Professional Documents

Culture Documents

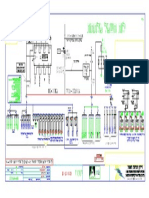

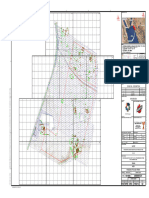

A3-106304-02005-01-A General Arrangement S310

A3-106304-02005-01-A General Arrangement S310

Uploaded by

Chandra KanthOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A3-106304-02005-01-A General Arrangement S310

A3-106304-02005-01-A General Arrangement S310

Uploaded by

Chandra KanthCopyright:

Available Formats

8 7 6 5 4 3 2 1

N-10

N1-2A N1-2B

N-3 N-8 N6-A

N7-A N7-B N-2 N1-3

F F

6000´

N1-1 M-1A N6-B

° N-5

53

.

52

CLIPS SUPPORTS

~9000 MAXIMUM LEVEL

OF PRODUCT

10200

6084

1200

E ECUATOR ECUATOR E

4400

00

~23800

00

23477

R=2

METE

16084

A

I

NNERD

I INNER LADDER

4400

STILLING

13380

WELLS

4400

47.1

NAME PLATE

EARTHING LUG

TOG 530.55m VORTEX

3383

1600

3383

FIREPROOFING

1500

2880

SUPPORTS BREAKER

TOC 530.50m N9-A N9-B

D D

N-4

GL 530.0m

(GROUTING)

500

GL 530.0m

50

130

COLUMN CIRCLE = 19550

FOUNDATIONS TIE RODS

ELEVATION

SCHEMATIC VIEW NOTES:

1.- THIS IS AN SCHEMATIC DRAWING AND IT IS NOT INTENDED TO SHOWN ANY ORIENTATION.

FOR ASSEMBLY PARTS AND ORIENTATION, REFER THE DRAWINGS LIST C-106304-02001

2.- ALL PLATES WITH WELDED NOZZLES AT SHOP, SHALL BE SUBMITTED TO THE POST WELD HEAT TREATMENT IN SHOP.

PLANT GRAPHIC TEMP. / TIME FOR PWHT

4.- INSPECTION L.R. INSURANCE INC.

PLANT NORTH

TRUE 5.- TEST WATER TEMPERATURE 25° C MIN.

NORTH TEMP.

NORTH 6.- ALL DIMENSIONS ARE IN mm. UNLESS NOTED OTHERWISE.

270° (°C) 7.- DIMENSIONAL TOLERANCES PER A3-106304-02023-01.

3° 1

.77

6

27

. ° 625° 8.- FOR SPHERE LAYOUT , SEE DRAWING R3-77598

3 36° SOAK TIME

6

1.

610° 9.- ALL ELEMENTS WELDED TO THE VESSEL, SHALL BE SA-516 Gr.70 (N) + S5

AXIS CENTRAL PLATES

° 18 .

° 81°

8 595° 10.- GL = GROUND LEVEL

.

MA

36 ° 8

h

6. 1

.8 TOC = TOP OF CONCRETE

56 C/

8

X.

1

MI

/h

8° TOG = TOP OF GROUTING

0°

N.

1

8.

°C

15

MI .12

11.- FLEXIBLE GRAPHITE WITH SS316L INNER AND C.S. OUTER RING.

55

3°

18°

PREVAILING 8.

°C

C/

C C

6°

N.

X

12.- HOP DIP GALVANIZED

MA

/h

.3

h

WIND 13.- TO BE DONE AFTER FINAL HYDROSTATIC TEST.

16

430° 14.- AND INTERNAL COMPONENTS WELDED TO THE VESSEL IN EACH FACE.

TE NG

15.- INTERNAL SURFACE OF VESSEL (FROM BOTTOM TO 1m HEIGHT) SHALL BE COATED WITH PHENOLIC EPOXY COATING

CO

AT

AT

WITH DFT NOT LESS THAN 300 MICRONS.

OL

HE

16.- MIN. 2 EARTHING BOSSES SHALL BE PROVIDED ON SUPPORTS DIAMETRICALLY OPPOSITE TO EACH OTHER.

AM

I

NG

RA

EE

B.

FR

FR

TE

EE

EXTERNAL LADDER

MP

.

A 24.11.2023 ISSUED FOR REVIEW DE PM EM

1h. 53 min. TIME

454

REV DATE ISSUE, SCOPE OF REVISION PREPARED CHECKED APPROVED

PROJECT TITLE:

200

DESIGN, SUPPLY AND CONSTRUCTION OF NEW LPG STORAGE B

1

80°

30

1

FACILITIES IN FIVE SPHERICAL VESSELS AT

00

0

°

ZARKA REFINERY SITE PROJECT

N 3557925.68

15

4400

COMPANY:

00

E 228033.13

B

JORDAN LIQUEFIED PETROLEUM GAS MANUFACTURING

& FILLING COMPANY

90

200

21

1

EPC CONTRACTOR:

1

MID CONTRACTING

TETCO GROUP

4400

CONSULTANT:

NAME PLATE

990

ILF CONSULTING ENGINEERS

9

0° 11 SUPPORT COLUMNS

A

1

150 4400 1

2002

SUBCONTRACTOR:

000

DURO FELGUERA ENERGY STORAGE

8

867

Energy Storage

A

1

072

8 DRAWING TITLE :

GENERAL ARRANGEMENT

ORIGINAL SHEET SIZE - A3

(S-310)

PLANT VIEW(S-310)

PROJECT No. - 15488

"Copying ofthis documentand giving itto others and the use

FI-825 8252 S-310 or communication of the contents thereof are forbidden SCALE: DRAWING NO: SHEET OF REV.

withoutexpress authority.Offenders are liable to the payment

ofdamages.Allrights are reserved in the eventofthe grantof

JOB Nº SERIAL Nº EQUIPMENT a patent or the registration of a utility model of design"

S/E A3-106304-02005-01 1 1 A

8 7 6 5 4 3 Printing:06.11.2023 1

You might also like

- Lk-Op416001a PsuDocument1 pageLk-Op416001a Psuahmadba70No ratings yet

- Rumble 200 V3 Schematics-DiagramsDocument4 pagesRumble 200 V3 Schematics-DiagramsOrlandd Sanchezz100% (1)

- Cucumber Tutorial PDFDocument78 pagesCucumber Tutorial PDFNagaNo ratings yet

- Twelve Angry MenDocument2 pagesTwelve Angry MenAthul George33% (3)

- Fender Rumble 100 V3 TDA8950-88534Document7 pagesFender Rumble 100 V3 TDA8950-88534Claudio Ariel Vera trussy100% (1)

- DC Machine 2Document20 pagesDC Machine 2Fadhil A. HasanNo ratings yet

- Blood Report TateDocument4 pagesBlood Report TateGina Watkins100% (2)

- Yamaha Alba PDFDocument11 pagesYamaha Alba PDFJawale Chetan100% (2)

- A3-106304-02013-01-A General Arrangement S312Document1 pageA3-106304-02013-01-A General Arrangement S312Chandra KanthNo ratings yet

- A3-106304-02017-01-A General Arrangement S313Document1 pageA3-106304-02017-01-A General Arrangement S313Chandra KanthNo ratings yet

- A3-106304-02001-01-A General Arrangement S309Document1 pageA3-106304-02001-01-A General Arrangement S309Chandra KanthNo ratings yet

- A3-106304-02009-01-A General Arrangement S311Document1 pageA3-106304-02009-01-A General Arrangement S311Chandra KanthNo ratings yet

- MBAA Placa Canal Pw18.0 MBAA-251433Document1 pageMBAA Placa Canal Pw18.0 MBAA-251433Sergio SilvaNo ratings yet

- 5e3 Like ApproachDocument1 page5e3 Like Approachdisse_detiNo ratings yet

- 2047 1803 Ecv Dla 1001 - CDocument1 page2047 1803 Ecv Dla 1001 - CphanikrishnabNo ratings yet

- Haier 21f9d-tDocument1 pageHaier 21f9d-tadithyanvsNo ratings yet

- Esq Nobreak Sen T08075-00 Manager III 1000 RS232 PDFDocument1 pageEsq Nobreak Sen T08075-00 Manager III 1000 RS232 PDFrenanNo ratings yet

- תוכנית לוח חשמל מלתחות PDFDocument1 pageתוכנית לוח חשמל מלתחות PDFdoriaNo ratings yet

- ZXSpectrum Multi IODocument1 pageZXSpectrum Multi IOMihaiNo ratings yet

- Scamec 2000 S 100129425 #FB214 Grease SystemDocument23 pagesScamec 2000 S 100129425 #FB214 Grease SystemIvan Andres Seguel BristiloNo ratings yet

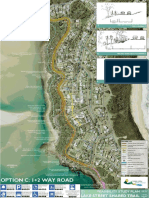

- Option C: 1+2 Way Road: Lake Street Shared TrailDocument1 pageOption C: 1+2 Way Road: Lake Street Shared TrailNeenNo ratings yet

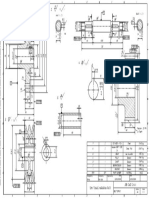

- BELT DRIVE 25 Jan 2024Document1 pageBELT DRIVE 25 Jan 2024bimaditya281No ratings yet

- POSICIONAMIENTODocument1 pagePOSICIONAMIENTODEYBER LUISEDUARDO ROSAS ALCALDENo ratings yet

- FL3B-434-M-2070-0.0 (434T007) EOP Filtrate TankDocument1 pageFL3B-434-M-2070-0.0 (434T007) EOP Filtrate TanknyaptoNo ratings yet

- 4020-188-S-010 - PipeRack Structure Plan Sheet 1 of 2-Rev5 (Signed) 2Document1 page4020-188-S-010 - PipeRack Structure Plan Sheet 1 of 2-Rev5 (Signed) 2thoriq ikhwanNo ratings yet

- Chasis AssemblyDocument1 pageChasis Assemblyravi cdacNo ratings yet

- Chasis CY8873CDocument4 pagesChasis CY8873Cpolancos05No ratings yet

- Veri. 0: CO T Ic DiDocument4 pagesVeri. 0: CO T Ic Dicfrias_13No ratings yet

- Chasis TMPA8873CSCNG6V11 PDFDocument4 pagesChasis TMPA8873CSCNG6V11 PDFMax Fredi Quispe AguilarNo ratings yet

- 5wiring DiagramDocument12 pages5wiring DiagramBurgart JassahelNo ratings yet

- Sonata in B Minor K27 L449 by Domenico ScarlattiDocument5 pagesSonata in B Minor K27 L449 by Domenico ScarlattiAxel MaturanoNo ratings yet

- Ground Floor Plan: Scale 1:100Document2 pagesGround Floor Plan: Scale 1:100CSEC Uganda Ltd.No ratings yet

- Rabello Sete CordasDocument4 pagesRabello Sete CordasRafael SouzaNo ratings yet

- Shaft Guide 2. Rubberpad 3. Plate Guide A 4. Plate Guide B 5. Hub GuideDocument3 pagesShaft Guide 2. Rubberpad 3. Plate Guide A 4. Plate Guide B 5. Hub GuidePramudya Sperow SajaNo ratings yet

- FL3B-434-M-2073-0.0 (434T010) D1 Filtrate TankDocument1 pageFL3B-434-M-2073-0.0 (434T010) D1 Filtrate TanknyaptoNo ratings yet

- Project Oxygas (15687558)Document2 pagesProject Oxygas (15687558)Mario Alberto Pineda CastilloNo ratings yet

- ARCH راشد المزروعي PDFDocument4 pagesARCH راشد المزروعي PDFIvanna GlonNo ratings yet

- J26 Axis-1 Abutment Segment Cd-Layout2Document1 pageJ26 Axis-1 Abutment Segment Cd-Layout2ahmed fathyNo ratings yet

- Fender Rumble 40 v3 SCHDocument7 pagesFender Rumble 40 v3 SCHCarlos ZaninNo ratings yet

- G90 Ssigbd 2.0.6 Gai03Document1 pageG90 Ssigbd 2.0.6 Gai03my_scribd_20100607No ratings yet

- A A A A A A: Tank Testing Plan With Sounding TablesDocument1 pageA A A A A A: Tank Testing Plan With Sounding TablesMD shawonNo ratings yet

- Plamen Plamen - Pale I MenekaDocument1 pagePlamen Plamen - Pale I MenekaLuka DzogovicNo ratings yet

- Option A: One Way Road: Lake Street Shared TrailDocument1 pageOption A: One Way Road: Lake Street Shared TrailNeenNo ratings yet

- V71A00016600Document2 pagesV71A00016600X94905XNo ratings yet

- 11 181000 4800000121 RGF SRV DRG 100212 - 02Document1 page11 181000 4800000121 RGF SRV DRG 100212 - 02ahmad.suliman.saeedNo ratings yet

- General Sheet Notes - Floor Plans: Ecopark Daesung International SchoolDocument1 pageGeneral Sheet Notes - Floor Plans: Ecopark Daesung International SchoolVũ Việt DũngNo ratings yet

- The Secrete Life of Plants Bob Ber 83Document8 pagesThe Secrete Life of Plants Bob Ber 83Rodolfo VaraniNo ratings yet

- DW044 P03 PRB SL 1059Document1 pageDW044 P03 PRB SL 1059mohammad shabazNo ratings yet

- SBVT - Rnav Kigok 1b Mikem 1b Rwy 06 - Star - 20230323Document1 pageSBVT - Rnav Kigok 1b Mikem 1b Rwy 06 - Star - 20230323Valiense FilmesNo ratings yet

- Vendor:: Column Cell No.1 Column Cell Feed DistributorDocument1 pageVendor:: Column Cell No.1 Column Cell Feed DistributorJoseph Junior Jahuira TaparaNo ratings yet

- Silent night holy night 기본Document2 pagesSilent night holy night 기본obedientcrimeNo ratings yet

- Thermocouple Position - Miniatur Microsite Rev.17Document1 pageThermocouple Position - Miniatur Microsite Rev.17tam amiNo ratings yet

- Estab-Hexus 500 V.2 - Biv - Rev03Document1 pageEstab-Hexus 500 V.2 - Biv - Rev03Fernando SilvaNo ratings yet

- Typical Supply 3Document1 pageTypical Supply 3Mohamed MagdyNo ratings yet

- Grundig-Beko Delta dps-174bp PsuDocument3 pagesGrundig-Beko Delta dps-174bp PsuMy USERNAME100% (1)

- Ban Ve P&ID 06.10.2017 - TUAN KHANH 22-4-2020Document68 pagesBan Ve P&ID 06.10.2017 - TUAN KHANH 22-4-2020Thái NgọcNo ratings yet

- E-02-02 - Power Coming & Substation System-E-02-02Document1 pageE-02-02 - Power Coming & Substation System-E-02-02Duong Thai BinhNo ratings yet

- Schematic - KIM M50 EDITED - 2023-07-05Document1 pageSchematic - KIM M50 EDITED - 2023-07-05Estang Da VieNo ratings yet

- Vcc1 Vcc2Document1 pageVcc1 Vcc2nakelectronics5No ratings yet

- Fa Rsag7.820.1947Document3 pagesFa Rsag7.820.1947ies837No ratings yet

- General NotesDocument1 pageGeneral Notesmustafa1989ocNo ratings yet

- February Monthly Collection, Grade 5From EverandFebruary Monthly Collection, Grade 5Rating: 3 out of 5 stars3/5 (1)

- A3-106304-02017-01-A General Arrangement S313Document1 pageA3-106304-02017-01-A General Arrangement S313Chandra KanthNo ratings yet

- 02 July 2022 - Journey of Hajj - 03 Dhul Hijjah 1443Document11 pages02 July 2022 - Journey of Hajj - 03 Dhul Hijjah 1443Chandra KanthNo ratings yet

- 07 July 2022 - Journey of Hajj - 08 Dhul Hijjah 1443Document7 pages07 July 2022 - Journey of Hajj - 08 Dhul Hijjah 1443Chandra KanthNo ratings yet

- 30 June 2022 - Journey of Hajj - 01 Dhul Hijjah 1443Document11 pages30 June 2022 - Journey of Hajj - 01 Dhul Hijjah 1443Chandra KanthNo ratings yet

- TF A5SalahBooklet R3a 1Document38 pagesTF A5SalahBooklet R3a 1Chandra KanthNo ratings yet

- Garden of Hajj - Children SeriesDocument8 pagesGarden of Hajj - Children SeriesChandra KanthNo ratings yet

- CB SampleDocument2 pagesCB SampleChandra KanthNo ratings yet

- Namazu Siddantamulu Mobile FriendlyDocument156 pagesNamazu Siddantamulu Mobile FriendlyChandra KanthNo ratings yet

- Attendance 26th SepDocument21 pagesAttendance 26th SepChandra KanthNo ratings yet

- Design of Base PlateDocument3 pagesDesign of Base PlateChandra KanthNo ratings yet

- Base Plate - Anchor Bolt and Shear Key Design - P1Document3 pagesBase Plate - Anchor Bolt and Shear Key Design - P1Chandra Kanth100% (1)

- For Review: PetrofacDocument1 pageFor Review: PetrofacChandra KanthNo ratings yet

- For Construction: PetrofacDocument1 pageFor Construction: PetrofacChandra Kanth100% (1)

- 0188PF N DG DG05 ST Dte 1032 001 A01Document2 pages0188PF N DG DG05 ST Dte 1032 001 A01Chandra KanthNo ratings yet

- Research On Utilizing Recycled Plastic To Make Environment-Friendly PlywoodDocument2 pagesResearch On Utilizing Recycled Plastic To Make Environment-Friendly PlywoodAnela KimNo ratings yet

- Applying OntoUML For Structural Definitions of Normalized Systems ExpandersDocument79 pagesApplying OntoUML For Structural Definitions of Normalized Systems ExpandersGabrielle de la PuenteNo ratings yet

- MAGENTO v1.0.19700 - Database DiagramDocument1 pageMAGENTO v1.0.19700 - Database Diagrampravash_znNo ratings yet

- 7a - Work and Energy WorksheetDocument2 pages7a - Work and Energy Worksheetpicket1019No ratings yet

- General Requirements For Carbon and Low Alloy Steel TubesDocument10 pagesGeneral Requirements For Carbon and Low Alloy Steel TubesPaulo GalvãoNo ratings yet

- Mercedes-Benz: U.S. ApplicationsDocument2 pagesMercedes-Benz: U.S. ApplicationsEdixo ReyesNo ratings yet

- 31 JULY 2019: For Our Latest Research Publications, For Current Investment OpportunitiesDocument1 page31 JULY 2019: For Our Latest Research Publications, For Current Investment OpportunitiesYeshmssNo ratings yet

- 70 - 140H - 8 - HYD Cylinder PDFDocument33 pages70 - 140H - 8 - HYD Cylinder PDFQuangĐạoNo ratings yet

- Electrical and Electronic Circuits: 12-IS-EE101Document25 pagesElectrical and Electronic Circuits: 12-IS-EE101Diptashree BanerjeeNo ratings yet

- Datasheet - Turck Module IM1-22EX-T - ENDocument4 pagesDatasheet - Turck Module IM1-22EX-T - ENscm balikpapanNo ratings yet

- Zigbee WirelessDocument9 pagesZigbee WirelessSajad RatherNo ratings yet

- Mansheyet Elhorreya STP Mass Balance-03jun2019Document16 pagesMansheyet Elhorreya STP Mass Balance-03jun2019Hemant KaleNo ratings yet

- Preview: Comptia Linux+ Certification Powered by LpiDocument78 pagesPreview: Comptia Linux+ Certification Powered by LpiMactearsNo ratings yet

- Commercial Line: 72 Cells Mono 5Bb M3 - 158.75x158.75mm / 6.25x6.25" Year Linear Power Warranty Year Product WarrantyDocument2 pagesCommercial Line: 72 Cells Mono 5Bb M3 - 158.75x158.75mm / 6.25x6.25" Year Linear Power Warranty Year Product WarrantyAriel RuizNo ratings yet

- Centrifugal Pumps (T-60015)Document4 pagesCentrifugal Pumps (T-60015)Phuong0% (1)

- 3405P369 - Tool For Tightness TestDocument4 pages3405P369 - Tool For Tightness TestSylvek91No ratings yet

- Lecture Notes: Probability and Statistics Engr. Darwin M. MurilloDocument4 pagesLecture Notes: Probability and Statistics Engr. Darwin M. MurilloJeremiah MalagueñoNo ratings yet

- INF 340 Course Career Path Begins Inf340dotcomDocument9 pagesINF 340 Course Career Path Begins Inf340dotcommaterial4No ratings yet

- NEXUS 7-Speed Internal Hub W/coaster BrakeDocument1 pageNEXUS 7-Speed Internal Hub W/coaster BrakesolerviNo ratings yet

- Multi Sarana TekindoDocument9 pagesMulti Sarana TekindoHepi Achmad FauziNo ratings yet

- Undergraduate Scholarships Application FormDocument3 pagesUndergraduate Scholarships Application FormAbdul Rehman ShejwalkarNo ratings yet

- TDS - Aqua PU Anti-SkidDocument2 pagesTDS - Aqua PU Anti-SkidHeramb TrifaleyNo ratings yet

- Physic Fire Alaram Micro Project Second SemDocument12 pagesPhysic Fire Alaram Micro Project Second SemYuvraj NehulNo ratings yet

- Stepper Catalog PDFDocument36 pagesStepper Catalog PDFCano VoyNo ratings yet

- Construction Contract CloseoutDocument16 pagesConstruction Contract CloseoutShahid Akram100% (1)