Professional Documents

Culture Documents

Extracted Pages From A001064 - 12E

Extracted Pages From A001064 - 12E

Uploaded by

Awais8888Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Extracted Pages From A001064 - 12E

Extracted Pages From A001064 - 12E

Uploaded by

Awais8888Copyright:

Available Formats

4 Liquid Fuels

4.1 Diesel fuels – General information

Important

Dispose of used fluids and lubricants in accordance with local regulations.

Used oil must never be disposed of via the combustion engine!

Selection of a suitable diesel fuel

The quality of the fuel is very important for satisfactory engine performance, long engine service life and ac-

ceptable exhaust emission levels.

Important

Diesel fuels are not available worldwide in the quality required according to (→ Table 12).

The fuel properties depend on many factors, in particular, region, time of year and storage.

Important

If the fuel is to be stored in storage tanks for an extended period of time, we strictly recommend the use of

B0 fuel (biodiesel/FAME-free fuel).FAME (Fatty Acid Methyl Ester) stands for first generation biodiesel.

Rolls-Royce Solutions GmbH provides project-specific consultation on request.

We recommend that you determine the oxidation stability (EN ISO 12205/ASTM D 2274) to check the

quality.

Unsuitable fuel usually leads to a reduced service life of engine components and can also cause engine dam-

age.

Further details on fuel qualities, tank care and filtration are available in the publication "Useful information on

fuels, tank systems and filtration" (publication number A060631/..).

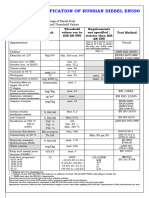

Applicable fuel limit values

Characteristics of the fuel Test method Limit values

ASTM

Composition The diesel fuel must be free

of inorganic acids, visible

water, solid foreign matter

and chlorine compounds.

Total contamination (= elements max. D6217 EN 12662 24 mg/kg

insoluble in fuel)

Density at 15 °C min. D1298 EN ISO 3675 0.820 g/ml

max. D4052 EN ISO 12185 0.860 g/ml

API gravity at 60 °F min. D287 41

TIM-ID: 0000060900 - 009

max. 33

Viscosity at 40 °C min. D445 EN ISO 3104 1.5 mm²/s

max. 4.5 mm²/s

Flashpoint (closed crucible) greater D93 DIN EN ISO 55 °C

2719

1)

see series-specific injection / and exhaust gas aftertreatment systems (→ Table 16) for the Defini-

tion as to whether an exhaust gas aftertreatment system is installed.

2)

Note: 1% by weight = 10000 mg/kg = 10000 ppm

36 | Liquid Fuels | A001064/12E 2021-12

Characteristics of the fuel Test method Limit values

ASTM

Boiling curve: D86 EN 17306

– Initial boiling point 160 to 220 °C

– Volume share at 250 °C max. 65% by volume

– Volume share at 350 °C min. 85% by volume

– Residue and loss max. 3% by volume

Fatty acid methyl ester content max. EN 14078 7.0% by volume

(FAME) Internal Rolls-

("Biodiesel") Royce Solutions

procedure

Proportion of water: (absolute, no max. D6304 EN ISO 12937 200 mg/kg

free water)

Carbon residue from 10% distilla- max. D189 EN ISO 10370 0.30% by weight

tion residue

Oxide ash:1) D482 EN ISO 6245

– Engines without exhaust gas af- max. 0.01% by weight

tertreatment or recirculation (100 mg/kg)

– Engines with exhaust gas after- max. 0.001 % by weight

treatment or recirculation (10 mg/kg)

Sulfur content:1) max. D5453, EN ISO 20846, 0.5% by weight

– Engines without exhaust gas af- D2622 EN ISO 20884 (5000 mg/kg)2)

tertreatment or recirculation

– Engines with exhaust gas after- max. 0.0015% by weight

treatment or recirculation (15 mg/kg)2)

– 2000Gx6 max. 0.05% by weight

(500 mg/kg)2)

Cetane number min. D613 EN ISO 5165, 45

EN ISO 15195

Cetane index min. D976 EN ISO 4264 42

Copper corrosion Max. de- D130 EN ISO 2160 1a

3 hrs at 50 °C gree of

corro-

sion

Oxidation stability(Rancimat) min. EN 15751 20 hours

Oxidation stability max. D2274 EN ISO 12205 25 g/m³

Lubricity at 60 °C max. D6079 EN ISO 12156-1 520 µm

(HFRR value)

TIM-ID: 0000060900 - 009

Neutralization number max. D974 0.2 mg KOH/g

1)

see series-specific injection / and exhaust gas aftertreatment systems (→ Table 16) for the Defini-

tion as to whether an exhaust gas aftertreatment system is installed.

2)

Note: 1% by weight = 10000 mg/kg = 10000 ppm

Table 12: Applicable fuel limit values

Diesel fuels in winter operation

At low outdoor temperatures, the diesel fuel's fluidity can be inadequate on account of paraffin precipitation.

It is the fuel supplier's responsibility to provide a fuel that will assure correct engine operation at the expect-

ed minimum temperatures and under the given geographical and other local conditions.

A001064/12E 2021-12 | Liquid Fuels | 37

The operating company must ensure that there is always sufficient fuel to meet the corresponding climatic

requirements.

In order to prevent operational problems (e.g. clogged filters) during the winter months, diesel fuel with suita-

ble cold-flow characteristics is available on the market. Deviations are possible during transitional periods

and in individual countries.

The following parameters define the cold-flow characteristics:

Test method Limit values

ASTM

Filter plugging point (CFPP) D6371 DIN EN 116 See Note 1)

Cloud Point D2500 DIN EN 23015 See Note 2)

Table 13: Parameters to define the cold-flow characteristics

1)

Filter plugging point or Cold Filter Plugging Point (CFPP) denotes the temperature at which a test filter is

blocked under defined conditions by precipitated paraffins. This characteristic is used for diesel fuels as per

DIN EN 590 to describe the climatic requirements (e.g. summer and winter diesel).

2)

The cloud point is the temperature at which a liquid product becomes turbid in the test glass due to precip-

itation of paraffin. This must not be higher than the ambient temperature.

Use of fuels with higher sulfur content:

The engines are certified for operation with the fuels approved in these Fluids and Lubricants Specifications.

The component TBO specified in the maintenance schedule relates to operation of the engine with diesel fuel

as per DIN EN 590.

For operation with a high sulfur content in the fuel, the following must be observed:

Series 4000

When a fuel with sulfur content > 3000 mg/kg is used, the times specified in the maintenance schedule for

component TBO of the cylinder head may be reduced, see following table (→ Page 38).

TBO cylinder head as a function of sulfur content in the fuel

Sulfur content in fuel (mg/kg) TBO cylinder head (h)

<3000 according to maintenance schedule

3000 - 4500 70001)

4500 - 5000 5000 1)

Table 14: TBO cylinder head as a function of sulfur content in the fuel

1)

= If the TBO for the cylinder head specified in the maintenance schedule is shorter, the shorter TBO shall

always apply.

Engines with exhaust gas recirculation and/or exhaust gas aftertreatment system must not be operated with

increased sulfur content in the fuel. The limit values in the Fluids and Lubricants Specifications apply.

TIM-ID: 0000060900 - 009

Important

If the sulfur content in the fuel is > 0.5 % by weight (> 5000 ppm), please consult with Rolls-Royce Solutions

GmbH (Application).

When engines are operated with diesel fuels with a sulfur content of more than 0.5% by weight, appropriate

engine oils must be used. The criteria for the selection of engine oils can be found in the chapter "Engine

oils" (→ Page 8).

38 | Liquid Fuels | A001064/12E 2021-12

Note

The limit values named in the table (→ Table 12) must be observed at the interface [(→ Figure 3), item 6] at

the latest to guarantee safe and efficient engine operation. This applies in particular to water and total con-

tamination.

Important

In addition to the limit values listed in the table (→ Table 12), a particle distribution in the fuel in acc. with

ISO 4406 must be observed, see (→ Table 15).

Particle distribution for fuels

Particle distribu- Test method Limit values

tion

ASTM 2000 Gx6 2000 Gx5

4000 Gx3

4000 Gx4

4000 Gx5

Particle distribution D7619 Coding of number max. ISO Code max. ISO Code

for fuel between D7647 of particles as per 18/17/14 for 21/20/17 for

last tank before en- ISO 4406 4/6/14 µm particle 4/6/14 µm particle

gine and prefilter size size

[(→ Figure 3), item

6]

Table 15: Particle distribution for fuels

Important

The limit values named in the table (→ Table 15) must already be observed in the feed between the last

tank before the engine and the prefilter (if necessary, with water separator).

For plants without a prefilter, this refers to the feed between the last tank and the scope of supply of Rolls-

Royce Solutions. For the analysis of the fuel quality, an interface (sample extraction cock) must be provided

for sample extraction during operation.

For existing plants without an accessible feed, a sample extraction point in the last tank before the scope of

supply of Rolls-Royce Solutions is permissible.

TIM-ID: 0000060900 - 009

A001064/12E 2021-12 | Liquid Fuels | 39

You might also like

- OMM SEBU9236-5 DE Series Generator Set With Cat C1.1, C1.5, and C2.2 Engine CaterpillarDocument106 pagesOMM SEBU9236-5 DE Series Generator Set With Cat C1.1, C1.5, and C2.2 Engine Caterpillarnixcalo100% (5)

- Fuel Oil SpecificationDocument7 pagesFuel Oil Specificationmichael_forraNo ratings yet

- Petroleum Chemistry Labs PDFDocument54 pagesPetroleum Chemistry Labs PDFHassan AnwerNo ratings yet

- 002 ADERCO General PresentationDocument14 pages002 ADERCO General PresentationaravindNo ratings yet

- Biodiesel Puri Fication and Upgrading Technologies: Hbateni@iastate - EduDocument44 pagesBiodiesel Puri Fication and Upgrading Technologies: Hbateni@iastate - EduRyan FebrinoNo ratings yet

- Literature Review 2.1 BiodieselDocument18 pagesLiterature Review 2.1 BiodieselRichard ObinnaNo ratings yet

- Crown Oil HVODocument1 pageCrown Oil HVOLuca CarazzoloNo ratings yet

- Marine Fuel3Document2 pagesMarine Fuel3Finito TheEndNo ratings yet

- 2 Specification Russian EN590Document1 page2 Specification Russian EN590Sephiwe MafilikaNo ratings yet

- Turbine Oil Specifications TGO2-0171-E00000/B 02.03.16Document7 pagesTurbine Oil Specifications TGO2-0171-E00000/B 02.03.16balaji3110No ratings yet

- Biodiesel Standards & PropertiesDocument6 pagesBiodiesel Standards & PropertiesMarta Lopez BerralNo ratings yet

- D2 JP54 Spec PDFDocument3 pagesD2 JP54 Spec PDFcesarjabbour1No ratings yet

- Quality Control of Products in Petroleum RefiningDocument29 pagesQuality Control of Products in Petroleum RefiningAdrian RodriguezNo ratings yet

- Specification For Biodiesel B100Document1 pageSpecification For Biodiesel B100anggaeryantoNo ratings yet

- Test Specifications For Biodiesel FuelDocument6 pagesTest Specifications For Biodiesel FuelYariela CedeñoNo ratings yet

- Technical Aspects of Identifying and Managing Bunker Problems PDFDocument58 pagesTechnical Aspects of Identifying and Managing Bunker Problems PDFMannMannNo ratings yet

- Biodiesel Spec SheetDocument3 pagesBiodiesel Spec SheetMohamed HalemNo ratings yet

- Specification For BIODIESEL (B100) - ASTM D6751-09: Property ASTM Method Limits UnitsDocument1 pageSpecification For BIODIESEL (B100) - ASTM D6751-09: Property ASTM Method Limits UnitsAbraham Garcia Maldonado100% (1)

- ASTM 6751 Spec PDFDocument2 pagesASTM 6751 Spec PDFAlush Joe0% (1)

- ASTM Biodiesel Specs - Nov08Document1 pageASTM Biodiesel Specs - Nov08Alejandra RojasNo ratings yet

- 7th International İstanbul Bunker Conference Chris Fisher PDFDocument39 pages7th International İstanbul Bunker Conference Chris Fisher PDFBatul KhuzemaNo ratings yet

- ENGEN GASOIL Import Spec - Diesel 10Document2 pagesENGEN GASOIL Import Spec - Diesel 10basharat121100% (2)

- Marine Gas Oil - DistillatesDocument1 pageMarine Gas Oil - DistillatesVilius BukysNo ratings yet

- Nateria MJ 40Document1 pageNateria MJ 40Anibal RiosNo ratings yet

- Rop 10 Ton Per Day Internal Tanpa LahanDocument26 pagesRop 10 Ton Per Day Internal Tanpa Lahanhadi prasetio100% (1)

- Shell Marine Gas Oil (DMA) : Test Property Unit MethodDocument1 pageShell Marine Gas Oil (DMA) : Test Property Unit MethodVilius BukysNo ratings yet

- Chapter Two Literature ReviewDocument4 pagesChapter Two Literature ReviewifiokNo ratings yet

- Screenshot 2019-12-28 at 4.13.33 PMDocument10 pagesScreenshot 2019-12-28 at 4.13.33 PMDave Acang100% (1)

- BPL-TRANSFORMER-OILDocument3 pagesBPL-TRANSFORMER-OILceragonNo ratings yet

- Evolution Full-Tech Fe 5w-30 EngDocument1 pageEvolution Full-Tech Fe 5w-30 EngDaniel MartínNo ratings yet

- Fuel Lub #1Document141 pagesFuel Lub #1chNo ratings yet

- RxqLAqoza7pbNi3pvz1GfRieVcYTaAbfFuel Specifications EN590-10PPMDocument1 pageRxqLAqoza7pbNi3pvz1GfRieVcYTaAbfFuel Specifications EN590-10PPMalbert.mamuevNo ratings yet

- Bio Diesel b20, En590 b5 SpecificationsDocument1 pageBio Diesel b20, En590 b5 Specificationsmohammed wajidNo ratings yet

- DieselDocument1 pageDieselBepdjNo ratings yet

- Carlos Types of FuelDocument5 pagesCarlos Types of FuelDaiane LavrattiNo ratings yet

- 02 Fuel, Lubricating Oil, Cooling WaterDocument14 pages02 Fuel, Lubricating Oil, Cooling Waterhmandioussama1No ratings yet

- En 590Document1 pageEn 590osmankoc812No ratings yet

- En 590Document1 pageEn 590anil divveNo ratings yet

- 1506 OmmDocument3 pages1506 OmmMohamed IsmailNo ratings yet

- II StandardsDocument96 pagesII StandardsSami Onur VuralNo ratings yet

- ASTM MethodsDocument9 pagesASTM MethodsLe Nguyen Phuc ThienNo ratings yet

- UNIT II-CharacterizationDocument12 pagesUNIT II-CharacterizationSampanna AwareNo ratings yet

- Spec - Diesel S10Document1 pageSpec - Diesel S10Dylson ValenteNo ratings yet

- Cummins G12 Diesel Fuel Oil Use in Aggreko EnginesDocument2 pagesCummins G12 Diesel Fuel Oil Use in Aggreko EnginesAhmed AbdullahNo ratings yet

- Turbine EngDocument1 pageTurbine EngPeter_Phee_341No ratings yet

- TDS Castrol Perfecto XPG - Power VersionDocument2 pagesTDS Castrol Perfecto XPG - Power VersionTeguh SNo ratings yet

- 03 Blending PowerpointDocument70 pages03 Blending PowerpointNinhHoàngHải100% (4)

- TDS SP CNG 20W-50_ENGDocument2 pagesTDS SP CNG 20W-50_ENGSinh LeNo ratings yet

- 450F HsdviDocument2 pages450F HsdviJoJo kNo ratings yet

- Cat Biodiesel Presentation-NY - 03-13-07Document27 pagesCat Biodiesel Presentation-NY - 03-13-07Pablo Luis Pérez Postigo100% (1)

- Biodiesel, Analytical Aspects: Florence LACOSTE, Lionel LAGARDERE Institut Des Corps Gras, Rue Monge, Pessac (France)Document9 pagesBiodiesel, Analytical Aspects: Florence LACOSTE, Lionel LAGARDERE Institut Des Corps Gras, Rue Monge, Pessac (France)BijayNo ratings yet

- Bunker Specification Page 2Document15 pagesBunker Specification Page 2mohdfadhirul100% (1)

- Elf Solaris DPF 5w30Document1 pageElf Solaris DPF 5w30ionut dumitruNo ratings yet

- QSX15 Fuel RequirementDocument2 pagesQSX15 Fuel RequirementNikkikumarNo ratings yet

- Emd645 Mi1750 PDFDocument4 pagesEmd645 Mi1750 PDFAmin AminiNo ratings yet

- Marine Fuel Oil Rme 180 (Ifo 180)Document1 pageMarine Fuel Oil Rme 180 (Ifo 180)Pablo PaganiNo ratings yet

- SN 200Document1 pageSN 200rediwi3273No ratings yet

- Chapter - 6 Transformer Oil: Working Group MembersDocument6 pagesChapter - 6 Transformer Oil: Working Group MembersMukesh KumarNo ratings yet

- 2022 TSA Petrol Import SpecificationDocument2 pages2022 TSA Petrol Import Specificationmohamed fikryNo ratings yet

- Xado 15W40,20W50Document2 pagesXado 15W40,20W50GamalNo ratings yet

- Machinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityFrom EverandMachinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityRating: 3.5 out of 5 stars3.5/5 (5)

- MOTORTECH Manual MIC5 01.10.023 EN 2022 01 WEBDocument176 pagesMOTORTECH Manual MIC5 01.10.023 EN 2022 01 WEBAwais8888No ratings yet

- Schematics (C44D5 - C66D5) A041A368 - I1 - 201203Document3 pagesSchematics (C44D5 - C66D5) A041A368 - I1 - 201203Awais8888No ratings yet

- Communicationboard230210 1521630740 B6a3b533Document15 pagesCommunicationboard230210 1521630740 B6a3b533Awais8888No ratings yet

- Flonidan Uniflo 1200Document2 pagesFlonidan Uniflo 1200Awais8888No ratings yet

- Excitation SystemDocument15 pagesExcitation SystemAwais8888No ratings yet

- G3500C ActuatorServiceBulletin Rev1Document2 pagesG3500C ActuatorServiceBulletin Rev1Awais8888No ratings yet

- Tony Pytte PresentationDocument20 pagesTony Pytte PresentationtinberNo ratings yet

- LPG Marketing Feasibility Full NewDocument23 pagesLPG Marketing Feasibility Full NewAjas Aju100% (1)

- Car Lubricant PresentationDocument36 pagesCar Lubricant PresentationGia NicoNo ratings yet

- Renewable Energy Sources: RES Unit 4 1Document50 pagesRenewable Energy Sources: RES Unit 4 1sibirajNo ratings yet

- 05-Oimb-Philippine National Standards and Its Importance MCCCM Final April242018 PDFDocument44 pages05-Oimb-Philippine National Standards and Its Importance MCCCM Final April242018 PDFrasper pascualNo ratings yet

- AFRISO Hydrostatic Level Indicator TankControl01 en 05-12Document2 pagesAFRISO Hydrostatic Level Indicator TankControl01 en 05-12Rizwan ShaikhNo ratings yet

- Certificate of AnalysisDocument3 pagesCertificate of AnalysisBernabeNo ratings yet

- Alpha LPW2 G-Build Technical Data SheetDocument2 pagesAlpha LPW2 G-Build Technical Data SheetCristian S Cárdenas RiveraNo ratings yet

- Green Solutions For 0telecom TowerDocument16 pagesGreen Solutions For 0telecom TowerGuillermo AndradeNo ratings yet

- D 1250 - 08 (2013) E1Document7 pagesD 1250 - 08 (2013) E1toxablia100% (1)

- Training Programme GuideDocument46 pagesTraining Programme Guidelelameda100% (3)

- Class IX Science Natural Resources PPT ModuleDocument21 pagesClass IX Science Natural Resources PPT ModuleAarti SuryavanshiNo ratings yet

- City of Fort Collins CSU Stadium ReportDocument13 pagesCity of Fort Collins CSU Stadium ReportColoradoanNo ratings yet

- Ignition Probablity Hsl0550Document22 pagesIgnition Probablity Hsl0550Hashimi Juni100% (1)

- Material Safety Data Sheet Diesel Fuel - High Sulfur: Nfpa: Hmis IiiDocument11 pagesMaterial Safety Data Sheet Diesel Fuel - High Sulfur: Nfpa: Hmis IiiDeshanNo ratings yet

- 10 1016@j Matpr 2019 12 362 PDFDocument6 pages10 1016@j Matpr 2019 12 362 PDFCAMILO ANDRES CABARCAS MANJARREZNo ratings yet

- Studies The Influemce of Blending Palm Biodiesel and Sunflower Biodiesel On Cloud Point PropertiseDocument51 pagesStudies The Influemce of Blending Palm Biodiesel and Sunflower Biodiesel On Cloud Point PropertisenityaNo ratings yet

- Florida Motor Fuel Tax Relief Act of 2022Document9 pagesFlorida Motor Fuel Tax Relief Act of 2022ABC Action NewsNo ratings yet

- Micro Project: Title of The ProjectDocument12 pagesMicro Project: Title of The Projectomkar digamabar sononeNo ratings yet

- Problem Sets A: T-CPET121LA - Introduction To Computational ThinkingDocument5 pagesProblem Sets A: T-CPET121LA - Introduction To Computational Thinkingmarc San joseNo ratings yet

- 43 - Checklist of Pumps For Monthly PMDocument6 pages43 - Checklist of Pumps For Monthly PMSiraj AhmedNo ratings yet

- Diesel Mogas PipelineDocument6 pagesDiesel Mogas PipelineMuhammad ShahbazNo ratings yet

- 2018 Effect of Metal-Acid Balance On Hydroprocessed Renewable Jet Fuel Synthesis From Hydrocracking and Hydroisomerization of Biohydrogenated Di PDFDocument12 pages2018 Effect of Metal-Acid Balance On Hydroprocessed Renewable Jet Fuel Synthesis From Hydrocracking and Hydroisomerization of Biohydrogenated Di PDFmaiquynhchauNo ratings yet

- Eco Friendly Innovation Effectiveness of Oil Absorbent Pads Utilizing Processed Peanut ShellsDocument28 pagesEco Friendly Innovation Effectiveness of Oil Absorbent Pads Utilizing Processed Peanut Shells史朗EzequielNo ratings yet

- Novel Hydrotreating Technology For Production of Green Diesel - Haldor TopsoeDocument21 pagesNovel Hydrotreating Technology For Production of Green Diesel - Haldor Topsoebalarie100% (2)

- Biodiesel From Algae ThesisDocument7 pagesBiodiesel From Algae Thesisbk4p4b1c67% (3)

- Profile ReportDocument20 pagesProfile ReportAmol_Gunda_5727No ratings yet

- Implementasi B35 Rev01Document21 pagesImplementasi B35 Rev01ppd brcgNo ratings yet