Professional Documents

Culture Documents

General+Inspection+Group+2 November2023

General+Inspection+Group+2 November2023

Uploaded by

JanVpotCopyright:

Available Formats

You might also like

- Rigging Loft Management ProcedureDocument11 pagesRigging Loft Management Procedurekacang mete100% (2)

- Status Note On Collective Investment Schemes - 1326177032722-ADocument225 pagesStatus Note On Collective Investment Schemes - 1326177032722-AVivek Agrawal67% (3)

- Docs Slides Lecture11Document18 pagesDocs Slides Lecture11Irham DodotNo ratings yet

- Doc. No. FORM-PTSI-CIO-005-E Rev. 02 Date 16/11/15 Page 1 of 1 Doc. Ref. WI-PTSI-CIO-002-EDocument1 pageDoc. No. FORM-PTSI-CIO-005-E Rev. 02 Date 16/11/15 Page 1 of 1 Doc. Ref. WI-PTSI-CIO-002-ERiswan UthamiNo ratings yet

- Proforma Invoice: Organization Account Delivery ProjectDocument1 pageProforma Invoice: Organization Account Delivery ProjectM. SHOLA HuddinNo ratings yet

- Case - CFF GALA Rev 1 12-7-2023 2-00-47 PMDocument2 pagesCase - CFF GALA Rev 1 12-7-2023 2-00-47 PMIjoel Chuvu Part IINo ratings yet

- Corrective and Preventive Action Request Form: Pt. Akura Bina CitraDocument1 pageCorrective and Preventive Action Request Form: Pt. Akura Bina CitraAndreasSembiringNo ratings yet

- Corrective and Preventive Action Request Form: Pt. Akura Bina CitraDocument1 pageCorrective and Preventive Action Request Form: Pt. Akura Bina CitraAndreasSembiringNo ratings yet

- Inspection Kendaraan Area Up Stream (9 September 2023)Document7 pagesInspection Kendaraan Area Up Stream (9 September 2023)Gea LindriNo ratings yet

- Training Effectiveness IndividualDocument1 pageTraining Effectiveness IndividualRahul KumarNo ratings yet

- IBSPL-HSE-F17 HSE Violation ReportDocument1 pageIBSPL-HSE-F17 HSE Violation ReportAbdul RaheemNo ratings yet

- Test Report: Dilip Buildcon LimitedDocument5 pagesTest Report: Dilip Buildcon LimitedRitesh TiwariNo ratings yet

- Leave Application Form: For Employee UseDocument1 pageLeave Application Form: For Employee UseEldiiarNo ratings yet

- Assessment Coversheet AT3 Assessment 3 Portfolio Activities: BSB30115 Certificate III in BusinessDocument6 pagesAssessment Coversheet AT3 Assessment 3 Portfolio Activities: BSB30115 Certificate III in BusinessAnaya SharmaNo ratings yet

- Case - CFF GALA Rev 1 12-11-2023 10-39-48 AMDocument2 pagesCase - CFF GALA Rev 1 12-11-2023 10-39-48 AMIjoel Chuvu Part IINo ratings yet

- Annex 1 General Permit FormDocument1 pageAnnex 1 General Permit FormYunan EdhieNo ratings yet

- On-Site Audit ReportDocument6 pagesOn-Site Audit ReportSetyo Edy PrasetyoNo ratings yet

- Invoice No. INV.004 - BESMAN - 06 - 2022Document1 pageInvoice No. INV.004 - BESMAN - 06 - 2022ibnubesmanNo ratings yet

- 5M54C DC Duri0726120190423prf01Document26 pages5M54C DC Duri0726120190423prf01Ryan SinagaNo ratings yet

- Eni 10009E04 PDFDocument64 pagesEni 10009E04 PDFSammyNo ratings yet

- Pt. Sulawesi Resources: Pesanan Pembelian / Purchase RequisitionDocument4 pagesPt. Sulawesi Resources: Pesanan Pembelian / Purchase RequisitionPriambodo AriewibowoNo ratings yet

- Niti Ayog AIMDocument2 pagesNiti Ayog AIMShweta AgrawalNo ratings yet

- Diversity ReportDocument46 pagesDiversity ReportKunal Neha GognaNo ratings yet

- QUA-04-10-04 Action PlanDocument1 pageQUA-04-10-04 Action PlanEdwin MofokengNo ratings yet

- Spectro Lab Surface Burring Report - D201003041 - 1 - N35287 - F D201003041 1RST13207221020014741Document6 pagesSpectro Lab Surface Burring Report - D201003041 - 1 - N35287 - F D201003041 1RST13207221020014741Dtl DiagNo ratings yet

- PDF Professional Practice RQF Assignment DDDocument115 pagesPDF Professional Practice RQF Assignment DDlamo putiNo ratings yet

- Shanmugha Precision Forging Non - Conformance Report: Rejected Due To Chamfer Value: 5112Document1 pageShanmugha Precision Forging Non - Conformance Report: Rejected Due To Chamfer Value: 5112Ravichandran DNo ratings yet

- SupervisorDocument2 pagesSupervisorgrantNo ratings yet

- Flange ManagementDocument32 pagesFlange ManagementMike Manalu100% (4)

- Controls Narrative For Incinerator Package (X-5202) : Petroleum Development Oman Document NumberDocument16 pagesControls Narrative For Incinerator Package (X-5202) : Petroleum Development Oman Document NumberMuhammad IrfanNo ratings yet

- 11.3 Monthly Cert. of PaymentDocument1 page11.3 Monthly Cert. of Paymentjiean salinas100% (1)

- Corrective Action Request CAR 1 of 3: Please Sent Not More Than 5 Working Days To andDocument4 pagesCorrective Action Request CAR 1 of 3: Please Sent Not More Than 5 Working Days To andAgus DuriatNo ratings yet

- Yfg Berhad Corrective Action Request (Car) : QHSE-F11 Rev: 00Document2 pagesYfg Berhad Corrective Action Request (Car) : QHSE-F11 Rev: 00Therukumaran a/l NarayanasamyNo ratings yet

- JVT-W-QS-000-085-B.2 Work Permit Form - On O&M SiteDocument4 pagesJVT-W-QS-000-085-B.2 Work Permit Form - On O&M SiteGilbert GillNo ratings yet

- Formulir Isian Kualifiasi: Ival Pahlevi Direktur Cv. Pahlevi Dwi UtamaDocument7 pagesFormulir Isian Kualifiasi: Ival Pahlevi Direktur Cv. Pahlevi Dwi UtamaSyaef AzzuhryNo ratings yet

- Appendix E-Sub-Cons Vendor HSE Pre-Qualification Checklist Rev 2Document15 pagesAppendix E-Sub-Cons Vendor HSE Pre-Qualification Checklist Rev 2Justice AkuboNo ratings yet

- Rma Inw5008611321Document1 pageRma Inw5008611321310-Harikarasuthan PNo ratings yet

- Conoth HSE PlanDocument32 pagesConoth HSE Plannanda dwi ariyadiNo ratings yet

- Spill Response Procedures OCLDocument14 pagesSpill Response Procedures OCLThusithaNo ratings yet

- Corrective and Preventive Action Request Form: Pt. Akura Bina CitraDocument1 pageCorrective and Preventive Action Request Form: Pt. Akura Bina CitraAndreasSembiringNo ratings yet

- Sts23 Januari 201333Document53 pagesSts23 Januari 201333husen123 alhusadaNo ratings yet

- KN Network Services - Job Diary Information Sheet: Products To Be CompletedDocument3 pagesKN Network Services - Job Diary Information Sheet: Products To Be CompletedConstantin Emilian AvorniceseiNo ratings yet

- Annexure For Probition DeclaretionDocument3 pagesAnnexure For Probition DeclaretionPhanindra KottapalliNo ratings yet

- KN Network Services - Job Diary Information Sheet: Products To Be CompletedDocument3 pagesKN Network Services - Job Diary Information Sheet: Products To Be CompletedConstantin Emilian AvorniceseiNo ratings yet

- Corrective and Preventive Action Request Form: Pt. Akura Bina CitraDocument1 pageCorrective and Preventive Action Request Form: Pt. Akura Bina CitraAndreasSembiringNo ratings yet

- Approved CAF Dismantling and Re-Installation of Clerestory Window 1100416169Document5 pagesApproved CAF Dismantling and Re-Installation of Clerestory Window 1100416169Evangeline Anting EndrinaNo ratings yet

- Case - CFF GALA Rev 1 12-7-2023 1-51-11 PMDocument2 pagesCase - CFF GALA Rev 1 12-7-2023 1-51-11 PMIjoel Chuvu Part IINo ratings yet

- Equipment and Tools Inspection Submission FormDocument6 pagesEquipment and Tools Inspection Submission FormMuhammad TriansyahNo ratings yet

- Inspection Report - JELDocument5 pagesInspection Report - JELfery buyaNo ratings yet

- Deskide Service Report: Customer: Address: Reference: Oneservice Ticket No.: Contact: Telephone: EmailDocument2 pagesDeskide Service Report: Customer: Address: Reference: Oneservice Ticket No.: Contact: Telephone: EmailSeptian UtamaNo ratings yet

- KN Network Services - Job Diary Information Sheet: Products To Be CompletedDocument3 pagesKN Network Services - Job Diary Information Sheet: Products To Be CompletedConstantin Emilian AvorniceseiNo ratings yet

- DRSMMNaiduDocument11 pagesDRSMMNaiduMOHAN MAHALAKSHMI NAIDUNo ratings yet

- HSEP12F11 - Lockout Tagout PermitDocument2 pagesHSEP12F11 - Lockout Tagout Permitasheshdas189No ratings yet

- PTO - Shuttering and de Shuttering Rev 2Document2 pagesPTO - Shuttering and de Shuttering Rev 2grantNo ratings yet

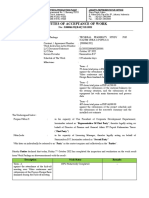

- Minutes of Acceptance of Work (Bap)Document2 pagesMinutes of Acceptance of Work (Bap)Kurniawan RusliNo ratings yet

- Form Overtime 10 Sep 2023Document1 pageForm Overtime 10 Sep 2023Tamago Kental ManisNo ratings yet

- F-3 IST Internal Event Proposal FormDocument2 pagesF-3 IST Internal Event Proposal FormMehza SayedNo ratings yet

- 8D Report For Eye Bolt Dim 0.625Document1 page8D Report For Eye Bolt Dim 0.625Kapil HarchekarNo ratings yet

- PCD-OSH-SF-35 PTW For Confine SpaceDocument2 pagesPCD-OSH-SF-35 PTW For Confine Spacerizal azizanNo ratings yet

- Burner Capacity Curves For Incinerator Package (X-5202) : Petroleum Development Oman Document NumberDocument4 pagesBurner Capacity Curves For Incinerator Package (X-5202) : Petroleum Development Oman Document NumberMuhammad IrfanNo ratings yet

- General Term & Condition:: Purchase Order (Po) No PO: P2102755 PO Date: 2021-08-16 Dept: A200 / ProjectDocument1 pageGeneral Term & Condition:: Purchase Order (Po) No PO: P2102755 PO Date: 2021-08-16 Dept: A200 / ProjectAnjar MusofaNo ratings yet

- Vendor Selection - Qa Form PT. KPSDocument2 pagesVendor Selection - Qa Form PT. KPSJanVpotNo ratings yet

- Struktur Organisasi PerusahaanDocument1 pageStruktur Organisasi PerusahaanJanVpotNo ratings yet

- Label B3Document1 pageLabel B3JanVpotNo ratings yet

- Sertifikat OHS MS (ISO 45001) & SMKP 15 October 2022 - M. Syahril S.Document1 pageSertifikat OHS MS (ISO 45001) & SMKP 15 October 2022 - M. Syahril S.JanVpotNo ratings yet

- 15 - Bbs & Stop CardDocument39 pages15 - Bbs & Stop CardJanVpotNo ratings yet

- Nation BrandingDocument36 pagesNation BrandingHarun or RashidNo ratings yet

- Generators Portable Ultrasilent DCA125USI Rev 1 60 HZ Manual DataId 19064 Version 1Document90 pagesGenerators Portable Ultrasilent DCA125USI Rev 1 60 HZ Manual DataId 19064 Version 1Duy Kha100% (2)

- Surface Treatment of FibreDocument10 pagesSurface Treatment of FibreAshokan KelothNo ratings yet

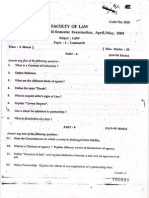

- 2nd Sem Previous Yr. Question Papers (5 Subjects)Document44 pages2nd Sem Previous Yr. Question Papers (5 Subjects)Muhammed Muktar0% (1)

- Section 1 General Introduction To VibrationDocument38 pagesSection 1 General Introduction To Vibrationsudhiruday31No ratings yet

- Technical Proposal BNCTL OECUSSEDocument26 pagesTechnical Proposal BNCTL OECUSSEMartins MartinsNo ratings yet

- Verbal Section Reading CompDocument35 pagesVerbal Section Reading CompBasharat AliNo ratings yet

- An Islamic Alternative (Zakat) To Poverty Alleviation: The PARSHI ModelDocument23 pagesAn Islamic Alternative (Zakat) To Poverty Alleviation: The PARSHI Modelziadiqbal19100% (2)

- Sony Ericsson T290Document86 pagesSony Ericsson T290NickNo ratings yet

- Equipo PanasonicDocument42 pagesEquipo PanasonicCarlos JaramilloNo ratings yet

- Commscope CV3PX308R1Document5 pagesCommscope CV3PX308R1klamar5No ratings yet

- SMTP Mail Doku v12 v1 0 enDocument32 pagesSMTP Mail Doku v12 v1 0 enAnonymous RAqew4bNo ratings yet

- Navair 00 25 403 2005Document195 pagesNavair 00 25 403 2005freddy_gNo ratings yet

- Self Compacting ConcreteDocument9 pagesSelf Compacting ConcreteVimal VimalanNo ratings yet

- Financial Planning and BudgetingDocument45 pagesFinancial Planning and BudgetingRafael BensigNo ratings yet

- Commercial Banking System and Role of RBI - Assignment June 2021Document6 pagesCommercial Banking System and Role of RBI - Assignment June 2021sadiaNo ratings yet

- Introduction To Advanced Level Economics: by Brian RopiDocument293 pagesIntroduction To Advanced Level Economics: by Brian RopiSimba NheperaNo ratings yet

- Wealth-Insight - May 2021Document66 pagesWealth-Insight - May 2021vnmasterNo ratings yet

- SPA Manage BusinessDocument2 pagesSPA Manage BusinessronaNo ratings yet

- Banking Laws Cases Diligence Required From BanksDocument4 pagesBanking Laws Cases Diligence Required From Bankslalyn100% (1)

- O DR Manager 201307Document2 pagesO DR Manager 201307Aziz Ur RehmanNo ratings yet

- Employees' Health Insurance and Pension (Shakai Hoken 社会保険)Document2 pagesEmployees' Health Insurance and Pension (Shakai Hoken 社会保険)Putri HalinNo ratings yet

- SpaceCAD Model Rocket SoftwareDocument7 pagesSpaceCAD Model Rocket Softwareheric19886445No ratings yet

- Rules/Terms of ServiceDocument8 pagesRules/Terms of ServiceBaptiste THEVENOTNo ratings yet

- Project SPECIFIC TECHNICAL REQUIREMENTS PDFDocument311 pagesProject SPECIFIC TECHNICAL REQUIREMENTS PDFadnan53No ratings yet

- Science Has Made Life Better But Not Easier.' Discuss.Document2 pagesScience Has Made Life Better But Not Easier.' Discuss.Yvette LimNo ratings yet

- L/4 L/4 Support Support Mid-Span: RC SlabDocument1 pageL/4 L/4 Support Support Mid-Span: RC SlabLarizza TesicoNo ratings yet

- Communication Letter - LivelihoodDocument34 pagesCommunication Letter - LivelihoodlzymxNo ratings yet

General+Inspection+Group+2 November2023

General+Inspection+Group+2 November2023

Uploaded by

JanVpotOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

General+Inspection+Group+2 November2023

General+Inspection+Group+2 November2023

Uploaded by

JanVpotCopyright:

Available Formats

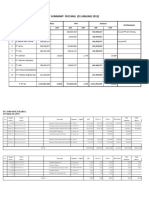

Doc No: CDC-GMT-013-F100

Page: 1 of 13 Version: 5.5 GENERAL MANAGEMENT

Approval Date: 7/7/2020 12:00:00 AM

Review Cycle: Years

Author: Supt. SHE Fixed Plant

AuthorPosID: SHE1504 Inspeksi Umum _General Inspection

Approval: Manager SHLP

ApprovalPosID: SHE1501

Petugas Inspeksi/ Inspectors Badge Nomor/ Number Tanggal Inspeksi/ Date Departmen/ Department Lokasi/ Location

Ronald Pangaribuan 10106765 Process Operation

Darius Varianemil 10106752 Process Operation

Atika Rahmawati 10307470 Process Operation

Deviana Perdana 10307671 Process Operation

Filter Plant & Jetty

Andhini Chrisetya Putri Mandira 10307734 23 November 2023 Process Operation

Afif Shidqi 10307820 Process Operation

Victor Suganda 10107068 Process Operation

Yeni Setyowati 30009071 SSB

Januar Hakkiki 30002989 SSB

Direview oleh Atasan Langsung/ Reviewing Supervisor Badge Nomor/ Number Direview Tanggal/ Review Date

Kode Uraian Tindakan Jenis Tindakan Jenis Solusi Saat ini ditugaskan Tanggal

Prioritas kepada jatuh tempo

Nomor Kelas Kondisi/ Conditions Tindakan Korektif/ Action Karyawan yang Tanggal WO Tanggal EHS360

/# Bahaya/ Corrective Actions Category Bertanggung jatuh tempo/ Neede Penyelesaian Nomor/

Hazard S= Sementara/ Jawab / Person Due Date d/ # / Completion Number

Class Temporary responsible Date

P= Tetap/

Permanent

THIS DOCUMENT IS UNCONTROLLED IN HARD COPY FORMAT

Doc No: CDC-GMT-013-F100

Page: 2 of 13 Version: 5.5 GENERAL MANAGEMENT

Approval Date: 7/7/2020 12:00:00 AM

Review Cycle: Years

Author: Supt. SHE Fixed Plant

AuthorPosID: SHE1504 Inspeksi Umum _General Inspection

Approval: Manager SHLP

ApprovalPosID: SHE1501

1 C1 Penataan ulang barang- P Triawan, Heri 7 Desember No

barang sesuai dengan Bambang Setyono 2023

rambu-rambu pada

lemari

Yeni Setyowati: Simbol B3 pada lemari tetapi

isinya bukan B3

THIS DOCUMENT IS UNCONTROLLED IN HARD COPY FORMAT

Doc No: CDC-GMT-013-F100

Page: 3 of 13 Version: 5.5 GENERAL MANAGEMENT

Approval Date: 7/7/2020 12:00:00 AM

Review Cycle: Years

Author: Supt. SHE Fixed Plant

AuthorPosID: SHE1504 Inspeksi Umum _General Inspection

Approval: Manager SHLP

ApprovalPosID: SHE1501

2 C1 Diganti dengan tag P Triawan, Heri 7 Desember No

APAR baru Bambang Setyono 2023

Ronald: Tag Apar di area tangki konsentrat

sudah berkarat

THIS DOCUMENT IS UNCONTROLLED IN HARD COPY FORMAT

Doc No: CDC-GMT-013-F100

Page: 4 of 13 Version: 5.5 GENERAL MANAGEMENT

Approval Date: 7/7/2020 12:00:00 AM

Review Cycle: Years

Author: Supt. SHE Fixed Plant

AuthorPosID: SHE1504 Inspeksi Umum _General Inspection

Approval: Manager SHLP

ApprovalPosID: SHE1501

3 C1 Memperbaiki P Triawan, Heri 7 Desember No

penempatan benda sesuai Bambang Setyono 2023

dengan kategori

bahayanya

Yeni Setyowati: symbol LB3 (cairan mudah

menyala) dipasang pada lemari penyimpanan

cat

4 C1 Penambahan eyewash P Triawan, Heri 7 Desember No

station Bambang Setyono 2023

THIS DOCUMENT IS UNCONTROLLED IN HARD COPY FORMAT

Doc No: CDC-GMT-013-F100

Page: 5 of 13 Version: 5.5 GENERAL MANAGEMENT

Approval Date: 7/7/2020 12:00:00 AM

Review Cycle: Years

Author: Supt. SHE Fixed Plant

AuthorPosID: SHE1504 Inspeksi Umum _General Inspection

Approval: Manager SHLP

ApprovalPosID: SHE1501

Darius: Belum ada eyewash station di area ship

loading

THIS DOCUMENT IS UNCONTROLLED IN HARD COPY FORMAT

Doc No: CDC-GMT-013-F100

Page: 6 of 13 Version: 5.5 GENERAL MANAGEMENT

Approval Date: 7/7/2020 12:00:00 AM

Review Cycle: Years

Author: Supt. SHE Fixed Plant

AuthorPosID: SHE1504 Inspeksi Umum _General Inspection

Approval: Manager SHLP

ApprovalPosID: SHE1501

5 C1 Melakukan monthly P Triawan, Heri 7 Desember No

inspection dan Bambang Setyono 2023

mengupdate checklist

inspection pada

kelengkapan alat P3K

Januar: Tidak ditemukan monthly checklist

inspection pada tas P3K

THIS DOCUMENT IS UNCONTROLLED IN HARD COPY FORMAT

Doc No: CDC-GMT-013-F100

Page: 7 of 13 Version: 5.5 GENERAL MANAGEMENT

Approval Date: 7/7/2020 12:00:00 AM

Review Cycle: Years

Author: Supt. SHE Fixed Plant

AuthorPosID: SHE1504 Inspeksi Umum _General Inspection

Approval: Manager SHLP

ApprovalPosID: SHE1501

6 C1 Perlu dilakukan P Triawan, Heri 7 Desember No

penggantian handle atau Bambang Setyono 2023

pergantian unit APAR

Deviana: Handle APAR di area tangki

konsentrat sudah berkarat

THIS DOCUMENT IS UNCONTROLLED IN HARD COPY FORMAT

Doc No: CDC-GMT-013-F100

Page: 8 of 13 Version: 5.5 GENERAL MANAGEMENT

Approval Date: 7/7/2020 12:00:00 AM

Review Cycle: Years

Author: Supt. SHE Fixed Plant

AuthorPosID: SHE1504 Inspeksi Umum _General Inspection

Approval: Manager SHLP

ApprovalPosID: SHE1501

7 C1 Mengganti pin pengaman P Triawan, Heri 7 Desember Yes

APAR dengan yang baru Bambang Setyono 2023

Afif: Pin pengaman APAR di area tangki

konsentrat rusak

THIS DOCUMENT IS UNCONTROLLED IN HARD COPY FORMAT

Doc No: CDC-GMT-013-F100

Page: 9 of 13 Version: 5.5 GENERAL MANAGEMENT

Approval Date: 7/7/2020 12:00:00 AM

Review Cycle: Years

Author: Supt. SHE Fixed Plant

AuthorPosID: SHE1504 Inspeksi Umum _General Inspection

Approval: Manager SHLP

ApprovalPosID: SHE1501

8 C1 Refill cleaning kit lensa P Triawan, Heri 7 Desember Yes

Bambang Setyono 2023

Ronald: Cleaning kit lensa sudah habis di area

workshop

9 C1 Penambahan inspection P Triawan, Heri 7 Desember No

tag untuk load ring Bambang Setyono 2023

Andhini: Tidak ditemukan tagging inspection

pada load ring

THIS DOCUMENT IS UNCONTROLLED IN HARD COPY FORMAT

Doc No: CDC-GMT-013-F100

Page: 10 of 13 Version: 5.5 GENERAL MANAGEMENT

Approval Date: 7/7/2020 12:00:00 AM

Review Cycle: Years

Author: Supt. SHE Fixed Plant

AuthorPosID: SHE1504 Inspeksi Umum _General Inspection

Approval: Manager SHLP

ApprovalPosID: SHE1501

10 C1 Penambahan tag pada P Triawan, Heri 7 Desember Yes

APAR Bambang Setyono 2023

Atika: APAR di area jetty tidak memiliki

tagging

THIS DOCUMENT IS UNCONTROLLED IN HARD COPY FORMAT

Doc No: CDC-GMT-013-F100

Page: 11 of 13 Version: 5.5 GENERAL MANAGEMENT

Approval Date: 7/7/2020 12:00:00 AM

Review Cycle: Years

Author: Supt. SHE Fixed Plant

AuthorPosID: SHE1504 Inspeksi Umum _General Inspection

Approval: Manager SHLP

ApprovalPosID: SHE1501

11 C1 Melakukan inspeksi Triawan, Heri 5 Desember

APAR dan mengupdate Bambang Setyono 2023

checklist pada tag APAR

Darius: Tag APAR pada unit loader 102 belum

ada checklist inspection bulan November

Kelas Bahaya/ Hazard Class Prioritas/ Jenis Solusi/ Parameter

Priority Action

Category

Prioritas tindakan “A” : Menangani bahaya yang mengancam keselamatan jiwa atau A1 Sementara Jatuh tempo ditentukan secara otomatis dalam waktu 24 jam sesuai tanggal

kesehatan dengan potensi kejadian level 4 atau 5 (misalnya, bekerja di ketinggian atau bekerja di dan waktu pembuatan Event

dekat "lubang" terbuka tanpa mengenakan harness dan lanyard, atau memasuki ruang terbatas tanpa Temporary Due Date automatically set to 24 hours based on the Date & Time the

mendapatkan izin dan melakukan uji gas/udara sebagaimana mestinya). Event is created.

“A” Priority actions address hazards immediately dangerous to life or health with the potential for a A2 Permanen Jatuh tempo harus ditentukan dalam jangka waktu 60 hari sesuai tanggal

Level 4 or 5 event. (e.g., working at height or near an “open” hole without a harness and lanyard, or pembuatan Event

entering a confined space without a permit and proper oxygen/gas testing). Permanent Due Date must be set within 60 Days based on the Date the Event is

created.

Prioritas tindakan “B”: Menangani kondisi atau praktik kerja yang membahayakan keselamatan B1 Sementara Jatuh tempo ditentukan secara otomatis dalam waktu 3 hari sesuai tanggal

manusia, merusak properti dan menggangu proses kerja (misalnya, melakukan pengelasa di ban dan waktu pembuatan Event

berjalan tanpa dilengkapi dengan alat pemadam kebakaran atau mengamati pekerja yang Temporary Due Date automatically set to 3 Days based on the Date the Event is

THIS DOCUMENT IS UNCONTROLLED IN HARD COPY FORMAT

Doc No: CDC-GMT-013-F100

Page: 12 of 13 Version: 5.5 GENERAL MANAGEMENT

Approval Date: 7/7/2020 12:00:00 AM

Review Cycle: Years

Author: Supt. SHE Fixed Plant

AuthorPosID: SHE1504 Inspeksi Umum _General Inspection

Approval: Manager SHLP

ApprovalPosID: SHE1501

menggunakan peralatan kerja yang tidak sesuai dengan jenis pekerjaan). created.

“B” Priority actions address a condition or practice which could cause harm to people, property B2 Permanen Jatuh tempo tidak boleh lebih dari 12 bulan sesuai tanggal pembuatan

and processes (e.g., welding on a conveyor belt without proper fire suppression support or observing Event

someone using an incorrect hand tool for the job). Permanent Due Date not to exceed 12 months based on the Date the Event is created.

Prioritas tindakan “C”: Menangani pelanggaran peraturan K3 atau terdapat kekurangan yang C1 Sementara Jatuh tempo ditentukan secara otomatis dalam waktu 14 hari sesuai

membutuhkan tindakan perbaikan meskipun tidak begitu berbahaya, atau memerlukan upaya tanggal pembuatan Event

pencegahan agar tidak timbul kejadian serupa di kemudian hari (misalnya, tempat cuci mata yang Temporary Due Date automatically set to 14 Days based on the Date the Event is

rusak, akses keluar atau akses menuju lokasi alat pemadam kebakaran yang terhambat, pelindung created.

yang rusak atau retak, atau label peringatan pipa).

“C” Priority actions address safety violations or deficiencies requiring corrective action but are not C2 Permanen Jatuh tempo tidak boleh lebih dari 12 bulan sesuai tanggal pembuatan

immediately dangerous, or a preventative measure to prevent the same (e.g., inoperable eye wash Event

station, blocking an exit or fire extinguisher, broken or cracked guards, or labeling of pipelines). Permanent Due Date not to exceed 12 months based on the Date the Event is created.

Jenis Solusi/

Action Category:

Tindakan Tindakan korektif atau preventif yang harus segera diambil untuk mengendalikan suatu bahaya yang pada tanggal tertentu di masa mendatang akan dilanjutkan dengan tindakan permanen

Sementara yang lebih tegas. Tindakan sementara dapat berupa upaya penampungan darurat, pemasangan barikade dan pengaman, pemasangan label “rusak” pada peralatan/alat berat, dll.

Temporary An immediate, corrective or preventative action to control a hazard that will be replaced at a future date by a robust, permanent control. Temporary actions include emergency

Actions bunding/containment, interim barricades and guards, and “out of service” tags on equipment

Tindakan Tindakan korektif atau preventif yang bersifat permanen untuk mengendalikan bahaya dan risiko terkait lainnya. Pada umumnya, tindakan permanen menerapkan upaya pengendalian

Permanen sesuai “Hirarki Kontrol”, membutuhkan waktu untuk menerapkannya, seperti tahapan persiapan dan persetujuan AFE agar dapat melakukan kontrol teknis, pembuatan platform kerja, atau

Permanent Action pembelian perkakas dan peralatan yang diperlukan untuk pekerjaan khusus.

An enduring, corrective or preventative action to control a hazard and its associated risks. Typically, permanent actions use the “Hierarchy of Controls”, require additional time to

implement and include such activities as the preparation and approval of an AFE to implement an engineering control, construction of a work platform, or the purchasing of equipment or

tools for a specific job or task.

THIS DOCUMENT IS UNCONTROLLED IN HARD COPY FORMAT

Chemical handling &

Doc No: CDC-GMT-013-F100 Machine Guarding Electrical equipment Hand Tools Rigging Lifting gear Rigging Lifting gear PPE

labeling

Page: 13 of 13 Version: 5.5 GENERAL MANAGEMENT

Approval Date: 7/7/2020 12:00:00 AM

Chemical Substance

Review Cycle: Labeled

Years The Nip-point and shear The cords used/place along HAMMER /Palu. WIRE ROPE SLINGS: HOOKS AND Hard Hat / Safety Glasses/Face

Bahan

Author:kimia diberi

Supt. SHElabel

Fixed Plant hazards have guard the floor properly Not modified SWL clearly displayed SHACKLES: TURN Shields, Safety boots/Shoes Worn

Titik jepit pada peralatan Kabeldipakai/ditempatkan Tdk di modifikasi SWL terbaca jelas BUCKLE AND EYE Properly

AuthorPosID: SHE1504

Properly Stored telah di pasang pelindung

Inspeksi Umum _General

sepanjang lantai dengan baik

Inspection

The handle not broken No broken wires or strands BOLT: Helm Pengaman,

Approval: Manager SHLP

Disimpan dengan benar

ApprovalPosID: SHE1501 dan aman oily,greazy/ 10% SWL clearly displayed Kacamata,pelindung muka,

The rotating part have guards Gagang tdk rusak,kena, oil Kerusakan kawat/ stran tidak SWL terbaca jelas sepatu dikenakan dengan benar

Spill sorbent available Peralatan yang The wire properly insulated/ gemuk - lebih 10 % No Damaged, Not modified Tidak

penyerap tumpahan tersedia? bergerak/berputar telah Kabel terisolasi dengan baik No"Masroomed"striking No excessive wear to rusak, tidak dimodifikasi

terpasang pelindung heads / No core damage, bird caging load bearing surfaces -

Ventilation Working The connections are proper kepala tdk berbentuk jamur and rope twist Tidak ada bekas beban Hearing protection/ Respiratory,

ventilasi dalam kondisi baik The hopper or chute opening tight/ kinked, high stranded berlebih Gloves, Fall Protection Worn

MSDS Available have guards Sambungan terikat dg baik SCREWDRIVERS / Obeng Core tidak rusak, membentuk where required, Proper type, Good

MSDS tersedia Hopper atau Chute yang Not modified / sarang burung atau terpilin Condition

Threads and linkages are

terbuka terpasang pelindung. Electric Hand Tools free from Tdk di modifikasi Alat Pelindung Pendengaran, alat

in good condition

MSDS accessible to oil grace or water Not bent,crack,or badly pelindung pernafasan, sarung

No cracked fitting Thread dan linkage

employee The loading, Perkakas tangan listrik bebas chipped etc/ tangan, alat pelindung jatuh

Tidak retak pada fitting kondisi baik

MSDS mudah diperoleh unloading,discharge point dari olie , grace, air Tdk bengkok,retak atau dikenakan jika diperlukan, Tipe

karyawan? have guards sumbing dll yang sesuai

Tempat pemuatan The electrical switch breaker No rusted, inlaying, reduce Safety latches are fitted dalam kondisi baik

The handle not broken

MSDS complete pages and pembongkaran, penumpahan has proper lock/ diameter, stretched. and in good working

Gagang tidak rusak

binder? terpasang pelindung, hand switch breaker dilengkapi Tidak berkarat, tidak order. Personal Floatation Device/

Halaman dan binder MSDS rail/ pagar dengan gembok berkurang diameter, tegang. Safety latch terpasang Worn where required with

Blade/Gergaji

lengkap? Switch breaker has protect dan konsidi baik. condition properly/ Pelampung

The blade not bent

The opening floor have guards from water rain CHAIN SLINGS / COME dikenakan ketika diperlukan sesuai

corrosive,crack etc/

Stored at MSDS Green Box? Lantai kerja yang terbuka Switch breaker terlindung dari ALONG: SYNTHETIC SLINGS dengan keadaan.

mata gregaji tdk

Disimpan di kotak hijau terpasang pelindung air hujan SWL clearly marked on tag (WEBBING SLING): -Life vest in good condition Baju

bengkok,berkarat,retak

MSDS? SWL terbaca jelas SWL clearly displayed pelampung dalam kondisi baik

Not modified /

Emergency stops working The electrical equipment used SWL terbaca jelas

Tdk di modifikasi -

Emergency stops berfungsi three pin The handle not broken, oily No cracks, nick

Peralatan listrik menggunakan greazy gouges or pits eyes no overload damage

Inter locks operational tiga pin/kaki Gagang tidak rusak,terkena oli Tidak retak, takik, lubang Tidak ada kerusakan krn

Interlock berfungsi gemuk stretching or elongation beban berlebih

The electrical equipment has The handle not broken Tidak tertarik

Emergency Pull Cords proper ground / Gagang tidak rusak Stitching and fiber no

good condition access not Perlatan listrik dilengkapi excessive drag wear, bent damage

blocked dengan pembumian OTHERS / lAIN - LAIN worn 10% Jahitan dan fiber tidak

Emergency Pull Cords kondisi Crowbar, mattock tidak melebihi beban, bengkok rusak

baik tidak terhalang Electrical Cords Free from Clamps.Snip,Wrenches etc/ rusak lebih 10%

defect, Protect from hazard linggis,sekop,cangkul No oil, grease or

Kabel listrik tidak rusak, penjepit,gunting, kunci Safety latches in good chemical contamination

Terlindung dari bahaya inggris Safety kondisi baik Tidak beroli, berminyak,

terkontaminasi bahan

kimia.

Walkways, ladders, stairs, Fire & Emergency Material storage Environmental Hazards

Work Permits Compressed gas cylinders Scaffolding

aisle Equipment facilities

Excavation Permits, exist Proper Labeling and Scaffolds are properly tagged Portable ladders stored Portable Fire Extinguisher Material storage Environmental spill kit (drums,

properly, fill completed identification of the contents Scaffold dipasang tag sesuai horizontally in suitable racks. Pemadam Portable Tempat penyimpanan absorbents, shovel, gloves) Peralatan

Izin penggalian ada dan di isi Telah diberi label dan isinya Tangga portable di simpan material spill – Drum, absorben, skop, sarung

dengan lengkap dan benar diketahui Scaffolds have proper level secara horizontal Inspect regularly - Load limits/Batas tangan.

Confined space entry permits, The compress gas cylinder Scaffolds tidak miring Di inspeksi secara berkala beban Chemical & oil containment (125%

exist properly, fill completed tied off properly/ Portable ladders equipped Pressure on standard - Secure/Pengikatan capacity, no water, valves are

Izin memasuki ruang terbatas Silinder bertekanan terikat Scaffolds secured to the with slip-resistant bases. Tekanan dalam standard - Shelving closed) Kontenmen bahan kimia dan

ada dan di isi dengan lengkap dengan benar/kuat adjacent structure Tangga portable di lengkapi proper/Pengaturan oli (125% kapasitas penampungan,

dan benar Inspection cylinder, valve and Scaffolds terlindung dari dengan dasar anti slip Cylinder and handle no rusted yang sesuai tidak ada air, valve dalam keadaan

Pre-use inspection, exist protective cover valve, bangunan terdekat Tabung dan pegangan tidak - Height/Ketinggian tertutup).

properly, fill completed

Pemeriksaan sebelum

corrosion / THIS DOCUMENT

Pemeriksaan silinder, katub

Scaffolds insulated

ISfromUNCONTROLLED

Portable metal ladders shall IN HARD COPY FORMAT

not be used for any electrical

berkarat

Proper placed

-

yang

Stable loads/Beban Potentials for spillages (valves,

hoses, pumps, pipe fittings) Potensi

penggunaan alat, ada dan di isi dan tutup katup, korosi contact and ground potential work. Penempatan yang sesuai stabil terjadinya tumpahan (keran/valve,

dengan lengkap dan benar Name of the gasses to be from all exposed electrical Tangga portable dari metal slang/hose, pompa, sambungan

Pre-shift inspection, exist stored an NO SMOKING sources. tidak boleh di gunakan pada Fire Hydrant House Keeping pipa).

You might also like

- Rigging Loft Management ProcedureDocument11 pagesRigging Loft Management Procedurekacang mete100% (2)

- Status Note On Collective Investment Schemes - 1326177032722-ADocument225 pagesStatus Note On Collective Investment Schemes - 1326177032722-AVivek Agrawal67% (3)

- Docs Slides Lecture11Document18 pagesDocs Slides Lecture11Irham DodotNo ratings yet

- Doc. No. FORM-PTSI-CIO-005-E Rev. 02 Date 16/11/15 Page 1 of 1 Doc. Ref. WI-PTSI-CIO-002-EDocument1 pageDoc. No. FORM-PTSI-CIO-005-E Rev. 02 Date 16/11/15 Page 1 of 1 Doc. Ref. WI-PTSI-CIO-002-ERiswan UthamiNo ratings yet

- Proforma Invoice: Organization Account Delivery ProjectDocument1 pageProforma Invoice: Organization Account Delivery ProjectM. SHOLA HuddinNo ratings yet

- Case - CFF GALA Rev 1 12-7-2023 2-00-47 PMDocument2 pagesCase - CFF GALA Rev 1 12-7-2023 2-00-47 PMIjoel Chuvu Part IINo ratings yet

- Corrective and Preventive Action Request Form: Pt. Akura Bina CitraDocument1 pageCorrective and Preventive Action Request Form: Pt. Akura Bina CitraAndreasSembiringNo ratings yet

- Corrective and Preventive Action Request Form: Pt. Akura Bina CitraDocument1 pageCorrective and Preventive Action Request Form: Pt. Akura Bina CitraAndreasSembiringNo ratings yet

- Inspection Kendaraan Area Up Stream (9 September 2023)Document7 pagesInspection Kendaraan Area Up Stream (9 September 2023)Gea LindriNo ratings yet

- Training Effectiveness IndividualDocument1 pageTraining Effectiveness IndividualRahul KumarNo ratings yet

- IBSPL-HSE-F17 HSE Violation ReportDocument1 pageIBSPL-HSE-F17 HSE Violation ReportAbdul RaheemNo ratings yet

- Test Report: Dilip Buildcon LimitedDocument5 pagesTest Report: Dilip Buildcon LimitedRitesh TiwariNo ratings yet

- Leave Application Form: For Employee UseDocument1 pageLeave Application Form: For Employee UseEldiiarNo ratings yet

- Assessment Coversheet AT3 Assessment 3 Portfolio Activities: BSB30115 Certificate III in BusinessDocument6 pagesAssessment Coversheet AT3 Assessment 3 Portfolio Activities: BSB30115 Certificate III in BusinessAnaya SharmaNo ratings yet

- Case - CFF GALA Rev 1 12-11-2023 10-39-48 AMDocument2 pagesCase - CFF GALA Rev 1 12-11-2023 10-39-48 AMIjoel Chuvu Part IINo ratings yet

- Annex 1 General Permit FormDocument1 pageAnnex 1 General Permit FormYunan EdhieNo ratings yet

- On-Site Audit ReportDocument6 pagesOn-Site Audit ReportSetyo Edy PrasetyoNo ratings yet

- Invoice No. INV.004 - BESMAN - 06 - 2022Document1 pageInvoice No. INV.004 - BESMAN - 06 - 2022ibnubesmanNo ratings yet

- 5M54C DC Duri0726120190423prf01Document26 pages5M54C DC Duri0726120190423prf01Ryan SinagaNo ratings yet

- Eni 10009E04 PDFDocument64 pagesEni 10009E04 PDFSammyNo ratings yet

- Pt. Sulawesi Resources: Pesanan Pembelian / Purchase RequisitionDocument4 pagesPt. Sulawesi Resources: Pesanan Pembelian / Purchase RequisitionPriambodo AriewibowoNo ratings yet

- Niti Ayog AIMDocument2 pagesNiti Ayog AIMShweta AgrawalNo ratings yet

- Diversity ReportDocument46 pagesDiversity ReportKunal Neha GognaNo ratings yet

- QUA-04-10-04 Action PlanDocument1 pageQUA-04-10-04 Action PlanEdwin MofokengNo ratings yet

- Spectro Lab Surface Burring Report - D201003041 - 1 - N35287 - F D201003041 1RST13207221020014741Document6 pagesSpectro Lab Surface Burring Report - D201003041 - 1 - N35287 - F D201003041 1RST13207221020014741Dtl DiagNo ratings yet

- PDF Professional Practice RQF Assignment DDDocument115 pagesPDF Professional Practice RQF Assignment DDlamo putiNo ratings yet

- Shanmugha Precision Forging Non - Conformance Report: Rejected Due To Chamfer Value: 5112Document1 pageShanmugha Precision Forging Non - Conformance Report: Rejected Due To Chamfer Value: 5112Ravichandran DNo ratings yet

- SupervisorDocument2 pagesSupervisorgrantNo ratings yet

- Flange ManagementDocument32 pagesFlange ManagementMike Manalu100% (4)

- Controls Narrative For Incinerator Package (X-5202) : Petroleum Development Oman Document NumberDocument16 pagesControls Narrative For Incinerator Package (X-5202) : Petroleum Development Oman Document NumberMuhammad IrfanNo ratings yet

- 11.3 Monthly Cert. of PaymentDocument1 page11.3 Monthly Cert. of Paymentjiean salinas100% (1)

- Corrective Action Request CAR 1 of 3: Please Sent Not More Than 5 Working Days To andDocument4 pagesCorrective Action Request CAR 1 of 3: Please Sent Not More Than 5 Working Days To andAgus DuriatNo ratings yet

- Yfg Berhad Corrective Action Request (Car) : QHSE-F11 Rev: 00Document2 pagesYfg Berhad Corrective Action Request (Car) : QHSE-F11 Rev: 00Therukumaran a/l NarayanasamyNo ratings yet

- JVT-W-QS-000-085-B.2 Work Permit Form - On O&M SiteDocument4 pagesJVT-W-QS-000-085-B.2 Work Permit Form - On O&M SiteGilbert GillNo ratings yet

- Formulir Isian Kualifiasi: Ival Pahlevi Direktur Cv. Pahlevi Dwi UtamaDocument7 pagesFormulir Isian Kualifiasi: Ival Pahlevi Direktur Cv. Pahlevi Dwi UtamaSyaef AzzuhryNo ratings yet

- Appendix E-Sub-Cons Vendor HSE Pre-Qualification Checklist Rev 2Document15 pagesAppendix E-Sub-Cons Vendor HSE Pre-Qualification Checklist Rev 2Justice AkuboNo ratings yet

- Rma Inw5008611321Document1 pageRma Inw5008611321310-Harikarasuthan PNo ratings yet

- Conoth HSE PlanDocument32 pagesConoth HSE Plannanda dwi ariyadiNo ratings yet

- Spill Response Procedures OCLDocument14 pagesSpill Response Procedures OCLThusithaNo ratings yet

- Corrective and Preventive Action Request Form: Pt. Akura Bina CitraDocument1 pageCorrective and Preventive Action Request Form: Pt. Akura Bina CitraAndreasSembiringNo ratings yet

- Sts23 Januari 201333Document53 pagesSts23 Januari 201333husen123 alhusadaNo ratings yet

- KN Network Services - Job Diary Information Sheet: Products To Be CompletedDocument3 pagesKN Network Services - Job Diary Information Sheet: Products To Be CompletedConstantin Emilian AvorniceseiNo ratings yet

- Annexure For Probition DeclaretionDocument3 pagesAnnexure For Probition DeclaretionPhanindra KottapalliNo ratings yet

- KN Network Services - Job Diary Information Sheet: Products To Be CompletedDocument3 pagesKN Network Services - Job Diary Information Sheet: Products To Be CompletedConstantin Emilian AvorniceseiNo ratings yet

- Corrective and Preventive Action Request Form: Pt. Akura Bina CitraDocument1 pageCorrective and Preventive Action Request Form: Pt. Akura Bina CitraAndreasSembiringNo ratings yet

- Approved CAF Dismantling and Re-Installation of Clerestory Window 1100416169Document5 pagesApproved CAF Dismantling and Re-Installation of Clerestory Window 1100416169Evangeline Anting EndrinaNo ratings yet

- Case - CFF GALA Rev 1 12-7-2023 1-51-11 PMDocument2 pagesCase - CFF GALA Rev 1 12-7-2023 1-51-11 PMIjoel Chuvu Part IINo ratings yet

- Equipment and Tools Inspection Submission FormDocument6 pagesEquipment and Tools Inspection Submission FormMuhammad TriansyahNo ratings yet

- Inspection Report - JELDocument5 pagesInspection Report - JELfery buyaNo ratings yet

- Deskide Service Report: Customer: Address: Reference: Oneservice Ticket No.: Contact: Telephone: EmailDocument2 pagesDeskide Service Report: Customer: Address: Reference: Oneservice Ticket No.: Contact: Telephone: EmailSeptian UtamaNo ratings yet

- KN Network Services - Job Diary Information Sheet: Products To Be CompletedDocument3 pagesKN Network Services - Job Diary Information Sheet: Products To Be CompletedConstantin Emilian AvorniceseiNo ratings yet

- DRSMMNaiduDocument11 pagesDRSMMNaiduMOHAN MAHALAKSHMI NAIDUNo ratings yet

- HSEP12F11 - Lockout Tagout PermitDocument2 pagesHSEP12F11 - Lockout Tagout Permitasheshdas189No ratings yet

- PTO - Shuttering and de Shuttering Rev 2Document2 pagesPTO - Shuttering and de Shuttering Rev 2grantNo ratings yet

- Minutes of Acceptance of Work (Bap)Document2 pagesMinutes of Acceptance of Work (Bap)Kurniawan RusliNo ratings yet

- Form Overtime 10 Sep 2023Document1 pageForm Overtime 10 Sep 2023Tamago Kental ManisNo ratings yet

- F-3 IST Internal Event Proposal FormDocument2 pagesF-3 IST Internal Event Proposal FormMehza SayedNo ratings yet

- 8D Report For Eye Bolt Dim 0.625Document1 page8D Report For Eye Bolt Dim 0.625Kapil HarchekarNo ratings yet

- PCD-OSH-SF-35 PTW For Confine SpaceDocument2 pagesPCD-OSH-SF-35 PTW For Confine Spacerizal azizanNo ratings yet

- Burner Capacity Curves For Incinerator Package (X-5202) : Petroleum Development Oman Document NumberDocument4 pagesBurner Capacity Curves For Incinerator Package (X-5202) : Petroleum Development Oman Document NumberMuhammad IrfanNo ratings yet

- General Term & Condition:: Purchase Order (Po) No PO: P2102755 PO Date: 2021-08-16 Dept: A200 / ProjectDocument1 pageGeneral Term & Condition:: Purchase Order (Po) No PO: P2102755 PO Date: 2021-08-16 Dept: A200 / ProjectAnjar MusofaNo ratings yet

- Vendor Selection - Qa Form PT. KPSDocument2 pagesVendor Selection - Qa Form PT. KPSJanVpotNo ratings yet

- Struktur Organisasi PerusahaanDocument1 pageStruktur Organisasi PerusahaanJanVpotNo ratings yet

- Label B3Document1 pageLabel B3JanVpotNo ratings yet

- Sertifikat OHS MS (ISO 45001) & SMKP 15 October 2022 - M. Syahril S.Document1 pageSertifikat OHS MS (ISO 45001) & SMKP 15 October 2022 - M. Syahril S.JanVpotNo ratings yet

- 15 - Bbs & Stop CardDocument39 pages15 - Bbs & Stop CardJanVpotNo ratings yet

- Nation BrandingDocument36 pagesNation BrandingHarun or RashidNo ratings yet

- Generators Portable Ultrasilent DCA125USI Rev 1 60 HZ Manual DataId 19064 Version 1Document90 pagesGenerators Portable Ultrasilent DCA125USI Rev 1 60 HZ Manual DataId 19064 Version 1Duy Kha100% (2)

- Surface Treatment of FibreDocument10 pagesSurface Treatment of FibreAshokan KelothNo ratings yet

- 2nd Sem Previous Yr. Question Papers (5 Subjects)Document44 pages2nd Sem Previous Yr. Question Papers (5 Subjects)Muhammed Muktar0% (1)

- Section 1 General Introduction To VibrationDocument38 pagesSection 1 General Introduction To Vibrationsudhiruday31No ratings yet

- Technical Proposal BNCTL OECUSSEDocument26 pagesTechnical Proposal BNCTL OECUSSEMartins MartinsNo ratings yet

- Verbal Section Reading CompDocument35 pagesVerbal Section Reading CompBasharat AliNo ratings yet

- An Islamic Alternative (Zakat) To Poverty Alleviation: The PARSHI ModelDocument23 pagesAn Islamic Alternative (Zakat) To Poverty Alleviation: The PARSHI Modelziadiqbal19100% (2)

- Sony Ericsson T290Document86 pagesSony Ericsson T290NickNo ratings yet

- Equipo PanasonicDocument42 pagesEquipo PanasonicCarlos JaramilloNo ratings yet

- Commscope CV3PX308R1Document5 pagesCommscope CV3PX308R1klamar5No ratings yet

- SMTP Mail Doku v12 v1 0 enDocument32 pagesSMTP Mail Doku v12 v1 0 enAnonymous RAqew4bNo ratings yet

- Navair 00 25 403 2005Document195 pagesNavair 00 25 403 2005freddy_gNo ratings yet

- Self Compacting ConcreteDocument9 pagesSelf Compacting ConcreteVimal VimalanNo ratings yet

- Financial Planning and BudgetingDocument45 pagesFinancial Planning and BudgetingRafael BensigNo ratings yet

- Commercial Banking System and Role of RBI - Assignment June 2021Document6 pagesCommercial Banking System and Role of RBI - Assignment June 2021sadiaNo ratings yet

- Introduction To Advanced Level Economics: by Brian RopiDocument293 pagesIntroduction To Advanced Level Economics: by Brian RopiSimba NheperaNo ratings yet

- Wealth-Insight - May 2021Document66 pagesWealth-Insight - May 2021vnmasterNo ratings yet

- SPA Manage BusinessDocument2 pagesSPA Manage BusinessronaNo ratings yet

- Banking Laws Cases Diligence Required From BanksDocument4 pagesBanking Laws Cases Diligence Required From Bankslalyn100% (1)

- O DR Manager 201307Document2 pagesO DR Manager 201307Aziz Ur RehmanNo ratings yet

- Employees' Health Insurance and Pension (Shakai Hoken 社会保険)Document2 pagesEmployees' Health Insurance and Pension (Shakai Hoken 社会保険)Putri HalinNo ratings yet

- SpaceCAD Model Rocket SoftwareDocument7 pagesSpaceCAD Model Rocket Softwareheric19886445No ratings yet

- Rules/Terms of ServiceDocument8 pagesRules/Terms of ServiceBaptiste THEVENOTNo ratings yet

- Project SPECIFIC TECHNICAL REQUIREMENTS PDFDocument311 pagesProject SPECIFIC TECHNICAL REQUIREMENTS PDFadnan53No ratings yet

- Science Has Made Life Better But Not Easier.' Discuss.Document2 pagesScience Has Made Life Better But Not Easier.' Discuss.Yvette LimNo ratings yet

- L/4 L/4 Support Support Mid-Span: RC SlabDocument1 pageL/4 L/4 Support Support Mid-Span: RC SlabLarizza TesicoNo ratings yet

- Communication Letter - LivelihoodDocument34 pagesCommunication Letter - LivelihoodlzymxNo ratings yet