Professional Documents

Culture Documents

US2059487

US2059487

Uploaded by

Jean Delaronciere0 ratings0% found this document useful (0 votes)

3 views3 pagesThis document describes a muffler patent filed in 1932. The muffler aims to provide effective silencing of both high and low engine exhaust frequencies through a combination of acoustic and resonator chambers. It consists of a series of telescoped cylinders forming ring-shaped acoustic chambers. Additional fins can subdivide the space between cylinders to create elongated U-shaped resonator chambers tuned to specific low frequencies. The goal is to achieve high muffler efficiency and silencing of both high and low frequencies in a compact design.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document describes a muffler patent filed in 1932. The muffler aims to provide effective silencing of both high and low engine exhaust frequencies through a combination of acoustic and resonator chambers. It consists of a series of telescoped cylinders forming ring-shaped acoustic chambers. Additional fins can subdivide the space between cylinders to create elongated U-shaped resonator chambers tuned to specific low frequencies. The goal is to achieve high muffler efficiency and silencing of both high and low frequencies in a compact design.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

3 views3 pagesUS2059487

US2059487

Uploaded by

Jean DelaronciereThis document describes a muffler patent filed in 1932. The muffler aims to provide effective silencing of both high and low engine exhaust frequencies through a combination of acoustic and resonator chambers. It consists of a series of telescoped cylinders forming ring-shaped acoustic chambers. Additional fins can subdivide the space between cylinders to create elongated U-shaped resonator chambers tuned to specific low frequencies. The goal is to achieve high muffler efficiency and silencing of both high and low frequencies in a compact design.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 3

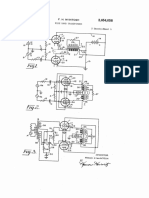

Nov. 3, 1936. P. G.

PEIK 2,059,487

MUFFLER

Filed Oct. 31, 1932

22:34

32

sts, 764-w, Woelf (loore,

... --- 8tow

Patented Nov. 3, 1936 2,059,487

UNITED STATES PATENT OFFICE

2,059,487

MUFFER

Paul G. Pelk, Chicago, Ill., assignor to The Halsey

W. Taylor Company, Warren, Ohio, a corpora

tion of Ohio

Application October 31, 1932, Serial No. 640,558

Claim. (C. 181-41)

This invention relates to mufflers for silencing gas stream. Their efficiency is limited due to the

the exhaust noises of engines, particularly of in multiplicity of sound waves in the exhaust stream .

ternal combustion engines. of an internal combustion engine and the varia

The general object of the invention is to pro tion of the sound waves due to acceleration and

vide a combined acoustic and resonator muffler, deceleration of the engine. Their length, which

of exceptionally low production, cost having a is governed by the wave length of the low fre

degree of compactness heretofore unattained in quencies in an exhaust gas stream, is considerable

mufflers of comparable efficiency. and therefore the manufacturing costs of reaSon

Another object of the invention is to provide ably efficient resonator mufflers are high and their

10 a durable efficient combined acoustic and reso use is limited to automobiles with relatively iarge O

nator muffler of low construction cost which emi frame structures.

bodies a Series of resonator chambers of Substan The objects and advantages of the invention

tial length when compared with the length of the will become more apparent from the following

muffler. description, when taken in conjunction with the

15 Still another object of the invention is to pro accompanying drawing, wherein: 15

vide a combined acoustic and resonator muffler Figure i is a longitudinal sectional view of an

Of the type referred to above with a series of res exhaust muffler according to thie invention, the

Onator chambers tuned within narrow ranges section being taken on line - of Figure 2;

With respect to each other to broaden the range Figure 2 is a transverse sectional view taken

20 of frequencies in which the muffler Will silence on line 2-2 of Figure 1, 20

low sound frequencies. - Figures 3 and 4 are transverse sectional views

Fundamentally all sound deadening is due to taken on lines 3-3 and 4-4 respectively of Fig

resonance action. The highest efficiency of ure 1;

Sound deadening-that is, elimination of any Figures 5 through 8 show a slightly modified

25 SOund Wave in One cycle-is attained only by pro form of the muffler provided with Separating fins 25

viding a separate chamber tuned exactly to the to increase the number of resonator chambers

length of that Waye. This method is not feasible employed, thus, Figure 5 is a longitudinal Sec

in a muffler, due to the multiplicity of sound tional view through the modified muffler taken

waves in the exhaust stream, and the constant on line 5-5 of Figure 6;

30 variation of their frequency due to the accelera Figure 6 is a transverse sectional view taken on 30

tion and de-celeration of the engine. While each line 6-6 of Figure 5;

individual air space in sound absorbing material Figures 7 and 8 are transverse sectional views

employed in mufflers of the so-called acoustic taken on lines 1-7 and 8-8 respectively of

type, is far too small to have an efficient sound Figure 5.

35 deadening action in one cycle, acoustic mufflers Referring more particularly to the structure 35

are nevertheless very efficient in deadening high disclosed in Figures 1 through 4 of the drawing,

frequencies of sound due to the multiplicity of tie muffler comprises a series of telescoped cylin

air Spaces and the high rate of oscillation of the ders 2, 3 and 4 arranged in spaced relationship

high frequencies. Thus, the so-called acoustic with respect to each other. The outer cylinder 2

40 mufflers are extremely efficient in eliminating the and the adjoining cylinder 3 are connected at 40

high frequencies, but (for reasons which are ex opposite ends in any suitable manner, as by Weld

plained later) are So inefficient in their action on ing to the front and rear end walls 5 and 6 re

the low frequencies that such mufflers must be spectively, thus forming resonator chamber 7 of

made in a considerable length to obtain the neces ring shaped cross-section between these two cyl

45 Sary elimination of the low Sound frequencies, so inders. End wall 5 is formed with an inlet exten 45

long in fact that it is common practice, to make sion 8 having an outlet opening 9, and end wall

then in two units so that they can be mounted 6 is centrally perforated to form an opening 0.

between the re-inforcing members of the modern The third cylinder 4 is somewhat shorter and at

automobile chassis. its rear end welded to rear end wall 6. The front

50 The following brief reference to acoustic muf end of cylinder 4 is welded to an inner wall 2 50

fiers and resonator mufflers will Serve to show which in turn is secured to the inner wall of cylin

how the above objects are attained and to bring der 3. Front end wall 5 is spaced a slight dis

out the main features of the invention. tance from inner wall 2 due to the difference in

Resonator mufflers in turn are extremely eff length between cylinders 3 and 4, thus forming

55 cient in deadening low frequencies in an exhaust a chamber f4 at the front end of the muffler. 55

2 2,059,487

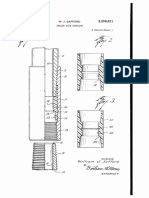

Cylinder 4 encloses a round sleeve or pipe is in usually complex combination of distinct loud pe

axial alignment with the respective inlet and out riods of low frequencies the number of resonator

let openings 9 and 0, and extending from inlet chambers of the muffler is preferably increased.

opening 3 in inner wall 2 of shell 4 to and Such a structure is disclosed in Figures 5 to 8 of

through opening O in rear end wall 8, thus form the drawing, wherein I show a muffler closely re

ing a ring shaped chamber f within cylinder 4. sembling the structure shown in Figures 1-4,

Pipe 5, which is made of perforated sheet metal, with the exception that the space between shells

communicates through its perforations with the 2 and 3 and shells 3 and 4 is subdivided by fins

interior of cylinder 4 surrounding said pipe. The 22 and 28 respectively, whereby two elongated

O ring shaped chamber in cylinder 4 is packed reversed or U-shaped resonator chambers 24 and O

with any sound absorbing fire proof material 8 25 of substantial length are formed, which there

such as expanded micaceous material, slag wool, fore function as a simple resonator. The length

steel wool etc. and communicates with the space of chambers 24 and 25 may be individually adapt

inside of pipe 5, as previously described, which ed to silence the loudest periods of the two lowest

5 space constitutes an unobstructed main passage Sound frequencies of the exhaust gas stream by 5

for the exhaust gas. arranging the communicating openings or slots

The silencing eficiency of the structure just 20', 20' in cylinders 3 and 4 more or less apart

described is nore effective on the high Sound fre from the end of said cylinders, but slots 20" should

quencies than on the lower ones, the latter being be so positioned that the chambers 24 and 25 will

20 more readily muffled or silenced by resonating be substantially longer than the length of the 20

action. Good muffling on both high and low fre outer cylinder 2 and consequently longer than

quencies has heretofore only been obtained by the length of the muffler as a whole. The corn

employing relatively long mufflers, which as municating passages 2 between the halves of

25

pointed out above cannot be used on reinforced chambers 24 and 25 are arranged similarly to

short frame structures of automobiles. In order openings 2 in the muffler previously described. 25

to obtain a resonator effect in combination with It will be understood that mufflers according

the acoustic action of the muffler so far described to the invention can readily be built with any

without greatly increasing the length of the muf number of simple resonator chambers of the re

fler, the space between shells 2, 3 and 4 is utilized quired tuning either by providing further sub

30 as a resonator chamber 9. Chamber 9 which divisions by means of additional fins, or by in 30

may be tuned to silence the loudest period of the creasing the number of shells or cylinders, and

low sound frequencies of the exhaust gas stream, that these mufflers possess very high mufting

is approximately twice the length of the outer cyl efficiency despite the fact that the length of the

inder 2 and consequently is about double the muffler is comparatively short.

35 length of the muffler as a whole, one half of the Having thus described my invention, what I 35

length of chamber 9 constituting the outer ring claim is:

shaped space between cylinders 2 and 3, and the A muffler for silencing the exhaust noise of in

other half constituting the inner ring-shaped ternal combustion engines, comprising an unob

space between cylinders 3 and 4 which in effect structed main passage having a plurality of per

serves as a second resonator chamber. forations therein, an expansion chamber having

A series of openings or slots 20 in the wall of Sound absorbing material packed therein and en

cylinder 3 close to one end thereof provide direct circling said passage and communicating there

communication between the two halves of chann with through said perforations, and two substan

ber 9, and a series of openings 2 in the wall of tially U-shaped resonator chambers, each being

said cylinder close to the opposite end thereof of substantially greater length than said muffler

provide direct communication between chamber and each being in communication with the main

4 and one end only of resonator chamber 9. passage, said resonator chambers being spaced

Therefore as the chambers are connected in series from the main passage by different radial dis

the same will be caused to function as a compound tances.

50 resonator. PAUL G. PEK.

For internal combustion engines having an un

You might also like

- Lesson Plan For Observation A Detailed Lesson Plan in Grade 9Document3 pagesLesson Plan For Observation A Detailed Lesson Plan in Grade 9Gerald E Baculna40% (5)

- Applications Philips 9710 MDocument79 pagesApplications Philips 9710 Marensattic88% (8)

- Cross Country Piping Stress AnalysisDocument8 pagesCross Country Piping Stress Analysisprabu2001No ratings yet

- Designing and Calculation of MufflerDocument7 pagesDesigning and Calculation of MufflerPravin Patil100% (1)

- Design of Shear KeyDocument12 pagesDesign of Shear KeyMEP100% (2)

- BS 6364 Cryogenic ValveDocument5 pagesBS 6364 Cryogenic ValvePasquale Cutri100% (1)

- US2442773Document3 pagesUS2442773Jean DelaronciereNo ratings yet

- July 8, 1930. I - C. GRANT ' 1,770,234Document3 pagesJuly 8, 1930. I - C. GRANT ' 1,770,234Hermano PeixotoNo ratings yet

- Exhaust Muffler Design PrinciplesDocument9 pagesExhaust Muffler Design Principlespaulomareze67% (3)

- Noise Reduction in Centrifugal Fans: A Literature SurveyDocument29 pagesNoise Reduction in Centrifugal Fans: A Literature SurveyPooria1989No ratings yet

- Noise Reduction in Centrifugal Fans: A Literature SurveyDocument29 pagesNoise Reduction in Centrifugal Fans: A Literature SurveyPooria1989No ratings yet

- Noise in Ventilation Ducts Sound in DuctsDocument8 pagesNoise in Ventilation Ducts Sound in DuctsRohitash NitharwalNo ratings yet

- United States Patent (191: Taddeo Patent Number: Date of PatentDocument4 pagesUnited States Patent (191: Taddeo Patent Number: Date of PatentseansotoNo ratings yet

- To Silence Centrifugal Blowers: The Use of ResonatorsDocument11 pagesTo Silence Centrifugal Blowers: The Use of ResonatorsmaryaoannaNo ratings yet

- Noise in Ventilation DuctsDocument9 pagesNoise in Ventilation DuctslkakeanNo ratings yet

- Altec Tranny MotionPicJournalDocument13 pagesAltec Tranny MotionPicJournalRobert GabrielNo ratings yet

- IIII: United States Patent (19 11 Patent Number: 5,500,632Document9 pagesIIII: United States Patent (19 11 Patent Number: 5,500,632Leonardo MarraffiniNo ratings yet

- Sept. 29, 1953 F. H. Mcntosh 2,654,058Document9 pagesSept. 29, 1953 F. H. Mcntosh 2,654,058Leonardo MarraffiniNo ratings yet

- A Study of Radiator Cooling Fan With Labyrinth SealDocument9 pagesA Study of Radiator Cooling Fan With Labyrinth SealDarel DalmassoNo ratings yet

- Improving The Bass Response of SchroederDocument11 pagesImproving The Bass Response of Schroeder从依云No ratings yet

- Us3266821 PDFDocument5 pagesUs3266821 PDFDiogo CorreaNo ratings yet

- Loss of Head in BendsDocument6 pagesLoss of Head in BendsaikareiNo ratings yet

- Us 5197855Document6 pagesUs 5197855John SmithNo ratings yet

- Welcome - Contents Back: Faist Anlagenbau GMBHDocument31 pagesWelcome - Contents Back: Faist Anlagenbau GMBHBo PeNo ratings yet

- Anechoic Wind TunnelsDocument39 pagesAnechoic Wind TunnelsDaniel HatfieldNo ratings yet

- Suction Muffler Design For Noise Reduction On High Efficiency RecDocument11 pagesSuction Muffler Design For Noise Reduction On High Efficiency RecThai VoNo ratings yet

- A Low Frequency Horn of Small DimensionsDocument9 pagesA Low Frequency Horn of Small DimensionsBob BeduneauNo ratings yet

- @81j @HW/ Wam ¿61x: No. 582,485. Patented May 11,1897Document3 pages@81j @HW/ Wam ¿61x: No. 582,485. Patented May 11,1897Igor BentesNo ratings yet

- Design and Performance of High Pressure Blowoff SilencersDocument8 pagesDesign and Performance of High Pressure Blowoff SilencersBrent100% (1)

- Auxiliary VentilationDocument20 pagesAuxiliary VentilationNikhil Asha JainNo ratings yet

- E. B. Toot Walwe Construction For Wind Musical InstrumentsDocument5 pagesE. B. Toot Walwe Construction For Wind Musical InstrumentsLmute MedioliNo ratings yet

- TEPZZ - 98957B - T: European Patent SpecificationDocument10 pagesTEPZZ - 98957B - T: European Patent Specificationzweisteine777No ratings yet

- Dec. 6, 1966 R. M. Schrmer 3,289,409: (S Tij SDocument4 pagesDec. 6, 1966 R. M. Schrmer 3,289,409: (S Tij SAncaBotocNo ratings yet

- Ported Box Enclosures Speaker SystemDocument13 pagesPorted Box Enclosures Speaker SystemSubaru_10150% (2)

- 'I Ini: March 28, l1961 .1. E. Dalgleish 2,976,679Document5 pages'I Ini: March 28, l1961 .1. E. Dalgleish 2,976,679ShameekaNo ratings yet

- Us 2993091Document5 pagesUs 2993091EduardoNo ratings yet

- Chen Noise Characteristics and Simulation of Several Full Scale Turbojet Engines at Hush-HouseDocument7 pagesChen Noise Characteristics and Simulation of Several Full Scale Turbojet Engines at Hush-HouseKen SuNo ratings yet

- Calculation of An Acoustic Phase InverterDocument7 pagesCalculation of An Acoustic Phase InverterAnonymous DjWqKpZ1No ratings yet

- Auxiliary VentilationDocument21 pagesAuxiliary Ventilationvishal prasadNo ratings yet

- Double-Tuning and Experimental Validation of Rotated-Offset Inlet-OutletDocument16 pagesDouble-Tuning and Experimental Validation of Rotated-Offset Inlet-OutletÖMER KORCAN ATEŞNo ratings yet

- Use of Dissipative SilencersDocument9 pagesUse of Dissipative SilencersmukeshkumarjNo ratings yet

- Auxiliary Ventilation in MiningDocument21 pagesAuxiliary Ventilation in Miningsharif skNo ratings yet

- United States Patent (191: (54) Vibrostimulative DeviceDocument5 pagesUnited States Patent (191: (54) Vibrostimulative Devicejalepa_esNo ratings yet

- T9 Loudspeakers: Chapter - 3Document29 pagesT9 Loudspeakers: Chapter - 3lvsaru100% (1)

- EP0229675B1Document10 pagesEP0229675B112348No ratings yet

- US3420058Document5 pagesUS3420058moonstarNo ratings yet

- Absorptive SilencersDocument5 pagesAbsorptive SilencersDaniel SmsNo ratings yet

- Acoustics Model Library ManualDocument641 pagesAcoustics Model Library ManualFernando SantosNo ratings yet

- Unlted States Patent (191 1111 3,736,693: Koch 1451 June 5, 1973Document4 pagesUnlted States Patent (191 1111 3,736,693: Koch 1451 June 5, 1973fgrt45No ratings yet

- 11111111mumnlllgglotgggglgggggnn - : United States Patent (19) (11) Patent Number: 5,613,555Document5 pages11111111mumnlllgglotgggglgggggnn - : United States Patent (19) (11) Patent Number: 5,613,555mohammadreza91No ratings yet

- Experimental and Numerical Study On A New Noise Reduction Design For A Small Axial FanDocument15 pagesExperimental and Numerical Study On A New Noise Reduction Design For A Small Axial Fan柯以祥No ratings yet

- Us4506432 PDFDocument5 pagesUs4506432 PDFchemsNo ratings yet

- US5815587Document5 pagesUS5815587Morena SlpNo ratings yet

- Noise Suppression: Fig. 19-3 Change of Exhaust Jet Pattern To Reduce Noise LevelDocument79 pagesNoise Suppression: Fig. 19-3 Change of Exhaust Jet Pattern To Reduce Noise LevelAbas NjarkhatirNo ratings yet

- Aerodynamically Induced Resonance in Rectangular Cavities: Sound VibDocument11 pagesAerodynamically Induced Resonance in Rectangular Cavities: Sound VibRehan NaseerNo ratings yet

- C147-Rindel BNAM2021 Flute AcousticsDocument17 pagesC147-Rindel BNAM2021 Flute AcousticsGöksu DirilNo ratings yet

- Soot Blower Lance Tube CorrosionDocument11 pagesSoot Blower Lance Tube CorrosionMiguel Kühnert FrichenbruderNo ratings yet

- FCU Acoustic Guide Nov09 PDFDocument18 pagesFCU Acoustic Guide Nov09 PDFprasathinusaNo ratings yet

- Technical Review 1967-4Document40 pagesTechnical Review 1967-4Aleks ProxNo ratings yet

- US20060112676A1Document7 pagesUS20060112676A1Muhammed Cm SönmezNo ratings yet

- Transactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Tests of Creosoted Timber, Paper No. 1168From EverandTransactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Tests of Creosoted Timber, Paper No. 1168No ratings yet

- US8991551Document10 pagesUS8991551Jean DelaronciereNo ratings yet

- US10228210Document24 pagesUS10228210Jean DelaronciereNo ratings yet

- US8950546Document12 pagesUS8950546Jean DelaronciereNo ratings yet

- MK 13Document5 pagesMK 13Jean DelaronciereNo ratings yet

- Krico-Folder DDocument2 pagesKrico-Folder DJean DelaronciereNo ratings yet

- EP3237829B1Document34 pagesEP3237829B1Jean DelaronciereNo ratings yet

- Doing Naval History Essays Toward Improvement (John B. Hattendorf)Document162 pagesDoing Naval History Essays Toward Improvement (John B. Hattendorf)Jean DelaronciereNo ratings yet

- Illusion 9 Manual - ManualzzDocument11 pagesIllusion 9 Manual - ManualzzJean DelaronciereNo ratings yet

- ZEISS Hunting Catalogue 2019Document43 pagesZEISS Hunting Catalogue 2019Jean DelaronciereNo ratings yet

- BA STEYR SSG 04 EU 03 Civil Eng SP 1 BA 6007 2Document112 pagesBA STEYR SSG 04 EU 03 Civil Eng SP 1 BA 6007 2Jean DelaronciereNo ratings yet

- Truck Total Vehicle, Final TestDocument10 pagesTruck Total Vehicle, Final TestPutra JawaNo ratings yet

- Campro Engine SpecificationDocument14 pagesCampro Engine SpecificationAshalena Jeffery43% (14)

- 2 Shell and Tube ExchangerDocument8 pages2 Shell and Tube ExchangerarulrakkNo ratings yet

- Operation and Maintenance Manual-1Document27 pagesOperation and Maintenance Manual-1Daniel TekleNo ratings yet

- Transmission Hydraulic Control Operation 966Document12 pagesTransmission Hydraulic Control Operation 966Walid HouranNo ratings yet

- WPS Api 1104Document85 pagesWPS Api 1104Jose nuñez100% (1)

- Pedal - Powered - Washing MachineDocument17 pagesPedal - Powered - Washing MachineFaiyu MechNo ratings yet

- Prepared By: Engr. Lucia V. Ortega 8/28/20 Statics of Rigid BodiesDocument11 pagesPrepared By: Engr. Lucia V. Ortega 8/28/20 Statics of Rigid BodiesJoren JamesNo ratings yet

- Compact Valve - 1/4: Series DS2 Manually Operated Valve - G1/4Document6 pagesCompact Valve - 1/4: Series DS2 Manually Operated Valve - G1/4gopi_krishnan_29No ratings yet

- Lift You R Con Ide Nce: WK-DW-E-1804Document16 pagesLift You R Con Ide Nce: WK-DW-E-1804Manuel PosadaNo ratings yet

- Physics OscillationsDocument16 pagesPhysics Oscillationsmohammad rihelNo ratings yet

- Chapter 2 ProblemsDocument2 pagesChapter 2 ProblemsJantzenCaliwliwNo ratings yet

- EC2 Design Tool Robin AtkinsonDocument108 pagesEC2 Design Tool Robin Atkinsoncornelo2007No ratings yet

- United States Patent (10) Patent No.: Us 7,229,250 B2: Mccallum Et Al. (45) Date of Patent: Jun. 12, 2007Document14 pagesUnited States Patent (10) Patent No.: Us 7,229,250 B2: Mccallum Et Al. (45) Date of Patent: Jun. 12, 2007Валентин ДимитровNo ratings yet

- Citroën C5: Ready To Set OffDocument2 pagesCitroën C5: Ready To Set OffLeandro MesquitaNo ratings yet

- Haldex QuickDocument84 pagesHaldex QuickAndherson DasilvaNo ratings yet

- Asco Sintering ISO 9001:2000: ConfidentialDocument3 pagesAsco Sintering ISO 9001:2000: ConfidentialsachNo ratings yet

- Stainless Steel Standard Knife Gate ValvesDocument18 pagesStainless Steel Standard Knife Gate ValvescmontminyNo ratings yet

- Made by Techni SA Athens GreeceDocument24 pagesMade by Techni SA Athens Greeceشرف نعيمNo ratings yet

- Roller Chain MaintenanceDocument8 pagesRoller Chain MaintenanceRodrigo SenedezeNo ratings yet

- Develoment of A High-Speed Cryogenic Tribometer Design Concept and Experimental ResultsDocument8 pagesDeveloment of A High-Speed Cryogenic Tribometer Design Concept and Experimental ResultsDavid Rafael RamírezNo ratings yet

- UMC-1000 SS PP Layout Drawing 2019-11BDocument7 pagesUMC-1000 SS PP Layout Drawing 2019-11BHau Le TrungNo ratings yet

- Statistical Mechanics Notes: Leonard Susskind's LecturesDocument21 pagesStatistical Mechanics Notes: Leonard Susskind's LecturesWycliffe OmwansuNo ratings yet

- Self Balancing RobotDocument10 pagesSelf Balancing RobotVasu RockstarNo ratings yet

- Vanos Timing Adjustment InstructionsDocument61 pagesVanos Timing Adjustment InstructionsGerardo Degollado0% (1)

- TJ 1710 Brochure RusDocument8 pagesTJ 1710 Brochure Rustystar_21No ratings yet