Professional Documents

Culture Documents

1.2 Spark

1.2 Spark

Uploaded by

Patricio Valencia0 ratings0% found this document useful (0 votes)

57 views34 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

57 views34 pages1.2 Spark

1.2 Spark

Uploaded by

Patricio ValenciaCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 34

SECTION 1C1

ENGINE MECHANICAL - 1.2L DOHC

Caution : Disconnect the negative battery cable before removing or installing any electrical

unit or when a tool or equipment could easily come in contact with exposed electrical

erminals. Disconnecting this cable will help prevent personal injury and damage to the

vehicle. The ignition must also be in LOCK unless otherwise noted.

SPECIFICATIONS

Engine Specifications

Application Description

General Data:

Engine Type 4 Cylinder (In-Line)

Displacement 1,206 cm*

Bore Stroke 69.7 x79 mm (2.7441 x3.1102 in.)

‘Compression Ratio 105+02:1

Firing Order 1-3-4-2

Cy der Bore:

Diameter 69.7 mm (2.7441 in.)

[Out of Round (Maximum) (0,005 mm (0.0002 in.)

Taper (Maximum) 0.07 x30"

Piston:

Diameter 69.7 mm (2.7441 in)

(Clearance to Bore 0.035 £ 0,010 mm (0.0013 + 0.0177 in)

Piston Rings:

Ring, End Gap:

Top Compression 0.15 ~ 0.30 mm (0.0059 ~ 0.0118 in.)

‘2nd Compression (0.3 ~ 0.45 mm (0.0118 ~ 0.0177 in.)

(Groove Clearance:

Top Impression 0.02 ~ 0.06 mm (0.00078 ~ 0.00236 in)

2nd Impression 0.06 ~ 0.1 mm (0.00236 ~ 0.00393 in.)

Piston Pin :

Diameter 16.995 ~ 17.000 mm (0.6691 ~ 0.6693 in.)

Clearance to Bore 0.006 ~ 0.019 mm (0.00078 ~ 0.00236 in.)

Camshaft:

End Play 0.08 ~ 0.26 mm (0.0032 ~ 0.0102 in)

Journal OD:

No.1 23.939 ~ 23.96 mm (0.9425 ~ 0.9433 in.)

No.2 23.939 ~ 23.96 mm (0.9425 ~ 0.9433 in.)

No.3 23.939 ~ 23.96 mm (0.9425 ~ 0.9433 in.)

No.4 23.939 ~ 23.96 mm (0.9425 ~ 0.9433 in.)

No.5 23.939 ~ 23.96 mm (0.9425 ~ 0.9433 in.)

Journal 1D:

No.1 23 ~ 23.021 mm (0.9055 ~ 0.9063 in.)

No.2 23 ~ 23.021 mm (0.9055 ~ 0.9063 in.)

No. 3 23 ~ 23.021 mm (0.9055 ~ 0.9063 in.)

No.4 23 ~ 23.021 mm (0.9055 ~ 0.9063 in.)

No.5 23 ~ 23.021 mm (0.9055 ~ 0.9063 in)

Lift Intake 40.00 mm (1.5748 in.)

Lift- Exhaust 39.45 mm (1.5531 in.)

Crankshaft :

Main Journal

Diameter (All) 48.982 ~ 49.000 mm (1.9284 ~ 1.9291 in)

any Bearing Clearance 0.020 ~ 0.040 mm (0.00079 ~ 0.00158 in.)

Crankshaft End Play

0.08 ~ 0.26 mm (0.0032 ~0.0102 in.)

Connecting Rod Journal:

Diameter (Alll)

Rod Bearing Clearance (All)

41.000 ~ 41.018 mm (1.6142 ~ 1.6149 in)

0.02 ~ 0.04 mm (0.0008 ~ 0.0016 in.)

Bending

0.03 mm (0.0012 in.)

\Valve System:

[Seat Inner Diameter:

take 23.862 mm (0.9394 in.)

Exhaust 21.079 mm (0.8299 in. )

Valve Guide Inside Diameter (All)

5.0 ~ 5.012 mm (0.1968 ~ 0.1973 in.)

Valve Stem Diameter

Intake 4.972 & 0.007 mm (0.1957 + 0.0002 in.)

Exhaust 4.963 + 0.007 mm (0.1954 + 0.0002 in.)

\Valve Length:

Intake 99.17 + 0.225 mm (3.904 + 0.009 in)

Exhaust 100.01 + 0.225 mm (3.937 # 0.009 in.)

Valve Spring

Free Legnth 43.57 mm (1.715 in.)

Valve Closed 260 + 13 N (191 + 9.6 lbs) @ 32 mm (1.25 in.)

Fastener Tightening Specifcations

Application Nem Lb-Ft

Exhaust Manifold Retaining Nuts 20 147

Exhaust Manifold Retaining Bolts 25 18.4

Intake Manifold Support Bracket Upper Bolts 2 15

Transmission Assembly Blots (MT & A/T) 60 442

Cylinder Head Cover Bracket Bolts 10 74

Cylinder Head Bolts 22482" | 16.2+82°

Cylinder Head Cover Bolts 10 74

[Accessory Tensioner-Generator Assembly Bracket Mounting Bolt 25 184

[Generator Adjusting Bolt 20 147

[Air Cleaner Assembly Bolts 6 44

[Air Filter Upper Housing Bolts 2 15

Engine Mount Retaining Bolts 55 40.5

Engine Mount Bracket Retaining Bol/Nuts 65 479

Oil Level Gage Tube Retaining Bolt 10.5 77

Oil Pan Retaining Bolts 10.5 77

Oil Pump Cover Bolts 10 74

\Water Pump Retaining Bolts 33 243

[Spark Plugs Cable Cover Bolts 10 74

(Catalytic Converter Retaining Nuts 40 295

Camshaft Cap Bolts, 10 74

Camshaft Sprocket Retaining Bolts 60 442

Connecting Rod Bearing Cap Nuts 33 243

(Crankshaft Rear Oil Seal Cover Bolts (M6 x 1.0) 10.5 77

Crankshaft Bearing Cap Bolts 575 424

(Crankshaft Pulley Bolt 85 627

Timing Chain Guide Retaining Bolts 10 74

Timing Chain Lever Retaining Bolts 10 74

Timing Chain Cover Retaining Bolts (M6 x 1.0) 10.5 77

Timing Chain Cover Retaining Bolts (M8 x 1.25) 20 14.7

Timing Chain Tensioner Retaining Bolts 12 88

[A/C Compressor Mounting Bracket Bolts 30 22.1

Power Steering Pump Bracket Mounting Bolts 25 184

Power Steering Pump Mounting Bolts 20 147

Front Exhaust Pipe-to-Main Catalytic Converter Nuts 40 295

Front Exhaust Pipe-to-Front Muffler Nuts 40 295

Flywheel/Flexible Plate Bolts 45 33.2

Intake Manifold Retaining Bolts 10 7A

Exhaust Manifold Heat Shield Bolts 15 4

Oil Pressure Switch Fitting 30 22.1

[Accessory Tensioner Hex-Socket Bolt (M8) 45 33.2

SPECIAL TOOLS

Special Tools Table

DWw010-010

“Engine & Transaxle Assembly Support

Remover/lnstaller”

EN-48356

Fixture-Engine

KM-135

Adapter

EN-49072

Installer-Crankshaft Front Seal

EN-49074

Compressor-Universal Valve Spring

EN-49076

Adapter-Cylinder Pressure

EN-49078

Installer-Piston

DW100-030

Stand-Engine Overhaul

KM-498-A

Gauge-Oil Pressure

EN-49071

Installer-Crankshaft Rear Seal

EN-49073

Pin-Timing Chain Tensioner

EN-49075

Adapter-Valve Spring Compressing

EN-49077

Gauge-Compression Pressure

KM-470-B

Angular Torque Gauge

DIAGNOSIS

Engine Diagnosis

Reviewing the description and operation information provided will assist in determining whether

the condition described by the customer is a fault or normal engine operation.

Symptoms

Strategy Based Diagnosis

1. Review the system operations to familiarise yourself with the system functions, refer

to Section 1A, General Engine Information and Section 1F1, Engine Control — General

Information.

2. Perform an engine management Diagnostic System Check, refer toSection 11 Engine

Control — Diagnostics.

Alldiagnosis on a vehicle should follow a logical process. Strategy based diagnosis is a uniform

approach for repairing all vehicle systems. The strategy based diagnostic flow chart may always

be used to resolve a system problem. The diagnostic flow chart is the place to start when repairs

are required. For a detailed explanation of strategy based diagnosis and the flow chart, refer

to Section 1F1 Engine Control = Diagnostics.

Visual / Physical Inspection

1. Inspect the vehicle for aftermarket accessories which may adversely affect engine operation

2. Inspect the easily accessible or visible system components for obvious signs of damage or

conditions that may cause the symptom.

3. Check the engine lubrication system for the following

© correct oil level,

© correct lubricant viscosity,

© correct oil filter application, and

© contaminated or bumt oil

4, Confirm the exact operating conditions under which the fault occurs. Note factors such as

© engine speed (r.p.m.),

© ambient temperature,

© engine temperature,

© engine warm-up time, and

© vehicle road speed.

5. Compare the engine sounds, if applicable, to a known good engine, and ensure you are not

trying to diagnose a normal operating condition.

Intermittent

For intermittent faults, test the vehicle under the same conditions the customer reported in order to

confirm whether the system is operating correctly.

Compression Test

Inspect the engine compression pressure as following procedure:

1. Crank the engine to be at normal operating temperature(coolant temperature : 80~90°C).

2. Stop the engine and remove all the high-tension cables and ignition plugs.

Caution : Not to use tools when installing the adapter-cylinder pressure. If use tools, it

may be forced excessively and make a damage to the engine performance.

3. Install the adapter-cylinder pressure(EN-49076)(b) and gauge-cylinder pressure(EN-49077)

a).

4,2 persons should be needed while compression pressure testing. One person accelerate the

pedal to make the throttle valve be fully opened and crank the engine.

5, The other person reads the maximum of the measured gauge value.

Measured value should meet the specification or limit.

Specification : 9 Bar(9.17 Kgicm2)

Limit: under 10%

Ignition plug torque : 27 Nem (19.9 lb-ft)

Valve Clearance Test

Measuring & Inspection

Caution : Valve clearance test should be tested when coolant temperature is

normal(15~25°C). In addition, should be tested only when cylinder head and block is

assembled.

1. Remove the cylinder head cover. Refer to “Cylinder Head" in this section.

2. Rotate the crankshaft pulley and adjust the pulley groove to the “0” point as following picture:

This is to adjust TDC of the No.1 cylinder.

3. Check the both camshaft sprocket and timing chain.

4, Measure the valve clearance at each point as following picture.

5. Rotate the crankshaft pulley to 360° and adjust the pulley groove to the “O" point.

6. Measure the valve clearance at each point as following picture

© Intake Specification : 0.075~0.125 mm (coolant temperature : 20°C)

© Exhaust Specification : 0.245~0.305 mm (coolant temperature : 20°C)

7. f the measured value is out of specification, replace the vaive tappet. Refer to "Unit Repair -

Valve Train Components" in this section.

Replacing Valve Tappet

Caution : Must use the following table and assemble an adequate valve tappet before

replacing valve tappet.

1, Calculate the value of the valve tappet.

© Intake : Separated tappet Thickness + Measured valve clearance — 0.1 mm = New

tappet thickness

© Exhaust : Separated tappet Thickness + Measured valve clearance — 0.27 mm = New

tappet thickness

2. Use the following table and assemble with an adequate valve tappet.

3. Replace the New valve tappet. Refer to "Unit Repair - Valve Train Components"in this

section.

NO. PART NO. THICKNESS MARKING NO.

1 96 449 601 3.12 + 0.01 312

2 96 449 602 3.1440.01 314

3 96 449 603 3.16 + 0.01 316

4 96 449 604 3.18 + 0.01 318

5 96 449 605 3.20 + 0.01 320

6 96 449 606 3.22 + 0.01 322

7 96 449 607 3.24 40.01 324

8 96 449 608 3.26 + 0.01 326

9 96 449 609 3.28 + 0.01 328

10 96 449 610 3.30 + 0.01 330

1 96 449 611 3.32 + 0.01 332

12 96 449 612 3.34 + 0.01 334

13 96 449 613 3.36 + 0.01 336

14 96 449 614 3.38 + 0.01 338

15 96 449 615 3.40+0.01 340

16 96 449 616 3.424001 342

17 96 449 617 3.444001 344

18 96 449 618 3.46 40.01 346

19 96 449 619 3.48 + 0.01 348

20 96 449 620 3.50 + 0.01 350

24 96 449 621 3.52 £0.01 352

22 96 449 622 3.54 + 0.01 354

23 96 449 623 3.56 + 0.01 356

24 96 449 624 3.58 + 0.01 358

25 96 449 625 3.60 + 0.01 360

26 96 449 626 3.62 + 0.01 362

27 96 449 627 3.64 + 0.01 364

28 96 449 628 3.66 + 0.01 366

29 96 449 629 3.68 + 0.01 368

30 96 449 630 3.70 + 0.01 370

31 96 449 631 3.724001 372

32 96 449 632 3.74 0.01 374

33 96 449 633 3.76 +0.01 376

34 96 449 634 3.78+0.01 378

35 96 449 635 3.80 + 0.01 380

36 96 449 636 3.824001 382

37 96 449 637 3.84 + 0.01 384

38 96 449 638 3.86 + 0.01 386

39 96 449 639 1 388

40 96 449 640 3.90 + 0.01 390

Oil Pressure Test

Step ‘Action Value(s) Yes No

Is the oil pressure warming lamp on?

Go toStep 2

System OK

\Check the oil level in the crankcase

Is the oil level low?

Go toStep 3

Go toStep 4

[Add oil so that the oil level is up to the full mark

lon the indicator.

ls the repair complete?

Go toStep 1

ICheck the idle speed.

Is the idle speed below the specified value 7

840 ¢ 20 rpm

Go toStep 5

Go toStep 6

Increase the idle speed

Is the speed increased?

Go toStep 1

Inspect the oil pressure switch.

Is the oil pressure switch incorrect or

Imatfunctioning?

Go toStep 7

Go toStep 8

install a new oil pressure switch.

Is the repair complete?

Go toStep 1

inspect the oil pressure gauge.

Is the oil pressure gauge incorrect or

imatfunctioning?

Go toStep 9

Go toStep 10

Install a new oil pressure gauge.

Is the repair complete?

Go toStep 1

Inspect the engine oil.

Is the engine oil in the crankcase diluted or of

the improper viscosity?

Go toStep 11

Go toStep 12

Install new engine oil of the proper viscosity for

ithe expected temperatures.

is the repair complete?

Go toStep 1

Inspect the oil pump.

Is the pump worn or dirty?

Go toStep 13

Go toStep 14

Replace the oil pump.

is the repair complete?

Go toStep 1

Inspect the oil fiter.

is the oil filter plugged?

Go toStep 15

Go toStep 16

Install a new oil filter.

is the repair complete?

Inspect the oil pickup screen.

is the oil pickup screen loose or plugged?

Tighten or replace the oil pickup screen, as

necessary.

Is the repair complete?

Go toStep 1

Go toStep 17|

Go toStep 1

Go toStep 18

Inspect the oil pickup tube.

JAre there any holes in the oil pickup tube?

Go toStep 19

Go toStep 20

Replace the oil pickup tube.

is the repair complete?

Go toStep 1

Inspect the bearing clearances. Crankshaft

[Are the bearing clearances more than the Journal

specified values? Bearing Oil

Clearance

(0.020 ~ 0.040)

mm (0.00079

~ 0.00158 in.)

20

Go toStep 21|Go toStep 22

24 [Replace the bearing, ifnecessary,

is the repair complete? Go toStep 1 :

Inspect the oil galleries.

22 |Are the oil galleries cracked, porous, or :

plugged? Go toStep 23| Go toStep 24

123 [Repair or replace the engine block

Is the repair complete? Go toStep 1 :

Inspect the gallery plugs

24 |Are any of the gallery plugs missing or installed :

improperly? Go toStep 25|Go toStep 26

25, [stall the plugs or repair, as necessary.

is the repair complete? Go toStep 1 -

Inspect the camshaft.

26 |Is the camshaft wom or is there evidence of -

lpoor machining? Go toStep 27| System OK

27 [Replace the camshaft.

is the repair complete? Go toStep 1 -

Oil Leak Diagnosis

Most fluid oil leaks are easily located and repaired by visually finding the leak and replacing or

repairing the necessary parts. On some occasions, a fluid leak may be difficult to locate or repair.

The following procedures may help you in locating and repairing most leaks

Finding the Leak:

1. Kdentify the fluid. Determine whether it is engine oil, automatic transmission fluid, power

steering fluid, etc.

2. Kentify where the fluid is leaking from.

1. After running the vehicle at normal operating temperature, park the vehicle over a large

sheet of paper.

2. Wait a few minutes.

3. Find the approximate location of the leak by the drippings on the paper.

3. Visually check around the suspected component. Check around all the gasket mating

surfaces for leaks. A mirror is useful for finding leaks in areas that are hard to reach.

4. Ifthe leak still cannot be found, it may be necessary to clean the suspected area witha

degreaser, steam, or spray solvent.

1. Thoroughly clean the area.

2. Dry the area.

3. Operate the vehicle for several miles at normal operating temperature and varying

speeds.

4. After operating the vehicle, visually check the suspected component.

5. Ifyou stil cannot locate the leak, try using the powder or black light and dye method,

Powder Method:

1, Clean the suspected area.

2. Apply an aerosol-type powder, (such as foot powder), to the suspected area.

3. Operate the vehicle under normal operating conditions.

4. Visually inspect the suspected component. Trace the leak path over the white powder

surface to the source.

Black Light and Dye Method:

A dye and light kit is available for finding leaks. Refer to the manufacturer's directions when using

the kit

41. Pour the specified amount of dye into the engine oil fill tube.

2. Operate the vehicle under normal operating conditions as directed in the kit.

3, Direct the light toward the suspected area, The dyed fluid will appear as a yellow path

leading to the source.

Repairing the Leak

Onee the origin of the leak has been pinpointed and traced back to its source, the cause of the

leak must be determined in order for it to be repaired properly, fa gasket is replaced, but the

sealing flange is bent, the new gasket will not repair the leak. The bent flange must be repaired

also. Before attempting to repair a leak, check for the following conditions and correct them as they

may cause a leak.

Gaskets:

The fluid level/pressure is too high.

The crankcase ventilation system is malfunctioning

The fasteners are improperly tightened or the threads are dirty or damaged.

The flanges or the sealing surface is warped

There are scratches, burrs or other damage to the sealing surface

The gasket is damaged or won,

There is cracking or porosity of the component.

+ Animproper seal was used, (where applicable).

Seals:

The fluid level/pressure is too high.

The crankcase ventilation system is malfunctioning.

The seal bore is damaged, scratched, burred or nicked.

The seal is damaged or worn,

Improper installation is evident.

+ There are cracks in the component.

+ The shaft surface is scratched, nicked or damaged.

+ Aloose or worn bearing is causing excess seal wear.

Base Engine Misfire without Internal Engine Noises

Condi

Action

|Abnormalities (severe cracking,

bumps or missing areas) in the

accessory drive belt.

|Also wom, damaged, or misaligned

accessory drive components or

excessive pulley runout.

[Abnormalities in the accessory drive belt and/or

components may cause engine RPM variations, noises

similar to a faulty lower engine and also lead to a misfire

condition. A misfire code may be present without an actual]

misfire condition.

1. Inspect the accessory drive components.

2. Repair or replace all damaged components

Loose and/or damaged crankshaft

pulley

JA misfire code may be present without an actual misfire

condition,

1. Inspect crankshaft pulley and pulley bolt.

2. Repair or replace all damaged components

Loose torque converter bolts

JA misfire code may be present without an actual misfire

condition.

1. Inspect torque converter bolts and flywheel

2. Repair or replace all damaged components

Loose and/or damaged flywheel

[A misfire code may be present without an actual misfire

condition

1. Inspect flywheel and flywheel attaching botts

2. Repair or replace all damaged components.

Restricted exhaust system

|A severe restriction in the exhaust flow can cause

significant loss of engine performance and may set a

Imisfire code. Possible causes of restrictions include

collapsed or dented pipes, plugged mufflers and/or

catalytic converters.

Repair or replace all damaged components.

\Air in fuel system

1. Inspect fuel filter, fuel system for leaks and/or

restrictions.

2. Repair or replace all damaged components

Bent and/or worn valve bridge and

Hinger-follower.

1. Inspect valve bridge and valve finger-follower.

2. Repair or replace all damaged components

Sticking valve

Carbon on the valve stem or valve seat may cause the

lvalve to stick.

Inspect valves and valve guides.

Repair or replace all damaged components.

po

Damaged or misaligned timing gears

Inspect timing gears.

Replace all damaged components.

po

Wom or faulty camshaft lobes

inspect camshaft lobes.

Repair or replace all damaged components.

no

Excessive piston-to-cylinder bore

clearance

Perform compression tests.

Inspect the piston, piston rings and cylinder bore

Repair or replace all damaged components.

Faulty cylinder head gaskets and/or

cracking or other damage to the

cylinder heads and engine block

cooling system passages. (Coolant

consumption may or may not cause

ithe engine to overheat.)

Perform compression tests.

Inspect the piston, piston rings and cylinder bore

Repair o replace all damaged components.

Base Engine Misfire with

Abnormal Internal Lower Engine Noises

Condition

Action

lAbnormalities (severe cracking,

bumps or missing areas) in the

accessory drive belt.

[Abnormalities in the accessory drive belt and/or

components may cause engine RPM variations, noises

similar to a faulty lower engine and also lead to a misfire

condition. A misfire code may be present without an actual]

misfire condition.

1. Inspect the accessory drive components.

2. Repair or replace all damaged components

lWorn, damaged, or misaligned

laccessory drive components or

lexcessive pulley runout

[A misfire code may be present without an actual misfire

condition.

1. Inspect the accessory drive components.

2. Repair or replace all damaged components

Loose and/or damaged crankshaft

pulley

JA misfire code may be present without an actual misfire

condition.

1. Inspect crankshaft pulley and pulley bolt.

2. Repair or replace all damaged components

[A misfire code may be present without an actual misfire

Loose torque converter bolts

condition.

1. Inspect torque converter bolts and flywheel

2. Repair or replace all damaged components

Loose and/or damaged flywheel

JA misfire code may be present without an actual misfire

condition.

1. inspect flywheel and flywheel attaching botts

2. Repair or replace all damaged components.

Excessive piston-to-cylinder bore

clearance

1. Perform cylinder leak down and compression tests

2. Inspect the piston, piston rings and cylinder bore

3. Repair or replace all damaged components.

Excessive crankshaft thrust bearing

clearance

[Severely wom thrust surfaces on the crankshaft and/or

Ithrust bearing may permit for and aft movement of the

crankshaft and create a misfire code without an actual

Imisfire condition.

1. Inspect the crankshaft end play and crankshaft thrust

bearings.

2. Repair or replace all damaged components

Base Engine Misfir

‘e with Abnormal Valve Train Noise

Condition

Action

Loose, worn or damaged valve bridge

land finger-follower

1. Inspect valve bridge and finger-follower.

2. Repair or replace all damaged components

Broken valve springs

1. Inspect valve springs.

2. Repair or replace all damaged components.

Sticking valve

(Carbon on the valve stem or valve seat may cause the

\valve to stick.

1. Inspect valves and vaive guides.

2. Repair or replace all damaged components

‘Wom or faulty camshaft lobes

1. Inspect camshaft lobes.

2. Repair or replace all damaged components

Base Engine Mi

isfire with Coolant Consumption

Inspection

Action

Definition : Base engine misfire with coolant consumption

Preliminary Inspection

|\Verify that there are no external coolant leaks. Refer

|toSection 1D, Engine Cooling.

Isolate Affected Cylinders

Cylinder balance test with scan tool

Cooling system pressurization

Inspection of glow plugs

* Compression test

EGR System Inspection

inspect EGR valve and intake system for evidence of

coolant leakage.

Replace the EGR cooler if any problem is found

‘Cylinder Head Gasket Leakage

Remove cylinder heads of the affected cylinder bank’

and inspect for damage.

Replace components as necessary.

Cylinder Head or Engine Block

Damage

Inspect the cylinder heads for cracks.

Inspect the cylinder block for damage.

Inspect the cylinder block to head mating surface for

staightness.

Replace components as necessary.

Base Engine Misfir

‘e with Excessive Oil Consumption

Condition

Action

Wom valve guides

1. Inspect the valves and valve guides.

2. Repair or replace all damaged components.

\Wom valve stem oil seals

1. Inspect the valve stem oil seals.

2. Repair or replace all damaged components.

Excessive piston-to-cylinder bore

clearance

Perform compression tests to determine the cause

Inspect the piston rings for low ring tension, broken

or wom rings.

Inspect cylinder bore.

Repair or replace all damaged components.

no

Engine Noise on Start.

-Up, but Only Lasting a Few Seconds

Condition

Action

Incorrect oil viscosity

Drain the oil.

Install the correct viscosity oil.

po

Excessive piston-to-cylinder bore

clearance

Inspect the piston and piston skirt, connecting rod,

and cylinder bore.

Repair or replace all damaged components.

Upper Engine Nol

ise, Regardless of Engine Speed

Condition

Action

Low oil pressure

Insufficient or poor oil supply to valve train.

1, Perform oil pressure test.

2. Repair or replace all damaged components.

Improper lubrication to the valve finger-

\follower

1. Inspect valve finger-follower, valve bridge, valve

finger follower lifter, oil pump and engine block oil

galleries.

2. Repair or replace all damaged components.

Wom or damaged valve finger follower

1. Inspect valve bridge and finger-follower.

2. Repair or replace all damaged components

Sticking valve

Carbon on the valve stem or valve seat may cause the

lvalve to stick,

1. Inspect valves and valve guides.

2. Repair or replace all damaged components

Wom or faulty camshaft lobes

1, Inspect camshaft lobes.

2. ff damaged replace camshaft and all valve finger-

followers.

Damaged or misaligned timing gears

Lower Engine Noi

1. Inspect timing gears

2. Replace alll damaged components.

ise, Regardless of Engine Speed

Condition

Action

Wom accessory drive components

(abnormalities such as severe

icracking, bumps or missing areas in

the accessory drive belt and/or

misalignment of the system

components.)

1. Inspect the accessory drive components.

2. Repair or replace all damaged components

Low oil pressure

Insufficient or poor oil supply to crankshaft and connecting

rod bearings.

1, Perform oil pressure test.

2. Repair or replace all damaged components

1 Insnect the evinder halance with sean taal ta heln

Leaking and/or sticking fuel injection

nozzle (A stuck fuel injection nozzle

ican cause a noise similar to a

damaged piston, rod or rod bearing.)

locate the cylinder that is the source of the noise.

2. If you cannot locate the cylinder that is the source of

the noise, diagnose the engine for mechanical

damage.

3. fit has been determined that the fuel injection nozzle}

is causing the noise, replace the fuel injection

nozzle.

Loose and/or damaged crankshaft

pulley

inspect crankshaft pulley and pulley bolt.

Repair or replace all damaged components.

no

Loose torque converter bolts

Inspect torque converter bolts and flywheel

Repair or replace all damaged components

no

Loose and/or damaged flywheel

Inspect flywheel and fyweel attaching bolts

Repair or replace all damaged components.

Ro

Excessive piston pin-to-bore

clearance

1. Inspect the piston, piston pin, and the connecting

rod.

2. Repair or replace all damaged components

Misaligned or bent connecting rod

Inspect connecting rod and connecting rod bearings.

Repair or replace all damaged components.

po

Excessive connecting rod bearing

clearance

1. Inspect the connecting rod bearings, connecting

rods, crankshaft and crankshaft journals.

2. Repair or replace all damaged components.

Excessive crankshaft bearing

clearance

1. Inspect the crankshaft bearings and crankshaft

journals,

2. Repair or replace all damaged components

Engine Noise Under Load

Cause

Correction

Low oil pressure

Insufficient or poor oil supply to components.

1, Perform oil pressure test.

2. Repair or replace all damaged components

Loose torque converter bolts

1. Inspect the torque converter bolts and flywheel.

2. Repair or replace all damaged components

Loose and/or damaged flywheel

1. Inspect the flywheel and flywheel attaching botts.

2. Repair or replace all damaged components.

Excessive pistor-to-cylinder bore

clearance

1. Inspect the piston rings for low ring tension, broken

or wom rings, inspect cylinder bore.

2. Repair or replace all damaged components

Excessive crankshaft thrust bearing

clearance

1. inspect the crankshaft end play and crankshaft thrust

bearings.

2. Repair or replace all damaged components

Excessive crankshaft bearing

clearance

1. Inspect the crankshaft bearings and crankshaft

journals,

2. Repair or replace all damaged components

Engine Will Not Crank - Crankshaft Will Not Rotate

Cause

Correction

Seized accessory drive system

component

1. Inspect the accessory drive system components.

2. Repair or replace all damaged components

Hydraulically locked cylinder

© Coolanvantifreeze in

cylinder

© Oilin cylinder

© Fuel in cylinder

Inspect for broken head gasket(s).

Inspect for cracked engine block or cylinder head

Inspect for a sticking fuel injector.

ena

‘Seized automatic transmission torque

converter

‘Seized manual transmission

1, Remove the engine assembly. The torque converter

bolts are not accessible with the engine installed to

the transmission.

Rotate crankshaft at the pulley.

N

Disengage the clutch.

Rotate crankshaft at the pulley.

nN

Refer to Unit Repair Manual - Manual Transmission.

Material in cylinder :

© Broken valve

© Piston material

© Foreign material

* Inspect cylinder for damaged components and/or

foreign materials.

+ Repair or replace as required.

‘Seized crankshaft or connecting rod

bearings

* Inspect crankshaft and connecting rod bearings.

* Repair as required.

Bent or broken connecting rod

* inspect connecting rods.

+ Repair as required.

+ nspect cannsnan,

Broken crankshaft * Repair as required.

Coolant in Combustion Chamber

Inspection Action

Definition : Excessive white smoke and/or coolant type odor coming from the exhaust pipe may

indicate coolant in the combustion chamber. Low coolant levels, an inoperative cooling fan, or a

lraulty thermostat may lead to an “overtemperature" condition which may cause engine component:

damage.

|\Verify that there are no external coolant leaks. Refer

Preliminary inspection Losec

Section 1D, Engine Cooling.

* Cylinder balance test with scan tool

+ Cooling system pressurization

Isolate Affected Cylinders + Compression test

* Inspect EGR valve and intake system for evidence of

coolant leakage.

EGR System Inspection + Replace the EGR cooler if any problem is found

* Remove cylinder heads of the affected cylinder bank

and inspect for damage.

Cylinder Head Gasket Leaka

vinder Head Gasket Leakage + Replace components as necessary.

* Inspect the cylinder heads for cracks.

* Inspect the cylinder block for damage

Cylinder Head or Engine Block * Inspect the cylinder block to head mating surface for

Damage straightness.

+ Replace components as necessary.

Coolant in Engine Oil

Cause Correction

Definition : Foamy or discolored oil or an engine oil "overfil” condition may indicate coolant

lentering the engine crankcase. Low coolant levels, an inoperative cooling fan, or a faulty

thermostat may lead to an “overtemperature" condition which may cause engine component

damage. Contaminated engine oil and oil fiter should be changed.

1, Inspect the oil for excessive foaming or an overfill condition. Oil diluted by coolant may not

properly lubricate the crankshaft bearings and may lead to component damage. Refer

to "Lower Engine Noise, Regardless of Engine Speed’ in this section.

2. Inspect by performing a Cylinder Leak-Down Test. During this test, excessive air bubbles

within the cooling system may indicate a faulty gasket or damaged component.

3. Inspect by performing a cylinder compression test. Two cylinders "side-by-side" on the

engine block with low compression may indicate a failed cylinder head gasket. Refer

to"Engine Compression Test" in this section.

Replace the head gasket and components as required

Refer toSection 1C1, Engine Mechanical.

Replace the cylinder head gasket. Refer toSection 1C/.

Engine Mechanical.

Faulty cylinder head gasket

Warped cylinder head

Cracked cylinder head Replace the cylinder head and gasket.

Cracked engine block Replace the components as required.

Cylinder head, block, or manifold Replace the components as required,

porosity

Leaking engine oil cooler Replace components as required.

Fuel in Engine Oil

Definition : Iffuel is suspected of leaking into the crankcase, the following procedure should be

performed to verify the condition.

1, Remove the oil level indicator and allow oil to drop onto a clean white paper towel.

2. I the oil is diluted with fuel, it will become apparent as the towel wicks the fuel away from the

drop of oil on the towel. The fuel will expand out in a ring around the oil droplet.

3. fuel dilution is apparent, inspect the vehicle for aftermarket performance accessories that

may cause damage to the injection pump. After repairs are completed, perform the test

again to verify the condition is corrected

4. Ifno fuel dilution is present, verify the oil level and correct as needed.

Drive Belt Chirp

Notice : Chirping during start-up in cold damp conditions that abates once the engine

reaches operating temperature is considered normal.

Diagnostic Aids

The symptom may be intermittent due to moisture on the drive belts or pulleys. it may be necessary

to spray a small amount of water on the drive belt to duplicate and confirm a customers concem. If

spraying water onto the drive belt system duplicates the symptom, cleaning the belt pulleys may be

the solution.

A loose of incorrectly installed body component, suspension component or other item may be the

cause of the noise.

Test Description

The numbers below refer to steps in the diagnostic table.

2. The noise may not be engine related. This step is to confirm the engine is making the noise.

I the engine is not making the noise, do not proceed further with this diagnostic procedure.

3. The noise may be an internal engine noise. Removing the drive belt and operating the engine

briefly will confirm whether or not the noise is related to the drive belt

4. inspect all drive pump pulleys for pilling

Notice : Pilling is the small balls (pills) or strings of rubber in the belt grooves caused by

the accumulation of rubber dust.

6. Misalignment of the accessory drive system pulleys may be caused by incorrect mounting of

an accessory drive component (A/C compressor, generator etc.) or pulley. Misalignment may

also be caused by incorrect installation of a pulley during a previous repair. Test for a

misaligned pulley using a straight edge in the pulley grooves across two or three pulleys. ifa

misaligned pulley is found, refer to the relevant component service information for the correct

installation and removal procedures

10. nspecting the fasteners can eliminate the possibility that an incorrect fastener has been

installed.

12. Inspecting the pulleys for being bent should include inspecting for a dent or other damage

that would prevent the drive belt from not seating correctly in all of the pulley grooves or on the

smooth surface when the back end of the beltis used as the driving surface.

14, Replacing the drive belt when it is not damaged and there is no excessive pilling will only be

a temporary repair.

Diagnostic Table

Notice : Chirping during start-up in cold damp conditions that abates once the engine

reaches operating temperature is considered normal.

Definition : Accessory drive belt chirping can be defined as a high-pitched noise that is heard once

er revolution of the drive belt or a pulley.

Step| Action Value(s) Yes No

Did you review the information provided in

1 |Symptoms, and perform the required -

inspections. Go to Step 2|Go toSymptoms.

Confirm the customer complaint. Is there a Refer to

2 chirping noise? - Diagnostic Aids

Go to Step 3| in this Section

1, Remove the drive belt, refer toSection ‘Accessory

1C1, Engine Mechanical. drive system

2. Operate the engine for no more than 40 OK.

3 seconds. . Go to

‘Symptoms,

Does the chirping noise still exist? and restart

the diagnosis|

ofthe noise | Go to Step 4

Inspect for severe piling, i.e. in excess of

4 |33% of the belt groove depth. :

Do the belt have pilling?

omhe Belt grooves have ping Goto Step 5| Goto Step 6

Clean the drive belt pulleys with a wire brush. Go to Step

|Are the belt pulleys clean? 15 Go to Step 6

Inspect for misalignment of the pulleys.

lAre the pulleys misaligned? Goto Step 7) Goto Step 8

7_ [Replace or repair misaligned pulleys Go to Step

Did you complete the repair? 15 .

inspect for any bent or damaged accessory

8 {drive component mounting brackets.

Did you find any bent or damaged brackets? Goto Step 9| Goto Step 10

Replace or repair any bent or damaged

9 Brackets. Go to Step

Did you complete the repairs? 15 -

Inspect for missing, loose or incorrect

40 |fasteners.

Did you find any missing, loose or incorrect Go to Step

lrasteners? fo Go to Step 12

Tighten any loose fasteners to the torque

41 |Specification.

Replace any incorrect or missing fasteners. Go to Step

Did you complete the repairs? 15 -

42 |hspect for a bent pulley. Go to Step

Did you find any bent pulleys? 13 Go to Step 14

13 [Replace bent pulleys as required Go to Step

Did you complete the repair? 15 -

Replace the accessory drive belt, refer

14 |toSection 11, Engine Mechanical. Go to Step

Did you complete the repair? 15 -

Reinstall the accessory drive belt and Go

‘operate the system to confirm the repair. Accessory |toSymptoms.and|

15 |Did you correct the chirp noise? drive system | _ restart the

OK diagnosis

Drive Belt Squeal

Diagnostic Aids

ifthe noise is intermittent, confirm the accessory drive components by varying their loads, making

sure they are operated to their maximum capacity. An overcharged A/C system, restrictions in the

power steering pressure circuit or a faully generator is likely causes of accessory drive belt squeal.

A loose or incorrectly installed body component, suspension component or other item may be the

cause of the noise.

Test Description

The numbers below refer to steps in the diagnostic table.

2. The noise may not be engine related. This step is to confirm the engine is making the noise

Ifthe engine is not making the noise, do not proceed further with this diagnostic procedure

The noise may be an internal engine noise. Removing the drive belt and operating the engine

briefty will confirm whether or not the noise is related to the drive belt.

Confirms an accessory drive component does not have a seized bearing. With the belt

removed, test the bearings in the accessory drive components spin free and smooth.

Confirms the drive belt tensioner is operating correctly. I the drive belt tensioner is not

operating correctly, drive belt tension will not be maintained, resulting in a belt squealing

noise.

Confirms the belt is not too long, which would prevent the tensioner from working as

intended. Also, if an excessively long belt has been fitted, it may also be routed incorrectly

and may be turning an accessory drive component in the wrong direction.

Misalignment of the pulleys may be caused by one of the following :

© Incorrect mounting of an accessory drive component,

© Incorrect installation of an accessory drive pulley or,

© Bent or damaged pulley.

Test for a misaligned pulley using a straight edge in the pulley grooves across 2 or 3

pulleys. Ifa misaligned pulley is found, refer to the relevant component service

information for the correct installation and removal procedures.

This test is to confirm the pulleys are the correct diameter and/or width. Using a known good

vehicle, compare the pulley sizes.

Diagnostic Table

Definition : Accessory drive belt squealing can be defined as a loud screeching noise caused bya

slipping drive belt. Belt squeal is unusual in mult-rib belts. Drive belt squeal generally occurs when

a hea

vy load is applied to the drive belt, such as an air-conditioning compressor engagement,

snapping the throttle, seized pulley or a faulty accessory drive component.

Step Action Value(s) Yes No

Did you review the information provided in

1 |Symptoms, and perform the required -

inspections. Go to Step 2|Go toSymptoms

(Confirm the customer complaint, & there a Refer fo

2 |squealing noise? - Diagnostic Aids

Go to Step 3| inthis Section

1, Remove the drive belt, refer toSection ‘Accessory

1€1, Engine Mechanical. drive system

2, Operate the engine for no more than 40 OK.

3 seconds. . Go to

Symptoms,

Does the squealing noise still exist? and restart

the diagnosis

ofthe noise | Go to Step 4

Inspect the accessory drive components for al

seized bearing and general matfunctions.

4 |Did you find and correct any seized bearings -

lor general malfunctions in the accessory

drive system? Goto Step 9| Goto Step 5

Test the accessory drive belt tensioner for

correct operation, refer to Drive Belt

5. [Tensioner Diagnosis

Did you find and repair any problems with the

tensioner?

Goto Step 9

Goto Step 6

Inspect the accessory drive beltis the correct!

length.

Did you find and repair any problems with the

drive belt length?

Goto Step 9

Goto Step 7

Inspect the accessory drive pulleys for

7 |misalignment.

Did you find and correct any misaligned

accessory drive pulleys?

Goto Step 9

Goto Step &

Check the accessory drive pulleys are the

8 correct size.

Did you find and replace any incorrect

Refer to

Diagnostic Aids

pulleys? Go to Step 9| inthis Section

Reinstall the accessory drive belt and Go

g_ [operate the system to confirm the repair Accessory |toSymptoms,and

Did you correct the squeal noise? drive system] restart the

OK diagnosis

Drive Belt Whine

Diagnostic Aids

Test Description

The numbers below refer to steps in the diagnostic table.

The drive belts themselves wil not cause a whine. I the noise is intermittent, confirm the accessory

drive components by varying their loads, making sure they are operated to their maximum

capacity. An overcharged A/C system, restrictions in the power steering pressure circuit or a faulty

generator is likely causes of accessory drive belt whine.

3. The noise may be an internal engine noise. Removing the drive belt and operating the engine

briefly will confirm whether or not the noise is related to the drive belt.

4. The inspection of bearings should include the following accessory drive components

drive belt tensioners,

drive bet idlers,

generator,

power steering pump,

AIC compressor.

The drive belt may need to be installed and the accessory drive components operated

separately, at varying loads to confirm the location of the faulty bearing, refer to the

relevant Sections for component inspection and repair procedures.

Diagnostic Table

Definition : Accessory drive belt whine can be defined as a high-pitched continuous noise that is

most likely to be caused by a failed bearing in one of the accessory drive components

Step] Action Value(s) Yes No

Did you review the information provided in

1 |Symptoms, and perform the required -

inspections. Go to Step 2|Go toSymptoms,

Confirm the customer complaint. s there a Refer to

2 [whining noise? - Diagnostic Aids

Go to Step 3| in this Section

1, Remove the drive belt, refer toSection ‘Accessory

1C1, Engine Mechanical. drive system

2. Operate the engine for no more than 40 OK.

3 seconds. - Go to

‘Symptoms,

Does the whining noise still exist? and restart

the diagnosis| Go to Step 4

Inspect the accessory drive components for a

Htaulty or seized bearings and general

4, {Matfunctions. .

Did you find and correct any faulty/seized Refer to

bearings or general malfunctions in the Diagnostic Aids

accessory drive system? Go to Step 5| inthis Section

Reinstall the accessory drive belt and Go

5, [operate the system to confirm the repair, - Accessory |toSymptoms,and

Did you correct the whine? drive system | restart the

OK diagnosis

Drive Belt Rumble

Diagnostic Aids

Vibration from the engine may cause a body component or other parts to emit a rumbling noise

The drive belt may have a condition that cannot be seen or felt. Sometimes the replacement of the

belt may be the only way to confirm the belt is faulty.

ifthe drive belt has been replaced and the diagnostic table completed, but the rumble is still

present only when the drive belt is installed, an accessory drive component such as the A/C

compressor may be the cause. Varying the load to each accessory drive component in tum, should

help isolate which component is causing the noise.

Test Description

The numbers below refer to steps in the diagnostic table.

2. Confirms the symptom exists at the time of diagnosis. Other vehicle components may be

causing the noise.

3. Confirms the accessory drive beltis the cause of the noise. Drive belt rumbiing is often

confused with an internal engine noise due to the similarity in the description. Removing the

drive belt and operating the engine briefly will confirm whether or not the noise is related to

the drive belt.

Inspecting the drive belt is to ensure that itis not causing the noise. Small cracks across the

ribs of the drive belt will not cause the noise and are not justification alone to replace the belt

Belt separation can be identified by the ply of the belt separating and may be seen at the

edge of the belt or felt as lumps under the belt.

‘Small amounts of pilling is a normal condition and is deemed acceptable. When the pilling is

severe (33% of the belt groove depth), the belt does not have a smooth surface to run on and

should be replaced.

Diagnostic Table

Definition : Definition: Accessory drive belt rumble can be defined as a low pitch tapping, knocking

or thumping noise heard at or just above idle, once per rotation of the drive belt or a specific

component. Drive belt rumble is generally caused by one of the following :

pilling or strings in the drive belt grooves,

separation of the drive belt, or

a damaged or faulty drive belt.

Notice : Pilling is the small balls (pills) or strings of rubber in the belt grooves caused by

the accumulation of rubber dust.

Step] Action Value(s) Yes No

Did you review the information provided in

1 |Symptoms, and perform the required -

inspections. Go to Step 2|Go toSymptoms

(Confirm the customer complaint. Is there a Refer to

2. |rumbling noise? - Diagnostic Aids

Go to Step 3| inthis Section

1. Remove the drive belt, refer toSection ‘Accessory

1C1. Engine Mechanical. drive system

2. Operate the engine for no more than 40 OK.

3 seconds. - Go to

Symptoms,

Does the rumbling noise still exist? and restart

the diagnosis] Go to Step 4

Inspect the accessory drive belt for damage,

4, {Separation or sections of missing ribs .

Did you find any damaged, separated or

missing ribs? Go to Step 7| Go to Step 5

Inspect the accessory drive belt for severe

pilling (exceeding 33% of the belt groove

5 |depth). -

i 2

Did you find sever pilling Go to Step 6| Go to Step 5

‘Clean the drive belt using a suitable wire

brush and reinstall to the engine, refer

ito Section 1C1, Engine Mechanical.

Did you complete the repairs? Goto Step 8 -

Install a new accessory drive belt, refer

7 |toSection 1C1, Engine Mechanical. -

Did you replace the accessory drive belt? Goto Step & -

Frequired, reinstall the accessory drive belt Go

g_ [and operate the system to confirm the repair, . Accessory |toSymptoms,and

Did you correct the rumbling noise? drive system] restart the

oK diagnosis

Drive Belt Vibration

Diagnostic Aids

The accessory drive components such as the A/C compressor or generator can have an affect on

engine vibration.

To aid in locating which component is causing the vibration, vary the load to each accessory drive

component in tum and note the effect it has on the vibration if any.

Test Description

The numbers below refer to steps in the diagnostic table

2. Confirms the symptom exists at the time of diagnosis. Other vehicle components may be

causing the noise.

3. Confirms the accessory drive belt is the cause of the noise. Drive belt rumbling is often

confused with an internal engine noise due to the similarity in the description. Removing the

drive belt and operating the engine briefly will confirm whether or not the noise is related to

the drive belt.

4, The drive belt may cause a vibration, inspecting the drive belt is considerably easier while

the drive belt is removed.

6. Inspecting the fasteners can eliminate the possibilty that an incorrect fastener has been

installed.

8. This step should only be performed if the cootant pump is driven by the drive belt. Inspect the

coolant pump for a bent shaft. Also inspect the coolant pump bearings for smooth operation

and excessive play. Compare the coolant pump with a known good pump.

9. Accessory drive component brackets that are bent, cracked or loose may put extra strain on

the accessory component causing it to vibrate

Diagnostic Table

Definition : Accessory drive belt vibration can be defined as a drive belt that jumps, shakes or

rattles. Accessory drive belt vibration is usually indicated by one of the following :

* the vibration is engine speed related, or

+ the vibration is sensitive to accessory drive system load.

‘Step Action Value(s) Yes No

Did you review the information provided in

1. |Symptoms, and perform the required - Go

inspections. Go to Step 2| toSymptoms

[Confirm the customer complaint. s there a Refer to

2 {rumbling noise? . Diagnostic

Aids in this

Goto Step 3| Section

1. Remove the drive belt, refer toSection ‘Accessory

1C1, Engine Mechanic: drive system

2. Operate the engine for no more than 40 OK.

3 seconds. - Goto

Symptoms,

Does the vibration noise still exist? and restart

the diagnosis| Go to Step 4

Inspect the accessory drive belt for damage,

|wear, debris build-up or sections of missing

4 |ribs. -

Did you find any damage, wear, debris build-up

lor missing ribs? Go to Step 5| Go to Step 6

install a new accessory drive belt, refer

5 |toSection 1C1, Engine Mechanical. -

Did you replace the accessory drive belt? Go to Step 9 -

Inspect for incorrect, loose, missing or

g {damaged fasteners. .

Did you find any incorrect, loose, missing or

damaged fasteners? Go to Step 7| Goto Step 8

Tighten any loose fasteners to the correct

7 [torque specification. .

Replace any incorrect or missing fasteners.

Did you complete the repairs? Go to Step 9 :

Inspect for bent, cracked or damaged Refer to

g_ {accessory drive component mounting brackets. . Diagnostic

Did you find and repair any bent brackets? Aids in this

Go to Step 9}| Section

if required, reinstall the accessory drive belt and Refer to

g_ [operate the system to confirm the repair. . Accessory | Diagnostic

Did you correct the vibration? drive system | Aids in this

OK Section

Drive Belt Falls Off

Diagnostic Aids

ifthe accessory drive belt repeatedly falls off the drive pulleys, this is most likely due to pulley

misalignment.

Anextra load that is quickly applied and released by an accessory drive component (e.g. A/C

compressor) may cause the accessory drive belt to fall off. In this circumstance, confirm the fautt by

operating the accessory drive components in turn, noting which one caused the belt to fall off.

Lack of drive belt tension may also cause the belt to fall off the pulleys. Low drive belt tension could

be caused by one of the following :

+ anincorrect drive belt length,

+ a faulty drive belt tensioner, or

+ asstretched or faulty drive belt.

Test Description

The numbers below refer to steps in the diagnostic table.

2. Confirms the condition of the drive belt. Damage may have occurred to the drive belt when it

first fell off or it may have been damaged which caused the belt to fall off.

4. Misalignment of the pulleys may be caused by

© the incorrect installation or mounting of an accessory drive component,

© the incorrect installation of an accessory drive component pulley, or

© adamaged or bent accessory drive pulley.

Test for a misaligned pulley using a suitable straight edge in the pulley grooves across

two or more pulleys. if'a misaligned pulley is found, refer to the service information for

the particular component, for the correct pulley replacement procedures.

5. Inspecting the pulleys should include an inspection for dents or other damage that would

prevent the drive belt from seating correctly in all of the pulley grooves or on the smooth

surface of a pulley when the back side of the belt is used.

6. Accessory drive component mounting brackets that are bent will cause the drive belt to fall

off.

7. Inspection of the fasteners can eliminate the possibility that an incorrect fastener was

installed. Missing, loose or incorrect fasteners may cause pulley misalignment from the

fasteners moving under load. Over-tightening of the fasteners may cause deflection of

mounting brackets and result in misaligned accessory drive pulleys.

Diagnostic Table

Definition : The drive belt falls off during normal operation or does not ride correctly on the

accessory drive pulleys.

Step’ Action Value(s) Yes No

Did you review the information provided in

1 Symptoms, and perform the required : Go

inspections. Go toStep 2 | toSymptoms

2. [Inspect for a damaged accessory drive belt. .

Did you find any damage on the drive belt? Go toStep 3 | Go to Step 4

install a new accessory drive belt, refer

3 |toSection 11, Engine Mechanical. -

Does the drive belt continue to fall off? Go toStep 4 |Go to Step 12)

Inspect the accessory drive system pulleys for

misalignment.

Did you find and repair any misaligned drive

Isystem pulleys?

Go toStep 12

Goto Step 5

Inspect for a dented or cracked accessory drive|

Isystem pulley.

Did you find and repair any dented or cracked

ldrive system?

Go toStep 12

Goto Step 6

Inspect for bent accessory drive component

Imounting brackets.

Did you find and repair any bent mounting

brackets?

Go toStep 12

Goto Step 7

Inspect for incorrect, loose, missing or

damaged fasteners.

Did you find any incorrect, loose, missing or

damaged fasteners?

Go toStep 8

Goto Step 9

Tighten any loose fasteners to the correct

torque specification

Replace any incorrect or missing fasteners.

Does the drive belt continue to fall off?

Go toStep 9

Go to Step 12]

Test the accessory drive belt tensioner for

lcorrect operation, refer toSection 1C1, Engine

Mechanical,

Did you accessory drive belt tensioner operate

correctly?

Go toStep 11

Go to Step 10)

10

Replace the drive belt tensioner, refer

ltoSection 1C1, Engine Mechanical.

Does the drive belt continue to fall off?

Go toStep 11

Go to Step 12!

1

Inspect for a failed drive belt idler and drive belt

tensioner bearings.

Did you find and repair any failed bearings?

Go toStep 12

Refer to

Diagnostic

Aids in this

Section

12

If required, reinstall the accessory drive belt and|

loperate the system to confirm the repair.

Does the drive belt continue to fall off?

Go toStep 2

‘Accessory

drive system

OK

Drive Belt Excessive Wear

Diagnostic Aids

Excessive wear of a drive beltis usually caused by an incorrect installation or an incorrect drive

belt fitted. Minor pulley misalignment will not cause excessive wear, but will cause the drive belt to

fall off. Major pulley misalignment may cause excessive wear, but would also result in the drive belt

falling off.

Test Description

The numbers below refer to steps in the diagnostic table.

2. Confirms the drive belt is correctly installed onto all of the accessory drive system pulleys.

Wear on the drive belt may be caused by incorrectly positioning the drive belt by one or more

grooves to a particular pulley.

3. The installation of the drive belt that is the incorrect width will cause wear on the drive belt

The drive belt ribs should match all the grooves on all the pulleys in the accessory drive

system.

4, Confirms the drive belt is not contacting any parts of the engine or body while the engine is

running. There should be sufficient clearance when the accessory drive component loads

varies. The drive belt should not come into contact with any engine or body parts

Diagnostic Table

Definition : Excessive wear can be defined as wear at the outside ribs of the drive belt (frayed

edges), usually caused by an incorrectly installed drive belt.

Step Action Value(s) Yes No

Did you review the information provided in

1 Symptoms, and perform the required : Go

inspections. Go toStep 2 | toSymptoms

Inspect the accessory drive belt for correct

2 |installation. -

Is the drive belt installed correctly? Go toStep 5 | Go to Step 3

Ensure that the drive beltis the correct one for

3. |the application. -

is the correct drive belt installed? Go toStep 5 | Go to Step 4

Is the drive belt contacting any engine or body Refer to

4. [eomponents with the engine running? . Diagnostic

Aids in this

GotoStep 6| Section

install a new accessory drive belt, refer

5 |toSection 1C1, Engine Mechanical. a

Did you replace the accessory drive belt? Go toStep 6 :

if required, reinstall the accessory drive belt and! ‘Accessory

6 operate the system to confirm the repair. : drive system

Did you correct the excessive wear? OK Goto Step 2

COMPONENT LOCATOR

Cylinder Head

1, Spark Plug Cable Cover

Engine Oil Cap

Cylinder Head Cover

Cylinder Head Cover Gasket

Spark Plug Cable

Spark Plug

Ignition Coil (DIS) Bracket

Ignition Coil (DIS)

Camshaft Cap

10. Camshaft (Intake)

14, Camshaft (Exhaust)

12. Valve Tappet

13, Valve Key

14. Valve Spring Retainer

45. Valve Spring

16. Valve Stem Seal

17. Cylinder Head

18. Valve (Intake)

19. Valve (Exhaust)

20. Cylinder Head Gasket

21. Cylinder Head Bolt

22. Camshaft Position Sensor

23, Coolant Outlet Case Gasket

24, Coolant Outlet Case

25. Coolant Temperature Sensor

26. EGR Valve Gasket

27. EGR Valve

O©@NAARWN

Cylinder Block

Piston Ring

Piston

Piston Pin Retainer

Piston Pin

Connecting Rod Cap Stud

Connecting Rod

Connecting Rod Bearing

Connecting Rod Cap

Dowel Pin

10. Cylinder Block

11, Timing Chain Cover

12. Crankshaft Front Oilseal

13. Oil Pump Inner Rotor

14, Oil Pump Outer Rotor

15. Oil Pump Cover

Ce2VOTRONS

16

17

18

19

20.

21

22.

23,

24,

25.

26.

27.

28.

29.

© @NAARWRA

10.

4

12

13

14,

15.

16.

17

18

19.

20.

21

22

Oil Relif Valve

Oil Relif Valve Spring

Oil Relif Valve Cap

Oil Relif Vaive Retainer

Oil Filter Stud

Oil Filter

Key

Crankshaft

Crankshaft Bearing Cap

Oil Strainer

Oil Pan

Crankshaft Rear Oil Seal

Cylinder Block Plate Plug

Cylinder Block Plate Plug Gasket

Manifold & Air Charging System

Resonator

Duet

Air Filter Snorkel Hose

Air Filter Lower Housing

Air Filter Element

Air Filter Upper Cover

Air Outlet Hose

Resonator

Resonator

Throttle Body

ACV (dle Air Control Valve)

Throttle Position Sensor

Intake Manifold

EGR Pipe

EGR Pipe Gasket

EGR Valve

Thermostat Housing

Coolant Outlet Case

Fuel Rail

hijector

Exhaust Manifold

Exhaust Manifold Heat Shield

Timing System & Mount

Timing Chain

Camshaft Sprocket (Intake)

Camshaft Sprocket (Exhaust)

Bushing

Camshaft Sprocket Retaining Bolts

Timing Chain Lever

Timing Chain Tensioner

Timing Chain Guide

Crankshaft Sprocket

10. Engine Mount Assembly

11, Rear Mount Bracket

12. Transmission Rear Mount

13, Transmission Mount Assembly

14, Transmission Mount Bracket

CHVOMRONS

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- 2012 Chevrolet Sonic 1.8L Motor LUWDocument612 pages2012 Chevrolet Sonic 1.8L Motor LUWPatricio ValenciaNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- 2003 Jeep Cherokee Laredo Diagramas EconomicosDocument32 pages2003 Jeep Cherokee Laredo Diagramas EconomicosPatricio Valencia100% (2)

- I10 - 2014 PDFDocument6 pagesI10 - 2014 PDFPatricio ValenciaNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Fusiblera de Hyunday TiburonDocument6 pagesFusiblera de Hyunday TiburonPatricio ValenciaNo ratings yet

- D4BH (2.5 TCI) Diesel Engine D4BH (2.5 TCI) Diesel Engine: ( (C CO OV VE EC C - F F) )Document51 pagesD4BH (2.5 TCI) Diesel Engine D4BH (2.5 TCI) Diesel Engine: ( (C CO OV VE EC C - F F) )Patricio ValenciaNo ratings yet

- Silverado 2001 4Document1 pageSilverado 2001 4Patricio ValenciaNo ratings yet

- Mazda 121 PCM 2000-2002Document8 pagesMazda 121 PCM 2000-2002Patricio ValenciaNo ratings yet

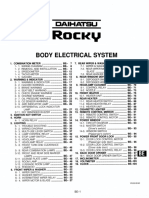

- 92rocky CH Charging - SystemDocument24 pages92rocky CH Charging - SystemPatricio ValenciaNo ratings yet

- 92Rocky-BE-Body Electrical SystemDocument105 pages92Rocky-BE-Body Electrical SystemPatricio ValenciaNo ratings yet

- 520 Fuse Box in The Engine CompartmentDocument4 pages520 Fuse Box in The Engine CompartmentPatricio ValenciaNo ratings yet