Professional Documents

Culture Documents

02 - Burgmann M3

02 - Burgmann M3

Uploaded by

Ruddy Fabrizio Galvez JustinianoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

02 - Burgmann M3

02 - Burgmann M3

Uploaded by

Ruddy Fabrizio Galvez JustinianoCopyright:

Available Formats

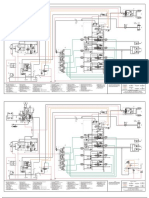

Mechanical seals • Mechanical seals for pumps · Pusher seals

1 M3N 1

l8 Seat alternatives

Mechanical seals

b l5 l6 l6 l 16 l 16 l6

l6

l5 l5 l 15 l 15 l5

30°

30°

20°

20°

20°

l 28 l 14 l 13 l 19

+0,1

+0,1

H11

H7

H11

H7

H8

H8

H11

H8

l 10 l 12 l 11 l 18

d 11

d 12

d 12

d 11

d7

d6

d7

d6

d6

d7

1.4 1.3 1.2 1.1 2 3 G9 (EN 12756) G6 (EN 12756) G4 G13 G16 (EN 12756)

min

H11

h6

H8

d3

db

d1

d6

d7

Dimensions in mm

d1 d3 d6 d7 d8 d111) d121) d13 db l1N l33) l5 l6 l7 l8 l9 l10 l11 l12 l13 l14 l15 l16 l18 l19 l213) l22 l23 l28 b2) R

6 14 – – – 11.5 16.0 16 8 – – – – – – – – 9.0 6.5 7.1 5.6 1.2 3.8 – – 10.5 11.9 – – – 1.2

8 18 – – – 15.5 19.2 18 11 – – – – – – – – 9.0 8.0 7.1 7.0 1.2 3.8 – – 15.5 16.9 – – – 1.2

10* 19 17 21 3 15.5 19.2 20 13 40 15.5 1.5 4 8.5 17.5 10.0 7.5 9.0 7.5 7.1 6.6 1.2 3.8 – – 15.5 16.9 – 6.6 (8) 1.2

20° 12* 21 19 23 3 17.5 21.6 22 16 40 16.0 1.5 4 8.5 17.5 10.0 7.5 10.0 6.5 7.6 5.6 1.2 3.8 – – 15.5 17.4 – 6.6 (8) 1.2

14* 23 21 25 3 20.5 24.6 24 18 40 16.5 1.5 4 8.5 17.5 10.0 7.5 10.0 6.5 7.6 5.6 1.2 3.8 – – 15.5 17.4 16.5 6.6 (8) 1.2

Features d8 15 24 – – – 20.5 24.6 25 19 – – – – – – – – 11.0 7.5 8.6 6.6 1.2 3.8 – – 15.5 17.4 – – – 1.2

3) 16* 26 23 27 3 22.0 28.0 26 21 40 18.0 1.5 4 8.5 17.5 10.0 7.5 11.5 8.5 9.0 7.5 1.5 5.0 – – 17.5 19.5 16.5 6.6 (8) 1.5

• For plain shafts l 3 / l 21 l9 5 18* 29 27 33 3 24.0 30.0 31 23 45 19.5 2.0 5 9.0 19.5 11.5 8.5 12.5 9.0 10.0 8.0 1.5 5.0 15 7 18.5 20.5 18.0 7.5 (8) 1.5

• Single seal l 1N l 7 +0,5 20* 31 29 35 3 29.5 35.0 34 26 45 22.0 2.0 5 9.0 19.5 11.5 8.5 12.5 8.5 9.5 7.5 1.5 5.0 15 7 20.0 22.0 19.0 7.5 (8) 1.5

• Unbalanced 22* 33 31 37 3 29.5 35.0 36 28 45 21.5 2.0 5 9.0 19.5 11.5 8.5 12.5 8.5 9.5 7.5 1.5 5.0 15 7 21.5 23.5 20.5 7.5 (8) 1.5

• Rotating conical spring 24* 35 33 39 3 32.0 38.0 38 30 50 23.5 2.0 5 9.0 19.5 11.5 8.5 12.5 8.5 9.5 7.5 1.5 5.0 15 7 23.0 25.0 22.0 7.5 (8) 1.5

25* 36 34 40 3 32.0 38.0 39 31 50 26.5 2.0 5 9.0 19.5 11.5 8.5 12.5 8.5 9.5 7.5 1.5 5.0 15 7 24.5 26.5 23.5 7.5 (8) 1.5

• Dependent on direction of rotation 26 37 – – – 34.0 40.0 40 32 – – – – 9.0 – – – 13.0 9.0 10.0 8.0 1.5 5.0 – – 24.5 26.5 23.5 – – 1.5

Item Part no. to DIN 24250 Description 28* 40 37 43 3 36.0 42.0 42 35 50 26.5 2.0 5 9.0 19.5 11.5 8.5 14.0 10.0 11.0 9.0 1.5 5.0 15 7 24.5 26.5 24.5 7.5 (8) 1.5

Advantages 1.1 472 Seal face 30* 43 39 45 3 39.2 45.0 44 37 50 26.5 2.0 5 9.0 19.5 11.5 8.5 14.0 11.5 11.0 10.5 1.5 5.0 15 7 24.5 25.0 24.5 7.5 (8) 1.5

• Universal application opportunities 1.2 412.1 O-Ring 32* 46 42 48 3 42.2 48.0 46 39 55 28.5 2.0 5 9.0 19.5 11.5 8.5 14.0 11.5 11.0 10.5 1.5 5.0 15 7 28.0 28.5 28.0 7.5 (8) 1.5

33* 47 42 48 3 – – 47 40 55 28.5 2.0 5 9.0 19.5 11.5 8.5 – 12.0 – – – – 15 7 – – – 7.5 (8) 1.5

• Insensitive to low solids content 1.3 474 Thrust ring 35* 49 44 50 3 46.2 52.0 49 43 55 28.5 2.0 5 9.0 19.5 11.5 8.5 14.5 12.0 11.5 11.0 1.5 5.0 15 7 28.0 28.5 28.0 7.5 (8) 1.5

• No damage of the shaft by set screws 1.4 478 Righthand spring 38* 53 49 56 4 49.2 55.0 54 45 55 33.5 2.0 6 9.0 22.0 14.0 10.0 14.5 11.3 11.5 10.3 1.5 5.0 16 8 31.0 32.2 31.0 9.0 7.5 1.5

• Large choice of materials 1.4 479 Lefthand spring 40* 56 51 58 4 52.2 58.0 56 49 55 36.0 2.0 6 9.0 22.0 14.0 10.0 14.5 11.8 11.5 10.8 1.5 5.0 16 8 34.0 34.7 34.0 9.0 (8) 1.5

• Short installation lengths possible (G16) 2 475 Seat (G9) 42 59 – – – 53.3 62.0 58 52 – – – – 9.0 – – – 17.0 13.2 14.3 12.0 2.0 6.0 – – 35.0 37.3 35.0 – – 2.5

43* 59 54 61 4 – – 59 52 60 38.5 2.0 6 9.0 22.0 14.0 10.0 – 13.2 – – 2.0 – 16 8 – – – 9.0 7.5 2.5

• Variants with shrink-fitted seal face available 3 412.2 O-Ring 45* 61 56 63 4 55.3 64.0 61 55 60 39.5 2.0 6 9.0 22.0 14.0 10.0 17.0 12.8 14.3 11.6 2.0 6.0 16 8 36.5 39.2 36.5 9.0 (8) 2.5

48* 64 59 66 4 59.7 68.4 64 58 60 46.0 2.0 6 9.0 22.0 14.0 10.0 17.0 12.8 14.3 11.6 2.0 6.0 16 8 42.0 44.7 42.0 9.0 (8) 2.5

Operating range (see note on page 1) Product variants 50* 66 62 70 4 60.8 69.3 66 61 60 45.0 2.5 6 9.0 23.0 15.0 10.5 17.0 12.8 14.3 11.6 2.0 6.0 17 9.5 43.0 45.7 43.0 9.5 (8) 2.5

Shaft diameter: d1 = 6 ... 80 mm (0.24" ... 3.15") M3 M37G 53* 69 65 73 4 – – 69 64 70 47.0 2.5 6 9.0 23.0 15.0 12.0 – 13.5 – – – – 17 9.5 – – – 11.0 8.0 2.5

55* 71 67 75 4 66.5 75.4 71 66 70 49.0 2.5 6 9.0 23.0 15.0 12.0 18.0 14.5 15.3 13.3 2.0 6.0 17 9.5 47.0 49.0 47.0 11.0 (8) 2.5

Pressure: p1 = 10 bar (145 PSI) Items and description as M3N. Items and descriptions as for type M3N, but with shrink 58* 76 70 78 4 69.5 78.4 78 69 70 55.0 2.5 6 9.0 23.0 15.0 12.0 18.0 14.5 15.3 13.3 2.0 6.0 18 10.5 50.0 52.0 50.0 11.0 (8) 2.5

Temperature: t = –20 °C ... +140 °C (–4 °F ... +355 °F) Seal face: Special cast CrMo steel (S) fitted silicon carbide seal face to the seal face carrier 60* 78 72 80 4 71.5 80.4 79 71 70 55.0 2.5 6 9.0 23.0 15.0 12.0 18.0 14.5 15.3 13.3 2.0 6.0 18 10.5 51.0 55.0 51.0 11.0 (8) 2.5

Sliding velocity: vg = 15 m/s (50 ft/s) Seat G13: Carbon graphite antimony impregnated (A), (Item no. 1.1). 63* 83 75 83 4 – – 83 74 70 55.0 2.5 6 9.0 23.0 15.0 12.0 – 14.2 – – – – 18 10.5 – – – 11.0 (8) 2.5

Axial movement: ±1.0 mm Carbon graphite resin impregnated (B) Shaft diameter: d1 = 16 ... 80 mm (0.63" ... 3.15") 65* 84 77 85 4 76.5 85.4 85 77 80 55.0 2.5 6 9.0 23.0 15.0 12.0 18.0 14.2 15.3 13.0 2.0 6.0 18 10.5 52.0 54.3 52.0 11.0 (8) 2.5

68* 88 81 90 4 82.7 91.5 88 80 80 55.0 2.5 7 9.0 26.0 18.0 12.5 19.0 14.9 16.0 13.7 2.0 6.0 18.5 11 53.0 55.3 52.7 11.3 (8) 2.5

Temperature: t = –20 °C ... +180 °C ( –4 °F ... +355 °F) 70* 90 83 92 4 83.0 92.0 90 83 80 57.0 2.5 7 9.0 26.0 18.0 12.5 18.0 14.2 15.3 13.0 2.0 6.0 19 11.5 54.0 56.3 54.0 11.3 (10) 2.5

Materials M32 Sliding velocity: vg = 10 m/s (33 ft/s) 75* 98 88 97 4 90.2 99.0 98 88 80 62.0 2.5 7 9.0 26.0 18.0 12.5 18.0 15.2 15.3 14.0 2.0 6.0 19 11.5 55.0 56.3 54.0 11.3 (10) 2.5

Seal face: CrMo special cast steel (S) Items and descriptions as for type M3N, but with carbon 80* 100 95 105 4 95.2 104.0 103 93 90 61.8 3.0 7 9.0 26.2 18.2 13.0 19.0 16.2 16.3 15.0 2.0 6.0 19 11.5 58.0 59.3 58.0 12.0 10.0 2.5

1) Fitting dimensions d and d only apply to type M37G with d >16 mm

Seat G9: Carbon graphite antimony impregnated (A), graphite seal face shrink-fitted into the seal face carrier Seal face: Silicon carbide (Q12, Q22), 11 12 1

2) Dimensions in brackets lie either above or below l

Carbon graphite resin impregnated (B) (Item no. 1.1) Tungsten carbide (U22) 3) l valid for M3...N, l valid for M3

1N

3 21

Seat G4: Silicon carbide (Q1, Q2) *) According to EN 12756

Standards and approvals Seal face: Carbon graphite antimony impregnated (A), Seat G13: Carbon graphite antimony impregnated (A),

• EN 12756 Carbon graphite resin impregnated (B) Carbon graphite resin impregnated (B)

Seat G4: Special cast CrMo steel (S), Seat G6 (M37GN4): Silicon carbide (Q1, Q2)

Recommended applications Silicon carbide (Q1, Q2) Seat G9 (M37GN): Carbon graphite antimony impregnated

• Process industry Seat G6 (M32N4): Special cast CrMo steel (S), (A), Carbon graphite resin impregnated (B),

• Water and waste water technology Silicon carbide (Q1, Q2) Silicon carbide (Q1, Q2)

• Chemical industry Seat G9 (M32N): Silicon carbide (Q1, Q2)

• Food and beverage industry Seat G6 also available in A, B = G30 (longer installation

• Low solids content media Seat G6 also available in A, B = G30 (longer installation length than G6)

• Water and sewage water pumps length than G6)

• Submersible pumps

• Chemical standard pumps

• Eccentric screw pumps

• Cooling water pumps

• Basic sterile applications

l22 l 23

d 13

d 13

M32 M37G

8 9

You might also like

- Scania: GR860 - GRE860Document5 pagesScania: GR860 - GRE860William BernardinoNo ratings yet

- SP408..1010 Englisch Zarges - 2016-02Document45 pagesSP408..1010 Englisch Zarges - 2016-02Lê Thanh TùngNo ratings yet

- Pile CapDocument1 pagePile CapUlul Azmi AINo ratings yet

- Fiber FilmDocument4 pagesFiber FilmDavid GarciaNo ratings yet

- Piratas Del Caribe RI50 Tuba 8Document3 pagesPiratas Del Caribe RI50 Tuba 8YakoButlerGarcíaNo ratings yet

- GERD-GSV06-7813-VHS-DAS Rotor Mounting Support Base Rev ADocument1 pageGERD-GSV06-7813-VHS-DAS Rotor Mounting Support Base Rev AKumlachew AliNo ratings yet

- 6 72431 Linked PDFDocument8 pages6 72431 Linked PDFАнатолій ГуменюкNo ratings yet

- Vincenzo Galilei - Saltarello - 1Document1 pageVincenzo Galilei - Saltarello - 1javierfep4244No ratings yet

- BAR Design Ation (JIS) Nominal Dimensions Semisircular Hook (MM) L - Shape Hook (MM) Bent Bar (MM) Rigid Frame (MM)Document7 pagesBAR Design Ation (JIS) Nominal Dimensions Semisircular Hook (MM) L - Shape Hook (MM) Bent Bar (MM) Rigid Frame (MM)FadliNo ratings yet

- (14-21"color TV Basic Schematic Diagram) : CRT BoardDocument1 page(14-21"color TV Basic Schematic Diagram) : CRT BoardAndrei Blas Azaña100% (1)

- Haydn Serenade Haydn 8008 PDFDocument2 pagesHaydn Serenade Haydn 8008 PDFElahe EsNo ratings yet

- El AbsolutoDocument2 pagesEl AbsolutoFranklin W Espinal WilderNo ratings yet

- Que Nem Jilo Trompete SwingDocument1 pageQue Nem Jilo Trompete SwingartesetiseductoNo ratings yet

- Alto Saxophone Animal CrossingDocument3 pagesAlto Saxophone Animal Crossingelli Papa100% (1)

- X20030751002PROMINENCEPROPERTIESINC OrchardPlaceResidencesDocument1 pageX20030751002PROMINENCEPROPERTIESINC OrchardPlaceResidencesRhobbie NolloraNo ratings yet

- Piratas Del Caribe RI50 Tuba PDFDocument3 pagesPiratas Del Caribe RI50 Tuba PDFYakoButlerGarcíaNo ratings yet

- 16 Map PrintableversionDocument1 page16 Map PrintableversionjaywNo ratings yet

- Amor, Amor, Amor!: 1st Alto SaxophoneDocument1 pageAmor, Amor, Amor!: 1st Alto SaxophoneJaime Allende CuevasNo ratings yet

- Avid SawanoHiroyukinZkmizuki Avid Animenz Arr Eighty Six EDDocument9 pagesAvid SawanoHiroyukinZkmizuki Avid Animenz Arr Eighty Six ED135017No ratings yet

- Marilia Mendonça ClarineteDocument1 pageMarilia Mendonça ClarineteJaimin LinsNo ratings yet

- CHA-LA HEAD-CHA-LA-Trombone 1Document2 pagesCHA-LA HEAD-CHA-LA-Trombone 1dbasslin0814No ratings yet

- Lestere Beach PiccoloDocument1 pageLestere Beach PiccoloTom beauvoirNo ratings yet

- Autor Da Minha Fé-Cresc. 02 Flute 1Document1 pageAutor Da Minha Fé-Cresc. 02 Flute 1Walison CarlosNo ratings yet

- (Free Com Schubert Franz Peter Impromptu Dur 12032Document13 pages(Free Com Schubert Franz Peter Impromptu Dur 12032Camila86% (7)

- ThursdayDocument3 pagesThursdayJim LethamNo ratings yet

- I Like It Like That-MDL_Tenor_LineDocument2 pagesI Like It Like That-MDL_Tenor_LineCool8saurioNo ratings yet

- Three Blind Mice: Soprano SaxophoneDocument2 pagesThree Blind Mice: Soprano SaxophoneJenniferVargaNo ratings yet

- ALL THAT JAZZ PianoDocument9 pagesALL THAT JAZZ Pianor.v.straatenNo ratings yet

- Cupid - Fifty Fifty-Tenor - SaxophoneDocument1 pageCupid - Fifty Fifty-Tenor - SaxophoneVisvanath RavindranNo ratings yet

- Hiace Turn Signal and Hazard Warning Light-01-01Document1 pageHiace Turn Signal and Hazard Warning Light-01-01Kudakwashe KurangwaNo ratings yet

- 1TB01005 005D01 Fos Im LG DWG Ar 71900Document1 page1TB01005 005D01 Fos Im LG DWG Ar 71900Dixit PatelNo ratings yet

- 15 Somos Biota Labordeta TubaDocument1 page15 Somos Biota Labordeta TubaRober Laita PunkyNo ratings yet

- 15 SOMOS BIOTA LABORDETA TubaDocument1 page15 SOMOS BIOTA LABORDETA TubaRober Laita PunkyNo ratings yet

- CONSAGRAÇÃO II Violino PDFDocument1 pageCONSAGRAÇÃO II Violino PDFana Luiza nascimentoNo ratings yet

- Amor, Amor - 1st Tuba - 2008-08-09 1019Document1 pageAmor, Amor - 1st Tuba - 2008-08-09 1019losesplendidosNo ratings yet

- Gambar Peningkatan Jaringan Tambak Budidaya 3.000 Ha Di Kabupaten Aceh UtaraDocument117 pagesGambar Peningkatan Jaringan Tambak Budidaya 3.000 Ha Di Kabupaten Aceh UtaraMuhammad FawziNo ratings yet

- Site Plan Lahan Pribadi Kec. Neoling: Jalan Komplek Lebar Jalan 6 MeterDocument1 pageSite Plan Lahan Pribadi Kec. Neoling: Jalan Komplek Lebar Jalan 6 MeterMuhammad HasbiNo ratings yet

- Simple Vco 0.1 20200524Document2 pagesSimple Vco 0.1 20200524MpuNetraningtyasNo ratings yet

- BLM Fire Holiday Farm Closure MapDocument1 pageBLM Fire Holiday Farm Closure MapSinclair Broadcast Group - EugeneNo ratings yet

- Relatos1 Bajos 1Document4 pagesRelatos1 Bajos 1Jose CastilloNo ratings yet

- The CamperVan and Motorhome BookDocument74 pagesThe CamperVan and Motorhome Bookdevil fixitNo ratings yet

- Nokia 5200 5300 Schematics PDFDocument32 pagesNokia 5200 5300 Schematics PDFEriflonaNo ratings yet

- Lejos de Tí: Tango 1948Document2 pagesLejos de Tí: Tango 1948DaylenaCalleUtimaNo ratings yet

- QUY50C Hydraulic System DiagramDocument1 pageQUY50C Hydraulic System DiagramMohamed SabryNo ratings yet

- 04 Augusto Alves - OboeDocument3 pages04 Augusto Alves - OboeRomeu SilvaNo ratings yet

- The Japanese American News 1938.8.11Document1 pageThe Japanese American News 1938.8.11Trystan HuangNo ratings yet

- Hs-Se40-Intl Rev BDocument1 pageHs-Se40-Intl Rev BSaurabh GuptaNo ratings yet

- Adagio in C Minor-ViolonceloDocument2 pagesAdagio in C Minor-ViolonceloMarcos Paulo B. GoulartNo ratings yet

- Adagio in C Minor-ViolonceloDocument2 pagesAdagio in C Minor-ViolonceloMarcos Paulo B. GoulartNo ratings yet

- 1 - Accepted: Type 1 Type 2Document1 page1 - Accepted: Type 1 Type 2Nagabhushana HNo ratings yet

- Allegro: Richard SiDocument1 pageAllegro: Richard SiRSNo ratings yet

- Pero Ella: Pop LatinoDocument2 pagesPero Ella: Pop Latinomartin salgadoNo ratings yet

- Cello_Mantis LordsDocument1 pageCello_Mantis LordssunshineNo ratings yet

- Drake Toosie Slide PDFDocument5 pagesDrake Toosie Slide PDFdridNo ratings yet

- A Minha Vida É Do Mestre Alto SaxophoneDocument2 pagesA Minha Vida É Do Mestre Alto SaxophoneJosimar CostaNo ratings yet

- Kajiura Tsubasachronicle Amrita ViolinDocument3 pagesKajiura Tsubasachronicle Amrita ViolinBob LedadNo ratings yet

- +++03 PO03020-13-Hxxx ZDocument22 pages+++03 PO03020-13-Hxxx Zhamzeh100% (1)

- Moment For Morricone-1st Trumpet in BBDocument3 pagesMoment For Morricone-1st Trumpet in BBFran LubiánsNo ratings yet

- BITZER Updated On 13-7-23-1Document14 pagesBITZER Updated On 13-7-23-1Hassan AhmedNo ratings yet

- February Monthly Collection, Grade 5From EverandFebruary Monthly Collection, Grade 5Rating: 3 out of 5 stars3/5 (1)

- Fill Your Glass With Gold-When It's Half-Full or Even Completely ShatteredFrom EverandFill Your Glass With Gold-When It's Half-Full or Even Completely ShatteredNo ratings yet

- It's So Easy Going Green: An Interactive, Scientific Look at Protecting Our EnvironmentFrom EverandIt's So Easy Going Green: An Interactive, Scientific Look at Protecting Our EnvironmentNo ratings yet

- The Rough Guide to Beijing (Travel Guide eBook)From EverandThe Rough Guide to Beijing (Travel Guide eBook)Rating: 2 out of 5 stars2/5 (1)

- Megachem 200-150-400Document1 pageMegachem 200-150-400Ruddy Fabrizio Galvez JustinianoNo ratings yet

- Jereh-Bomba de PistonDocument32 pagesJereh-Bomba de PistonRuddy Fabrizio Galvez JustinianoNo ratings yet

- CEM7 Rev2015Document133 pagesCEM7 Rev2015Ruddy Fabrizio Galvez JustinianoNo ratings yet

- Separadores CentrifugosDocument7 pagesSeparadores CentrifugosRuddy Fabrizio Galvez JustinianoNo ratings yet

- Ecoline GTC 150-600Document16 pagesEcoline GTC 150-600Ruddy Fabrizio Galvez JustinianoNo ratings yet

- Catalogo KSB SPBlocDocument8 pagesCatalogo KSB SPBlocRuddy Fabrizio Galvez Justiniano0% (1)

- SICCADocument24 pagesSICCARuddy Fabrizio Galvez JustinianoNo ratings yet

- MANUAL CENTRAL M6 - Rev1-FDocument24 pagesMANUAL CENTRAL M6 - Rev1-FRuddy Fabrizio Galvez JustinianoNo ratings yet

- BetriebsanleitungDocument26 pagesBetriebsanleitungRuddy Fabrizio Galvez JustinianoNo ratings yet

- IL-NT-MRS-2.2 Reference GuideDocument131 pagesIL-NT-MRS-2.2 Reference GuideRuddy Fabrizio Galvez Justiniano100% (1)

- Ib116 A Corrosion Resistant PumpsDocument9 pagesIb116 A Corrosion Resistant PumpsRuddy Fabrizio Galvez JustinianoNo ratings yet

- Ib117-A - High Temperature LiquidsDocument4 pagesIb117-A - High Temperature LiquidsRuddy Fabrizio Galvez JustinianoNo ratings yet

- DENTAL FLYER P 816 ED tcm11 8154Document1 pageDENTAL FLYER P 816 ED tcm11 8154Ruddy Fabrizio Galvez JustinianoNo ratings yet

- Submersible Portable Slurry Dewatering Pump: Single-Phase 550wattsDocument2 pagesSubmersible Portable Slurry Dewatering Pump: Single-Phase 550wattsRuddy Fabrizio Galvez JustinianoNo ratings yet

- Ia118-C SF PDFDocument3 pagesIa118-C SF PDFRuddy Fabrizio Galvez JustinianoNo ratings yet

- Con KRS2 ES - WEB PDFDocument4 pagesCon KRS2 ES - WEB PDFRuddy Fabrizio Galvez JustinianoNo ratings yet

- GS /GS: High Volume Dewatering PumpsDocument6 pagesGS /GS: High Volume Dewatering PumpsRuddy Fabrizio Galvez JustinianoNo ratings yet

- Catalogo Bombas Sumergibles Con Agitador TsurumiDocument8 pagesCatalogo Bombas Sumergibles Con Agitador TsurumiRuddy Fabrizio Galvez JustinianoNo ratings yet

- Con KRS ES - WEB PDFDocument4 pagesCon KRS ES - WEB PDFRuddy Fabrizio Galvez JustinianoNo ratings yet

- Con HSD ES - WEB PDFDocument4 pagesCon HSD ES - WEB PDFRuddy Fabrizio Galvez JustinianoNo ratings yet

- Con GPN ES - WEB PDFDocument4 pagesCon GPN ES - WEB PDFRuddy Fabrizio Galvez JustinianoNo ratings yet

- Ia124-A Family PDFDocument2 pagesIa124-A Family PDFRuddy Fabrizio Galvez JustinianoNo ratings yet

- Submersible Propeller PumpsDocument2 pagesSubmersible Propeller PumpsRuddy Fabrizio Galvez JustinianoNo ratings yet

- LH/LH-W GSZ-4: Submersible General Dewatering High Head PumpsDocument5 pagesLH/LH-W GSZ-4: Submersible General Dewatering High Head PumpsRuddy Fabrizio Galvez JustinianoNo ratings yet

- Perf 01 LH23.0W-60Document1 pagePerf 01 LH23.0W-60Ruddy Fabrizio Galvez JustinianoNo ratings yet

- Con GSZ ES - WEB PDFDocument4 pagesCon GSZ ES - WEB PDFRuddy Fabrizio Galvez JustinianoNo ratings yet

- RS (S, A, R) : Printed On Recycled Paper With Soy Ink - Evidence of Our Commitment To The EnvironmentDocument5 pagesRS (S, A, R) : Printed On Recycled Paper With Soy Ink - Evidence of Our Commitment To The EnvironmentRuddy Fabrizio Galvez JustinianoNo ratings yet

- AgitatorPumps Curves Specs PDFDocument1 pageAgitatorPumps Curves Specs PDFRuddy Fabrizio Galvez JustinianoNo ratings yet

- Submersible Extra High Head Pump: Max. 230m Head and Excellent Durability, Optimum For High Head ApplicationsDocument2 pagesSubmersible Extra High Head Pump: Max. 230m Head and Excellent Durability, Optimum For High Head ApplicationsRuddy Fabrizio Galvez JustinianoNo ratings yet

- Floating Scum Skimmers: Matchless!!Document2 pagesFloating Scum Skimmers: Matchless!!Ruddy Fabrizio Galvez JustinianoNo ratings yet

- Select Series: Standby GeneratorsDocument4 pagesSelect Series: Standby GeneratorsGerman E.No ratings yet

- Chemical and Petrochemical Statistics at A Glance - 2017 - 0Document240 pagesChemical and Petrochemical Statistics at A Glance - 2017 - 0KAUSTUBH TIRPUDENo ratings yet

- 1W High Power LED PDFDocument16 pages1W High Power LED PDFDan Jeric Arcega RustiaNo ratings yet

- CTH Muka DepanDocument8 pagesCTH Muka DepanMohamad Rizal MukhtarNo ratings yet

- Informacion Tecnica Deka SolarDocument2 pagesInformacion Tecnica Deka SolarGA16DETNo ratings yet

- BETE TF MetricDocument2 pagesBETE TF Metricajo2402No ratings yet

- Principles of Foundry Technology-1Document479 pagesPrinciples of Foundry Technology-1Patil Amol PandurangNo ratings yet

- FM 1510 Fire Hydrants (Dry Barrel Type) For Private Fire ServiceDocument13 pagesFM 1510 Fire Hydrants (Dry Barrel Type) For Private Fire ServiceDanny SeeNo ratings yet

- Feedwater Heaters Inspection ProcedureDocument2 pagesFeedwater Heaters Inspection ProcedureAlmario SagunNo ratings yet

- LES VI Boiler SpecDocument3 pagesLES VI Boiler SpecliamcsNo ratings yet

- Graco Agitators and MixersDocument14 pagesGraco Agitators and Mixerscumpio425428No ratings yet

- Milestones+Tool Devises Follow Up - CopieDocument23 pagesMilestones+Tool Devises Follow Up - CopieSalma Elle mangadNo ratings yet

- FOARTE BUN +Sistema-de-Lubricacion-MaK-M-25-C-Manual PDFDocument8 pagesFOARTE BUN +Sistema-de-Lubricacion-MaK-M-25-C-Manual PDFCorina StanculescuNo ratings yet

- Timing Chain Replacement On A Volvo 3.2L EngineDocument10 pagesTiming Chain Replacement On A Volvo 3.2L EnginegrupoamsgarageNo ratings yet

- Mechanical Properties of Cobalt ChromeDocument6 pagesMechanical Properties of Cobalt ChromeAliciar RearmyNo ratings yet

- Tds Premix RMDocument3 pagesTds Premix RMvasantsunerkarNo ratings yet

- Fume Controls GuideDocument6 pagesFume Controls Guidereview20No ratings yet

- 510 Closed Exam ADocument24 pages510 Closed Exam AAPINo ratings yet

- Delivery Wise ReportDocument133 pagesDelivery Wise Reportswapon kumar shillNo ratings yet

- A Review On Seismic Behavior of Ultra-High Performance Concrete MembersDocument16 pagesA Review On Seismic Behavior of Ultra-High Performance Concrete Membersdragon HNo ratings yet

- M0080743 - Ball Stud Breaker (524-9370 Hammer Group) PDFDocument47 pagesM0080743 - Ball Stud Breaker (524-9370 Hammer Group) PDFCarlos LoboNo ratings yet

- Limit State of ServiceabiityDocument5 pagesLimit State of Serviceabiityvvn123963No ratings yet

- Bomb SamplerDocument2 pagesBomb SamplerSaravana Vijayan RNo ratings yet

- B. Prestart Checks of Boiler LightupDocument14 pagesB. Prestart Checks of Boiler LightupPrudhvi RajNo ratings yet

- Bei026 NDTDocument1 pageBei026 NDTpritheemadanNo ratings yet

- Simply Supported BeamsDocument5 pagesSimply Supported Beamscataice100% (1)

- Understanding Technical English-2Document91 pagesUnderstanding Technical English-2Ega Marga Putra100% (1)