture Documents

Lecture 1 Functional Failure

Lecture 1 Functional Failure

Uploaded by

renad0 ratings0% found this document useful (0 votes)

9 views11 pagesOriginal Title

lecture 1 functional failure

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

9 views11 pagesLecture 1 Functional Failure

Lecture 1 Functional Failure

Uploaded by

renadCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 11

~ CHAPTER (1) Functional Failure

Pa a ¢ failure process,

es a comprehensive idea about the failure. proc

eee nd concentrating on functional

ty

lure that will be

s. Figure (1-1) briefly summarizes types o}

iscussed in detail hereinafter.

I

Overall

pt lasoS) agp) ola Siructure

Gils Be

I

Gs Ved | ie

2. Failure

T

i I

T

Figure (1-1) Types of failure in reinforced concrete structures

ned functional failure,

unctional failure t

id related to str

The previously de

fakes many forms from

which the most frequent forn ‘uctural engineering are

illustrated,

1

‘camScanner U8 pau

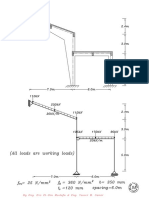

The common and most farniliar er

ctural failure

engineering environs tructural fa)

On the other

functional failure, if its presence

structures requiring specific orientation with the ¢

track girders or even stairs, Figure (1-2) shows diff

resulting in functional and structural failure

‘camScanner U8 pau

settlement may cause traditional buildings to

II be unable to move or perform ordinary

Figure (1-3) shows buildings confronting

Extreme differential

malfunction, because habitants wt

ctivities + structure stably, !

eee eer sent in semi urban un-planned Egyptian districts

izza inclined tower

an excessive differential settlement

compared with the Italian famous P

1s gle

1-2_Overall settlement

The overall settlement is un-doug!

ily classified as a functional failure

ai does note-lead-to-any-increase in straining actions, or internal rel The

main problem resulting from overall settlement (a s place is the oe : oo,

specialiysineentrancessthatymaysface: a decreasesinsthesflaoreroofaclearanc®

which affects habitants maneuvering. Overall settlement-also affects building’s

utilitiesprespecially water’ supply: and"sewerage pipes. ‘Dangerous’ pipes

natural gas supply pipes should be connected to building via flexible sleeves in

order to avoid! hazardousness resulting: from pipes:fracture or micro-cracking,

Figure (1-4) shows an example of overall settlement of a building, where it

could be noticed that the separate stairs of the entrance are still in their initial

position, while the whole building already settled. A crushed zone across the

building-ground interface is also obvious.

Il settlement of a building

Rotation rarely takes place in

loads due to their high counter ‘weight

retaining structures are the most

main Supporting mainly gravitational

en to the laterally rotating load. earth

Co A SST h ; “nt structures subjecte rotati

al ls to either the high ratio between lateral —— alte

‘0 Sub-structure problems (e.g, soil Tee ee

ati slip cirele), Fi

B eto la . Figure (1-5) ¢

otation due to lateral loads and sub-structure eee 5) shows examples of

lems.

CCamScanner is tsa

‘ design c) rotation due to slip circle

2) rotation due to improper ) rotation

, Figure (1-5) Rotation of retaining walls

shown in figure (1-6)

4) displacement due to lateral loads) displace

ent due 10 sei

Figure (1-6) Displaceme

il ayers siding

nt Of structures

4

‘camScanner U8 pau

Since both machinery and structural element

gic of dealing with such problems is

ting medium via dampers.

ential for some structures, the los

tion between the source and the propagal

b) plaster softenin

1g due to water leakage

fer leakage in bathrooms °

ure (1-7) Effects of wat

‘camScanner U8 pau

7

lated through: modulus of

1-7 etn ererrel

sformation are F¢

it should be noted that srength and deVOrT ET ould be clearly noticed it

elasticity (slope of stre er wo different materials (a) and

figure (2-8) that compares

(b) loaded axially. a

Material (a) deforms to a large §

extent, but shows higher strength thal g% Mat. (a)

material (b), that deforms less than (a).

Habitants or structure users could not

judge the residual strength of a J

Mat. (b)

structural element, but they can easily

notice deformations. That is why | /

noticeable deformations are considered |

a functional failure or a serviceability

criterion, in addition _ noticeable \/

deformations are considered an alarm _

of an increase in stresses.

- Strain

Figure (1-8) Difference between deformation and strength

shows an example of a highly deflected floo

Figure (1-9) Noticeable deformations in floors

Defeats appearing on concrete surfaces are usuall

ase of fair face concrete. Most of theses defect

walls of large surface area,

ly unacceptable; especially in

S appear in concrete slabs or

6

CCamScanner ies do suaa!

Figure (1-10) Conerete Surface Dusting

eer PURGROEREREEESTETEEY 2s shown in

Figure (1-11)

oncrete surface blisters

‘camScanner Wd pau

* . -

Figure (1-13) Concrete surface sealing iy

‘camScanner U8 pau

Jed: byusingieitheralmenteained.concrete

puld be avoid

ler

surface sealing: €6

[solutions to uring

Conere’

orapplyngaleiwenehemicd

LASS Popouts

a Popouts are £

breaking out of the coneret

aringennrenrerOFie ormeoneatefragmente

crally appe

TET eeawatiownvinofigure (1-14)

surlace, as

a) Slab Popouts Jumn Popouts

Figure (1-14) Conerete surface popouts

Popouts usually occur as a result of using porous aggregate that absorbs

too much water during mixing and placing processes, this leads to aggregate

expansion that forms this phenomenon. Popouts may also occur due to the

alkali-silica reaction (ASR) that takes place between alkali concrete products

(cement) and silica, presented in aggregate, Minimizing popouts could be

established by producing air-entrained concrete with low water content, using

durable (low porous) aggregate, and using low alkali products in case of the

activation of alkali-silica reaction.

<= \-8-6 Discoloration

Discoloration appears as gross color changes over large areas, as shown in

figure (1-15). Discoloration is usually the result of any of the following:

I~ The usage of calcium chloride

admixtures.

2. Non-uniform curing.

3- Heterogeneity in water

cement ratio of concrete mix

over the concrete surface.

Figure (1- n

Bure (I-15) Concrete surface discoloration "31

‘camScanner U8 pau

concrete or masonry

PAST Efflorescence

ced

It appears in the form of a white p

surfaces? Figure (1-16) shows an example

conerete beam and supported masonry wall

lable layer on

of efflorescence in a reinfor

yD

¢

Figure (1-16) Surface efflorescence

Efflorescence refers to the leakage of water through porous bodies (e.g.

concrete or brick), dissolving internal salts and transmitting them to the surface.

After that, water evaporates, leaving salts in the previously described pattern on

the body surface. This phenomenon leads to an improper aesthetical view, in

addition to plastering separation, if present. Efflorescence effects could be

minimized by using aggregate and bricks of low salts content, in addition to

applying surface layers of water protection sheets or emulsions to minimize

water leakage at humid areas.

sss Vertical Surface Scouring

Scouring concrete vertical

surfaces forms a pattern that

resembles a map of a river delta,

with wide lower base and sharp

upper apex. Figure (1-17) shows

and example of a concrete wall

surface scour. Surface scour is

caused by water moving

upwards against the face of the

formwork. It is a sign of

excessively wet concrete, and

its prevention is a matter of

concrete mix design,

Figure (1-17) Conerete vertical surface scouring!!!

10

CcamScanner Wd pau

1-9_d

‘Aesthetical effects of joints are considered a functional tailure, because

ser’s ions towards

i ely affects user’s impressions

iniproper appearance of joints passive! \ imp s r

sasma durability. The most frequently faced joint sete ware interlil

tracks: They represent a natural separation between two continuurmss Spot

joints and-masonry-concrete interfaces represent the major pereentag hese

. as shown in figure (1-18).

a) bad-treated expansion Joint

by steel net sheets used to connect interfaces c) masonry-conerete column Interface crack

Figure (1-18) Concrete joint defects

Difference in coefficients of thermal expansion between contacted

materials, subjected to thermal loading, may also lead joints cracks.

CcamScanner Wd pau

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Question Bank 2023-2024 WithoutDocument9 pagesQuestion Bank 2023-2024 WithoutrenadNo ratings yet

- Model Answer Quez1 - 2021 - EPW - CVE311 Traffic Engineering (Model Answer) Model 1Document1 pageModel Answer Quez1 - 2021 - EPW - CVE311 Traffic Engineering (Model Answer) Model 1renadNo ratings yet

- Assignment-No.-1-Sight DistanceDocument3 pagesAssignment-No.-1-Sight DistancerenadNo ratings yet

- Example: Settlement Due To Secondary ConsolidationDocument1 pageExample: Settlement Due To Secondary ConsolidationrenadNo ratings yet

- 02.2-Assignment (1) - Model Answer - Fall T 2020.2021-SAN425-Sanitary EngineeringDocument9 pages02.2-Assignment (1) - Model Answer - Fall T 2020.2021-SAN425-Sanitary EngineeringrenadNo ratings yet

- Sol Prob 3Document11 pagesSol Prob 3renadNo ratings yet

- Problem 2 in MidtermDocument2 pagesProblem 2 in MidtermrenadNo ratings yet

- Sol Prob 1Document11 pagesSol Prob 1renadNo ratings yet

- Consolidation - Foundation 1Document11 pagesConsolidation - Foundation 1renadNo ratings yet

- Sol Prob 2Document10 pagesSol Prob 2renadNo ratings yet