Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

4 views1 Preliminary Considerations: 1.1 Mechanical Characteristics of Steel

1 Preliminary Considerations: 1.1 Mechanical Characteristics of Steel

Uploaded by

Bill H1. When a tensile load is applied to a steel specimen, the relationship between stress and strain forms a curve with three distinct regions: an initial linear elastic region, a yielding region of large deformations at near-constant stress, and a hardening region of increasing stress with further deformation.

2. The yield strength represents the stress at which the material starts to yield permanently rather than elastically. It is the most significant parameter for characterizing the mechanical properties of steel.

3. For calculations, the stress-strain curve can be simplified to two linear segments, with an initial elastic segment followed by a horizontal plastic segment, representing the steel's elastic and plastic behaviors respectively. This simplified model is commonly used

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Verbal (Non Verbal) Therapeutic Communication Technique Used Rationale and Feelings of Nurse EvaluationDocument13 pagesVerbal (Non Verbal) Therapeutic Communication Technique Used Rationale and Feelings of Nurse EvaluationLei Ortega80% (10)

- The UK Property Portals Industry Porter's Five Forces AnalysisDocument1 pageThe UK Property Portals Industry Porter's Five Forces AnalysisBoghiu Z0% (1)

- .Aku 1597472083000Document2 pages.Aku 1597472083000Josa Itz Constantine100% (2)

- 4 - Mechanical Properties of MaterialsDocument28 pages4 - Mechanical Properties of MaterialsYusf ari jerjisNo ratings yet

- Stress Strain CurveDocument4 pagesStress Strain Curvekirandasi123No ratings yet

- Stress-Strain CurveDocument7 pagesStress-Strain CurveR BNo ratings yet

- Fig.1 Stress-Strain Curve Typical of A Low Carbon SteelDocument7 pagesFig.1 Stress-Strain Curve Typical of A Low Carbon SteelFredNo ratings yet

- Stress Strain Curve ExplanationDocument8 pagesStress Strain Curve ExplanationGptc Chekkanurani0% (1)

- L in Which It Was Measured, Thereby Obtaining: Chapter 2 - Simple Strain 2-A. IntroductionDocument8 pagesL in Which It Was Measured, Thereby Obtaining: Chapter 2 - Simple Strain 2-A. IntroductionJasleneDimarananNo ratings yet

- Stress Strain CurveDocument16 pagesStress Strain CurveMedakayala Nagasravanthi 20PHD7125No ratings yet

- Stress Strain DiagramDocument4 pagesStress Strain DiagramMartine CastroNo ratings yet

- PowerPoint PresentationDocument65 pagesPowerPoint PresentationMRIDUL SINGLA100% (1)

- Stress Strain CurveDocument4 pagesStress Strain CurveTherese Kyle LauritoNo ratings yet

- Mechanics of Materials II: UET, Taxila Lecture No.Document48 pagesMechanics of Materials II: UET, Taxila Lecture No.danemsalNo ratings yet

- Mechanical Properties of MetalsDocument15 pagesMechanical Properties of MetalsLaurence Bande Del RosarioNo ratings yet

- Material Properties ReportDocument8 pagesMaterial Properties ReportazizsaafanNo ratings yet

- Simple Stress and StrainDocument4 pagesSimple Stress and StrainDarius MegamindNo ratings yet

- Lecture 4Document45 pagesLecture 4SAIF ULLAHNo ratings yet

- Brockenbrough. Structural Steel Designer's Handbook 3ed - Parte7Document5 pagesBrockenbrough. Structural Steel Designer's Handbook 3ed - Parte7Nicolás GuerreroNo ratings yet

- Mechanical Properties of Materials - MechaniCalcDocument11 pagesMechanical Properties of Materials - MechaniCalcharieduidNo ratings yet

- CHAPTER FOUR: Mechanical Properties of MaterialsDocument9 pagesCHAPTER FOUR: Mechanical Properties of Materialsيسرى عامر صبيحNo ratings yet

- Stress-Strain Diagram (Curve)Document4 pagesStress-Strain Diagram (Curve)kevinNo ratings yet

- Assignment No. 5 JJJJJJDocument9 pagesAssignment No. 5 JJJJJJNicholas Bonn SingNo ratings yet

- Street Strain CurveDocument2 pagesStreet Strain CurveAnamika YadavNo ratings yet

- CH 2Document45 pagesCH 2Said EliasNo ratings yet

- Corrected True Stress - True Strain CurvDocument3 pagesCorrected True Stress - True Strain CurvPunith MlNo ratings yet

- Strength of materialCHAPTER 1Document29 pagesStrength of materialCHAPTER 1Hiwot DemisseNo ratings yet

- Stress and StrainDocument12 pagesStress and StrainZewdieNo ratings yet

- ENCI 317 - LAB 1 - Lab MaterialDocument15 pagesENCI 317 - LAB 1 - Lab MaterialSherry YousafNo ratings yet

- Mechanical Properties of MetalsDocument258 pagesMechanical Properties of MetalsIsza Marie N. SocorinNo ratings yet

- Stresses and Strains PDFDocument44 pagesStresses and Strains PDFAnvi JainNo ratings yet

- HOME ASSIGNMENT 2 (AutoRecovered)Document15 pagesHOME ASSIGNMENT 2 (AutoRecovered)ATIF KHANNo ratings yet

- Stress Strain CurveDocument12 pagesStress Strain CurveGlerommie CastroNo ratings yet

- GET 208 Lecture Note 1Document6 pagesGET 208 Lecture Note 1Jehu RanyangNo ratings yet

- Stress and Strain - Class 1Document21 pagesStress and Strain - Class 1Ahmad AliyuNo ratings yet

- Imot 2176 Tensile PropertiesDocument4 pagesImot 2176 Tensile PropertiesEry KuswantoroNo ratings yet

- Mechanical PropertiesDocument25 pagesMechanical PropertiesUmesh ChandraNo ratings yet

- force (that is, the force per unit area) is called the stress and is commonly denoted by the Greek letter σ (Sigma)Document11 pagesforce (that is, the force per unit area) is called the stress and is commonly denoted by the Greek letter σ (Sigma)Tolera GutuNo ratings yet

- Unit-1 Mechanical PropertiesDocument51 pagesUnit-1 Mechanical PropertieskameshvvNo ratings yet

- Chapter 1Document9 pagesChapter 1TemesgenAbiyNo ratings yet

- Strength of Materials (15CV 32) : Module 1: Simple Stresses and StrainsDocument34 pagesStrength of Materials (15CV 32) : Module 1: Simple Stresses and StrainsAnonymous Qm0zbNkNo ratings yet

- Lecture 11Document6 pagesLecture 11Mechanical ZombieNo ratings yet

- BucklingDocument8 pagesBucklingalphading100% (1)

- Tension Long RevisedDocument19 pagesTension Long RevisedNiraj ThakkerNo ratings yet

- 06 Deformation in A System of Axially Loaded Members StudentsDocument5 pages06 Deformation in A System of Axially Loaded Members StudentsEJ GonzalesNo ratings yet

- Chapter 1-ElasticityDocument34 pagesChapter 1-ElasticityGüneş DilberNo ratings yet

- Publication 1 5775 569Document22 pagesPublication 1 5775 569Abdalmalek ShamsanNo ratings yet

- CE 323/ BES 222 Mechanics of Deformable Bodies: Chapter 2 - StrainDocument6 pagesCE 323/ BES 222 Mechanics of Deformable Bodies: Chapter 2 - StrainNadlor Gasco OzausNo ratings yet

- Strength of MweeaterialsDocument7 pagesStrength of MweeaterialsChristianNo ratings yet

- Unit 1 Consolidated-1Document16 pagesUnit 1 Consolidated-1vijayakumarNo ratings yet

- Mechanical Properties of MetalsDocument16 pagesMechanical Properties of MetalsShione T MundawararaNo ratings yet

- Stress - Strain Curve of Ductile Material Under TensionDocument4 pagesStress - Strain Curve of Ductile Material Under TensionKshitiz RawatNo ratings yet

- Mechanics of MaterialsDocument31 pagesMechanics of Materialsps4haris.ch3534No ratings yet

- Strength of Materials (15CV 32) : Module 1: Simple Stresses and StrainsDocument34 pagesStrength of Materials (15CV 32) : Module 1: Simple Stresses and Strainscoolguyraj.bkNo ratings yet

- Unit 1Document30 pagesUnit 1lakshmi narayanaNo ratings yet

- Chapter 1 Simple StressDocument13 pagesChapter 1 Simple Stressمصطفى احمد محيسنNo ratings yet

- Unit 5 Metal: Topic OutlineDocument13 pagesUnit 5 Metal: Topic OutlineIvyy Joyce BuanNo ratings yet

- Ch3. Stress and StrainsDocument49 pagesCh3. Stress and StrainsAbimael wendimuNo ratings yet

- The Mechanical Properties of Wood: Including a Discussion of the Factors Affecting the Mechanical Properties, and Methods of Timber TestingFrom EverandThe Mechanical Properties of Wood: Including a Discussion of the Factors Affecting the Mechanical Properties, and Methods of Timber TestingNo ratings yet

- Theory of Elastisity, Stability and Dynamics of Structures Common ProblemsFrom EverandTheory of Elastisity, Stability and Dynamics of Structures Common ProblemsNo ratings yet

- Battery Cooling Techniques in Electric Vehicle CFD Flow EngineeringDocument31 pagesBattery Cooling Techniques in Electric Vehicle CFD Flow EngineeringBill HNo ratings yet

- Corrosion Behavior of Different Alloys in Industrial MediaDocument9 pagesCorrosion Behavior of Different Alloys in Industrial MediaBill HNo ratings yet

- IJISET - Thermal Analysis of SSHEDocument6 pagesIJISET - Thermal Analysis of SSHEBill HNo ratings yet

- AmmoniaDocument4 pagesAmmoniaBill HNo ratings yet

- 19/05/2021 Visit Date 39Y/Male Age & Gender Med110222452 Customerid MR.L Venkatachalam CustomernameDocument5 pages19/05/2021 Visit Date 39Y/Male Age & Gender Med110222452 Customerid MR.L Venkatachalam Customernamesyed imranNo ratings yet

- JournalsDocument9 pagesJournalsapi-302089675No ratings yet

- White Paper Introduction of SAP GTS - The Customs Solution: SapstroomDocument7 pagesWhite Paper Introduction of SAP GTS - The Customs Solution: SapstroomRafael RibNo ratings yet

- American Government Pre-TestDocument3 pagesAmerican Government Pre-TestMatt HasquinNo ratings yet

- Enhance PYPDocument29 pagesEnhance PYPRumana ChowdhuryNo ratings yet

- Test 3 MаrlinsDocument2 pagesTest 3 MаrlinsStaicy ErmakovitchNo ratings yet

- Fiitjee Leader Recr 2015Document1 pageFiitjee Leader Recr 2015Mahesh BabuNo ratings yet

- Primordial Perpetuity 2 - The Small Book of Answers For The WAY OUT!!Document158 pagesPrimordial Perpetuity 2 - The Small Book of Answers For The WAY OUT!!The Nacre GodNo ratings yet

- Short Story Analysis - The Doctor's Word by R.K. NarayanDocument1 pageShort Story Analysis - The Doctor's Word by R.K. Narayanjay pal0% (1)

- Sphera PHA Pro BrochureDocument2 pagesSphera PHA Pro BrochurefarinaNo ratings yet

- Comparative Reviewer of Corporation CodeDocument2 pagesComparative Reviewer of Corporation CodelawNo ratings yet

- RDS ManualDocument105 pagesRDS ManualSuwatchai SittipanichNo ratings yet

- Core, Care, Cure ModelDocument33 pagesCore, Care, Cure ModelThushara Krishnas50% (2)

- Different Approaches To Atopic Dermatitis by Allergists, Dermatologists, and PediatriciansDocument9 pagesDifferent Approaches To Atopic Dermatitis by Allergists, Dermatologists, and PediatriciansyelsiNo ratings yet

- Irregular Siap PrintDocument3 pagesIrregular Siap PrintGerald TeufNo ratings yet

- Deer HitDocument6 pagesDeer HitTiffany HorsfordNo ratings yet

- The Actor and The Theatre: Week 6 (Part 3) Introduction To Theatre College of The DesertDocument13 pagesThe Actor and The Theatre: Week 6 (Part 3) Introduction To Theatre College of The DesertBradley BesterNo ratings yet

- The Family Law Act 1975 (CWLTH)Document6 pagesThe Family Law Act 1975 (CWLTH)lankaz_finestNo ratings yet

- Exercise 1 - Metacognitive Reading ReportDocument1 pageExercise 1 - Metacognitive Reading ReportKhaizer D AmilNo ratings yet

- End-Time Events and The Last Generation by George R Knight Z-LiborgDocument138 pagesEnd-Time Events and The Last Generation by George R Knight Z-LiborgyaneciticaNo ratings yet

- Scaffolding: Larkin, M. (2002) - Using Scaffolded Instruction To Optimize Learning. ERIC DigestDocument2 pagesScaffolding: Larkin, M. (2002) - Using Scaffolded Instruction To Optimize Learning. ERIC DigestYong WangNo ratings yet

- Nutrition Support in Critically Ill PatientDocument19 pagesNutrition Support in Critically Ill PatienttantoNo ratings yet

- Course OutlineDocument2 pagesCourse Outlinenoman vadsariyaNo ratings yet

- Schwa Worksheets 1Document5 pagesSchwa Worksheets 1mohammedNo ratings yet

- CV - Ani CuedariDocument5 pagesCV - Ani CuedariCVsMH17competitionNo ratings yet

- Manual de Motor Fuera de Borda Mercury XP 115 ProDocument150 pagesManual de Motor Fuera de Borda Mercury XP 115 ProGestión De MantenimientoNo ratings yet

- 2017 Catalog PDFDocument60 pages2017 Catalog PDFHasnain KanchwalaNo ratings yet

1 Preliminary Considerations: 1.1 Mechanical Characteristics of Steel

1 Preliminary Considerations: 1.1 Mechanical Characteristics of Steel

Uploaded by

Bill H0 ratings0% found this document useful (0 votes)

4 views2 pages1. When a tensile load is applied to a steel specimen, the relationship between stress and strain forms a curve with three distinct regions: an initial linear elastic region, a yielding region of large deformations at near-constant stress, and a hardening region of increasing stress with further deformation.

2. The yield strength represents the stress at which the material starts to yield permanently rather than elastically. It is the most significant parameter for characterizing the mechanical properties of steel.

3. For calculations, the stress-strain curve can be simplified to two linear segments, with an initial elastic segment followed by a horizontal plastic segment, representing the steel's elastic and plastic behaviors respectively. This simplified model is commonly used

Original Description:

Original Title

978-3-540-49144-6_1

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1. When a tensile load is applied to a steel specimen, the relationship between stress and strain forms a curve with three distinct regions: an initial linear elastic region, a yielding region of large deformations at near-constant stress, and a hardening region of increasing stress with further deformation.

2. The yield strength represents the stress at which the material starts to yield permanently rather than elastically. It is the most significant parameter for characterizing the mechanical properties of steel.

3. For calculations, the stress-strain curve can be simplified to two linear segments, with an initial elastic segment followed by a horizontal plastic segment, representing the steel's elastic and plastic behaviors respectively. This simplified model is commonly used

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

4 views2 pages1 Preliminary Considerations: 1.1 Mechanical Characteristics of Steel

1 Preliminary Considerations: 1.1 Mechanical Characteristics of Steel

Uploaded by

Bill H1. When a tensile load is applied to a steel specimen, the relationship between stress and strain forms a curve with three distinct regions: an initial linear elastic region, a yielding region of large deformations at near-constant stress, and a hardening region of increasing stress with further deformation.

2. The yield strength represents the stress at which the material starts to yield permanently rather than elastically. It is the most significant parameter for characterizing the mechanical properties of steel.

3. For calculations, the stress-strain curve can be simplified to two linear segments, with an initial elastic segment followed by a horizontal plastic segment, representing the steel's elastic and plastic behaviors respectively. This simplified model is commonly used

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

1

Preliminary Considerations

1.1 Mechanical Characteristics of Steel

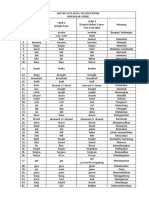

If we exert a tensile load on a specimen made of mild carbon steel, and we

transfer on the x-axis the values of the elongation per unit of length between

the references (ε) (called strain) and on the y-axis the values of the stress

(σ) that equals the load applied to the specimen divided by its original cross-

sectional area, we obtain a diagram qualitatively similar to the one shown in

Fig. 1.1.

We notice that there is proportionality between stress and strain in the

first portion of the curve, i.e., the steel follows Hooke’s law that constitutes

the basis of classic calculation in the elastic field. In fact, the steel behaves in

an elastic fashion, i.e., the deformations completely disappear after removal

of the load, and the specimen returns to its original shape.

The angular coefficient E of the straight portion given by the relationship

σ/ε is called modulus of elasticity, or Young’s modulus. The point on the

curve at the end of the linear section identifies a value of σ which is called

proportional limit.

Steel behaves in an elastic fashion even beyond the proportional limit,

as long as another characteristic point corresponding to stress called elastic

limit is not exceeded. Note that the two points mentioned above are near, and

the second one is not easy to determine. In practice, we typically equate the

proportional limit to the elastic limit.

By increasing the load applied to the specimen, we reach a point on the

curve corresponding to a stress σ, called upper yield strength, that represents

the maximum value of σ taking place at the onset of the yielding phenomenon.

In fact, after reaching the upper yield strength the load decreases, and we

reach a relative minimum of the curve that identifies the stress called lower

yield strength.

The yielding phenomenon is characterized by large deformations (when

compared to those typical of the elasticity field) under practically constant

load.

2 1 Preliminary Considerations

Fig. 1.1

This portion of the curve is then followed by a portion characterized by

progressive increase in stress with large deformations. This is the well-known

phenomenon of steel hardening, which persists until the stress reaches a maxi-

mum value called ultimate strength. After that σ decreases (again with regard

to the original cross-sectional area of the specimen), and we reach rupture.

Conversely, if we consider the actual cross-sectional area of the specimen in

the different stages, the highest value of σ is reached in correspondence with

the rupture point. In fact, substantial elongations in correspondence with

yielding and hardening areas happen together with a significant reduction of

the cross-sectional area.

The lower value of the yield strength (simply known as “yield strength,”

σs ) and the maximum value of σ that precedes the rupture are the most

significant parameters of the steel’s mechanical properties, and are therefore

indicated in test certificates and represent the basis of resistance calculus.

The yield strength basically shows the condition under which the material

starts yielding. At this point, the yielded fiber is not able to absorb growing

stresses, and thus to contribute to the equilibrium of forces applied to the

vessel. This is because we rule out the possibility that under safety conditions

the deformations become so large that one is forced to consider the hardening

phenomenon.

The fiber can be plastic deformed and, as we shall see, this has an

important impact on the behavior of neighboring fibers, if we start from the

assumption that they have not yet reached the yield strength. This leads to

a different kind of calculation, somewhat different from the classic one based

on the elasticity behavior of the entire component.

In view of the above considerations, one can replace the curve in Fig. 1.1

with that in Fig. 1.2, whereas in a first segment σ is proportional to ε (totally

elastic behavior of material) followed by a segment parallel to the x-axis (per-

fectly plastic behavior of the material). Such simplification is most frequently

used for resistance verification in the elastic–plastic field.

You might also like

- Verbal (Non Verbal) Therapeutic Communication Technique Used Rationale and Feelings of Nurse EvaluationDocument13 pagesVerbal (Non Verbal) Therapeutic Communication Technique Used Rationale and Feelings of Nurse EvaluationLei Ortega80% (10)

- The UK Property Portals Industry Porter's Five Forces AnalysisDocument1 pageThe UK Property Portals Industry Porter's Five Forces AnalysisBoghiu Z0% (1)

- .Aku 1597472083000Document2 pages.Aku 1597472083000Josa Itz Constantine100% (2)

- 4 - Mechanical Properties of MaterialsDocument28 pages4 - Mechanical Properties of MaterialsYusf ari jerjisNo ratings yet

- Stress Strain CurveDocument4 pagesStress Strain Curvekirandasi123No ratings yet

- Stress-Strain CurveDocument7 pagesStress-Strain CurveR BNo ratings yet

- Fig.1 Stress-Strain Curve Typical of A Low Carbon SteelDocument7 pagesFig.1 Stress-Strain Curve Typical of A Low Carbon SteelFredNo ratings yet

- Stress Strain Curve ExplanationDocument8 pagesStress Strain Curve ExplanationGptc Chekkanurani0% (1)

- L in Which It Was Measured, Thereby Obtaining: Chapter 2 - Simple Strain 2-A. IntroductionDocument8 pagesL in Which It Was Measured, Thereby Obtaining: Chapter 2 - Simple Strain 2-A. IntroductionJasleneDimarananNo ratings yet

- Stress Strain CurveDocument16 pagesStress Strain CurveMedakayala Nagasravanthi 20PHD7125No ratings yet

- Stress Strain DiagramDocument4 pagesStress Strain DiagramMartine CastroNo ratings yet

- PowerPoint PresentationDocument65 pagesPowerPoint PresentationMRIDUL SINGLA100% (1)

- Stress Strain CurveDocument4 pagesStress Strain CurveTherese Kyle LauritoNo ratings yet

- Mechanics of Materials II: UET, Taxila Lecture No.Document48 pagesMechanics of Materials II: UET, Taxila Lecture No.danemsalNo ratings yet

- Mechanical Properties of MetalsDocument15 pagesMechanical Properties of MetalsLaurence Bande Del RosarioNo ratings yet

- Material Properties ReportDocument8 pagesMaterial Properties ReportazizsaafanNo ratings yet

- Simple Stress and StrainDocument4 pagesSimple Stress and StrainDarius MegamindNo ratings yet

- Lecture 4Document45 pagesLecture 4SAIF ULLAHNo ratings yet

- Brockenbrough. Structural Steel Designer's Handbook 3ed - Parte7Document5 pagesBrockenbrough. Structural Steel Designer's Handbook 3ed - Parte7Nicolás GuerreroNo ratings yet

- Mechanical Properties of Materials - MechaniCalcDocument11 pagesMechanical Properties of Materials - MechaniCalcharieduidNo ratings yet

- CHAPTER FOUR: Mechanical Properties of MaterialsDocument9 pagesCHAPTER FOUR: Mechanical Properties of Materialsيسرى عامر صبيحNo ratings yet

- Stress-Strain Diagram (Curve)Document4 pagesStress-Strain Diagram (Curve)kevinNo ratings yet

- Assignment No. 5 JJJJJJDocument9 pagesAssignment No. 5 JJJJJJNicholas Bonn SingNo ratings yet

- Street Strain CurveDocument2 pagesStreet Strain CurveAnamika YadavNo ratings yet

- CH 2Document45 pagesCH 2Said EliasNo ratings yet

- Corrected True Stress - True Strain CurvDocument3 pagesCorrected True Stress - True Strain CurvPunith MlNo ratings yet

- Strength of materialCHAPTER 1Document29 pagesStrength of materialCHAPTER 1Hiwot DemisseNo ratings yet

- Stress and StrainDocument12 pagesStress and StrainZewdieNo ratings yet

- ENCI 317 - LAB 1 - Lab MaterialDocument15 pagesENCI 317 - LAB 1 - Lab MaterialSherry YousafNo ratings yet

- Mechanical Properties of MetalsDocument258 pagesMechanical Properties of MetalsIsza Marie N. SocorinNo ratings yet

- Stresses and Strains PDFDocument44 pagesStresses and Strains PDFAnvi JainNo ratings yet

- HOME ASSIGNMENT 2 (AutoRecovered)Document15 pagesHOME ASSIGNMENT 2 (AutoRecovered)ATIF KHANNo ratings yet

- Stress Strain CurveDocument12 pagesStress Strain CurveGlerommie CastroNo ratings yet

- GET 208 Lecture Note 1Document6 pagesGET 208 Lecture Note 1Jehu RanyangNo ratings yet

- Stress and Strain - Class 1Document21 pagesStress and Strain - Class 1Ahmad AliyuNo ratings yet

- Imot 2176 Tensile PropertiesDocument4 pagesImot 2176 Tensile PropertiesEry KuswantoroNo ratings yet

- Mechanical PropertiesDocument25 pagesMechanical PropertiesUmesh ChandraNo ratings yet

- force (that is, the force per unit area) is called the stress and is commonly denoted by the Greek letter σ (Sigma)Document11 pagesforce (that is, the force per unit area) is called the stress and is commonly denoted by the Greek letter σ (Sigma)Tolera GutuNo ratings yet

- Unit-1 Mechanical PropertiesDocument51 pagesUnit-1 Mechanical PropertieskameshvvNo ratings yet

- Chapter 1Document9 pagesChapter 1TemesgenAbiyNo ratings yet

- Strength of Materials (15CV 32) : Module 1: Simple Stresses and StrainsDocument34 pagesStrength of Materials (15CV 32) : Module 1: Simple Stresses and StrainsAnonymous Qm0zbNkNo ratings yet

- Lecture 11Document6 pagesLecture 11Mechanical ZombieNo ratings yet

- BucklingDocument8 pagesBucklingalphading100% (1)

- Tension Long RevisedDocument19 pagesTension Long RevisedNiraj ThakkerNo ratings yet

- 06 Deformation in A System of Axially Loaded Members StudentsDocument5 pages06 Deformation in A System of Axially Loaded Members StudentsEJ GonzalesNo ratings yet

- Chapter 1-ElasticityDocument34 pagesChapter 1-ElasticityGüneş DilberNo ratings yet

- Publication 1 5775 569Document22 pagesPublication 1 5775 569Abdalmalek ShamsanNo ratings yet

- CE 323/ BES 222 Mechanics of Deformable Bodies: Chapter 2 - StrainDocument6 pagesCE 323/ BES 222 Mechanics of Deformable Bodies: Chapter 2 - StrainNadlor Gasco OzausNo ratings yet

- Strength of MweeaterialsDocument7 pagesStrength of MweeaterialsChristianNo ratings yet

- Unit 1 Consolidated-1Document16 pagesUnit 1 Consolidated-1vijayakumarNo ratings yet

- Mechanical Properties of MetalsDocument16 pagesMechanical Properties of MetalsShione T MundawararaNo ratings yet

- Stress - Strain Curve of Ductile Material Under TensionDocument4 pagesStress - Strain Curve of Ductile Material Under TensionKshitiz RawatNo ratings yet

- Mechanics of MaterialsDocument31 pagesMechanics of Materialsps4haris.ch3534No ratings yet

- Strength of Materials (15CV 32) : Module 1: Simple Stresses and StrainsDocument34 pagesStrength of Materials (15CV 32) : Module 1: Simple Stresses and Strainscoolguyraj.bkNo ratings yet

- Unit 1Document30 pagesUnit 1lakshmi narayanaNo ratings yet

- Chapter 1 Simple StressDocument13 pagesChapter 1 Simple Stressمصطفى احمد محيسنNo ratings yet

- Unit 5 Metal: Topic OutlineDocument13 pagesUnit 5 Metal: Topic OutlineIvyy Joyce BuanNo ratings yet

- Ch3. Stress and StrainsDocument49 pagesCh3. Stress and StrainsAbimael wendimuNo ratings yet

- The Mechanical Properties of Wood: Including a Discussion of the Factors Affecting the Mechanical Properties, and Methods of Timber TestingFrom EverandThe Mechanical Properties of Wood: Including a Discussion of the Factors Affecting the Mechanical Properties, and Methods of Timber TestingNo ratings yet

- Theory of Elastisity, Stability and Dynamics of Structures Common ProblemsFrom EverandTheory of Elastisity, Stability and Dynamics of Structures Common ProblemsNo ratings yet

- Battery Cooling Techniques in Electric Vehicle CFD Flow EngineeringDocument31 pagesBattery Cooling Techniques in Electric Vehicle CFD Flow EngineeringBill HNo ratings yet

- Corrosion Behavior of Different Alloys in Industrial MediaDocument9 pagesCorrosion Behavior of Different Alloys in Industrial MediaBill HNo ratings yet

- IJISET - Thermal Analysis of SSHEDocument6 pagesIJISET - Thermal Analysis of SSHEBill HNo ratings yet

- AmmoniaDocument4 pagesAmmoniaBill HNo ratings yet

- 19/05/2021 Visit Date 39Y/Male Age & Gender Med110222452 Customerid MR.L Venkatachalam CustomernameDocument5 pages19/05/2021 Visit Date 39Y/Male Age & Gender Med110222452 Customerid MR.L Venkatachalam Customernamesyed imranNo ratings yet

- JournalsDocument9 pagesJournalsapi-302089675No ratings yet

- White Paper Introduction of SAP GTS - The Customs Solution: SapstroomDocument7 pagesWhite Paper Introduction of SAP GTS - The Customs Solution: SapstroomRafael RibNo ratings yet

- American Government Pre-TestDocument3 pagesAmerican Government Pre-TestMatt HasquinNo ratings yet

- Enhance PYPDocument29 pagesEnhance PYPRumana ChowdhuryNo ratings yet

- Test 3 MаrlinsDocument2 pagesTest 3 MаrlinsStaicy ErmakovitchNo ratings yet

- Fiitjee Leader Recr 2015Document1 pageFiitjee Leader Recr 2015Mahesh BabuNo ratings yet

- Primordial Perpetuity 2 - The Small Book of Answers For The WAY OUT!!Document158 pagesPrimordial Perpetuity 2 - The Small Book of Answers For The WAY OUT!!The Nacre GodNo ratings yet

- Short Story Analysis - The Doctor's Word by R.K. NarayanDocument1 pageShort Story Analysis - The Doctor's Word by R.K. Narayanjay pal0% (1)

- Sphera PHA Pro BrochureDocument2 pagesSphera PHA Pro BrochurefarinaNo ratings yet

- Comparative Reviewer of Corporation CodeDocument2 pagesComparative Reviewer of Corporation CodelawNo ratings yet

- RDS ManualDocument105 pagesRDS ManualSuwatchai SittipanichNo ratings yet

- Core, Care, Cure ModelDocument33 pagesCore, Care, Cure ModelThushara Krishnas50% (2)

- Different Approaches To Atopic Dermatitis by Allergists, Dermatologists, and PediatriciansDocument9 pagesDifferent Approaches To Atopic Dermatitis by Allergists, Dermatologists, and PediatriciansyelsiNo ratings yet

- Irregular Siap PrintDocument3 pagesIrregular Siap PrintGerald TeufNo ratings yet

- Deer HitDocument6 pagesDeer HitTiffany HorsfordNo ratings yet

- The Actor and The Theatre: Week 6 (Part 3) Introduction To Theatre College of The DesertDocument13 pagesThe Actor and The Theatre: Week 6 (Part 3) Introduction To Theatre College of The DesertBradley BesterNo ratings yet

- The Family Law Act 1975 (CWLTH)Document6 pagesThe Family Law Act 1975 (CWLTH)lankaz_finestNo ratings yet

- Exercise 1 - Metacognitive Reading ReportDocument1 pageExercise 1 - Metacognitive Reading ReportKhaizer D AmilNo ratings yet

- End-Time Events and The Last Generation by George R Knight Z-LiborgDocument138 pagesEnd-Time Events and The Last Generation by George R Knight Z-LiborgyaneciticaNo ratings yet

- Scaffolding: Larkin, M. (2002) - Using Scaffolded Instruction To Optimize Learning. ERIC DigestDocument2 pagesScaffolding: Larkin, M. (2002) - Using Scaffolded Instruction To Optimize Learning. ERIC DigestYong WangNo ratings yet

- Nutrition Support in Critically Ill PatientDocument19 pagesNutrition Support in Critically Ill PatienttantoNo ratings yet

- Course OutlineDocument2 pagesCourse Outlinenoman vadsariyaNo ratings yet

- Schwa Worksheets 1Document5 pagesSchwa Worksheets 1mohammedNo ratings yet

- CV - Ani CuedariDocument5 pagesCV - Ani CuedariCVsMH17competitionNo ratings yet

- Manual de Motor Fuera de Borda Mercury XP 115 ProDocument150 pagesManual de Motor Fuera de Borda Mercury XP 115 ProGestión De MantenimientoNo ratings yet

- 2017 Catalog PDFDocument60 pages2017 Catalog PDFHasnain KanchwalaNo ratings yet