Professional Documents

Culture Documents

544K - Ii - Pin - 1bz544ka - Elementos de Cambio

544K - Ii - Pin - 1bz544ka - Elementos de Cambio

Uploaded by

edwanlancheros6Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

544K - Ii - Pin - 1bz544ka - Elementos de Cambio

544K - Ii - Pin - 1bz544ka - Elementos de Cambio

Uploaded by

edwanlancheros6Copyright:

Available Formats

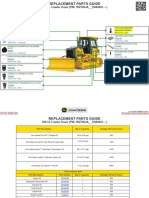

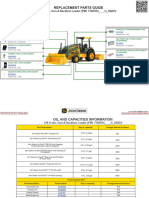

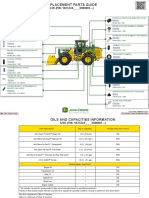

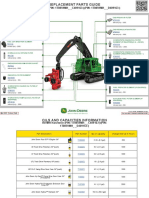

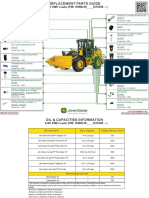

REPLACEMENT PARTS GUIDE

544K-II 4WD Loader (PIN: 1BZ544KA_ _D001001— )

ENGINE AIR CLEANER ELEMENT—

SECONDARY FILTER

AT314583

1

FUEL FILTER WITHOUT HEATER

Interval (hrs) - 1000 8

AT433554

ENGINE AIR CLEANER ELEMENT— Interval (hrs) - 500.

PRIMARY FILTER

FUEL FILTER WITH HEATER

AT300487 2

Interval (hrs) - 1000

9 AT365870

Interval (hrs) - 500.

HYDRAULIC RESERVOIR BREATHER

FILTER (ENGINE 6068HDW83) ENGINE ROCKER ARM COVER GASKET

T225008 3 (ENGINE 6068HDW74)

1

Interval (hrs) - 500 4

5

6

3

7

2 8 9

10

R524469

13 10

HYDRAULIC RESERVOIR BREATHER 12 Interval (hrs) - 2000.

FILTER (ENGINE 6068HDW74) 11

4 ENGINE ROCKER ARM COVER GASKET

AM39653 (ENGINE 6068HDW83)

11

Interval (hrs) - 500

R524497

CAB RECIRCULATING FILTER

Interval (hrs) - 2000.

AT307501 5

Interval (hrs) - As Required. IN-LINE FUEL STRAINER

AT223493

CAB FRESH AIR FILTER 12

Interval (hrs) - 500.

AT191102 6

Interval (hrs) - As Required.

CRANKSHAFT DAMPER

CRANKSHAFT DAMPER (ENGINE 6068HDW83)

(ENGINE6068HDW74) 13

7 RE508578

RE505881

Interval (hrs) - 4000.

Interval (hrs) - 4000.

CLICK PART NUMBER TO BUY

May.2022. Release Date. *See operator’s manual for addional details.

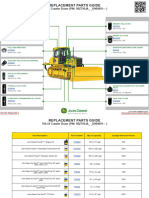

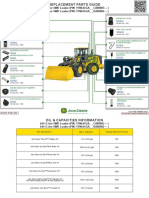

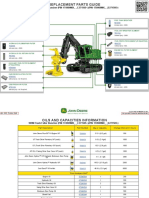

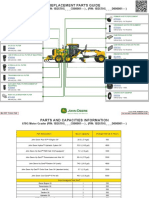

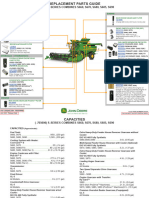

REPLACEMENT PARTS GUIDE

544K-II 4WD Loader (PIN: 1BZ544KA_ _D001001— )

OUTER PIN SEALS : NEVERGREASETM

FINAL FUEL FILTER (SEVERE APPLICATION)

STEERING CYLINDER JOINTS

(IF EQUIPPED) 14

20

AT526918

T277593 Interval (hrs) - 500.

Interval (hrs) - As Required.

PRIMARY FUEL FILTER

HYDRAULIC SYSTEM RETURN FILTER (SEVERE APPLICATION)

21

AT335977 AT365870

15

Interval (hrs) - 4000

15

14

PRIMARY FUEL FILTER

20

21

22 RE541922

AXLE OIL FILTERS (IF EQUIPPED) 19

22

23

AT367635 16 16

24 Interval (hrs) - 500.

Interval (hrs) - 1000 FINAL FUEL FILTER

17

TRANSMISSION OIL FILTER 2

23 RE522878

AT468647 17

Interval (hrs) - 500.

18

Interval (hrs) - 2000

ENGINE OIL FILTER

OUTER PIN SEALS : ATTACHMENT TO

BUCKET LINK JOINTS 24

RE504836

AT336321 18

Interval (hrs) - 500.

Interval (hrs) - As Required.

ENGINE AIR CLEANER DUST UNLOADER

VALVE

M89679 19

Interval (hrs) - 1000.

CLICK PART NUMBER TO BUY

May.2022. Release Date. *See operator’s manual for addional details.

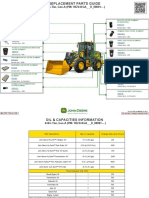

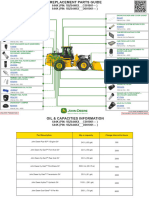

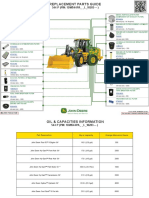

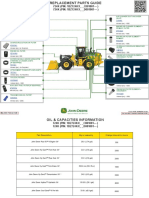

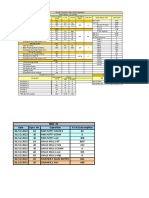

OIL & CAPACITIES INFORMATION

544K-II 4WD Loader (PIN: 1BZ544KA_ _D001001— )

Part Description Qty or capacity Change Interval In Hours

John Deere Plus-50™ II Engine Oil3 19.0 L (5.0 gal) 500

John Deere Hydrau™ Hydraulic Oil3 92.0 L (24.3 gal) 4000

John Deere Hy-Gard™ Transmission Oil2,3 21.5 L (5.7 gal) 2000

John Deere Hy-Gard™ Park Brake Oil3 300.0 mL (10.0 fl oz) 1000

John Deere Hy-Gard™ Front Axle Oil and Rear Axle Oil (each)3 17.0 L (4.5 gal) 2000

John Deere Cool-Gard™ Pre-Mix 22.5 L (5.9 gal) 6000

May.2022. Release Date. *See operator’s manual for addional details.

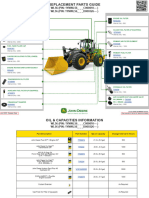

OIL & CAPACITIES INFORMATION

544K-II 4WD Loader (PIN: 1BZ544KA_ _D001001— )

Fluid Analysis Test Kits4

Part Description Qty or capacity Change Interval In Hours

Diesel Engine Oil 1 250

Transmission Oil 1 500

Axle Oil 2 500

Hydraulic Oil 1 500

Diesel Fuel 1 500

Engine Coolant 1 500

2

Reduce service intervals to 1500 hours in severe applications, which run the torque converter at high loads for more than approximately

25% of the time.

3

See operator's manual for recommended oil type and oil viscosities based on operating temperatures.

4

Based on fluid analysis results, intervals may need to be adjusted for operating conditions. Consult an authorized John Deere dealer.

Plus-50 is a trademark of Deere & Company

Hydrau is a trademark of Deere & Company

Hy-Gard is a trademark of Deere & Company

Cool-Gard is a trademark of Deere & Company

CLICK PART NUMBER TO BUY

May.2022. Release Date. *See operator’s manual for addional details.

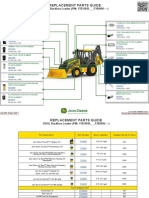

Service machine at intervals shown on this chart. Also, perform service on items at multiples of the original requirement. For example: at 500

hours, also service those items (if applicable) listed under 250 hours and 10 hours or daily.

Take fluid samples from each system as indicated on this form. The manufacturer of the fluid analysis kits will provide maintenance

Service Intervals

recommendations based upon the results of the fluid analysis and the operating information supplied. Regular fluid sampling extends the

operational life of machine.

As Required

□ Inspect tires and check pressure □ Drain water from primary fuel filter and water separator

□ Check wheel bolt torque □ Drain water from final fuel filter

□ Inspect engine air cleaner elements □ Drain water from auxiliary fuel filter and water separator (if equipped)

□ Inspect air conditioner compressor and alternator belt □ Check and clean or replace cab fresh air filter

□ Clean cooler cores □ Check and clean or replace cab recirculating air filter

□ Check windshield washer fluid level □ Check coolant condition

□ Check rear camera and radar object detection (ROD) system (if equipped)

Every 10 Hours or Daily

□ Clean air cleaner dust unloader valve □ Check hydraulic system oil level

□ Check coolant level in surge tank □ Check transmission oil level

□ Check engine oil level □ Inspect outer pin seals (if equipped)

Every 100 Hours

□ Lubricate loader linkage and cylinder pivots (unless NeverGrease™ equipped)

Initial Service—250 Hours1

□ Drain and refill front and rear axle oil □ Replace axle oil filters (if equipped)

□ Drain and refill engine oil and replace filter

Every 250 Hours

□ Take engine oil sample

Every 500 Hours

□ Lubricate driveline upper and lower sliding joints and lower U-joints □ Replace hydraulic reservoir breather filter

□ Check front and rear axle oil level □ Check park brake oil level

□ Lubricate front and rear axle shaft seals □ Lubricate front and rear shaft seals on park brake

□ Check battery electrolyte level and terminals □ Check ride control accumulator (if equipped)

□ Check air intake hoses and charge air cooler tube couplings □ Take engine coolant sample

□ Drain and refill engine oil and replace filter □ Take transmission oil sample

□ Replace primary fuel filter □ Take hydraulic oil sample

□ Replace final fuel filter □ Take axle oil sample

□ Replace auxiliary fuel filter (if equipped) □ Take diesel fuel sample

□ Replace in-line fuel strainer

Every 1000 Hours

□ Clean engine crankcase vent tube □ Drain and refill park brake oil

□ Replace air cleaner dust unloader valve □ Replace axle oil filters (if equipped)

□ Replace engine air cleaner elements □ Check coolant condition

□ Lubricate frame hinge pivots

Continued on next page MB60223,000053E -19-01DEC21-1/2

Every 2000 Hours

T386127X19(04MAR22)(ENGLISH)

□ Drain and refill transmission oil and replace filter2 □ Rerun transmission clutch calibration Worldwide Construction

□ Drain and refill front and rear axle oil □ Check and adjust engine valve lash

And Forestry Division

PRINTED IN U.S.A.

□ Clean front and rear axle oil recirculation screens (if equipped) □ Replace outer pin seals (if equipped)

Every 4000 Hours

□ Drain, flush, and refill hydraulic system oil □ Clean hydraulic pump case drain in-line screen

□ Clean hydraulic system fill strainer □ Replace crankshaft damper

□ Replace hydraulic system return filter

Every 4000 Hours

□ Inspect driveline damper

Every 6000 Hours

□ Drain and refill cooling system

NeverGrease is a trademark of Deere & Company

MB60223,000053E -19-01DEC21-2/2

Required Parts

Ensure machine performance and availability; use only genuine John Deere parts. Verify that any associated parts are also on

hand, i.e., filter O-rings.

May.2022. Release Date. *See operator’s manual for addional details.

You might also like

- Cambridge Igcse Chemistry Revision Guide - Public PDFDocument50 pagesCambridge Igcse Chemistry Revision Guide - Public PDFMoarz Galaxy62% (13)

- 700J II Crawler Dozer PIN 1BZ700JA D000001 Replacement Parts GuideDocument3 pages700J II Crawler Dozer PIN 1BZ700JA D000001 Replacement Parts Guidemauriciocosta1050kNo ratings yet

- 750J II Crawler Dozer PIN 1BZ750JA D000001 Replacement Parts Guide-1Document4 pages750J II Crawler Dozer PIN 1BZ750JA D000001 Replacement Parts Guide-1gerencia.manutencaomdNo ratings yet

- Pá Carregadeira John Deere 444gDocument4 pagesPá Carregadeira John Deere 444gislanmateusfr100% (1)

- SKIDDocument3 pagesSKIDguillermosNo ratings yet

- 444G Tier PIN 1BZ444GA D 00001 Replacement Parts GuideDocument4 pages444G Tier PIN 1BZ444GA D 00001 Replacement Parts GuideGabriel MarquesNo ratings yet

- 317G Compact Track Loader PIN 1T0317G J288093 Replacement Parts GuideDocument3 pages317G Compact Track Loader PIN 1T0317G J288093 Replacement Parts GuideNelson Andrade VelasquezNo ratings yet

- 410E II Articulated Dump Truck (PIN: 1DW410E - F708125-) : AT191102 RE539465Document5 pages410E II Articulated Dump Truck (PIN: 1DW410E - F708125-) : AT191102 RE539465Cristian Fernando Tarifa MartinezNo ratings yet

- WL56 PIN 1YNWL56 Replacement Parts GuideDocument4 pagesWL56 PIN 1YNWL56 Replacement Parts Guideedwanlancheros6100% (1)

- 524k Iid677549Document3 pages524k Iid677549MONBARRONNo ratings yet

- 210 G Tier Gen A Backhoe Loader PIN 1T0210G G 02263 Replacement Parts GuideDocument4 pages210 G Tier Gen A Backhoe Loader PIN 1T0210G G 02263 Replacement Parts GuideAlex Sandro dos SantosNo ratings yet

- 644 G Tier 4WD Loader PIN 1YN644GA CA00003 PIN 1YN644GA DA00002 Replacement Parts GuideDocument5 pages644 G Tier 4WD Loader PIN 1YN644GA CA00003 PIN 1YN644GA DA00002 Replacement Parts GuideNelson Andrade VelasquezNo ratings yet

- 310E PIN 1DW310E F708125 Replacement Parts GuideDocument4 pages310E PIN 1DW310E F708125 Replacement Parts GuideCristian Fernando Tarifa MartinezNo ratings yet

- 318G Skid Steer Loader PIN 1T0318G J288093 Replacement Parts GuideDocument3 pages318G Skid Steer Loader PIN 1T0318G J288093 Replacement Parts GuideNelson Andrade VelasquezNo ratings yet

- 620G Motor Grader (PIN - 1BZ620G - C000001-) (PIN - 1BZ620G - D000001-) Replacement Parts GuideDocument5 pages620G Motor Grader (PIN - 1BZ620G - C000001-) (PIN - 1BZ620G - D000001-) Replacement Parts GuideFagner Pires de SáNo ratings yet

- Part CatalogDocument4 pagesPart CatalogHery yauwryNo ratings yet

- 644 KD 001001Document4 pages644 KD 001001m92000409No ratings yet

- 524K PIN 1BZ524K D000001 Replacement Parts GuideDocument3 pages524K PIN 1BZ524K D000001 Replacement Parts GuideGabriel MarquesNo ratings yet

- 335D Knuckleboom Log Loader PIN 1T0335DX C184061 Replacement Parts GuideDocument3 pages335D Knuckleboom Log Loader PIN 1T0335DX C184061 Replacement Parts GuideNelson Andrade VelasquezNo ratings yet

- 859MH Tracked Harvester PIN 1T0859MH F293764 409162 PIN 1T0859MH L343926 409162 Replacement Parts GuideDocument5 pages859MH Tracked Harvester PIN 1T0859MH F293764 409162 PIN 1T0859MH L343926 409162 Replacement Parts GuideNelson Andrade VelasquezNo ratings yet

- Replacement Parts GuideDocument3 pagesReplacement Parts Guidebayu prasetyoNo ratings yet

- 909M Tracked Feller Buncher PIN 1T0909MX C271505 PIN 1T0909MX D271505 Replacement Parts GuideDocument3 pages909M Tracked Feller Buncher PIN 1T0909MX C271505 PIN 1T0909MX D271505 Replacement Parts GuideNelson Andrade VelasquezNo ratings yet

- 310 GRPGDocument4 pages310 GRPGjulianNo ratings yet

- Periódica 850J IIDocument4 pagesPeriódica 850J IIJonatasNo ratings yet

- 544 P PIN 1DW544PA L 10283 Replacement Parts GuideDocument4 pages544 P PIN 1DW544PA L 10283 Replacement Parts GuideNelson Andrade VelasquezNo ratings yet

- 333G Compact Track Loader PIN 1T0333G F300253 Replacement Parts GuideDocument3 pages333G Compact Track Loader PIN 1T0333G F300253 Replacement Parts GuideNelson Andrade VelasquezNo ratings yet

- 844K 4WD Loader PIN 1DW844K D642008 Replacement Parts GuideDocument3 pages844K 4WD Loader PIN 1DW844K D642008 Replacement Parts GuideNelson Andrade VelasquezNo ratings yet

- 759JH Tracked Feller Buncher Harvester Leveling PIN 1T0759JH C220452 Replacement Parts GuideDocument3 pages759JH Tracked Feller Buncher Harvester Leveling PIN 1T0759JH C220452 Replacement Parts GuideNelson Andrade Velasquez100% (1)

- 330G PIN 1T0330G F300253 Replacement Parts GuideDocument3 pages330G PIN 1T0330G F300253 Replacement Parts GuideNelson Andrade VelasquezNo ratings yet

- 850J II Crawler Dozer PIN 1BZ850JA C000001 PIN 1BZ850JA D000001 Replacement Parts GuideDocument3 pages850J II Crawler Dozer PIN 1BZ850JA C000001 PIN 1BZ850JA D000001 Replacement Parts GuidesocomgutNo ratings yet

- Preventivas 770 GDocument4 pagesPreventivas 770 GEderson Rodrigues FerreiraNo ratings yet

- Parts Manual Cat 420eDocument5 pagesParts Manual Cat 420eNelson Andrade VelasquezNo ratings yet

- 670G PIN 1BZ670G C000001 PIN 1BZ670G D000001 Replacement Parts GuideDocument4 pages670G PIN 1BZ670G C000001 PIN 1BZ670G D000001 Replacement Parts GuideNelson Andrade VelasquezNo ratings yet

- 859M Tracked Feller Buncher PIN 1T0859MX L409163 PIN 1T0859MX F409163 Replacement Parts GuideDocument5 pages859M Tracked Feller Buncher PIN 1T0859MX L409163 PIN 1T0859MX F409163 Replacement Parts Guidevaltra.maestroNo ratings yet

- Plano de Manutenção - MN-23 e 24 (JOHN DEERE 670-G)Document4 pagesPlano de Manutenção - MN-23 e 24 (JOHN DEERE 670-G)islanmateusfrNo ratings yet

- 316GR Skid Steer Loader PIN 1T0316G G298752 Replacement Parts GuideDocument3 pages316GR Skid Steer Loader PIN 1T0316G G298752 Replacement Parts GuideNelson Andrade Velasquez100% (1)

- 724K PIN 1BZ724KX C001001 PIN 1BZ724KX D001001 Replacement Parts GuideDocument4 pages724K PIN 1BZ724KX C001001 PIN 1BZ724KX D001001 Replacement Parts GuideNelson Andrade VelasquezNo ratings yet

- 770G and 770GP PIN 1DW770G F680878 PIN 1DW770G L700954 Replacement Parts GuideDocument4 pages770G and 770GP PIN 1DW770G F680878 PIN 1DW770G L700954 Replacement Parts GuideNelson Andrade VelasquezNo ratings yet

- 310 SLF 390996Document4 pages310 SLF 390996p0t2g047No ratings yet

- 672GP Grader Replacement Parts GuideDocument13 pages672GP Grader Replacement Parts GuideTutoHack Master100% (1)

- 672gp Ficha Filtros y AceitesDocument4 pages672gp Ficha Filtros y AceitesarcacompraNo ratings yet

- 444k PALADocument3 pages444k PALAWalter Acosta FretesNo ratings yet

- Filtos John Deere 8345Document3 pagesFiltos John Deere 8345helijunior67151No ratings yet

- 6 Series Tractors 6405 and 6605 Tractors South America Edition Filter Overview With Service Intervals and CapacitiesDocument2 pages6 Series Tractors 6405 and 6605 Tractors South America Edition Filter Overview With Service Intervals and CapacitiesYeison NavasNo ratings yet

- RP-C6358 - Apu Monitoring 1.0Document2 pagesRP-C6358 - Apu Monitoring 1.0Eve TashNo ratings yet

- 6015 PM Kit - PM 5000 HrsDocument1 page6015 PM Kit - PM 5000 HrsHendra MonoNo ratings yet

- 11-Iagt-301 Rb211 Tendencia InnovacionDocument20 pages11-Iagt-301 Rb211 Tendencia InnovacionTabiquera Guadalupe Victoria Texcoco De Mora100% (1)

- 4045HFS88Document2 pages4045HFS88olimpio.braga.salesmanagerNo ratings yet

- Toyota Corolla: Manual de Taller 2001-2004Document126 pagesToyota Corolla: Manual de Taller 2001-2004Erick Vargas MarcaNo ratings yet

- 8R TRACTORS (-099999) - 8270R, 8295R, 8320R, 8345R, 8370R Filter Overview With Service IntervalsDocument3 pages8R TRACTORS (-099999) - 8270R, 8295R, 8320R, 8345R, 8370R Filter Overview With Service IntervalsnatãNo ratings yet

- Maintenance Master Plan 2018 A For September 08, 2018Document4 pagesMaintenance Master Plan 2018 A For September 08, 2018Ritche Lim BragaisNo ratings yet

- (-765000) S-SERIES COMBINES S660, S670, S680, S685, S690: Engine EngineDocument3 pages(-765000) S-SERIES COMBINES S660, S670, S680, S685, S690: Engine EngineArthur VicenteNo ratings yet

- Consumable Parts ListDocument1 pageConsumable Parts Listmeli rizalNo ratings yet

- 40 Series Row Crop TractorDocument2 pages40 Series Row Crop TractorRafael SalazarNo ratings yet

- 400R Self Propelled Dry SpreaderDocument2 pages400R Self Propelled Dry Spreaderlaurentiu ruseNo ratings yet

- 01 Dec'22Document5 pages01 Dec'22RAJAT DEO AGRAWALNo ratings yet

- Nama Alat: Wheel Loader Merk Dan Type: Komatsu, WA380z-6 Kode Alat: WL-03Document5 pagesNama Alat: Wheel Loader Merk Dan Type: Komatsu, WA380z-6 Kode Alat: WL-03gumNo ratings yet

- S Series Combines S550 S660 S670 S680 S690 Filter Overview With Service Intervals and CapacitiesDocument2 pagesS Series Combines S550 S660 S670 S680 S690 Filter Overview With Service Intervals and CapacitiesJhasmaniEspinozaNo ratings yet

- Consumable Parts - I-C - AmadaDocument6 pagesConsumable Parts - I-C - AmadaShyam JanardhananNo ratings yet

- 5e and 5el Ft4 SeriesDocument2 pages5e and 5el Ft4 Seriesolimpio.braga.salesmanagerNo ratings yet

- Voltage Regulation Performance of Smart Inverters: Power Factor Versus Volt-VAR ControlDocument6 pagesVoltage Regulation Performance of Smart Inverters: Power Factor Versus Volt-VAR ControllucasNo ratings yet

- Learn Japanese in Fukuoka: Furoshiki Gift WrappingDocument2 pagesLearn Japanese in Fukuoka: Furoshiki Gift WrappingPianoteCubaNo ratings yet

- City Planning and Neighbourhood Design Case Studies1Document132 pagesCity Planning and Neighbourhood Design Case Studies1shinmiNo ratings yet

- Türkiye'deki Bazı Semi-Finish Grinding SistemleriDocument4 pagesTürkiye'deki Bazı Semi-Finish Grinding SistemleriTHAKARAR HARSHILNo ratings yet

- Periodontal Ligament-SummerDocument24 pagesPeriodontal Ligament-Summerapi-3775747100% (1)

- Drivewindow BasicsDocument34 pagesDrivewindow BasicsYaa ShinNo ratings yet

- HARRIS Instruction Manual 7-8 Imn-901600-E03Document268 pagesHARRIS Instruction Manual 7-8 Imn-901600-E03g_pargadeNo ratings yet

- Business Case Part 1 - Phase 2 - Group 212053 - 17 FDocument14 pagesBusiness Case Part 1 - Phase 2 - Group 212053 - 17 Fkaren stefania hortua curzNo ratings yet

- Group 3 CW - Role of NGOs in Socio EconomicDocument9 pagesGroup 3 CW - Role of NGOs in Socio EconomicKisyenene JamusiNo ratings yet

- ABG Lecture DR Lenora FernandezDocument60 pagesABG Lecture DR Lenora Fernandezapi-19431894No ratings yet

- CCE Quiz Batasan Set - SolutionDocument4 pagesCCE Quiz Batasan Set - SolutionJoovs JoovhoNo ratings yet

- Ross-Tech: Ross-Tech-Tip - VW/Audi Throttle Body AlignmentDocument1 pageRoss-Tech: Ross-Tech-Tip - VW/Audi Throttle Body AlignmentRubens PerazaNo ratings yet

- Astro-Logics Pub PDFDocument7 pagesAstro-Logics Pub PDFlbedar100% (1)

- Aquagen: Recombination System For Stationary BatteriesDocument2 pagesAquagen: Recombination System For Stationary BatteriestaahaNo ratings yet

- Readme CCRDocument51 pagesReadme CCRSesha SuryaNo ratings yet

- اسئلة بروتوكولات الفصل الاولDocument21 pagesاسئلة بروتوكولات الفصل الاولرسول ابراهيم عبد علي رويعيNo ratings yet

- Apollo 16 - Mission Operations ReportDocument393 pagesApollo 16 - Mission Operations Reportchez ezNo ratings yet

- Ex Lecture1Document2 pagesEx Lecture1AlNo ratings yet

- KMA CVDocument5 pagesKMA CVKhandoker Mostak AhamedNo ratings yet

- Anand RathiDocument95 pagesAnand Rathivikramgupta195096% (25)

- Marble and Granite Tiles: Installation TipsDocument1 pageMarble and Granite Tiles: Installation Tipsandresboy123No ratings yet

- DM No. 149 S. 2023 Addendum To Division Memorandum No. 412 S. 2022Document14 pagesDM No. 149 S. 2023 Addendum To Division Memorandum No. 412 S. 2022Jessa GeronNo ratings yet

- Practical Manual-Mass Commn PDFDocument36 pagesPractical Manual-Mass Commn PDFSSP GamerNo ratings yet

- Bosch Solar Cell M 3BB EnglischDocument2 pagesBosch Solar Cell M 3BB EnglischAlberto AbsantNo ratings yet

- Evaporation of Different Liquids PDFDocument2 pagesEvaporation of Different Liquids PDFMandyNo ratings yet

- 9479 Inst ManualDocument8 pages9479 Inst ManualfdkaNo ratings yet

- Allen StoneDocument4 pagesAllen StoneRubén FernándezNo ratings yet

- Indian Weekender Issue#96Document32 pagesIndian Weekender Issue#96Indian WeekenderNo ratings yet

- LevellingDocument11 pagesLevellingetikaf50% (2)