Professional Documents

Culture Documents

A36 WPS

A36 WPS

Uploaded by

JamesOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A36 WPS

A36 WPS

Uploaded by

JamesCopyright:

Available Formats

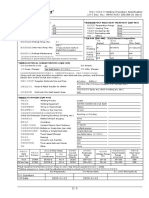

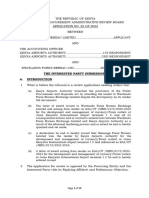

Welding procedure specification(WPS ) Yes [ ..

j]

Prequalified ..j Qualified by Testing __

or Procedure Qualification Records(PQR) Yes [ ]

.-tl.T £ ;A ~..

WPS no. AP WPJ. 004 V"","

ReViSion~.± :> Date 7-2-2009 By '§ R

Company Name HYSS Authorized ~/\'. Date 7-2-20(1

Welding Process( es) GMA W Type-Ma] \ Semi-Automatic[ .j]

Supporting PQR No.(s) prequalified Machine[ ] Automatic [ ]

Applicable standard AWS D 1.1

JOINT DESIGN USED POSITION

Type: Butt Position of Groove: IG Fillet: -

Single[ ] Double Weld[ .j] Vertical Progression: Up[] Down[]

Backing: Yes[ ] No[.j]

Backing Material: -

Root Opening 0~3mm Root Face Dimension 0~3mm

Groove Angle: 60° Radius O-U) - Transfer Mode (GMA W) Short-Circuiting[ ]

Back Gouging: Yes[.j] No[ ] Method Grinding globular[ .j] Spray[ ]

with grinder or carbon arc-air gouging Current: AC[ ] DCEP[ .j] DCEN[ ] Pulsed [ ]

BASE METALS Other

Material Spec. Tungsten Electrode(GTAW)

Type or Grade Size:

Thickness:Groove Type:

Diameter (Pipe)

TECHNIQUE

FILLER METALS Stringer or Weave Bead: Stringer

AWS Specification AS.I8 Multi-pass or Single Pass (per side) Multi-Pass

AWS Classification ER70S-3 Number of Electrodes 1

Maximum root pass thickness ~3/8H Electrode Spacing Longitudinal -

Maximum fill oass thickness ~1I4H

SHIELDING Lateral

Fl ux - Gas C02 mixed gas Angle

Composition 20%COz 80%Ar Contact Tube to Work Distance

Electrode-Flux (Class) ER70S-3 Flow Rate Peening

-

13~20Llmin Gas Cup Size 12# Interpass Cleaning:

PREHEAT POSTWELD HEAT PREATMENT

Preheat Temp.,Min O° C Temp. N.A.

Interpass Temp.,Min O° C Max 3S0° C Time -

WELDING PROCEDURE

Pass or Current Travel

Weld Process Amps or Wire Volts(V) Speed(m

Class Type&Polarity

m/min)

Layer(s) Feed Speed(A)

1 GMAW ER70S-3 <l>1. 2 DCEP 150-190 18-22 100-120

2 GMAW ER70S-3 <l>1. 2 DCEP 170-200 18-22 80-100

3 GMAW ER70S-3 <l>1. 2 DCEP 170-200 18-22 80-100

~

You might also like

- Bridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, OdishaDocument5 pagesBridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, Odishaniraj mouryaNo ratings yet

- WPS1Document10 pagesWPS1bhavin178No ratings yet

- Pwps Jo Wps Asme 016 Rev.001Document2 pagesPwps Jo Wps Asme 016 Rev.001Bagandi ManurungNo ratings yet

- Installation Guide FP2 9kW48V Fan OD 1.8m (B-351677.033-1-3) PDFDocument54 pagesInstallation Guide FP2 9kW48V Fan OD 1.8m (B-351677.033-1-3) PDFVasco Brandão100% (1)

- Port Management System: FeaturesDocument4 pagesPort Management System: FeaturesFarhan Khan NiaZiNo ratings yet

- DragonFace EnglishDocument26 pagesDragonFace EnglishAngel Diaz0% (1)

- Q345B WPSDocument1 pageQ345B WPSJamesNo ratings yet

- 03 WPS PQR For FCAWDocument3 pages03 WPS PQR For FCAWBrijesh Yadav100% (1)

- PhuBia-WPS-AWS D1.1-8-6-2011Document3 pagesPhuBia-WPS-AWS D1.1-8-6-2011poulmack100% (1)

- PhuBia-WPS-AWS D1.1-8-6-2011Document2 pagesPhuBia-WPS-AWS D1.1-8-6-2011poulmackNo ratings yet

- Afcons Infrastructure Limited: Procedure Qualification Record (PQR)Document21 pagesAfcons Infrastructure Limited: Procedure Qualification Record (PQR)GaapchuNo ratings yet

- WPS - 600 MW ChampaDocument7 pagesWPS - 600 MW ChampaAmjad PathanNo ratings yet

- Wps Emp 01-16 s275jr - s275jr BW P Smaw Awsd1 1Document2 pagesWps Emp 01-16 s275jr - s275jr BW P Smaw Awsd1 1Touil HoussemNo ratings yet

- Welding Procedure Specification SampleDocument2 pagesWelding Procedure Specification SampleBrown's P LikoNo ratings yet

- Wps (Gtaw & Smaw)Document3 pagesWps (Gtaw & Smaw)Ramadhan AdityaNo ratings yet

- Computer Engineering, Inc.: C PQR D1.1 - C - AWS 5.2.0 Form 2002 Rev. 0Document2 pagesComputer Engineering, Inc.: C PQR D1.1 - C - AWS 5.2.0 Form 2002 Rev. 0Erick GoyesNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document3 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (2)

- WPS Welding Performance SpecialistDocument2 pagesWPS Welding Performance SpecialistGobinath GovindarajNo ratings yet

- Welding Procedure Specification Sample - New EditionDocument2 pagesWelding Procedure Specification Sample - New EditiondanteNo ratings yet

- WPS-ASME-007-1 Rev0Document1 pageWPS-ASME-007-1 Rev0Ahmed LepdaNo ratings yet

- Welding Procedure Specification (WPS) Yes Prequalified X Qualified by Testing or Procedure Qualification Records (PQR) YesDocument2 pagesWelding Procedure Specification (WPS) Yes Prequalified X Qualified by Testing or Procedure Qualification Records (PQR) YessdgshhNo ratings yet

- QW 482 WPSDocument2 pagesQW 482 WPSsmit patelNo ratings yet

- Procedure Qualification SpecificationDocument4 pagesProcedure Qualification Specificationriyas.hvacworkNo ratings yet

- Piping WpsDocument37 pagesPiping WpsZulfokar FahdawiNo ratings yet

- WPS-ASME-009-1 Rev1Document1 pageWPS-ASME-009-1 Rev1Ahmed LepdaNo ratings yet

- PQR WPSDocument2 pagesPQR WPSMiguel Alejandro SierraNo ratings yet

- 4 - PREPARATION OF WPS - StudentDocument22 pages4 - PREPARATION OF WPS - Studentrazlan ghazaliNo ratings yet

- WPS SMAW - PL en V Con GaugingDocument1 pageWPS SMAW - PL en V Con GaugingLuis MirandaNo ratings yet

- 焊接工艺指导书 Welding Procedure Specification 文件号 Doc. No.: PWPS-A333 GR6-BW-01 Rev.0Document1 page焊接工艺指导书 Welding Procedure Specification 文件号 Doc. No.: PWPS-A333 GR6-BW-01 Rev.0ANIL PLAMOOTTILNo ratings yet

- P WPS Smaw Ceym 001 021Document1 pageP WPS Smaw Ceym 001 021juan carlos garavitoNo ratings yet

- PQR 03 2014Document2 pagesPQR 03 2014vinuNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document2 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed LepdaNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (1)

- 4 2WPSDocument2 pages4 2WPSsaravanans18910% (1)

- Arl-Al - WPS-001 PDFDocument2 pagesArl-Al - WPS-001 PDFrajuajiNo ratings yet

- Wps Aws d1.1 Ss400 To Ss400 Gmaw-RevDocument2 pagesWps Aws d1.1 Ss400 To Ss400 Gmaw-RevAnonymous zfC1zo9C100% (2)

- PQRDocument3 pagesPQRPradeep Lakum100% (1)

- QC E7018 CJP B-L1a OverheadDocument1 pageQC E7018 CJP B-L1a Overheadwmajordan13No ratings yet

- WPS 03 2014Document2 pagesWPS 03 2014vinuNo ratings yet

- Qw-482 Welding Procedure Specification (WPS)Document3 pagesQw-482 Welding Procedure Specification (WPS)Sagar GourNo ratings yet

- Metals Inspection Services, Inc.: QW - 482 Suggested Format For Welding Procedure Specification (WPS)Document6 pagesMetals Inspection Services, Inc.: QW - 482 Suggested Format For Welding Procedure Specification (WPS)Luis MuñozNo ratings yet

- Welding Procedure Specifications (WPS) : AWS D1.1Document2 pagesWelding Procedure Specifications (WPS) : AWS D1.1BS AhnNo ratings yet

- JOINTS (QW-402) : in Accordance With QW-200.1, Section IX, ASME BPVCDocument5 pagesJOINTS (QW-402) : in Accordance With QW-200.1, Section IX, ASME BPVCmkhalil1148No ratings yet

- 2G & 5GDocument2 pages2G & 5GRahul MoottolikandyNo ratings yet

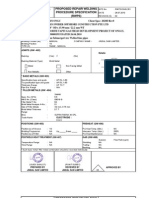

- Rev 2 - Proposed Repair WPSDocument2 pagesRev 2 - Proposed Repair WPSRakesh Patel75% (4)

- Main - Sample Welding Procedure Specification Wps FormDocument2 pagesMain - Sample Welding Procedure Specification Wps FormmuhammaddanishafandiNo ratings yet

- Welding Prosedur Specification Wps Pre QualifiedDocument8 pagesWelding Prosedur Specification Wps Pre QualifiedryanonedNo ratings yet

- WpsDocument3 pagesWpsPankaj KumarNo ratings yet

- Tungstenelectrodesize and Type' 2,4 MM As Per Sfa 5.12 Ewth - 2Document23 pagesTungstenelectrodesize and Type' 2,4 MM As Per Sfa 5.12 Ewth - 2Abdelkader AbdelkaderNo ratings yet

- Page No: 01: SA 240 GR 304 SA 240 GR 304Document5 pagesPage No: 01: SA 240 GR 304 SA 240 GR 304jobertNo ratings yet

- PQR DT Macro 60mm Smaw Astm A 516 Gr60Document4 pagesPQR DT Macro 60mm Smaw Astm A 516 Gr60Boran YelkenciogluNo ratings yet

- Preliminary Welding Procedure Specification (PWPS)Document2 pagesPreliminary Welding Procedure Specification (PWPS)Maneesh0% (1)

- DraftDocument32 pagesDraftAnilkumarNo ratings yet

- WPS Precalificado Aceros Moservin 2022Document2 pagesWPS Precalificado Aceros Moservin 2022Jonathan Espinoza MejiaNo ratings yet

- RK PWPS PC 001Document2 pagesRK PWPS PC 001SudeepDPoojaryNo ratings yet

- Welding Procedure SpecificationDocument27 pagesWelding Procedure SpecificationGopakumar K100% (3)

- Asme IxDocument1 pageAsme IxAxel Navarro AlbinesNo ratings yet

- Draf WPSDocument2 pagesDraf WPSMj EdinNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Settlement Deed A Case Study Study of LaDocument3 pagesSettlement Deed A Case Study Study of Lavaidehipragna pragnaNo ratings yet

- Lower Modi Khola Hydroelectric Project (20 MW) : Parbat District, Western Nepal Karthik 2073Document19 pagesLower Modi Khola Hydroelectric Project (20 MW) : Parbat District, Western Nepal Karthik 2073Sandeep LamsalNo ratings yet

- Elsie W. Rudisill and Coal, Feed and Lumber Company, Inc. v. Southern Railway Company, 548 F.2d 488, 4th Cir. (1977)Document2 pagesElsie W. Rudisill and Coal, Feed and Lumber Company, Inc. v. Southern Railway Company, 548 F.2d 488, 4th Cir. (1977)Scribd Government DocsNo ratings yet

- CARI-Checklist For Assessing Readiness For Implementation-BARWICKDocument5 pagesCARI-Checklist For Assessing Readiness For Implementation-BARWICKabbass.alseadyNo ratings yet

- 0 - 10 3 0 DBGFC 6 37 - I::.Batalog Pa&E Nqi 5 0 - Customer Part No. 11339772Document2 pages0 - 10 3 0 DBGFC 6 37 - I::.Batalog Pa&E Nqi 5 0 - Customer Part No. 11339772Miguel RojasNo ratings yet

- Public and Private AdministrationDocument42 pagesPublic and Private AdministrationUmair Iqbal Nagyal100% (6)

- A Software For Gravity Dam Stability AnalysisDocument9 pagesA Software For Gravity Dam Stability Analysislemi celemenNo ratings yet

- Customer Ledger Report 1693296028584Document2 pagesCustomer Ledger Report 1693296028584Al Faisal TVNo ratings yet

- Week 5 - TBM ExcavationDocument16 pagesWeek 5 - TBM ExcavationNilakshiManawaduNo ratings yet

- Flowchart, Tingkat Produksi Dan Lokasi Peleburan: Lampiran ADocument11 pagesFlowchart, Tingkat Produksi Dan Lokasi Peleburan: Lampiran Aanton wibowoNo ratings yet

- 06 08 DCF Quiz Questions Basic PDFDocument22 pages06 08 DCF Quiz Questions Basic PDFVarun AgarwalNo ratings yet

- HALL TICKET FOR SUMMER 2021 of 2000130177Document1 pageHALL TICKET FOR SUMMER 2021 of 2000130177Tejas ShivalkarNo ratings yet

- Algorithms For Data Science: CSOR W4246Document44 pagesAlgorithms For Data Science: CSOR W4246EarthaNo ratings yet

- E-502 - Field Processing and Surface Production Facilities: 10 Days Prod/FpspfDocument2 pagesE-502 - Field Processing and Surface Production Facilities: 10 Days Prod/FpspfMouradDjebriNo ratings yet

- Final Ward Secretariat DataDocument30 pagesFinal Ward Secretariat DataVS NaiduNo ratings yet

- Learner Activity Workbook CPC08 Construction, Plumbing and Services Training PackageDocument80 pagesLearner Activity Workbook CPC08 Construction, Plumbing and Services Training PackageKomal SharmaNo ratings yet

- Submissions WESTLANDS FOREX BUREAUDocument10 pagesSubmissions WESTLANDS FOREX BUREAUCHEMOIYWO PHILEMON KIPROPNo ratings yet

- Ka5Q-Series: KA5Q0765RT/KA5Q12656RT/KA5Q1265RF/ KA5Q1565RF Fairchild Power Switch (FPS)Document16 pagesKa5Q-Series: KA5Q0765RT/KA5Q12656RT/KA5Q1265RF/ KA5Q1565RF Fairchild Power Switch (FPS)EmanuelLanNo ratings yet

- Computer Simulation Techniques: The Definitive Introduction!Document176 pagesComputer Simulation Techniques: The Definitive Introduction!Emir HamidovicNo ratings yet

- Programme Club Inde 201113Document1 pageProgramme Club Inde 201113benteppeNo ratings yet

- 16 e Chapter 10Document29 pages16 e Chapter 10Yuki MiharuNo ratings yet

- Chapter 3Document18 pagesChapter 3shams221No ratings yet

- EdtpaDocument7 pagesEdtpaapi-310967404No ratings yet

- Building Serverless App PythonDocument266 pagesBuilding Serverless App PythonMatei Danut100% (3)

- Kathrikkadavu High Court of KeralaDocument6 pagesKathrikkadavu High Court of KeralaNikhil Viswam MenonNo ratings yet

- 1460-Article Text-95682-1-10-20220428Document18 pages1460-Article Text-95682-1-10-20220428AQILAH ADLA MazayaNo ratings yet

- Hotel Management System ProjectDocument16 pagesHotel Management System ProjectFarhan AhmedNo ratings yet