Professional Documents

Culture Documents

OSA-P-SRV-24 Testing Procedure For DPE Ball Valve (Refer To API 6D Specification)

OSA-P-SRV-24 Testing Procedure For DPE Ball Valve (Refer To API 6D Specification)

Uploaded by

deny0 ratings0% found this document useful (0 votes)

28 views12 pagesOriginal Title

OSA-P-SRV-24 Testing Procedure for DPE Ball Valve (refer to API 6D Specification)

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

28 views12 pagesOSA-P-SRV-24 Testing Procedure For DPE Ball Valve (Refer To API 6D Specification)

OSA-P-SRV-24 Testing Procedure For DPE Ball Valve (Refer To API 6D Specification)

Uploaded by

denyCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 12

“OSA

L ‘Work Procedure

s PT. OSA INDUSTRIES INDONESIA Rev. : 02

| nvsties ; faptsifoa |

indore bate 20 March 2012 | Page: 1/2_|

TESTING PROCEDURE FOR DPE BALL VALVE

(REFER TO API 6D SPECIFICATION)

Prepared by: Checked & Approved by

Operations Manager

QC Engineer

controlled C«

wot

| “]__ WorkProcedure

OSA PT. OSA INDUSTRIES INDONESIA No. :05 PV 24 [Rev 02

Indonesia [Date :30March2012 | Page: 2/12

TESTING PROCEDURE FOR DPE BALL VALVE

(REFER TO API GD SPECIFICATION)

Amendment Record Sheet

l 7

Date of Revision Item No. Issue No, | Description of Change

i | ‘Additional Simulation Test DPE

SFebruary 2011 17.0 Related Document 01._—_—| Ball Valve, Form No.: OSA-F-SRV-

23

| Logo OSA From “OSA industries” |

30 March 2012 Change Logo OSA on Bp “Osa indiesuies eae

Without “Coniraled Copy” stamp, document is Uncontolied= Z

Controlled Coy

ety

ca

OSA Work Procedure

| PT. OSA INDUSTRIES INDONESIA | No. Rev. : 02

industries | a

Indonesia _| Date :30 March 2012 | Page : 3/12

TESTING PROCEDURE FOR DPE BALL VALVE

(REFER TO API 6D SPECIFICATION)

1.0. PURPOSE

20

30

40

5.0

60

79

‘The purpose of this procedure is to maintain a system which identifies and plans the method,

acceptance criteria and responsibilities to perform Pressure Testing of Double Piston Valves

required by PT. OSA Industries Indonesia and/or the contracts

SCOPE

This procedure is intended to give necessary and adequate instructions in order to simulate the

real operating conditions, where the downstream end is de-pressurized first, after that the valve

cavity, but with the upstream/pipeline end remaining at pressure.

APPLICABILITY

This procedure applies to ball valves with valves seat execution Self Relieving x Double Piston.

REFERENCES

API 6D, ISO 5208 and ISO 14313,

TEST FLUID & EQUIPMENT

Hydrostatic test shall be carried out with potable water containing a corrosion inhibtor and

chloride content should not exceed than 30 ppm. Water PH should be between 6.5 and 8.5. Water

‘temperature should be maintained within 2 °C of ambient and not less than + 16 °C. Gas test shall

be carried out with Nitrogen gas.

Allvalves should be operated in dry condition, three times, before commencement of hydro test.

Test shall be carried out prior to any painting of valves bodies.

SAFETY AND ENVIRONMENTAL REQUIREMENTS

This procedure have to be executed by suitably competent and qualified personnel. Element of this,

procedure are of a dangerous nature and it is the responsibility of the user of this procedure to

adhere to all health and safety regulations.

PRESSURE GAUGES

7.1. Pressure gauges and pressure/temperature recorders shall be calibrated according to the QA

program (£ 2.% of full scale tolerance according to BS 5782).

7.2. The test pressure shall not be less then 30 % nor greater than 80 % of the full scale range Of

the pressure gauge.

Without “Controlled Copy” stamp, document is Uncontoled nee

ntrofied Co;

geno

| Work Procedure

OSA PT.OSA INDUSTRIES INDONESIA No. :0SA-P-SRV-24 | Rev, : 02 |

Industries | a

el | [ome a0 merch 20i2 | Page: 4/2

TESTING PROCEDURE FOR DPE BALL VALVE

iE (REFER TO API GD SPECIFICATION)

8.0 Tests

The tests that have to be applied on the Valves, as follow:

i

| ster st

fect

1 | shen Tex

> [Pain| Se A eavtet forward ent

5 pee Azer et Ios

Ba _| sie cece text forward seating

=

4 | Side A self relieving seat test

5 | Side C double piston

6 | Simulated operating test initial condition

7 | Simulated operating condition first test: test of Double piston seat side C

8 Simulated operating condition second test, test of forward seating side A

9 Simulating operating condition re-pressurization

10 _| Simulated operating test: Initial condition : other side

11 _ | Side A eat test, forward seating

12 _| Side C seat test, forward seating

Additional Operating Simulation Testing

13 | Side Aself relieving seat test

tolled Copy” stomp, documents Uncontrolled +

cantrotied COR?

ear

| Work Procedure

| \ eeeacat

OSA PT. OSA INDUSTRIES INDONESIA | No. :0SA-P-SRV-24 | Rev. : 02

industries

| Indonesia

Date :30 March 2012 | Page: 5/12 |

"TESTING PROCEDURE FOR DPE BALL VALVE |

(REFER TO API 6D SPECIFICATION)

9.0 NOMENCLATURE

SIDEA SELF RELIVING SIDE

SIDEB VALVE CAVITY

sIDEC DOUBLE PISTON SIDE

10.0 TEST OURATION

Duration of every test step shall be refer to the Table 3 {attached)

Test Simulation:

te = 1

Minimum Test Duration (minutes)

Valve Size (inch)

Shell test/Operating |

test initial condition |

| Stabilization | Seat Test

| 24 inch Wnecessary | 15 I 5

11.0 TEST PRESSURE

Test pressure as per listed in Table 2, and shall be specified as follow:

= Hydrostatic Shell test pressure Shall be min. 1.5 times Max Design Pessure

(ASME 8.16.34)

= Seat test pressures shall be min 1.1 times Max. Design Pressure (ASME B.16.34)

= Double Piston test shall be min, 1.1 times Max. Design Pressure (ASME B.16.34)

= Self reliving pressure shall be < 33 % Max Design Ptessure (ASME 8.16.34)

= The pressure value shall be maintained constant for the whole time of the test

12.0 ALLOWABLE LEAKAGES

Allowable Leakages Shall be refer to the Table 3, attached,

Witheut“Contoed Copy” stamp, dovuments Uncontraled™

controlled copy

QAaelr

OSA

Indsties

Ingonesia

Work Procedure

PT. OSAINDUSTRIES INDONESIA No. :0SA-P-SRV-24 | Rev. : 02

Date : 30 March 2012 | Page: 6/12

TESTING PROCEDURE FOR DPE BALL VALVE

(REFER TO API 6D SPECIFICATION)

13.0 HYDROSTATIC TESTING PROCEDURE

134

432

133

HYDRAULIC SHELL TEST PROCEDURE (STEP 1)

(TEST MEDIUM WATER)

‘With both ends closed and the bell in half open position, the valve shall be completely filled

with the test fluid including the cavity, apply the test pressure inside the valve body

through the ends plugs and vent the air off through the uppermost vent on the body (if

any), Ensure that all air has been expelled from the valve body. After stabilisaton, the

pressure shall be maintained for the specified time, Examine the entire surface of the valve

and the body/bonnet joint and ascertain that no drops, or sweating, or humidity is visible

‘during the duration of the test. Relieve the pressure leaving the valve body cavity filled with

water and turn the valve in closed position

HYDRAULIC HIGH PRESSURE SEAT TEST WITH THE VALVE IN CLOSSED

POSITION (STEP 2 & 3)

(TEST MEDIUM WATER)

‘The seat on each side shall be subject to separate seat test. The uppermost vent on the

body cavity shall be operated and excess medium allowed draining from the cavity. The

other section of the valve, adjacent to the pressure seat, shall be pressured at the pressure

specified in Para 8, and held for the specified time. The leakage rate across the seat shall be

measured at the body vent hole after a stabilization period. Upon completion of this test,

the valve shall be depressurized and the test repeated on the other seat.

SELF RELIVING & DOUBLE PISTON SEAT TEST (STEP 4 & 5)

(TEST MEDIUM WATER)

13.3.1. PRELIMINARY ACTIVITIES

‘With ball in half open position fill the water inside the valve from the valve drain

hole until the water leak out from the plastic pipe connected to the double piston

& self reliving seat side ends. Close the valve and start to pressurize the valve

‘through the body cavity (SIDE 8) and the double piston Side end (SIDE C]

13.3.2 SELF RELIVING SEAT TEST

During the first step it will be needed to check the self reliving system as follows:

= Increase the pressure until the self reliving seat starts to relieve the cavity

pressure, the relief pressure shall be recorded,

ACCEPTANCE CRITERIA RELIEF PRESSURE < 33 % of the maximum operating

pressure. IE: for 150 LBS valve it shall be <7 barG.

During the second step it will be needed to check the double piston effect as

follows :

= Stop the self releving seat side of the valve by means of a proper stop valve.

= Increase the pressure until the valve cavity (SIDE 8) and the self reliving side

{SIDE A) rises to the 1.1 maximum operating pressure.

Without “Controlled Copy” stamp, document is Unconvoled»

controlied Ce;

[9 1B

Work Procedure

| =

| OSA

Industries Sao

Indonesia Date :30March 2012 | Page: 7/12

"TESTING PROCEDURE FOR DPE BALL VALVE

(REFER TO API 6D SPECIFICATION)

PT. OSA INDUSTRIES INDONESIA No. :OSA-P-SRV-24 | Rev. : 02

The pressurization shall be done in THREE EQUAL STEP, during all step the

pressure shall be stabilized for $ minutes (LE. TEST PRESSURE BarG, 1” STEP 40

Barg 2° STEP 80 BarG, 3° STEP 110 BarG)

= Once the body cavity is stabilized to the testing pressure the tightness of the

double Piston seat can be tested,

14.0 GAS TESTING PROCEDURE (Additional operation simulation) TEST FLUID.

NITROGEN Gas

14.1 INITIAL CONDITION (STEP 6)

Utilizing the Nitrogen gas, the valves in closed position, shall be pressurized in all the areas

simultaneously (SIDE A SIDE 8 & SIDE C) at the testing pressure equal to 1.1 MOP and

maintainee for atime.

14.2 DOUBLE PISTON TEST (STEP 7}

The pressure on side shall be slowly reduced to zero and the pressure onside A & 8 shall

be continuosly moniotored by the pressure gauge connected on then,

4143 DOUBLE PISTON TEST (STEP 8)

Then completed the test as per item 13.2 the pressure on cavity shall be slowly reeuced to

zero in 7 cifferent steps (starting from the testing pressure 110 BarG).

On every step the pressure on side A shall be monitored and the leakage on Side Cshall be

recorded.

ACCEPTANCE CRITERIA

Leakage rate onside C shall be as per tem 12 during al the 7 depressurzation steps Slight

reduction of pressure on Side Ais acceptable during depressurization of B caused by the trim

deformation,

18.4 DOUBLE PISTON TEST (STEP 9)

‘Then completed the test as per item 13.3 the pressure on cavity shall be slowly increased up

to the testing pressure in 7 different steps.

On every step the pressure on side A shall be monitored and the leakage on Side C shall be

recorded,

ACCEPTANCE CRITERIA

Leakage rate on side C shall be as per item 11 during all the 7 pressurization steps. Slight

increasing pressure on Side A before stabilized is acceptable during the pressurization pof 8

caused by the trim deformation.

145. INITIAL CONDITION {STEP 10)

Then completed the test as per item 13.4 with the valve in fully closed position the pressure

on all parts {SIDE A B & C) shall be balanced at the testing pressure (1.1 MOP) as per par 9

and maintained for a time as per par &

After the test the valve shall be completely dedpressurized.

Without “Centolled Copy” stomp, docomentis Uacontraed

€]

-ontroited CC:

Waar

[Osa] Wed Proce

PT. OSA INDUSTRIES INDONESIA No. : OSA-P-SR)

Industries |

4 | Rev. = 02

Indonesia Date : 30 March 2012 Page : 8/12

| TESTING PROCEDURE FOR DPE BALL VALVE

(REFER TO API 6D SPECIFICATION)

14.6 CONVENTIONAL SEAT TEST SIDE A (STEP 11)

‘Then completed the test as per par 13.5 the conventional seat test shall be performed; with

the valve in fully closed position the pressure on side A shall be increased up to the testing

pressure (1.1 MOP) and maintained for a time as specified in par 8, with the side 8 and C

vented in atmosphere.

After the test the pressure on Side A shall be reduced to zero

ACCEPTANCE CRITERIA

True the cavity hole the leakage shall be measure by a flow-meter and shall be as per item

11 {Tabel 3)

14.7 CONVENTIONAL SEAT TEST SIDE € (STEP 11)

Then completed the test as per par 12.6 the conventional seat test shall be performed, with

the valve in fully closed position the pressure on side A shall be increased up to the testing

pressure (1.1 MOP) and maintained for a time as specified in Par 8, whit the side A and 8

vented in atmosphere.

After the test the pressure on C shall be reduced to zero.

ACCEPTANCE CRITERIA

‘True the cavity hole the leakage shall be measure by a Flow-meter and shall be as per item

11 (Tabel 3}

14.8 SELF RELIVING TEST ON SEAT A (STEP 12)

With the valve in fully closed position both side B and C shall be pressurized simultaneously

up to the relief pressure of SEAT A.

ACCEPTANCE CRITERIA

The release pressure shall be <33.%

Wheat “Coniated Copy” stomp, documents Uncontrolled»

pe

Cantroiled Coy

(Qa Ae

| OSA Vion Woceaur

PT. OSA INDUSTRIES INDONESIA | No. :OSA-P-SAV-24 | Rev. : O2

Industries —}—_——

Indonesia

r

Date :30 March 2012 | Page: 9/12 |

TESTING PROCEDURE FOR DPE BALL VALVE |

(REFER TO API 6D SPECIFICATION)

15.0 TESTSCHEME

Got “aa

pine me Sige peo

Bite oe

et wee

‘Without *Controied Copy” stam, document is Uncontrolled «

controled co

WAAQAT

[Tosa | enka

|

hel PT. OSA INDUSTRIES INDONESIA | No. :OSA-P-sRv-24 | Rev. : 02

industries, i

Indonesia | Date : 30 March 2012 | Page: 10 /12

TESTING PROCEDURE FOR DPE BALL VALVE

(REFER TO API 6D SPECIFICATION)

16.0 CERTIFICATION

Results of the hydraulic and simulation test shall be recorded on a proper test report.

As per Attachments A

Attachment A:

TEST REPORT T Report No. ‘Sheet 2 of 1

| SIMULATION TEST |

Valve Description Valve S.N Testing Procedure | __ GADrawing

OSAP-T0-38

Phase Test SideA | BCavity | SideC | Comment Test Rules

[a Shales P P P| Conventional shel Test | Eternal Lekage=Zer0

2 Side Seat Test, P Tand | ~Oand | Conventonalseat test | Pa)e.--86°G

forward Seating monitor | mentor Lesage on seat A

Test RESULTS

%/FSieCSeatTer | Oand | and P| Conventional vention | P(b]= Bare

e Forward Seating monitor | monitor Leakage on Seat 8 =

2) Bare HEE Test RESULT

= [a Silencer 3 EaseP | SHRP | Cavityandside Btobe [Sel Rehevng

\& Relevng Sea Test Pressurized TEST RESUUTS= |

| | i sieutaneousiy

3 | Sdet double P ? | cavity and side Atobe

Piston Pressured

2 Simitaneovsh

6 | Simulated ° P P| Valve pressure balanced |

‘operating Test | mah presuetvourbou |

ina Condition bilpors

7 | Simulated Fand | Pand Reduce] Ths would represent} Pla) = Bare

- Operating Montor | Monitor | Pressure | vertng/de-ressuriing | P(Q) = mnB¢G

g Condon fest to the i a9 Leakage on OP Seat C= |

3 teat ert of double stmosphe |

g piston ses sie rieand TeSTRESULTS

5 hott

2 [e_| simuaea Fant [ Ramee Oand | CheekTorany POF bare

3 Operating mentor | pressure | moniter | communication between Leakage on Seat €=

E Condition Second Slowly to cavity and elther

3 Test test of ‘Atmospheric upstream or downstream,

EB) _ | toward seating partly 9s pressure

z Side reduces. This veri all

g | seat deformation under |

6 rmacbad rom pine

3 Side/side A

S [9 | Simlatea Pand Tnerease | Oand | This simulates the fature | Pb)=.....Ba76

5 operating monitor | pressutein monitor | ofthe Asiseseatand | Leakage on Seat C=

2 cenaition faviytoP ‘demonsiates the side 8

repressuriation seat would eneze

ain, This verifies bal &

Seatintegrity/eontact

after max bad trom

| pipeline sde/Side A

Without “Controlled Copy” stamp, document is Uncontroled =

controtied Cony

AWAHAT

'osa | ee

PT. OSA INDUSTRIES INDONESIA | No. : OSA-P-SRV-24 Rev. : 02

Industries |

Indonesia _| Date: 30 March 2012 | Page: 11/12 _|

TESTING PROCEDURE FOR DPE BALL VALVE |

(REFER TO API 6D SPECIFICATION)

TEST REPORT Report No. aa Sheet 1 of 1

SIMULATION TEST

(Waive Description ValveSiN Testing Procedure | GADvawing

i O5APTO38 |

Phase [Test ide A_| B-Gaviy_| Se [comment Test Rules

0 Sues rye 7 | We presireblnced

serait | witnpressre weuthut

tatatcorton ree

caters

[se Reenter a Sand | Wad | Gomeatoal vata | eaage Sea A=

mee mentor _| center resratstrs

ae [Sees | oad | cand | | coment semtest —P Leakge onseste>

7 Ferdseaing | mentor | owner resrarsur=

sae TEN? | SSERP Gop andseDTo be | Set etelng > Bas

| tro Seat est mesure esr nest |

Srulteneush

17.0 RELATED DOCUMENT

OSA-F-SRV-23 Test Report Simulation Test DPE Ball Valve

Without “Contraied Copy” stomp, document is Uncontalled «

controiied copy

a

‘Work Procedure

| OSA PT. OSAINDUSTRIES INDONESIA | No. :OSA-P-SRV-24 _| Rev.

Industries ats

Indonesia _[ Date :30 March 2012_| Page : 12/12 |

TESTING PROCEDURE FOR DPE BALL VALVE

(REFER TO API 6D SPECIFICATION) _

OSA ‘TEST REPORT Feu: OS SAV20

nee SIMULATION TEST DPE BALL VALVE

amare

(iis — tae ape T =

ea per emaeers i

a

i

cece |

ee —

a=

Gace |: |. an

gl> race [mercer

i ae

t later

Ee eet ee +

alsa] { acrenecsonan

Peleeee sls | tafe Steere

pea pase | > eoteon|snanenclenenatanen —— (Strman

ead oem ras |

AS a ES eS ae er er

EA t = fe

tates | =e |e tee haa |

a | =

=

r

without “Contoled Copy” stamp, dcument ls Uncontroled « = €

Controfied Cepy

gage

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- OSA-P-SRV-22 Workshop Repair General ProcedureDocument8 pagesOSA-P-SRV-22 Workshop Repair General ProceduredenyNo ratings yet

- OSA-P-SRV-25 PSV Diagnostic and Maintenance Repair and Testing ProcedureDocument4 pagesOSA-P-SRV-25 PSV Diagnostic and Maintenance Repair and Testing ProceduredenyNo ratings yet

- Project Execution PlanDocument3 pagesProject Execution PlandenyNo ratings yet

- ADM-10-2011 - PR Office SuppliesDocument2 pagesADM-10-2011 - PR Office SuppliesdenyNo ratings yet

- OSA-P-SRV-26 Control Valve Diagnostic and Function Testing ProcedureDocument3 pagesOSA-P-SRV-26 Control Valve Diagnostic and Function Testing ProceduredenyNo ratings yet

- OSA-P-SRV-13 Testing Procedure For Check Valve (Refer To API 598 Specification)Document18 pagesOSA-P-SRV-13 Testing Procedure For Check Valve (Refer To API 598 Specification)denyNo ratings yet

- Do. 018 R 36Document1 pageDo. 018 R 36denyNo ratings yet

- AgengDocument2 pagesAgengdenyNo ratings yet

- TesonDocument1 pageTesondenyNo ratings yet

- Omar Syarief - CVDocument2 pagesOmar Syarief - CVdenyNo ratings yet

- 000 MARC-GTC Document AuditDocument4 pages000 MARC-GTC Document AuditdenyNo ratings yet

- To Do ListDocument1 pageTo Do ListdenyNo ratings yet

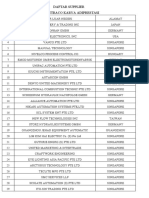

- Daftar SupplierDocument5 pagesDaftar SupplierdenyNo ratings yet

- Supporting Letter To PROMATCON TEPATGUNADocument1 pageSupporting Letter To PROMATCON TEPATGUNAdenyNo ratings yet

- TapScanner 18-03-2021-16.22Document1 pageTapScanner 18-03-2021-16.22denyNo ratings yet

- CV Akbar PutraDocument5 pagesCV Akbar PutradenyNo ratings yet

- NametagDocument4 pagesNametagdenyNo ratings yet

- Dokumen Penawaran: Subject: Blanket Purchase Agreement of Chemical Methanol Tender No: PROC104Document1 pageDokumen Penawaran: Subject: Blanket Purchase Agreement of Chemical Methanol Tender No: PROC104denyNo ratings yet

- Pt. Golden Solution Indonesia: Health and Safety EnvironmentDocument1 pagePt. Golden Solution Indonesia: Health and Safety EnvironmentdenyNo ratings yet

- Dokumen Penilaian Kualifikasi: Subject: Major Inspection (MI) of Frame-V GTG G101C Tender No: PS216A1D76Document1 pageDokumen Penilaian Kualifikasi: Subject: Major Inspection (MI) of Frame-V GTG G101C Tender No: PS216A1D76denyNo ratings yet