Professional Documents

Culture Documents

Baking Procedure

Baking Procedure

Uploaded by

gopuvinu4uOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Baking Procedure

Baking Procedure

Uploaded by

gopuvinu4uCopyright:

Available Formats

METAL SCOPE INDIA PVT LTD-PUDUCHERRY

ISO-9001-2008

PROCEDURE FOR BAKING & HOLDING OF WELDING ELECTRODE

WELDING ELECTRODE: E7018, E8018B2.

Ensure that electrode packets received are free from physical damage.

Where electrodes are damaged, the same shall be removed from use.

The storage area shall be clean and dry.

Steel racks may be used for storage. Avoid storing wood inside the storage

room.

While handling, avoid contact of oil, grease with electrodes. Do not use oily or

wet gloves.

It is recommended that not more than two days requirements are baked.

They shall have a temperature control facility upto 350 Deg C for baking oven

and 200 Deg C for holding oven.

A calibrated thermometer shall be provided for monitoring temperature.

On completion of baking, transfer the electrodes to holding oven, maintain a

Minimum temperature of 100Deg C till issue.

Unused, returned electrodes shall be segregated and kept in the holding oven.

Issue of welding electrodes shall be based on authorized Welding

Electrodes Issue Voucher.

METAL SCOPE INDIA PVT LTD-PUDUCHERRY

ISO-9001-2008

PROCEDURE FOR BAKING WELDING FLUX

WELDING FLUX: EL8-F7A0, EM12K-F7A4,EM12K-F7AZ.

Flux shall be free from Dirt, mill scale or other foreign Materials.

The packages can be stored not more than six months under normal

conditions.

Flux from the damaged packages shall be discarded or dried out at min 260

degree centigrade one hour before use.

Height of Flux bed while drying in pan shall not be more than 100mm

Wet flux shall not to be used.

Flux can be re-cycled successfully and the following guidelines should be

adopted for flux re-cycling:- During continuous welding operations unused flux

can be recycled and returned to the flux hopper for re-use.

Slag and metallic particles should be removed from the recycled flux and

discarded prior to using recycled flux.

Fines should be removed from recycled flux. Excessive levels of fines will

impair the welding performance of the flux and degrade the weld bead

appearance.

Re-crushed slag should not be used as flux for welding operations

You might also like

- App10 Fundamentals of ConnectionsDocument23 pagesApp10 Fundamentals of ConnectionsjdmacbookNo ratings yet

- Aluminium - BHEL Technical SpecificationDocument2 pagesAluminium - BHEL Technical SpecificationSimbu ArasanNo ratings yet

- Procedure For Receipt, Storage and Handling of Welding Consumable (Rev 1)Document8 pagesProcedure For Receipt, Storage and Handling of Welding Consumable (Rev 1)dee1985100% (2)

- 2018 Handling and Storage Recommendations - EN - Rev1!02!2018Document4 pages2018 Handling and Storage Recommendations - EN - Rev1!02!2018David Hortas CasasNo ratings yet

- Shell Corena S3 R 68: Performance, Features & BenefitsDocument3 pagesShell Corena S3 R 68: Performance, Features & BenefitsjkamraNo ratings yet

- Technical Specification: GID-PIP-TS-630 - (E)Document41 pagesTechnical Specification: GID-PIP-TS-630 - (E)santiagoNo ratings yet

- Weld Restoration of Disk - Example of Elliott Repair TechnologyDocument49 pagesWeld Restoration of Disk - Example of Elliott Repair TechnologyMachineryengNo ratings yet

- Denso Valve Flange Tape Wrapping SpecDocument3 pagesDenso Valve Flange Tape Wrapping SpecNaufal Firmansyah100% (1)

- Nord Lock Washers InfoDocument8 pagesNord Lock Washers InfoMaclean ArthurNo ratings yet

- 8 UPVc Pressure Pipes and FittingsDocument8 pages8 UPVc Pressure Pipes and FittingsNikita KadamNo ratings yet

- Catalog Swivel Joints PDFDocument24 pagesCatalog Swivel Joints PDFluiggi19970530No ratings yet

- Slewing Bearing Installation and Maintenance Manual: Yantai Haoyang Machinery Co.,LtdDocument22 pagesSlewing Bearing Installation and Maintenance Manual: Yantai Haoyang Machinery Co.,Ltddony ramdhaniNo ratings yet

- What TitleDocument17 pagesWhat TitleBernathTurnipNo ratings yet

- Slewing Bearing Slewing Ring Slewing Gear Swing CircleDocument15 pagesSlewing Bearing Slewing Ring Slewing Gear Swing Circlezczc32z5No ratings yet

- Sulphate Resisting Cement ManufactureDocument3 pagesSulphate Resisting Cement ManufactureshaayashanmugaNo ratings yet

- Catalog Steel Grating Type 2016-10-01Document12 pagesCatalog Steel Grating Type 2016-10-01Kho Chin NganNo ratings yet

- Marine Painting CourseDocument57 pagesMarine Painting CourseMin SoeNo ratings yet

- Ingress Protection (IP)Document2 pagesIngress Protection (IP)nileshb1985No ratings yet

- NR494 - R01 Classification For Buoy PDFDocument36 pagesNR494 - R01 Classification For Buoy PDFEsapermana RiyanNo ratings yet

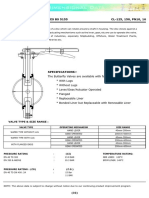

- Butterfly ValvesDocument28 pagesButterfly ValvesLAWRENCENo ratings yet

- ROCKWOOL RockTech B (Blanket) Series LR PDFDocument2 pagesROCKWOOL RockTech B (Blanket) Series LR PDFWasawat JoongjaiNo ratings yet

- Aogc 036 Pi Ess 001 (B1)Document19 pagesAogc 036 Pi Ess 001 (B1)amini_mohiNo ratings yet

- Datasheet Wear PadDocument3 pagesDatasheet Wear PadGILBERTO YOSHIDANo ratings yet

- Aluminium Coil / Sheet / Corrugated: Aluminium Alloy - AA 1100, 1050, 1060 - AA 3003 - AA 5005, 5052, 5754Document1 pageAluminium Coil / Sheet / Corrugated: Aluminium Alloy - AA 1100, 1050, 1060 - AA 3003 - AA 5005, 5052, 5754Aneesh JoseNo ratings yet

- Thread Types and UsesDocument1 pageThread Types and UsesJDPNetoNo ratings yet

- Rollix Slewing Ring Installation Maintenance English PDFDocument7 pagesRollix Slewing Ring Installation Maintenance English PDFBülent KabadayiNo ratings yet

- GlassRock Wire Mesh BlanketsDocument2 pagesGlassRock Wire Mesh BlanketsMohamedNo ratings yet

- Refinery InspectionDocument44 pagesRefinery InspectiongamadiyaNo ratings yet

- Steam TurbineDocument17 pagesSteam TurbineDicky Nicky November100% (1)

- Butterfly ValveDocument4 pagesButterfly ValveghjtyuNo ratings yet

- Alfagomma Industrial Rubber Hose Catalog PDFDocument68 pagesAlfagomma Industrial Rubber Hose Catalog PDFsiraphat.bmNo ratings yet

- Butterfly Valve CATALOGDocument36 pagesButterfly Valve CATALOGGloriaNo ratings yet

- Butterfly Valve Catalogue PDFDocument25 pagesButterfly Valve Catalogue PDFPriyanka rajpurohitNo ratings yet

- Process Industry Practices Coatings: PIP CTCE1000 External Coating System Selection CriteriaDocument27 pagesProcess Industry Practices Coatings: PIP CTCE1000 External Coating System Selection CriteriaCarlos Maldonado SalazarNo ratings yet

- Flange Insulation Brochure Rev3Document10 pagesFlange Insulation Brochure Rev3Gilberto YoshidaNo ratings yet

- Objective 2. Reference Documents 3. Procedure 4. Painting System 5. Inspection 6. Repairs 7. Safety AnnexuresDocument11 pagesObjective 2. Reference Documents 3. Procedure 4. Painting System 5. Inspection 6. Repairs 7. Safety AnnexuresChethanNo ratings yet

- Gadus s2 v220 2Document3 pagesGadus s2 v220 2ThinhNo ratings yet

- Bornemann TSP HP Doble TornilloDocument8 pagesBornemann TSP HP Doble TornilloJosé Luis CoronadoNo ratings yet

- 7465 - Sigmacover 435Document0 pages7465 - Sigmacover 435eraswastaNo ratings yet

- The Development of The Surface Finish StandardDocument7 pagesThe Development of The Surface Finish StandardSunilNo ratings yet

- Abrasive Blast Media Quick Selection Guide: Single Use Surface Preparation MediaDocument1 pageAbrasive Blast Media Quick Selection Guide: Single Use Surface Preparation MediaskNo ratings yet

- Guide To Design and Selection of Check ValvesDocument18 pagesGuide To Design and Selection of Check ValvessimitzuNo ratings yet

- Sae Spec For Steel Shot & GritDocument3 pagesSae Spec For Steel Shot & Gritsanoopvk100% (1)

- FloatingDocument12 pagesFloatingrobson2015No ratings yet

- AE-S-3527 Rev. 2: REV Prepared by Approved BY Date RemarksDocument6 pagesAE-S-3527 Rev. 2: REV Prepared by Approved BY Date RemarksQualityNo ratings yet

- Comparison List Copper Bronze 2011 1Document7 pagesComparison List Copper Bronze 2011 1NaldoVicenteNo ratings yet

- Copper Slag MSDSDocument1 pageCopper Slag MSDSanon_302374528No ratings yet

- OGN InsulationDocument7 pagesOGN InsulationAbhishek KumarNo ratings yet

- Chain Block & Puller Inspection ChecklistDocument1 pageChain Block & Puller Inspection Checklistibrahim100% (1)

- Quality Control System in The Fabrication of Heat ExchangersDocument5 pagesQuality Control System in The Fabrication of Heat ExchangersCorine CaracasNo ratings yet

- Ceramic Fiber BlanketDocument1 pageCeramic Fiber BlanketHanafi MansorNo ratings yet

- Moore Fans Maintenance and Operation ManualDocument10 pagesMoore Fans Maintenance and Operation ManualVivian AnastasyaNo ratings yet

- Denso Petrolatum TapeDocument1 pageDenso Petrolatum TapeAnonymous 4IpmN7OnNo ratings yet

- Virgin and Filled PTFE (Teflon) PDFDocument1 pageVirgin and Filled PTFE (Teflon) PDFAnjani PrabhakarNo ratings yet

- ZA0-2 35,0ae-03 00Document15 pagesZA0-2 35,0ae-03 00Marcos Dos Santos VieiraNo ratings yet

- 14.052 Rev. 0 - 9PE122 & 9PE123 - ECOPETROL - Cleaning Supervision, Inspection & Repair PDFDocument11 pages14.052 Rev. 0 - 9PE122 & 9PE123 - ECOPETROL - Cleaning Supervision, Inspection & Repair PDFVladimir Rodriguez LeonNo ratings yet

- Instrumentation Pipe & Weld Fittings: 6000psig, 10000psig and Standard RatingDocument5 pagesInstrumentation Pipe & Weld Fittings: 6000psig, 10000psig and Standard Ratinggohjh80No ratings yet

- Quality Control Procedure: WeldingDocument5 pagesQuality Control Procedure: WeldingAAISATNo ratings yet

- COR Handling+and+Storage+Recommendations EN Rev2 2018 GL 1003 PreviewDocument4 pagesCOR Handling+and+Storage+Recommendations EN Rev2 2018 GL 1003 PreviewAli AliNo ratings yet

- The Art of Welding: Practical Information and Useful Exercises for Oxyacetylene and Electric Arc WeldingFrom EverandThe Art of Welding: Practical Information and Useful Exercises for Oxyacetylene and Electric Arc WeldingNo ratings yet

- Automelt S33Document2 pagesAutomelt S33gopuvinu4uNo ratings yet

- 1192635811Document2 pages1192635811gopuvinu4uNo ratings yet

- Welding PositionDocument1 pageWelding Positiongopuvinu4uNo ratings yet

- Welding ProcessDocument58 pagesWelding Processgopuvinu4uNo ratings yet

- Joint ConfigurationDocument1 pageJoint Configurationgopuvinu4uNo ratings yet

- Torque ValueDocument1 pageTorque Valuegopuvinu4uNo ratings yet

- Test Plate Size Details-MaterialsDocument2 pagesTest Plate Size Details-Materialsgopuvinu4uNo ratings yet

- Asme Sec Ix 2013 EdDocument416 pagesAsme Sec Ix 2013 Edgopuvinu4u100% (1)

- SPL-MFP-MEC-IR-002A Rev. 0-PQR WELDER QUALIFICATION DATA SHEETDocument1 pageSPL-MFP-MEC-IR-002A Rev. 0-PQR WELDER QUALIFICATION DATA SHEETgopuvinu4uNo ratings yet

- Sfa 5.1Document44 pagesSfa 5.1gopuvinu4uNo ratings yet

- Sfa 5.18Document26 pagesSfa 5.18gopuvinu4uNo ratings yet

- TieDocument6 pagesTiegopuvinu4uNo ratings yet