Professional Documents

Culture Documents

25 - 789703004927 - Aquaprime Peraside 15pct 25 Gal Pail - en Us

25 - 789703004927 - Aquaprime Peraside 15pct 25 Gal Pail - en Us

Uploaded by

amaeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

25 - 789703004927 - Aquaprime Peraside 15pct 25 Gal Pail - en Us

25 - 789703004927 - Aquaprime Peraside 15pct 25 Gal Pail - en Us

Uploaded by

amaeCopyright:

Available Formats

Disinfection of Poultry Premises, Trucks, Coops and Crates: For heavily soiled areas, a pre-cleaning step is required.

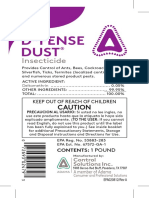

PRECAUTIONARY STATEMENTS

HAZARDS TO HUMANS AND DOMESTIC ANIMALS

Prepare a fresh solution for each use. Remove all poultry and feeds from premises, trucks, coops and crates. Remove all

litter and droppings from floors, walls and surfaces of facilities occupied or traversed by poultry. Empty all troughs, racks STORAGE AND DISPOSAL

and other feeding and watering appliances. Thoroughly clean all surfaces with a detergent and rinse with water. Saturate Storage: Never return this product to the original container after it has been removed. Avoid all contaminants, espe-

PERASIDE 15

DANGER CORROSIVE. Causes irreversible eye damage and skin burns. May be fatal if inhaled or absorbed through surfaces with a 0.16-0.61% v/v (1.0-3.9 fl. oz. per 5gal) solution of this product for a period of 10 minutes. This is equiv- cially dirt, caustic, reducing agents, and metals. Contamination and impurities will reduce shelf life and can induce

TM

skin. Harmful if swallowed. Do not breathe vapors or spray mist. Do not get in eyes, on skin, or on clothing. Wear alent to 266-1036 ppm PAA and 390-1520 ppm H2O2. Thoroughly scrub treated feed racks, troughs, automatic feeders, decomposition. In case of a decomposition, isolate container, spray container with cool water and dilute this product

goggles, face shield, rubber gloves and protective clothing with long sleeves when handling. Wash thoroughly with soap fountains and waters with a detergent and rinse with potable water before reuse. Ventilate buildings, coops and other with large volumes of water. Avoid damage to containers. Keep container closed at all times when not in use. Keep

and water after handling and before eating, drinking or using tobacco. Remove contaminated clothing and wash before closed spaces. Do not house poultry or employ equipment until treatment has been absorbed, set or dried. All treated container out of direct sunlight. To maintain product quality, store at temperatures below 86°F.

reuse. Do not enter an enclosed area without proper respiratory protection, or when uncoupling of product transfer equipment that will contact food, feed, or drinking water must be rinsed with potable water before reuse. See your tech- Procedure for Leak or Spill: Stop leak if this can be done without risk. Shut off ignition sources: no flames, smoking,

hoses. Wear a minimum of a NIOSH-approved elastomeric half mask respirator with organic vapor (OV) cartridges and flares, or spark producing tools. Keep combustible and organic materials away. Flush spilled material with large

AquaPrime PerasideTM 15 is a peroxyacetic acid-based microbiocide developed for

®

combination N1, R, or P filters; or a NIOSH-approved gas mask with OV canisters; or a NIOSH-approved powered air

nical representative for specific recommendations for all cleaning and rinsing requirements.

quantities of water. Undiluted material must not enter confined spaces.

Equipment Sanitizing, Disinfection, Aseptic Packaging and Bacteria, Fungi, Slime purifying respirator with OV cartridges and combination HE filters when handling concentrate product. Disinfection and Deodorizing of Animal Housing Facilities (Barns, Kennels, Hutches, Etc.): Remove animals and feed Pesticide Disposal: Pesticide wastes are acutely hazardous. Improper disposal of excess pesticide, spray mixture, or

and Odor Control in: Fruit and Vegetable Process Water Systems PHYSICAL OR CHEMICAL HAZARDS: from premises, vehicles, and enclosures. Remove litter, waste matter from floors, walls and surfaces of barns, pens, stalls, rinsate is a violation of Federal Law. If these wastes cannot be disposed by use according to label instructions, contact

STRONG OXIDIZING AGENT. CORROSIVE: Mix only with water below 140° F. Product must be diluted in accordance chutes, and other facilities and fixtures occupied or traversed by animals. Empty all troughs, racks and other feeding and your State Pesticide or Environmental Control Agency, or Hazardous Waste representative at the nearest EPA Regional

Active Ingredient: with label directions prior to use. This product is not combustible; however, at temperatures exceeding 156° F, decom- watering equipment. Thoroughly clean all surfaces with soap or detergent and rinse with water. Saturate surfaces by Office for guidance. If material has been spilled, an acceptable method of disposal is to dilute with at least 20 volumes

Peroxyacetic Acid.............................................................................................................15.0% position occurs releasing oxygen. The oxygen released could initiate combustion. applying a 0.16-0.61% v/v (1.0-3.9 fl. oz. per 5 gal) solution of this product with a mop, brush or spray. This is equivalent of water followed by discharge into suitable treatment system in accordance with all local, state and Federal environ-

ENVIRONMENTAL HAZARDS: to 266-1036 ppm PAA and 390-1520 ppm H2O2. Wet all surfaces and allow to remain wet for 10 minutes. Immerse all mental laws, rules, regulations, standards, and other requirements. Because acceptable methods of disposal may vary

Hydrogen Peroxide............................................................................................................22.0% by location, regulatory agencies must be contacted prior to disposal. This product which is to be discarded, must be

This pesticide is toxic to birds, fish and aquatic invertebrates. Caution must be used when applying indoors because halters, ropes, and other types of equipment used in handling and restraining animals, as well as forks, shovels and

Inert Ingredients: ..............................................................................................................63.0% pets may be at risk. Do not discharge effluent containing this product into lakes, streams, ponds, estuaries, oceans or disposed of as hazardous waste after contacting the appropriate local State or Federal agency to determine proper

Total: ............................................................................................................................100.0% scrapers used for removing litter and manure. Ventilate buildings and other closed spaces. Do not house livestock or

other waters unless in accordance with the requirements of the National Pollution Discharge System (NPDES) permit employ equipment until treatment has been absorbed, set, or dried. Thoroughly scrub all treated feed racks, mangers, procedures.

and the permitting authority has been notified in writing prior to discharge. Do not discharge effluent containing this troughs, automatic feeders, fountains and waterers with soap or detergent, and rinse with potable water before reuse. Container Disposal: Nonrefillable container. Do not reuse or refill this container. Clean container promptly after

EPA Registration No: 63838-2-66171 EPA Est. No. 63838-CA-01: 63838-AR-001 product into sewer systems without previously notifying the local sewage plant authority. emptying. Offer for recycling, if available. Triple rinse as follows: Empty the remaining contents into application

Commercial Agricultural or Industrial Water System Injection for the Oxidation of Odors When They Form: In well equipment or a mix tank. Fill the container ¼ full with water. Replace and tighten closures. Tip container on its side

Before Using This Product, Please Read This Entire Label Carefully. DIRECTIONS FOR USE systems, inject this product with a peristaltic pump through a ¼ inch plastic tube (or other comparable injection system) and roll it back and forth, ensuring at least one complete revolution, for 30 seconds. Stand the container on its end

It is a violation of Federal law to use this product in a manner inconsistent with its labeling. and tip it back and forth several times. Empty the rinsate into application equipment or a mix tank or store rinsate for

KEEP OUT OF REACH OF CHILDREN inserted into the well all the way to the well intake screens. Test the most distant faucet a hydrogen peroxide test strip until

a residual of 20-25 ppm hydrogen peroxide is detected indicating that the system has been thoroughly treated. Adjust he later use or disposal. Repeat this procedure two more times.

DANGER-PELIGRO

Note: All volumes given in ounces are fluid ounces. injection pump to deliver 25 ppm on a consistent basis to the water system. When treating the watering system for sick Container Handling: (Containers equal to or less than 5 gallons): Nonrefillable container. Do not reuse or refill this

animals, test the most distant faucet with a hydrogen peroxide test strip until a residual of 100-1,000 ppm hydrogen container. Triple rinse container (or equivalent) promptly after emptying. Triple rinse as follows: Empty the remaining

Certified to SANITIZATION peroxide is detected indicating that the system has been thoroughly treated. When this level is reached immediately reduce contents into application equipment or a mix tank and drain for 10 seconds after the flow begins to drip. Fill the

NSF/ANSI 60 Si usted no entiende la etiqueta, busque a alguien para que se la explique a usted en detalle. the injection until the test strip indicates the 25 ppm hydrogen peroxide is reached and the system is maintained at the 25 container ¼ full with water and recap. Shake for 10 seconds. Pour rinsate into application equipment or a mix tank

This peroxyacetic acid sanitizer is recommended for use on pre-cleaned surfaces such as equipment, pipelines, tanks, vats, ppm level. This process can be repeated monthly to ensure a clean water system and avoid screen clogging. or store rinsate for later use or disposal. Drain for 10 seconds after the flow begins to drip. Repeat the procedure two

(If you do not understand this label, find someone to explain it to you in detail.) more times. Then offer for recycling if available or puncture and dispose of in a sanitary landfill, or by incineration. Do

filters, evaporators, pasteurizers, and aseptic equipment in dairies, breweries, wineries, beverage and food processing/packing

plants, and egg processing/packing equipment surfaces. This product is effective as a sanitizer when solution is prepared in Cleaning Poultry and Livestock Drinking Water Lines: not burn, unless allowed by state and local ordinances.

water of up to 400 ppm hardness as CaCO3. This product has demonstrated greater than 99.999% reduction of For drinking water lines using holding tanks make a stock solution by one of the following methods:

FIRST AID Staphylococcus aureus and Escherichia coli in the AOAC Germicidal and Detergent Sanitizing Action of Disinfectants study. • Drinking water lines 500 feet in length or less: mix 0.78 gallons (100 fl. oz.) of this product with 100 gallons of water. 24 hr Emergency ChemTel Number: 1-800-424-9300

• Drinking water lines exceeding 500 feet in length: mix 1.55 gallons (200 fl. oz.) of this product with 200 gallons of water.

If in Eyes: • Hold eye open and rinse slowly and gently with water for 15-20 minutes. Sanitizing Food Contact Surfaces: Sanitize with a concentration of 0.7-3.8 fl. oz. of this product diluted in 10 gallons of Pump the stock solution, completely filling the drinking water lines.

• Remove contact lenses, if present, after the first 5 minutes, then continue rinsing eye. water (93-500 ppm active peroxyacetic acid and 136-733 ppm active hydrogen peroxide). Use immersion, spray or circulation If the drinking water lines are not supplied by water from holding tanks, prepare a stock solution by one of the following methods: DOT: UN 3109, Organic Peroxide Type F, Liquid (<=25% Peracetic Acid with <=26%

• Call a poison control center or doctor for treatment advice. techniques as appropriate to the equipment. All surfaces must be exposed to sanitizing solution for a period of at least 60 • Mix 0.38 gallons (49 fl. oz.) of this product with 49 gallons of water in a 50 gallon tank, pumping this solution into

seconds or more if specified by a governing code. Drain thoroughly and allow to air dry. Do not rinse. the water line, repeating the process as often as needed, until water line is filled. Hydrogen Peroxide) 5.2 (8)

If on Skin or • Take off contaminated clothing. • Fill the water line, using a proportioner, set to inject this product undiluted at a rate of 1:11 (0.9%).

Clothing: • Rinse skin immediately with plenty of water for 15-20 minutes. Sanitization of Conveyors and Equipment for Meat, Poultry, Seafood, Dairy, Fruit, Nuts and Vegetables: This product

is effective against the gram positive organism Staphylococcus aureus and gram negative organism Escherichia coli. For Lot #________________________

• Call a poison control center or doctor for treatment advice. After the waterline is filled with the stock solution, activate nipple drinkers to ensure contact with drinkers.

use in the static or continuous sanitizing, washing or rinsing of conveyors, slicers, saws, and equipment, apply a solution Allow the stock solution to remain in the water lines for 24–48 hours.

If Inhaled: • Move person to fresh air. of this product using a recommended 0.7-3.8 fl oz. per 10 gallons of water (93-500 ppm active peroxyacetic acid and Flush lines with fresh water until water is visibly clear.

• If person is not breathing, call 911 or an ambulance, then give artificial respiration, preferably by 136-733 ppm active hydrogen peroxide). Apply sanitizer solution to the return portion of the conveyor or equipment using Always make a fresh stock solution before use.

mouth-to-mouth, if possible. spray or similar means of wetting surfaces, so as to prevent puddling. Allow sanitizer to thoroughly wet surface for a

• Call a poison control center or doctor for treatment advice. minimum 60 seconds contact time. No rinse is needed. TREATMENT OF FRUIT AND VEGETABLE PROCESS WATER SYSTEMS

If Swallowed: • Call a poison control center or doctor immediately for treatment advice. Final Bottle or Container Rinse: This product may be used as a final sanitizer rinse for pre-cleaned returnable and This product can be used in water or ice that contacts raw or fresh, post-harvest or further processed fruits and vegetables

• Have person sip a glass of water if able to swallow. non-returnable bottles or containers at 93-500 ppm active peroxyacetic acid and 136-733 ppm active hydrogen peroxide for the control of spoilage and decay causing bacteria and fungi in commercial operations and packinghouses.

(0.7-3.8 fl. oz. of this product diluted in 10 gallons of water). The container must be drained as much as is practical prior

• Do not induce vomiting unless told to do so by a poison control center or doctor. to filling operations.

• Do not give anything by mouth to an unconscious person. Batch, Continuous or Spray System Processes: Fill vessel containing fruits and vegetables with known amount of water.

Ensure that water is circulating in vessel if using the submersion method. Add this product to no more than 500 ppm

QUESTIONS? 1-209-581-9576 POULTRY, SWINE, LIVESTOCK WATERING OPERATING SYSTEMS residual peroxyacetic acid to the use solution in accordance with Food Contact Notification #1738, effective March 28,

Have the product container or label with you when calling a poison control center or doctor, or going for treatment. 2017. This can be accomplished by initially adding 3.8 fl. oz. per 10 gallons of water. The recommended concentration is

After watering lines have been cleaned, use this product at 0.3-42 fl. oz. per 100 gallons of water (4-559 ppm as peroxy- between 30-300 ppm as peroxyacetic acid (0.23-2.3 fl. oz. per 10 gallons of water). The final concentration necessary to

NOTE TO PHYSICIAN acetic acid) to control algae and bacteria in drinking water and to control mineral build up in watering lines. Stop the use accomplish the intended task will vary from plant-to-plant. The fruits and vegetables can be continuously sprayed or

Probable mucosal damage may contraindicate the use of gastric lavage. of this product twenty-four (24) hours prior to vaccination via the water line. submerged (dipped) in the resulting solution. Periodic or continuous additions of this product to maintain the required Item No. 480020/2.5

concentration may be added as necessary. It is also recommended to apply this product during the washing, chilling, or

ANIMAL PREMISES physical cleaning processes, including the roller-spreader, washer or brush washer manifold, dip tank, or sorting process-

es. Contact time of 60 seconds is recommended to insure efficacy. A potable water rinse is not required.

This product is designed for use in animal hospitals, animal laboratories, kennels, pet shops, zoos, pet animal quarters, Manufactured for: Preserve International®

poultry premises, poultry hatcheries, and livestock quarters. When used as directed, this product is specifically designed Fogging: (Not for Use in California): For raw agricultural commodities, commercially-applied fogging methods may be used 944 Nandino Blvd., Lexington, KY 40511 U.S.A.

to disinfect, deodorize and clean inanimate, hard, surfaces such as walls, floors, sink tops, furniture, operating tables, provided the dilution rates of the resultant solution does not exceed those prescribed in this section (3.8 fl. oz. per 10 gal. L6541-1020

kennel runs, cages and feeding equipment. In addition, this product will deodorize those areas which are generally difficult of water). A potable water rinse is not required. Conventional corrosion-resistant fogging devices are recommended. Vacate

to keep smelling fresh, such as garbage storage areas, empty garbage bins and cans, and any other areas which are prone the area of all personnel prior to, during and after fogging until the total peroxide concentration is below 1.0 ppm, or there Preserve International® is a wholly-owned

Net Contents: 2.5 gal (9.46 L) to odors caused by microorganisms. is no strong odor present, characteristic of acetic acid. subsidiary of Neogen® Corporation

7 89703 00492 7

You might also like

- Fire Watch Training PDFDocument41 pagesFire Watch Training PDFHamdi Rafiek83% (24)

- FSSC Check List PRPDocument26 pagesFSSC Check List PRPAneel100% (3)

- 0400E-CHB - Sulfuric AcidDocument1 page0400E-CHB - Sulfuric AcidVeralord De VeraNo ratings yet

- Candlesticks Pattern WysetradeDocument2 pagesCandlesticks Pattern Wysetradeamae0% (1)

- Fire Safety Inspection ChecklistDocument8 pagesFire Safety Inspection ChecklistNikka LopezNo ratings yet

- Zaclon Galvanizing HandbookDocument127 pagesZaclon Galvanizing HandbookMohammed Abdallah100% (2)

- UP Star Gold 7.9 Bifenthrin1Document19 pagesUP Star Gold 7.9 Bifenthrin1Alejandro Zapata VicenteNo ratings yet

- Soft Bait: Kills Rats & Mice DeadDocument1 pageSoft Bait: Kills Rats & Mice DeadPatrick AskinNo ratings yet

- ECR Calcium Hypochlorite Granules Label1Document4 pagesECR Calcium Hypochlorite Granules Label1নিস্তব্ধতার প্রহরেNo ratings yet

- LD EMI000Document24 pagesLD EMI000John DoeNo ratings yet

- Tenopa SC LabelDocument4 pagesTenopa SC LabelSavvas DimitriadisNo ratings yet

- AlpinewsglabelDocument2 pagesAlpinewsglabelLeonasiaNo ratings yet

- AU Rentokil Maxxthor 100 LABEL en SDS 01 LabelDocument1 pageAU Rentokil Maxxthor 100 LABEL en SDS 01 LabelAfiq KolibaNo ratings yet

- Hyperox LabelDocument3 pagesHyperox LabelcanadianmoosethegreatNo ratings yet

- Nywilaz - May23 REVISED 2Document1 pageNywilaz - May23 REVISED 2kennysbomaNo ratings yet

- Vespex Label PDFDocument1 pageVespex Label PDFDeborahNo ratings yet

- Instructions For Use Efelab Sterilizing Gas Ampoules: Quality Sterilization SuppliesDocument2 pagesInstructions For Use Efelab Sterilizing Gas Ampoules: Quality Sterilization SuppliestensgNo ratings yet

- 19 25 53 23 02 2017 Provisia - NVA - 2017 04 522 0004Document12 pages19 25 53 23 02 2017 Provisia - NVA - 2017 04 522 0004jcffjmitfdvhyt643dNo ratings yet

- Drexel1h PAS-800 LabelDocument2 pagesDrexel1h PAS-800 Labelmocano26No ratings yet

- Maquat MQ624M: DangerDocument4 pagesMaquat MQ624M: Dangergerardo sifuentesNo ratings yet

- Cb-80 Extra MsdsDocument1 pageCb-80 Extra MsdsBatanNo ratings yet

- RHDV Cleaning GuidanceDocument4 pagesRHDV Cleaning GuidanceWDIV/ClickOnDetroitNo ratings yet

- Assignment2 SafetyDocument12 pagesAssignment2 SafetyNur SazlinNo ratings yet

- Essentria G Granule Insecticide Specimen LabelDocument2 pagesEssentria G Granule Insecticide Specimen LabelRobert ZacksNo ratings yet

- Herbicide: Only Use Herbicide With CONVISO SMART SeedsDocument8 pagesHerbicide: Only Use Herbicide With CONVISO SMART SeedsDonny CosminNo ratings yet

- Acticide MBSDocument4 pagesActicide MBSNRunixNo ratings yet

- Herbicide: Only Use Herbicide With CONVISO SMART SeedsDocument8 pagesHerbicide: Only Use Herbicide With CONVISO SMART SeedsDonny CosminNo ratings yet

- Bi Flex LabelDocument15 pagesBi Flex LabelMichael Salvador SaycoNo ratings yet

- Technical DataDocument4 pagesTechnical Datakevinmendez2009No ratings yet

- PRESEPTDocument6 pagesPRESEPTRiaadjsNo ratings yet

- Product Transparent Bird Gel TBG Product LabelDocument1 pageProduct Transparent Bird Gel TBG Product LabelNatallyNo ratings yet

- Cleaning and Disinfection:: VehiclesDocument2 pagesCleaning and Disinfection:: VehiclesEugene Mark DollolasaNo ratings yet

- A913 Line Dulux Pearl Glo Wall Finish PDFDocument2 pagesA913 Line Dulux Pearl Glo Wall Finish PDFdaredevils0286No ratings yet

- Galant Max ArgentinaDocument8 pagesGalant Max ArgentinaMigue SntNo ratings yet

- Summary Safety Data Sheet: Tretolite Dmo 86319Document2 pagesSummary Safety Data Sheet: Tretolite Dmo 86319Achraf Ben DhifallahNo ratings yet

- Anti Rodent Design PDFDocument9 pagesAnti Rodent Design PDFYudhi AdiNo ratings yet

- SteraminDocument1 pageSteraminnodi79No ratings yet

- WHO - Core Requirments - HafsahDocument53 pagesWHO - Core Requirments - Hafsahgul316991No ratings yet

- Great Stuff Consumer Safety Information: Warnings and PrecautionsDocument2 pagesGreat Stuff Consumer Safety Information: Warnings and PrecautionsjoeyNo ratings yet

- Permaclean Pc-11: DangerDocument3 pagesPermaclean Pc-11: DangerCarlyn Joyce Reyes BolorNo ratings yet

- EverGreen Pro 60-6 Specimen LabelDocument6 pagesEverGreen Pro 60-6 Specimen LabelKaustav MukherjeeNo ratings yet

- P Msds Img 28 MSDS HexaconazoleECDocument8 pagesP Msds Img 28 MSDS HexaconazoleECjpinternational81No ratings yet

- D-Fense Dust Label1Document15 pagesD-Fense Dust Label1Delhi VillanoNo ratings yet

- Ster BacDocument2 pagesSter Bacimranshaik3000No ratings yet

- P - Msds - Img - 47 - MSDS - Sulphur 80WDGDocument7 pagesP - Msds - Img - 47 - MSDS - Sulphur 80WDGjpinternational81No ratings yet

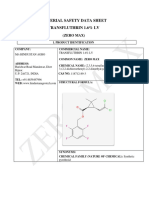

- Transfluthrin MSDS Zero MaxDocument8 pagesTransfluthrin MSDS Zero Maxsfda.badrmedicalNo ratings yet

- Responsar ES BayerDocument2 pagesResponsar ES Bayervb_scribd1234No ratings yet

- Dimethomorph Target Crop and PasteDocument21 pagesDimethomorph Target Crop and Pastesakib imran khanNo ratings yet

- AU - DW02829 Intergrain Universal Timber Oil: DescriptionDocument4 pagesAU - DW02829 Intergrain Universal Timber Oil: DescriptioninezNo ratings yet

- A921 Line Pentalite RetailDocument2 pagesA921 Line Pentalite RetailmandahandriNo ratings yet

- Caution: An Aqueous Suspension Biological Insecticide For Control of The Codling MothDocument3 pagesCaution: An Aqueous Suspension Biological Insecticide For Control of The Codling MothHrafnaet SorgenNo ratings yet

- Safety Measures in Pharmaaceutical IndustryDocument1 pageSafety Measures in Pharmaaceutical IndustryAnoosha FarooquiNo ratings yet

- Bio Security Guidelines Final 030113Document5 pagesBio Security Guidelines Final 030113freak009No ratings yet

- BASF Poast 17516 LabelDocument25 pagesBASF Poast 17516 Labelzvonko.jacimovskiNo ratings yet

- Safety Data Sheet ARDROX 6367: 1 Identification of The Substance/Preparation and The CompanyDocument8 pagesSafety Data Sheet ARDROX 6367: 1 Identification of The Substance/Preparation and The CompanyEDBNo ratings yet

- F202Document5 pagesF202mdlc6878No ratings yet

- Alpet D2 Tech Sheet 2017Document2 pagesAlpet D2 Tech Sheet 2017Jaime MunozNo ratings yet

- X Link AcrDocument5 pagesX Link Acrsajad gohariNo ratings yet

- Sds-Evamarine ExteriorDocument6 pagesSds-Evamarine ExteriorSaifuddin FahmiNo ratings yet

- LABEL Bifenthrin Termiticide Insecticide 1 LitreDocument14 pagesLABEL Bifenthrin Termiticide Insecticide 1 Litrelex_reynolds1No ratings yet

- Danger - Peligro: Acticide L30Document7 pagesDanger - Peligro: Acticide L30Julián Herrera RestrepoNo ratings yet

- Petronas Diesel Euro 2m Label2Document1 pagePetronas Diesel Euro 2m Label2mohdchemustafhaNo ratings yet

- Summary Safety Data Sheet: 1. Substance NameDocument2 pagesSummary Safety Data Sheet: 1. Substance NameAchraf Ben DhifallahNo ratings yet

- Mould Remediation ChartDocument1 pageMould Remediation ChartVarious TingsNo ratings yet

- After a Disaster: Information to Help You and Your Family RecoverFrom EverandAfter a Disaster: Information to Help You and Your Family RecoverNo ratings yet

- WO2020077263A1Document78 pagesWO2020077263A1amaeNo ratings yet

- SFDA TimelinesDocument1 pageSFDA TimelinesamaeNo ratings yet

- SAFRAX Technical BulletinDocument36 pagesSAFRAX Technical BulletinamaeNo ratings yet

- MSDS DutrionDocument7 pagesMSDS DutrionamaeNo ratings yet

- R.V.-124 Usage-CLDocument8 pagesR.V.-124 Usage-CLamaeNo ratings yet

- Candlesticks Pattern Wysetrade PDF FreeDocument2 pagesCandlesticks Pattern Wysetrade PDF Freeamae100% (1)

- NSTP CWTS 12 Mid Term ExamDocument3 pagesNSTP CWTS 12 Mid Term ExamShaira Staana100% (1)

- Formulation and Effectiveness of A Hand Sanitizer PDFDocument5 pagesFormulation and Effectiveness of A Hand Sanitizer PDFrizkaNo ratings yet

- KISS Notes Life On EarthDocument24 pagesKISS Notes Life On EarthJenniferBackhus100% (2)

- Blood, Sweat, and Buffers: PH Regulation During Exercise: Key ConceptsDocument10 pagesBlood, Sweat, and Buffers: PH Regulation During Exercise: Key ConceptsKrysny MontebonNo ratings yet

- Thermocouple Color CodesDocument8 pagesThermocouple Color CodesMohsin ShaukatNo ratings yet

- CanteenDocument28 pagesCanteenajay_430No ratings yet

- Experiment 3Document5 pagesExperiment 3thinaNo ratings yet

- NRAC Publication No. 170 An Introduction To Water Chemistry in Freshwater AquacultureDocument4 pagesNRAC Publication No. 170 An Introduction To Water Chemistry in Freshwater AquacultureSk RajNo ratings yet

- Creating High Quality Stick WeldsDocument2 pagesCreating High Quality Stick WeldsMaria MantillaNo ratings yet

- Bowel Prep Before ColonosDocument14 pagesBowel Prep Before ColonosDan BobeicaNo ratings yet

- Mineral Trioxide AggregatDocument5 pagesMineral Trioxide AggregatRicho AlristaNo ratings yet

- Epitaxy:: Growth of Thin Film With The Same Atomic Oreder As The Underlying SubstrateDocument47 pagesEpitaxy:: Growth of Thin Film With The Same Atomic Oreder As The Underlying SubstrateeniNo ratings yet

- Flow Control Devices Standing Valves / Test Tools: Europe Learning Centre WCP Training SchlumbergerDocument12 pagesFlow Control Devices Standing Valves / Test Tools: Europe Learning Centre WCP Training SchlumbergerAli Ali100% (1)

- 2061 e Vthlip103 en Voith Internal Gear Pumps IpvaDocument12 pages2061 e Vthlip103 en Voith Internal Gear Pumps IpvaAnonymous ARcPWq7L38No ratings yet

- Book 3 - Chemical Equations Balancing Work Sheet ChemistryDocument16 pagesBook 3 - Chemical Equations Balancing Work Sheet ChemistryAzain Cardenas100% (1)

- Flange PDFDocument13 pagesFlange PDFEsteban Calderón Navarro100% (1)

- As 2902-2005 Medical Gas Systems - Low Pressure Flexible Hose AssembliesDocument8 pagesAs 2902-2005 Medical Gas Systems - Low Pressure Flexible Hose AssembliesSAI Global - APACNo ratings yet

- Preparing and Cleaning FossilsDocument8 pagesPreparing and Cleaning FossilsDebabrata MahantaNo ratings yet

- Sulfonation Mechanism of Benzene With SO3 in Sulfuric Acid or Oleum PDFDocument37 pagesSulfonation Mechanism of Benzene With SO3 in Sulfuric Acid or Oleum PDFLaely Dian MarlindawatiNo ratings yet

- Extraction of Lycopene From Tomato With Environmentally Benign Solvents: Box-Behnken Design and OptimizationDocument11 pagesExtraction of Lycopene From Tomato With Environmentally Benign Solvents: Box-Behnken Design and OptimizationDevita AmeliaNo ratings yet

- Genetics, Chapter 3, DNA Replication Lectures (Slides)Document115 pagesGenetics, Chapter 3, DNA Replication Lectures (Slides)Ali Al-QudsiNo ratings yet

- TM 1-1500-204-23-2, Change 4Document259 pagesTM 1-1500-204-23-2, Change 4"Rufus"No ratings yet

- TeriparatideDocument14 pagesTeriparatidecozcozNo ratings yet

- Flyer Gas Analyser (En)Document2 pagesFlyer Gas Analyser (En)Ignacio Rodriguez CarrascosaNo ratings yet

- Zanussi ZDT - 6244 Dishwasher ManualDocument25 pagesZanussi ZDT - 6244 Dishwasher ManualPete MillsNo ratings yet

- Urgent Punch ListDocument42 pagesUrgent Punch ListsugiantobarusNo ratings yet