Professional Documents

Culture Documents

Building Wire - Low Voltage Cable

Building Wire - Low Voltage Cable

Uploaded by

Mohammed Hussain OMCopyright:

Available Formats

You might also like

- Sample Voltage Drop Calculation-ExcelDocument6 pagesSample Voltage Drop Calculation-ExcelMohammed Hussain OMNo ratings yet

- Atestat Limba EnglezaDocument20 pagesAtestat Limba EnglezaAliceNo ratings yet

- General Chemical Safety Inspection ChecklistDocument3 pagesGeneral Chemical Safety Inspection ChecklistRizwan Khan100% (2)

- Lenovo Thinkpad E495 E595 LCFC PICASSO EX95 JINN - DOOKU 2.0 FE495 - FE595 NM-C061 Rev 1.0 (0.1)Document65 pagesLenovo Thinkpad E495 E595 LCFC PICASSO EX95 JINN - DOOKU 2.0 FE495 - FE595 NM-C061 Rev 1.0 (0.1)Jose Mauro de SouzaNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Middle Ages Unit TestDocument10 pagesMiddle Ages Unit Testmrsheatherwest100% (1)

- 03 - BRIA FLATS - Electrical Works Technical SpecsDocument83 pages03 - BRIA FLATS - Electrical Works Technical SpecsChristian PechaNo ratings yet

- Cable TraysDocument4 pagesCable TraysMohammed Hussain OMNo ratings yet

- Grounding and Bonding of Electrical SystemDocument5 pagesGrounding and Bonding of Electrical SystemMohammed Hussain OMNo ratings yet

- Grounding and Bonding For Electrical Systems - Rev - 1Document4 pagesGrounding and Bonding For Electrical Systems - Rev - 1Hany NassimNo ratings yet

- SECTION 26 05 19 Low-Voltage Electrical Power Conductors and CablesDocument9 pagesSECTION 26 05 19 Low-Voltage Electrical Power Conductors and CablesDenyNo ratings yet

- SECTION 26 05 13 Medium-Voltage CablesDocument10 pagesSECTION 26 05 13 Medium-Voltage Cablesjesus marquez arvaezNo ratings yet

- Medium Voltage CablesDocument12 pagesMedium Voltage Cableswafikmh4No ratings yet

- Low Voltage Electrical Power Conductors and Cables 600 Volts and BelowDocument6 pagesLow Voltage Electrical Power Conductors and Cables 600 Volts and BelowyonnatanzewdduNo ratings yet

- 16139-Cable TraysDocument4 pages16139-Cable TraysNATHANNo ratings yet

- 16123-Wires and Cables For 600V CircuitsDocument5 pages16123-Wires and Cables For 600V Circuitstristan guarinoNo ratings yet

- Medium-Voltage CablesDocument10 pagesMedium-Voltage CablesRa ArNo ratings yet

- Conductors and Cables 16120 - Page 1 of 8: S0557-SPC-EL-01 REV 3Document8 pagesConductors and Cables 16120 - Page 1 of 8: S0557-SPC-EL-01 REV 3Ni ReNo ratings yet

- SECTION 16124 Medium Voltage CableDocument9 pagesSECTION 16124 Medium Voltage Cablemahmoudabdelmaged31No ratings yet

- Low-Voltage Electrical Power Conductors and Cables PDFDocument9 pagesLow-Voltage Electrical Power Conductors and Cables PDFJairo WilchesNo ratings yet

- Low Voltage Electrical Power Conductors and Cable - Rev - 2Document4 pagesLow Voltage Electrical Power Conductors and Cable - Rev - 2Hany NassimNo ratings yet

- Medium Voltage Cables Rev01Document8 pagesMedium Voltage Cables Rev01Mohamed HamedNo ratings yet

- 1 Grounding and Bonding For Electrical SystemsDocument4 pages1 Grounding and Bonding For Electrical SystemsronniedakingpouNo ratings yet

- Distribution SwitchboardDocument9 pagesDistribution SwitchboardMohammed Hussain OMNo ratings yet

- ITB-KEOC-2013-009 - Section VIII B - Electrical Specifications PDFDocument115 pagesITB-KEOC-2013-009 - Section VIII B - Electrical Specifications PDFjaliscoruedaNo ratings yet

- BS 5467-1989Document47 pagesBS 5467-1989Adel Klk100% (1)

- SECTION 16126 Cables, High Voltage (Above 600 Volts) Part 1 - General 1.1 DescriptionDocument11 pagesSECTION 16126 Cables, High Voltage (Above 600 Volts) Part 1 - General 1.1 Descriptionno nameNo ratings yet

- E16050Document39 pagesE16050HOFFERNo ratings yet

- Equipment Wiring SystemsDocument3 pagesEquipment Wiring SystemsMohammed Hussain OMNo ratings yet

- 26 05 19 Low Voltage Electrical Power Conductors & CablesDocument12 pages26 05 19 Low Voltage Electrical Power Conductors & CablesrijalradziNo ratings yet

- 16126Document13 pages16126uddinnadeemNo ratings yet

- 16120-Conductors and CablesDocument7 pages16120-Conductors and CablesNATHANNo ratings yet

- Spec Raceways, Boxes & Fittings PDFDocument7 pagesSpec Raceways, Boxes & Fittings PDFHerman Damanik0% (1)

- Electric Wires and CablesDocument9 pagesElectric Wires and Cableswafikmh4No ratings yet

- Hvac-05 Air CoilsDocument3 pagesHvac-05 Air CoilsCosphiiiNo ratings yet

- Wires and CablesDocument7 pagesWires and CablessallammohamedNo ratings yet

- Va 27 10 00Document5 pagesVa 27 10 00Curtis SontohartonoNo ratings yet

- 16050Document40 pages16050shyamsundharNo ratings yet

- Flexible Conduit SpecsDocument10 pagesFlexible Conduit Specsafraz_xecNo ratings yet

- Section 26 05 33-Electrical Raceways PDFDocument14 pagesSection 26 05 33-Electrical Raceways PDFmasoodaeNo ratings yet

- QCS-2014 Section 21 - Part 6-Compliance PVC Cables (04-09-2018)Document13 pagesQCS-2014 Section 21 - Part 6-Compliance PVC Cables (04-09-2018)Hossam AltalebNo ratings yet

- 16124-Medium Voltage CablesDocument6 pages16124-Medium Voltage CablesThanveerNo ratings yet

- Power and Control CablesDocument7 pagesPower and Control CablesJeeva GvaNo ratings yet

- SECTION 16460 Transformers (General Purpose)Document4 pagesSECTION 16460 Transformers (General Purpose)no nameNo ratings yet

- SECTION 16112 Busway Part 1 - General 1.1 DescriptionDocument4 pagesSECTION 16112 Busway Part 1 - General 1.1 Descriptionno nameNo ratings yet

- Section 260526 - Grounding and Bonding For Electrical SystemsDocument6 pagesSection 260526 - Grounding and Bonding For Electrical SystemsVCNo ratings yet

- 1.1 Section IncludesDocument15 pages1.1 Section IncludesLuis BaqueNo ratings yet

- Earthing SystemDocument6 pagesEarthing SystemsallammohamedNo ratings yet

- SECTION 16127 Cables, Low Voltage (600 Volts and Below)Document11 pagesSECTION 16127 Cables, Low Voltage (600 Volts and Below)no nameNo ratings yet

- MV Cable & TerminationsDocument13 pagesMV Cable & TerminationsHaytham BafoNo ratings yet

- Electrical Spec.'S Cables, Wires & Color Codes. 16120 - 1Document6 pagesElectrical Spec.'S Cables, Wires & Color Codes. 16120 - 1Waleed Abd El-HamiedNo ratings yet

- Spec Wiring DevicesDocument10 pagesSpec Wiring DevicesDolyNo ratings yet

- SpecificationsDocument3 pagesSpecificationsvenkat0236No ratings yet

- Low Voltage SwitchingDocument4 pagesLow Voltage SwitchingMohammed Hussain OMNo ratings yet

- Low Voltage Electrical Power Conductors and Cables-Rev05Document15 pagesLow Voltage Electrical Power Conductors and Cables-Rev05Mohamed HamedNo ratings yet

- SECTION 16110 Residential Wiring Connections, Rev 0Document12 pagesSECTION 16110 Residential Wiring Connections, Rev 0Ahmed HashimNo ratings yet

- Wiring DevicesDocument6 pagesWiring DevicesMohammed Hussain OMNo ratings yet

- Medium Voltage Cable SpecDocument3 pagesMedium Voltage Cable SpecOanh NguyenNo ratings yet

- SwitchboardsDocument6 pagesSwitchboardsbate chinsauba (bate963)No ratings yet

- Cable Trays For Electrical Systems-Rev05Document8 pagesCable Trays For Electrical Systems-Rev05Mohamed Hamed100% (1)

- SpecificationsDocument3 pagesSpecificationsvenkat0236No ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- KSS - Technical - Data-To - Pick - The - Right - Cable - Marker-EDocument1 pageKSS - Technical - Data-To - Pick - The - Right - Cable - Marker-EMohammed Hussain OMNo ratings yet

- Electrical IdentificationDocument3 pagesElectrical IdentificationMohammed Hussain OMNo ratings yet

- Low Voltage SwitchingDocument4 pagesLow Voltage SwitchingMohammed Hussain OMNo ratings yet

- Distribution SwitchboardDocument9 pagesDistribution SwitchboardMohammed Hussain OMNo ratings yet

- Harmonic Filter Bank TuningDocument4 pagesHarmonic Filter Bank TuningMohammed Hussain OMNo ratings yet

- UPS Backup Time CalculatorDocument1 pageUPS Backup Time CalculatorMohammed Hussain OMNo ratings yet

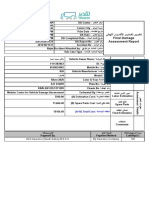

- ا رارــ ا رــ دــ ـ رـ رـ ـ Final Damage Assessment ReportDocument2 pagesا رارــ ا رــ دــ ـ رـ رـ ـ Final Damage Assessment Reportراكان العزبNo ratings yet

- Petitioners Vs Vs Respondents Arturo S. Santos For Petitioners. Conrado R. Mangahas & Associates For RespondentsDocument5 pagesPetitioners Vs Vs Respondents Arturo S. Santos For Petitioners. Conrado R. Mangahas & Associates For RespondentsAudrey DeguzmanNo ratings yet

- Failure To Detect and Report The Scams That Took Place Involving IL&FS and Its 21 Entities When They Were The Auditors of The IL&FSDocument4 pagesFailure To Detect and Report The Scams That Took Place Involving IL&FS and Its 21 Entities When They Were The Auditors of The IL&FSJay NirupamNo ratings yet

- Transpo - Prelims ReviewerDocument47 pagesTranspo - Prelims ReviewerMarrie SantiagoNo ratings yet

- FBI Summary About Alleged Flight 175 Hijacker Mohand AlshehriDocument11 pagesFBI Summary About Alleged Flight 175 Hijacker Mohand Alshehri9/11 Document Archive0% (1)

- EmkayDocument15 pagesEmkayCek IfaNo ratings yet

- Black Beauty AbrasiveDocument10 pagesBlack Beauty AbrasiveJesus De la RosaNo ratings yet

- Professional Practice RA 9266Document4 pagesProfessional Practice RA 9266Hana Yeppeoda100% (1)

- Cimapro19 CS3 1 EngDocument5 pagesCimapro19 CS3 1 EngReabetswe BodigeloNo ratings yet

- Voucher (Excel) - BLANKDocument15 pagesVoucher (Excel) - BLANKLOUEDA MAY Z. CARADONo ratings yet

- Philippine Cooperative Code of 2008 PDFDocument39 pagesPhilippine Cooperative Code of 2008 PDFNicole100% (1)

- R131S2 (B) - SANTOS VS NSODocument17 pagesR131S2 (B) - SANTOS VS NSOAllyza SantosNo ratings yet

- RCBC Vs de CastroDocument2 pagesRCBC Vs de Castrodominicci2026100% (1)

- Report: Informal Dialogue Between CSO and ASEAN Secretary General, Between CSO and ASEAN CPR and The 1st Jakarta Human Rights Dialogue (JHRD) Final PDFDocument84 pagesReport: Informal Dialogue Between CSO and ASEAN Secretary General, Between CSO and ASEAN CPR and The 1st Jakarta Human Rights Dialogue (JHRD) Final PDFYuyun WahyuningrumNo ratings yet

- Burke, Edmund. Reflections On The Revolution in France, Ed. J. C. D Clark. Stanford Stanford University Press, 2001.Document6 pagesBurke, Edmund. Reflections On The Revolution in France, Ed. J. C. D Clark. Stanford Stanford University Press, 2001.HippiasNo ratings yet

- The Letters of Peter Abelard and Heloise (12th Century)Document40 pagesThe Letters of Peter Abelard and Heloise (12th Century)Spun_GNo ratings yet

- Letter To DILGDocument2 pagesLetter To DILGVeda MariaNo ratings yet

- National Form Ucc-1Document4 pagesNational Form Ucc-1AaSima HajjaNo ratings yet

- Module 3 Math1 Ge3Document10 pagesModule 3 Math1 Ge3orogrichchelynNo ratings yet

- ANSYS Polyflow in ANSYS Workbench Users GuideDocument60 pagesANSYS Polyflow in ANSYS Workbench Users GuideV CafNo ratings yet

- County Noise OrdinanceDocument5 pagesCounty Noise Ordinancerp1858009462No ratings yet

- J 2005 SCC OnLine AP 316 2005 4 ALD 291 2005 33 AIC Suryachandrabadugu Dsnluacin 20230303 233718 1 9Document9 pagesJ 2005 SCC OnLine AP 316 2005 4 ALD 291 2005 33 AIC Suryachandrabadugu Dsnluacin 20230303 233718 1 9sunny baduguNo ratings yet

- Quotation For Food Stall For Mr. Abdullah Hamed Rev. 00Document2 pagesQuotation For Food Stall For Mr. Abdullah Hamed Rev. 00anwar surNo ratings yet

- Supreme Court of The United States: 1 Cite As: 601 U. S. - (2024) Per CuriamDocument20 pagesSupreme Court of The United States: 1 Cite As: 601 U. S. - (2024) Per CuriamABC News PoliticsNo ratings yet

- People v. Duca, October 9, 2009, G.R. No. 171175Document7 pagesPeople v. Duca, October 9, 2009, G.R. No. 171175brahmsNo ratings yet

- Mathematics of Finance HandoutDocument10 pagesMathematics of Finance Handoutleandro2620010% (2)

Building Wire - Low Voltage Cable

Building Wire - Low Voltage Cable

Uploaded by

Mohammed Hussain OMOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Building Wire - Low Voltage Cable

Building Wire - Low Voltage Cable

Uploaded by

Mohammed Hussain OMCopyright:

Available Formats

SECTION 16123

BUILDING WIRE AND LOW VOLTAGE CABLE

PART 1 GENERAL

1.01 SECTION INCLUDES

A. Building wire and low voltage cable. Wires and cables specified in this section shall

apply to all sections of these specifications.

B. Underground feeder and branch circuit cable.

C. Wiring connectors and connections.

1.02 RELATED SECTIONS

A. Section 16111 - Conduit.

B. Section 16130 - Boxes.

C. Section 16195 - Electrical Identification

1.03 REFERENCES

A. ANSI/NFPA 70 - National Electrical Code.

1.04 SUBMITTALS

A. Submit under provisions of Section 01300.

B. Product Data: Provide for each cable type.

C. Test Reports: Indicate procedures and values obtained.

D. Manufacturer's Installation Instructions: Indicate application conditions and limitations

of use stipulated by product testing agency specified under Regulatory Requirements.

1.05 QUALIFICATIONS

A. Manufacturer: Company specializing in manufacturing products specified in this

Section.

1.06 REGULATORY REQUIREMENTS

A. Conform to requirements of ANSI/NFPA 70.

B. Furnish products listed and classified by testing firm acceptable to authority having

jurisdiction as suitable for purpose specified and shown.

1.07 FIELD SAMPLES

A. Provide under provisions of Section 01400.

B. Submit two lengths, each 500 mm of cable assembly from each reel.

C. Select each length to include complete set of manufacturer markings.

D. Attach tag indicating cable size and application information.

1.08 PROJECT CONDITIONS

A. Verify that field measurements are as shown on Drawings.

B. Conductor sizes are based on copper.

C. Wire and cable routing shown on Drawings is approximate unless dimensioned.

Route wire and cable as required to meet Project Conditions.

D. Where wire and cable routing is not shown, and destination only is indicated,

determine exact routing and lengths required.

1.09 COORDINATION

A. Coordinate Work under provisions of contract documents

B. Determine required separation between cable and other work.

C. Determine cable routing to avoid interference with other work.

PART 2 PRODUCTS

2.01 MANUFACTURERS - BUILDING WIRE AND CABLES

A. Contractors option meeting specification.

2.02 BUILDING WIRE AND LOW VOLTAGE CABLE

A. Description: Single conductor insulated wire.

B. Conductor: Copper concentrically stranded, size as indicated on drawings.

C. Insulation Voltage Rating: 600/1000 volts.

D. Insulation: THHN or PVC 85ºC rated.

2.03 UNDERGROUND FEEDER AND BRANCH CIRCUIT CABLE

A. Description: ANSI/NFPA 70, Type UF.

B. Conductor: Copper

C. Insulation Voltage Rating: 600/1000 volts.

D. Insulation Temperature Rating: 900 C.

E. Where voltage connections are less than 100 volts, the wires or cables may be

insulated for 300 volts.

PART 3 EXECUTION

3.01 EXAMINATION

A. Verify that interior of building has been protected from weather.

B. Verify that mechanical work likely to damage wire and cable has been completed.

3.02 PREPARATION

A. Completely and thoroughly swab raceway before installing wire.

3.03 INSTALLATION

A. Install products in accordance with manufacturers instructions.

B. All the wires shall be stranded. No solid conductor shall be used even if it is less than

10 AWG ( 6 mm2.)

C. Use stranded conductors for control circuits.

D. Use 6mm2 (10 AWG) conductors for 20 ampere, 220 volt branch circuits longer than

61 m. For power and control minimum cable/wire size shall not be less than 4 mm².

E. Protect exposed cable from damage.

F. Use suitable cable fittings and connectors.

G. Neatly train and lace wiring inside boxes, equipment, and panelboards.

H. Clean conductor surfaces before installing lugs and connectors.

I. Make splices,taps, and terminations to carry full ampacity of conductors with no

perceptible temperature rise.

J. Use split bolt connectors for copper conductor splices and taps, 6 AWG and larger.

Tape uninsulated conductors and connector with electrical tape to 150 percent of

insulation rating of conductor.

K. Use solderless pressure connectors with insulating covers for copper conductor

splices and taps, 8 AWG and smaller.

L. Use insulated spring wire connectors with plastic caps for copper conductor splices

and taps, 10 AWG and smaller.

3.05 INTERFACE WITH OTHER PRODUCTS

A. Identify wire and cable under provisions of Section 16195.

B. Identify each conductor with its circuit number or other designation indicated on

Drawings.

C. Telephone or signal wires are included. The wiring for electric lighting, including

outlets for extension, clocks and fans, for electric power shall be furnished and

installed complete from point of service connections to all outlets indicated on

drawings.

D. Ample leads shall be provided for motor loops and service connection. Feeders shall

be of the sizes indicated on the drawings.

3.06 FIELD QUALITY CONTROL

A. Perform field inspection and testing under provisions of Section 01400.

B. Inspect wire and cable for physical damage and proper connection.

C. Measure tightness of bolted connections and compare torque measurements with

manufacturer's recommended values.

D. Verify continuity of each branch circuit conductor.

E. Perform insulation resistance test for wires after installations.

END OF SECTION

You might also like

- Sample Voltage Drop Calculation-ExcelDocument6 pagesSample Voltage Drop Calculation-ExcelMohammed Hussain OMNo ratings yet

- Atestat Limba EnglezaDocument20 pagesAtestat Limba EnglezaAliceNo ratings yet

- General Chemical Safety Inspection ChecklistDocument3 pagesGeneral Chemical Safety Inspection ChecklistRizwan Khan100% (2)

- Lenovo Thinkpad E495 E595 LCFC PICASSO EX95 JINN - DOOKU 2.0 FE495 - FE595 NM-C061 Rev 1.0 (0.1)Document65 pagesLenovo Thinkpad E495 E595 LCFC PICASSO EX95 JINN - DOOKU 2.0 FE495 - FE595 NM-C061 Rev 1.0 (0.1)Jose Mauro de SouzaNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Middle Ages Unit TestDocument10 pagesMiddle Ages Unit Testmrsheatherwest100% (1)

- 03 - BRIA FLATS - Electrical Works Technical SpecsDocument83 pages03 - BRIA FLATS - Electrical Works Technical SpecsChristian PechaNo ratings yet

- Cable TraysDocument4 pagesCable TraysMohammed Hussain OMNo ratings yet

- Grounding and Bonding of Electrical SystemDocument5 pagesGrounding and Bonding of Electrical SystemMohammed Hussain OMNo ratings yet

- Grounding and Bonding For Electrical Systems - Rev - 1Document4 pagesGrounding and Bonding For Electrical Systems - Rev - 1Hany NassimNo ratings yet

- SECTION 26 05 19 Low-Voltage Electrical Power Conductors and CablesDocument9 pagesSECTION 26 05 19 Low-Voltage Electrical Power Conductors and CablesDenyNo ratings yet

- SECTION 26 05 13 Medium-Voltage CablesDocument10 pagesSECTION 26 05 13 Medium-Voltage Cablesjesus marquez arvaezNo ratings yet

- Medium Voltage CablesDocument12 pagesMedium Voltage Cableswafikmh4No ratings yet

- Low Voltage Electrical Power Conductors and Cables 600 Volts and BelowDocument6 pagesLow Voltage Electrical Power Conductors and Cables 600 Volts and BelowyonnatanzewdduNo ratings yet

- 16139-Cable TraysDocument4 pages16139-Cable TraysNATHANNo ratings yet

- 16123-Wires and Cables For 600V CircuitsDocument5 pages16123-Wires and Cables For 600V Circuitstristan guarinoNo ratings yet

- Medium-Voltage CablesDocument10 pagesMedium-Voltage CablesRa ArNo ratings yet

- Conductors and Cables 16120 - Page 1 of 8: S0557-SPC-EL-01 REV 3Document8 pagesConductors and Cables 16120 - Page 1 of 8: S0557-SPC-EL-01 REV 3Ni ReNo ratings yet

- SECTION 16124 Medium Voltage CableDocument9 pagesSECTION 16124 Medium Voltage Cablemahmoudabdelmaged31No ratings yet

- Low-Voltage Electrical Power Conductors and Cables PDFDocument9 pagesLow-Voltage Electrical Power Conductors and Cables PDFJairo WilchesNo ratings yet

- Low Voltage Electrical Power Conductors and Cable - Rev - 2Document4 pagesLow Voltage Electrical Power Conductors and Cable - Rev - 2Hany NassimNo ratings yet

- Medium Voltage Cables Rev01Document8 pagesMedium Voltage Cables Rev01Mohamed HamedNo ratings yet

- 1 Grounding and Bonding For Electrical SystemsDocument4 pages1 Grounding and Bonding For Electrical SystemsronniedakingpouNo ratings yet

- Distribution SwitchboardDocument9 pagesDistribution SwitchboardMohammed Hussain OMNo ratings yet

- ITB-KEOC-2013-009 - Section VIII B - Electrical Specifications PDFDocument115 pagesITB-KEOC-2013-009 - Section VIII B - Electrical Specifications PDFjaliscoruedaNo ratings yet

- BS 5467-1989Document47 pagesBS 5467-1989Adel Klk100% (1)

- SECTION 16126 Cables, High Voltage (Above 600 Volts) Part 1 - General 1.1 DescriptionDocument11 pagesSECTION 16126 Cables, High Voltage (Above 600 Volts) Part 1 - General 1.1 Descriptionno nameNo ratings yet

- E16050Document39 pagesE16050HOFFERNo ratings yet

- Equipment Wiring SystemsDocument3 pagesEquipment Wiring SystemsMohammed Hussain OMNo ratings yet

- 26 05 19 Low Voltage Electrical Power Conductors & CablesDocument12 pages26 05 19 Low Voltage Electrical Power Conductors & CablesrijalradziNo ratings yet

- 16126Document13 pages16126uddinnadeemNo ratings yet

- 16120-Conductors and CablesDocument7 pages16120-Conductors and CablesNATHANNo ratings yet

- Spec Raceways, Boxes & Fittings PDFDocument7 pagesSpec Raceways, Boxes & Fittings PDFHerman Damanik0% (1)

- Electric Wires and CablesDocument9 pagesElectric Wires and Cableswafikmh4No ratings yet

- Hvac-05 Air CoilsDocument3 pagesHvac-05 Air CoilsCosphiiiNo ratings yet

- Wires and CablesDocument7 pagesWires and CablessallammohamedNo ratings yet

- Va 27 10 00Document5 pagesVa 27 10 00Curtis SontohartonoNo ratings yet

- 16050Document40 pages16050shyamsundharNo ratings yet

- Flexible Conduit SpecsDocument10 pagesFlexible Conduit Specsafraz_xecNo ratings yet

- Section 26 05 33-Electrical Raceways PDFDocument14 pagesSection 26 05 33-Electrical Raceways PDFmasoodaeNo ratings yet

- QCS-2014 Section 21 - Part 6-Compliance PVC Cables (04-09-2018)Document13 pagesQCS-2014 Section 21 - Part 6-Compliance PVC Cables (04-09-2018)Hossam AltalebNo ratings yet

- 16124-Medium Voltage CablesDocument6 pages16124-Medium Voltage CablesThanveerNo ratings yet

- Power and Control CablesDocument7 pagesPower and Control CablesJeeva GvaNo ratings yet

- SECTION 16460 Transformers (General Purpose)Document4 pagesSECTION 16460 Transformers (General Purpose)no nameNo ratings yet

- SECTION 16112 Busway Part 1 - General 1.1 DescriptionDocument4 pagesSECTION 16112 Busway Part 1 - General 1.1 Descriptionno nameNo ratings yet

- Section 260526 - Grounding and Bonding For Electrical SystemsDocument6 pagesSection 260526 - Grounding and Bonding For Electrical SystemsVCNo ratings yet

- 1.1 Section IncludesDocument15 pages1.1 Section IncludesLuis BaqueNo ratings yet

- Earthing SystemDocument6 pagesEarthing SystemsallammohamedNo ratings yet

- SECTION 16127 Cables, Low Voltage (600 Volts and Below)Document11 pagesSECTION 16127 Cables, Low Voltage (600 Volts and Below)no nameNo ratings yet

- MV Cable & TerminationsDocument13 pagesMV Cable & TerminationsHaytham BafoNo ratings yet

- Electrical Spec.'S Cables, Wires & Color Codes. 16120 - 1Document6 pagesElectrical Spec.'S Cables, Wires & Color Codes. 16120 - 1Waleed Abd El-HamiedNo ratings yet

- Spec Wiring DevicesDocument10 pagesSpec Wiring DevicesDolyNo ratings yet

- SpecificationsDocument3 pagesSpecificationsvenkat0236No ratings yet

- Low Voltage SwitchingDocument4 pagesLow Voltage SwitchingMohammed Hussain OMNo ratings yet

- Low Voltage Electrical Power Conductors and Cables-Rev05Document15 pagesLow Voltage Electrical Power Conductors and Cables-Rev05Mohamed HamedNo ratings yet

- SECTION 16110 Residential Wiring Connections, Rev 0Document12 pagesSECTION 16110 Residential Wiring Connections, Rev 0Ahmed HashimNo ratings yet

- Wiring DevicesDocument6 pagesWiring DevicesMohammed Hussain OMNo ratings yet

- Medium Voltage Cable SpecDocument3 pagesMedium Voltage Cable SpecOanh NguyenNo ratings yet

- SwitchboardsDocument6 pagesSwitchboardsbate chinsauba (bate963)No ratings yet

- Cable Trays For Electrical Systems-Rev05Document8 pagesCable Trays For Electrical Systems-Rev05Mohamed Hamed100% (1)

- SpecificationsDocument3 pagesSpecificationsvenkat0236No ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- KSS - Technical - Data-To - Pick - The - Right - Cable - Marker-EDocument1 pageKSS - Technical - Data-To - Pick - The - Right - Cable - Marker-EMohammed Hussain OMNo ratings yet

- Electrical IdentificationDocument3 pagesElectrical IdentificationMohammed Hussain OMNo ratings yet

- Low Voltage SwitchingDocument4 pagesLow Voltage SwitchingMohammed Hussain OMNo ratings yet

- Distribution SwitchboardDocument9 pagesDistribution SwitchboardMohammed Hussain OMNo ratings yet

- Harmonic Filter Bank TuningDocument4 pagesHarmonic Filter Bank TuningMohammed Hussain OMNo ratings yet

- UPS Backup Time CalculatorDocument1 pageUPS Backup Time CalculatorMohammed Hussain OMNo ratings yet

- ا رارــ ا رــ دــ ـ رـ رـ ـ Final Damage Assessment ReportDocument2 pagesا رارــ ا رــ دــ ـ رـ رـ ـ Final Damage Assessment Reportراكان العزبNo ratings yet

- Petitioners Vs Vs Respondents Arturo S. Santos For Petitioners. Conrado R. Mangahas & Associates For RespondentsDocument5 pagesPetitioners Vs Vs Respondents Arturo S. Santos For Petitioners. Conrado R. Mangahas & Associates For RespondentsAudrey DeguzmanNo ratings yet

- Failure To Detect and Report The Scams That Took Place Involving IL&FS and Its 21 Entities When They Were The Auditors of The IL&FSDocument4 pagesFailure To Detect and Report The Scams That Took Place Involving IL&FS and Its 21 Entities When They Were The Auditors of The IL&FSJay NirupamNo ratings yet

- Transpo - Prelims ReviewerDocument47 pagesTranspo - Prelims ReviewerMarrie SantiagoNo ratings yet

- FBI Summary About Alleged Flight 175 Hijacker Mohand AlshehriDocument11 pagesFBI Summary About Alleged Flight 175 Hijacker Mohand Alshehri9/11 Document Archive0% (1)

- EmkayDocument15 pagesEmkayCek IfaNo ratings yet

- Black Beauty AbrasiveDocument10 pagesBlack Beauty AbrasiveJesus De la RosaNo ratings yet

- Professional Practice RA 9266Document4 pagesProfessional Practice RA 9266Hana Yeppeoda100% (1)

- Cimapro19 CS3 1 EngDocument5 pagesCimapro19 CS3 1 EngReabetswe BodigeloNo ratings yet

- Voucher (Excel) - BLANKDocument15 pagesVoucher (Excel) - BLANKLOUEDA MAY Z. CARADONo ratings yet

- Philippine Cooperative Code of 2008 PDFDocument39 pagesPhilippine Cooperative Code of 2008 PDFNicole100% (1)

- R131S2 (B) - SANTOS VS NSODocument17 pagesR131S2 (B) - SANTOS VS NSOAllyza SantosNo ratings yet

- RCBC Vs de CastroDocument2 pagesRCBC Vs de Castrodominicci2026100% (1)

- Report: Informal Dialogue Between CSO and ASEAN Secretary General, Between CSO and ASEAN CPR and The 1st Jakarta Human Rights Dialogue (JHRD) Final PDFDocument84 pagesReport: Informal Dialogue Between CSO and ASEAN Secretary General, Between CSO and ASEAN CPR and The 1st Jakarta Human Rights Dialogue (JHRD) Final PDFYuyun WahyuningrumNo ratings yet

- Burke, Edmund. Reflections On The Revolution in France, Ed. J. C. D Clark. Stanford Stanford University Press, 2001.Document6 pagesBurke, Edmund. Reflections On The Revolution in France, Ed. J. C. D Clark. Stanford Stanford University Press, 2001.HippiasNo ratings yet

- The Letters of Peter Abelard and Heloise (12th Century)Document40 pagesThe Letters of Peter Abelard and Heloise (12th Century)Spun_GNo ratings yet

- Letter To DILGDocument2 pagesLetter To DILGVeda MariaNo ratings yet

- National Form Ucc-1Document4 pagesNational Form Ucc-1AaSima HajjaNo ratings yet

- Module 3 Math1 Ge3Document10 pagesModule 3 Math1 Ge3orogrichchelynNo ratings yet

- ANSYS Polyflow in ANSYS Workbench Users GuideDocument60 pagesANSYS Polyflow in ANSYS Workbench Users GuideV CafNo ratings yet

- County Noise OrdinanceDocument5 pagesCounty Noise Ordinancerp1858009462No ratings yet

- J 2005 SCC OnLine AP 316 2005 4 ALD 291 2005 33 AIC Suryachandrabadugu Dsnluacin 20230303 233718 1 9Document9 pagesJ 2005 SCC OnLine AP 316 2005 4 ALD 291 2005 33 AIC Suryachandrabadugu Dsnluacin 20230303 233718 1 9sunny baduguNo ratings yet

- Quotation For Food Stall For Mr. Abdullah Hamed Rev. 00Document2 pagesQuotation For Food Stall For Mr. Abdullah Hamed Rev. 00anwar surNo ratings yet

- Supreme Court of The United States: 1 Cite As: 601 U. S. - (2024) Per CuriamDocument20 pagesSupreme Court of The United States: 1 Cite As: 601 U. S. - (2024) Per CuriamABC News PoliticsNo ratings yet

- People v. Duca, October 9, 2009, G.R. No. 171175Document7 pagesPeople v. Duca, October 9, 2009, G.R. No. 171175brahmsNo ratings yet

- Mathematics of Finance HandoutDocument10 pagesMathematics of Finance Handoutleandro2620010% (2)