Professional Documents

Culture Documents

المحاضره الاولي ماشين 1

المحاضره الاولي ماشين 1

Uploaded by

Ahmed GamalOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

المحاضره الاولي ماشين 1

المحاضره الاولي ماشين 1

Uploaded by

Ahmed GamalCopyright:

Available Formats

Electrical Machines (1)

[ELC 218]

Spring 2022

Dr. Hany S. E. Mansour

Electrical Engineering Department, Faculty of Engineering, Suez Canal University

Email: hany_salem@eng.suez.edu.eg

Phone: 010 243 27 200

Contents

Chapter 1: Electro Magnetic Circuits

Chapter 2: Single Phase Transformers

Chapter 3: Three Phase Transformers

Chapter 4: DC Generator

Chapter 5: DC Motors

Dr. Hany S. E. Mansour Electrical Machines (1) Lec. #1 2

References

Dr. Hany S. E. Mansour Electrical Machines (1) Lec. #1 3

Assessment

Attendance 5

Midterm Exam 25

Tasks 10

Oral Exam 10

Final Exam 50

Total 100

Dr. Hany S. E. Mansour Electrical Machines (1) Lec. #1 4

Chapter One

Electro Magnetic Circuits

Dr. Hany S. E. Mansour Electrical Machines (1) Lec. #1 5

Comparison between Magnetic and Electric Circuits

Dr. Hany S. E. Mansour Electrical Machines (1) Lec. #1 6

Similarity between Magnetic and Electric Circuits

Dr. Hany S. E. Mansour Electrical Machines (1) Lec. #1 7

The Difference between Magnetic and Electric Circuits

Dr. Hany S. E. Mansour Electrical Machines (1) Lec. #1 8

Magnetic Circuit and its Analysis

➢ The closed path followed by magnetic flux is called a magnetic circuit.

➢ When current I ampere is passed through the solenoid, magnetic flux

𝜑 Wb is set-up in the core.

➢ Let l = mean length of magnetic circuit in m; a = area of cross-section of

core in m2; µr= relative permeability of core material.

➢ Flux density in the core material, B = 𝜑 / a Wb/m2

➢ Magnetizing force in the core material.

➢ According to work law, the work done in moving a unit pole once round the magnetic circuit

(or path) is equal to the ampere-turns enclosed by the magnetic circuit.

Dr. Hany S. E. Mansour Electrical Machines (1) Lec. #1 9

Magnetic Circuit and its Analysis

➢ The previous expression reveals that the amount of flux set-up in the core is:

✓ Directly proportional to N and I i.e., NI, called magnetomotive force (mmf). It shows that

the flux increases if either of the two increases and vice-versa.

✓ Inversely proportional to (l/a µ0 µr ) called reluctance of the magnetic path. In fact,

reluctance is the opposition offered to the magnetic flux by the magnetic path. The lower is

the reluctance, the higher will be the flux and vice-versa.

Dr. Hany S. E. Mansour Electrical Machines (1) Lec. #1 10

Important Terms

➢ Magnetic field:

✓ It is the region around a magnet where its poles exhibit a force of attraction or repulsion.

➢ Magnetic flux (𝝋):

✓ It is the amount of magnetic lines of force set-up in a magnetic circuit.

✓ Its unit is weber (Wb).

✓ It is analogous to electric current I in electric circuit.

➢ The magnetic flux density at a point (B):

✓ It is the flux per unit area at right angles to the flux at that point.

✓ Its unit is Wb/m2 or Tesla, i.e., B = 𝜑/A Wb/m2 or T.

Dr. Hany S. E. Mansour Electrical Machines (1) Lec. #1 11

Important Terms

➢ Permeability:

✓ It is the ability of a material to conduct magnetic lines of force through it.

➢ Relative permeability µr:

✓ It is the ratio of the permeability of material µ to the permeability of air or vacuum µ0.

Dr. Hany S. E. Mansour Electrical Machines (1) Lec. #1 12

Important Terms

➢ Magnetic field intensity (H):

✓ It is the force experienced by the unit north pole at that point.

✓ In simple terms, it is a measure of how strong or weak any magnetic field is.

✓ In magnetic circuits, it is defined as mmf per unit length of the magnetic path.

➢ Magnetomotive force (mmf):

✓ The magnetic pressure which sets-up or tends to set-up magnetic flux in a magnetic

circuit.

Dr. Hany S. E. Mansour Electrical Machines (1) Lec. #1 13

Important Terms

➢ Reluctance (S):

✓ The opposition offered to the magnetic flux by a magnetic circuit.

✓ It is measured in AT/Wb.

➢ Permeance:

✓ It is a measure of the ease with which flux can be set-up in the material.

✓ It is just reciprocal of reluctance of the material.

✓ It is measured in Wb/AT or henry.

➢ Reluctivity: It is specific reluctance and analogous to resistivity in electric circuit.

Dr. Hany S. E. Mansour Electrical Machines (1) Lec. #1 14

Leakage Flux – Fringing Effect

➢ The magnetic flux which does not follow the intended path in a

magnetic circuit is called leakage flux.

➢ Total flux produced by the solenoid:

➢ Leakage co-efficient or leakage factor 𝜆: The ratio of total flux (𝜑)

produced by the solenoid to the useful flux (𝜑u) set-up in the air gap

➢ Fringing: It may be seen in Fig. 1.7 that the useful flux when sets-up in the air gap, it tends to

bulge outwards at b and b’ since the magnetic lines set-up in the same direction repel each other.

This increases the effective area in the air gap and decreases the flux density. This effect is known

as fringing. The fringing is directly proportional to the length of the air gap.

Dr. Hany S. E. Mansour Electrical Machines (1) Lec. #1 15

Ampere-turns Calculations

➢ In a magnetic circuit, flux produced,

❖ Series Magnetic Circuits

➢ A magnetic circuit that has a number of

parts of different dimensions and

materials carrying the same magnetic

field is called a series magnetic circuit.

Dr. Hany S. E. Mansour Electrical Machines (1) Lec. #1 16

Ampere-turns Calculations

❖ Parallel Magnetic Circuits

➢ A magnetic circuit which has two or more than two paths for

the magnetic flux is called a parallel magnetic circuit.

Dr. Hany S. E. Mansour Electrical Machines (1) Lec. #1 17

Example 1

➢ An iron ring of 400 cm mean circumference is made from round iron of cross-section 20

cm2. Its permeability is 500. If it is wound with 400 turns, what current would be required

to produce a flux of 0.001 Wb?

➢ Solution

Dr. Hany S. E. Mansour Electrical Machines (1) Lec. #1 18

Example 2

➢ Estimate the number of ampere-turns necessary to produce a flux of 100,000 lines round an

iron ring of 6 cm2 cross section and 20 cm mean diameter having an air gap 2 mm wide

across it. Permeability of the iron may be taken 1200. Neglect the leakage flux outside the 2

mm air gap.

➢ Solution

Dr. Hany S. E. Mansour Electrical Machines (1) Lec. #1 19

Example 2

➢ Estimate the number of ampere-turns necessary to produce a flux of 100,000 lines round an

iron ring of 6 cm2 cross section and 20 cm mean diameter having an air gap 2 mm wide

across it. Permeability of the iron may be taken 1200. Neglect the leakage flux outside the 2

mm air gap.

➢ Solution

Dr. Hany S. E. Mansour Electrical Machines (1) Lec. #1 20

Example 2

➢ Estimate the number of ampere-turns necessary to produce a flux of 100,000 lines round an

iron ring of 6 cm2 cross section and 20 cm mean diameter having an air gap 2 mm wide across

it. Permeability of the iron may be taken 1200. Neglect the leakage flux outside the 2 mm air

gap.

➢ Solution

Dr. Hany S. E. Mansour Electrical Machines (1) Lec. #1 21

Magnetization or B-H Curve

➢ The graph plotted between flux density B and magnetizing force H of a material.

Dr. Hany S. E. Mansour Electrical Machines (1) Lec. #1 22

Magnetic Hysteresis

➢ When a magnetic material is magnetized first in one

direction and then in the other (i.e., one cycle of

magnetization), it is found that flux density B in the

material lags behind the applied magnetizing force H.

This phenomenon is known as magnetic hysteresis.

➢ The phenomenon of flux density B lagging behind the

magnetizing force H in a magnetic material is called

magnetic hysteresis.

Dr. Hany S. E. Mansour Electrical Machines (1) Lec. #1 23

Magnetic Hysteresis

➢ When the field intensity H is increased gradually by

increasing current in the solenoid (by decreasing the value

of R), the flux density B also increases until saturation

point a is reached and curve so obtained is oa.

➢ If now the magnetizing force (H) is gradually reduced to

zero by decreasing current in the solenoid to zero. The

flux density (B) does not become zero and the curve so

obtained is ab as shown in Fig. 1.25.

➢ When magnetizing force H is zero, the flux density (B)

still has value ob.

Dr. Hany S. E. Mansour Electrical Machines (1) Lec. #1 24

Magnetic Hysteresis

➢ Residual Magnetism and Retentivity

➢ This value of flux density ‘ob’ retained by the magnetic

material is called residual magnetism.

➢ The power of retaining this residual magnetism is

called retentivity of the material.

➢ To demagnetize the magnetic ring, the magnetizing

force H is reversed by reversing the direction of flow

of current in the solenoid. This is achieved by changing

the position of double pole, double throw switch (i.e.,

position ‘2’).

Dr. Hany S. E. Mansour Electrical Machines (1) Lec. #1 25

Magnetic Hysteresis

➢ When H is increased in reverse direction, the flux density

(B) starts decreasing and becomes zero and curve follows

the path bc.

➢ Thus, residual magnetism of the magnetic material is

wiped off by applying magnetizing force oc in opposite

direction.

➢ Coercive Force

➢ It is the value of magnetizing force oc required to wipe

off the residual magnetism.

Dr. Hany S. E. Mansour Electrical Machines (1) Lec. #1 26

Magnetic Hysteresis

➢ To complete the loop, the magnetizing force H is

increased further in reverse direction till saturation

reaches (point ‘d’) and the curve follows the path cd.

➢ Again H is reduced to zero and the curve follows the

path de. Where oe represents the residual magnetism.

➢ Then H is increased in the positive direction by changing

the position of reversible switch to position ‘1’ and

increasing the flow of current in the solenoid. The curve

follows the path of efa and the loop is completed.

Dr. Hany S. E. Mansour Electrical Machines (1) Lec. #1 27

Magnetic Hysteresis

➢ Again of is the magnetizing force utilized to wipe off

the residual magnetism oe.

➢ Hence, cf is the total coercive force required in one

cycle of magnetization to wipe off the residual

magnetism.

➢ Since the meaning of hysteresis is lagging behind, and

in this case flux density B always lags behind the

magnetizing force, H, therefore, loop (abcdefa) so

obtained is called hysteresis loop.

Dr. Hany S. E. Mansour Electrical Machines (1) Lec. #1 28

Hysteresis Loss

➢ When a magnetizing force (H) is applied, the magnetic material is magnetized, and the

molecular magnets are lined up in a particular direction.

➢ However, when the magnetizing force in a magnetic material is reversed, the internal friction of

the molecular magnets opposes the reversal of magnetism, resulting in hysteresis.

➢ To overcome this internal friction of the molecular magnets (or to wipe off the residual

magnetism), a part of the magnetizing force is used.

➢ The work done by the magnetizing force against this internal friction of molecular magnets

produces heat.

➢ This energy, which is wasted in the form of heat due to hysteresis, is called hysteresis loss.

Dr. Hany S. E. Mansour Electrical Machines (1) Lec. #1 29

Hysteresis Loss

➢ Hysteresis loss occurs in all the magnetic parts of electrical machines where there is reversal of

magnetization.

➢ This loss results in wastage of energy in the form of heat. Consequently, it increases the

temperature of the machine which is undesirable.

➢ Therefore, a suitable magnetic material is selected for the construction of such parts, e.g.,

silicon steel is most suitable in which hysteresis loss is minimum.

Dr. Hany S. E. Mansour Electrical Machines (1) Lec. #1 30

You might also like

- Solenoid Actuators: Theory and Computational MethodsFrom EverandSolenoid Actuators: Theory and Computational MethodsRating: 3 out of 5 stars3/5 (1)

- Soal Analisa VibrasiDocument15 pagesSoal Analisa VibrasiAdi FirmantoNo ratings yet

- Chapter No. 01: Magnetic CircuitsDocument53 pagesChapter No. 01: Magnetic CircuitsUmar SheikhNo ratings yet

- 1.1 Review of Magnetic CircuitsDocument14 pages1.1 Review of Magnetic Circuitsdharanika100% (2)

- FG - Warehouse A - Rack - ReportDocument14 pagesFG - Warehouse A - Rack - ReportcihuyNo ratings yet

- Introduction To Magnetic CircuitsDocument23 pagesIntroduction To Magnetic Circuitssharad kumarNo ratings yet

- Mod 1bDocument32 pagesMod 1bDeepa ShreeNo ratings yet

- Unit 1 Magnetism and ElectromagnetismDocument53 pagesUnit 1 Magnetism and ElectromagnetismOdellien Saja100% (1)

- Magnetic Circuits: Chapter # 1Document35 pagesMagnetic Circuits: Chapter # 1teza maruNo ratings yet

- E-Books Electrical Machines by Mr. S. K. Sahdev-27-103Document77 pagesE-Books Electrical Machines by Mr. S. K. Sahdev-27-103Atina StyaNo ratings yet

- EEEE2045 - EM - Semester 2 Lecture 6Document42 pagesEEEE2045 - EM - Semester 2 Lecture 6Harshal KanumuriNo ratings yet

- Magnetic CircuitsDocument52 pagesMagnetic Circuitsgopi_905100% (1)

- Unit I (Magnetic Field and Circuits - Electromagnetic Force and Torque)Document43 pagesUnit I (Magnetic Field and Circuits - Electromagnetic Force and Torque)UpasnaNo ratings yet

- Unit-1-2 MachineDocument21 pagesUnit-1-2 Machinedd3613667No ratings yet

- ES Unit-3Document23 pagesES Unit-3Mazin VoraNo ratings yet

- Unit-1 Magnetic CircuitDocument52 pagesUnit-1 Magnetic Circuitollata kalanoNo ratings yet

- QB105341Document11 pagesQB105341KURAKULA VIMAL KUMARNo ratings yet

- Electomagnetic Induction:-Faraday's Law: Project ReportDocument17 pagesElectomagnetic Induction:-Faraday's Law: Project ReportSushantSinghNo ratings yet

- Sapna Physics PDFDocument17 pagesSapna Physics PDFDivya ChaturvediNo ratings yet

- Introduction To Electrical Machine Week 1Document38 pagesIntroduction To Electrical Machine Week 1vitileeNo ratings yet

- Magnetism and ElectromagnetismDocument8 pagesMagnetism and ElectromagnetismArvin Palma Dela RocaNo ratings yet

- EMINewDocument10 pagesEMINewMohith DasNo ratings yet

- FARADAYDocument12 pagesFARADAYbeatsxnation5555555No ratings yet

- Why Ac DC TransformersDocument21 pagesWhy Ac DC Transformersapi-252130436No ratings yet

- Chapter OneDocument15 pagesChapter OneBirukNo ratings yet

- Magnetic Circuits, Energy Conversion and Three Phase TheoryDocument88 pagesMagnetic Circuits, Energy Conversion and Three Phase Theoryn02219827hNo ratings yet

- Physics Investigatory Project On EMIDocument14 pagesPhysics Investigatory Project On EMINiyati100% (1)

- Chapter One Electromagnetic Principle-1Document68 pagesChapter One Electromagnetic Principle-1DANIEL WELDAYNo ratings yet

- Lecture MagnetisimDocument32 pagesLecture Magnetisimahmedalmanfy59No ratings yet

- Case Study 5 EmiDocument12 pagesCase Study 5 EmiSANJAY RNo ratings yet

- Lecture 1Document62 pagesLecture 1dronemehmetNo ratings yet

- EM-1 - (2 Marks &16 Marks)Document23 pagesEM-1 - (2 Marks &16 Marks)Dr. R. SANKAR CITNo ratings yet

- EE352 Chapter#2 Electromagnetism and Magnetic CurcuitsDocument55 pagesEE352 Chapter#2 Electromagnetism and Magnetic CurcuitsCan ARABACINo ratings yet

- EE-101 (Unit-3)Document83 pagesEE-101 (Unit-3)Chauhan AyushmaanNo ratings yet

- Magnetic Materials and Circuits: Describe, Explain and Calculate Fundamental of Electricity, Magnetism and CircuitsDocument56 pagesMagnetic Materials and Circuits: Describe, Explain and Calculate Fundamental of Electricity, Magnetism and Circuitscarlos beltranNo ratings yet

- Magnetics CH 1Document55 pagesMagnetics CH 1NAHOM ANTENEHNo ratings yet

- Chapter 1 Magnetics 32095Document46 pagesChapter 1 Magnetics 32095NatyBNo ratings yet

- Magnet Is Am NotesDocument18 pagesMagnet Is Am Notesapi-26587237No ratings yet

- 1.1 Historical Developments: 1.1.1 Jedlik's DynamoDocument16 pages1.1 Historical Developments: 1.1.1 Jedlik's DynamoIrfan NaqviNo ratings yet

- Chapter 3 EMIDocument52 pagesChapter 3 EMIMayank MeghaniNo ratings yet

- PDF Physics Investigatory Project Abhishek Class XiiDocument19 pagesPDF Physics Investigatory Project Abhishek Class Xiinandish gupta100% (1)

- Basic Electrical FundamentalsDocument26 pagesBasic Electrical Fundamentalskhan adilNo ratings yet

- 6.question Bank With Answers (2 Marks) - 1Document10 pages6.question Bank With Answers (2 Marks) - 1Durgesh DhoreNo ratings yet

- Unit III - Magnetic CircuitsDocument71 pagesUnit III - Magnetic CircuitsSanthosh PNo ratings yet

- EEC 125 Note UpdatedDocument23 pagesEEC 125 Note UpdatedElijah EmmanuelNo ratings yet

- Chapter 1Document37 pagesChapter 1playerNo ratings yet

- Magnetic Circuits: - Series Magnetic Circuit - Parallel Magnetic Circuit - Series-Parallel Magnetic CircuitsDocument37 pagesMagnetic Circuits: - Series Magnetic Circuit - Parallel Magnetic Circuit - Series-Parallel Magnetic CircuitsprashanthNo ratings yet

- Application of Electrical Machines Electromagnetism: Review Analogies Between Electric and Magnetic Circuits Faraday's Law Motor ActionDocument27 pagesApplication of Electrical Machines Electromagnetism: Review Analogies Between Electric and Magnetic Circuits Faraday's Law Motor ActionTuankuBadzlinHashfiNo ratings yet

- Electrical Machines: Magnetic CircuitsDocument6 pagesElectrical Machines: Magnetic CircuitsShankar PoudelNo ratings yet

- Ee201 Notes1 HoleyDocument47 pagesEe201 Notes1 HoleyUmamaheswar ReddyNo ratings yet

- Unit 1 EM-1Document41 pagesUnit 1 EM-1Pranesh KaNo ratings yet

- M2 Magnitic CircuitDocument15 pagesM2 Magnitic Circuitm.investment.kNo ratings yet

- Electromagnetic InductionDocument12 pagesElectromagnetic InductionPrasad MehtaNo ratings yet

- Unit IIIDocument160 pagesUnit IIIquatumhumanNo ratings yet

- CH1Document37 pagesCH1ffffff100% (6)

- Magnetic CircuitsDocument38 pagesMagnetic CircuitsHanan KemalNo ratings yet

- CH 1 ElectromagnetismDocument26 pagesCH 1 Electromagnetismሳጃው ፀብአይመርጥምNo ratings yet

- CHAPTER 1 Introduction+Magnetic CircuitsDocument42 pagesCHAPTER 1 Introduction+Magnetic CircuitsTomNo ratings yet

- Electromagnetic Induction NOtesDocument76 pagesElectromagnetic Induction NOtesashunaik409No ratings yet

- Power No.1Document16 pagesPower No.1Ahmed GamalNo ratings yet

- Lec 3 الكترونيةDocument29 pagesLec 3 الكترونيةAhmed GamalNo ratings yet

- CamScanner ٠٨-١٦-٢٠٢٢ ١٣.٠٤Document11 pagesCamScanner ٠٨-١٦-٢٠٢٢ ١٣.٠٤Ahmed GamalNo ratings yet

- Sheet 1 هندسة الكترونيهDocument4 pagesSheet 1 هندسة الكترونيهAhmed GamalNo ratings yet

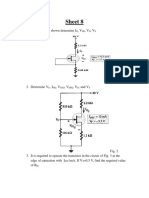

- Sheet 8Document4 pagesSheet 8Ahmed GamalNo ratings yet

- هندسه الكترونيه 1Document38 pagesهندسه الكترونيه 1Ahmed GamalNo ratings yet

- Midterm Sol. OSDocument3 pagesMidterm Sol. OSAhmed GamalNo ratings yet

- Os Mid22Document2 pagesOs Mid22Ahmed GamalNo ratings yet

- Chapter 1 AnswersDocument2 pagesChapter 1 AnswersAhmed GamalNo ratings yet

- 4 - Fourier Analysis For DT Signals - Part1Document16 pages4 - Fourier Analysis For DT Signals - Part1Ahmed GamalNo ratings yet

- AP Physics 1 Formula ChartDocument2 pagesAP Physics 1 Formula ChartJACK ECKSTEINNo ratings yet

- Experiment No 2 - Add SituationsDocument7 pagesExperiment No 2 - Add SituationsJOSE FERNANDO GEMPERLENo ratings yet

- The Bearing Capacity For HPDC Machine InstallationsDocument3 pagesThe Bearing Capacity For HPDC Machine InstallationsbharatsharmamechNo ratings yet

- Re 4.3 (Mio)Document6 pagesRe 4.3 (Mio)Angel PerezNo ratings yet

- Lesson 09 2015Document44 pagesLesson 09 2015abimalainNo ratings yet

- Moment of InertiaDocument16 pagesMoment of InertiaDiane Dinglasa TobiasNo ratings yet

- Serra Do Mel 3 A 6 - Project - VC1-ReportDocument13 pagesSerra Do Mel 3 A 6 - Project - VC1-Reportjosimar gomes da silva filhoNo ratings yet

- Part 1 - Route and Site Surveys-1Document21 pagesPart 1 - Route and Site Surveys-1Adaminovic Mrisho100% (1)

- Faraday's Law of Induction - WikipediaDocument26 pagesFaraday's Law of Induction - WikipediaBunny MorlaNo ratings yet

- Pss - 1-6h7a - A 8400A (PFA)Document28 pagesPss - 1-6h7a - A 8400A (PFA)schreyarNo ratings yet

- Report of Student Industrial Work Experience Scheme (Siwes) Training ProgrammeDocument45 pagesReport of Student Industrial Work Experience Scheme (Siwes) Training ProgrammeAdefila Sunday DadaNo ratings yet

- Ds CP 0ACG Series-2000946Document5 pagesDs CP 0ACG Series-2000946fernando lozanoNo ratings yet

- Module Details: Name: Strand: Block: SUBJECT: General Physics 2 Grade LevelDocument8 pagesModule Details: Name: Strand: Block: SUBJECT: General Physics 2 Grade LevelIan PadillaNo ratings yet

- Atmospheric Blowdown Tank Calculation ReportDocument49 pagesAtmospheric Blowdown Tank Calculation ReporttauqeerNo ratings yet

- D 4015 - 15e1 - Resonant ColumnDocument22 pagesD 4015 - 15e1 - Resonant ColumnDalimNo ratings yet

- Vissim Training - 8. Model Calibration and ValidationDocument12 pagesVissim Training - 8. Model Calibration and Validationisakpiter13No ratings yet

- Ibong Tiririt Pipe 4Document9 pagesIbong Tiririt Pipe 4Mc LesterNo ratings yet

- Part 4 - Module 2 - Solutions, Volumetric Analysis and WaterDocument14 pagesPart 4 - Module 2 - Solutions, Volumetric Analysis and WaterParthive Bala SanthoshNo ratings yet

- UNIT-1 Process Modeling SimulationDocument17 pagesUNIT-1 Process Modeling Simulationkritika negiNo ratings yet

- (Student) SI Units and ConversionsDocument11 pages(Student) SI Units and ConversionsAnthony QuanNo ratings yet

- L - 01 - Energy Transfer Concepts DetailDocument32 pagesL - 01 - Energy Transfer Concepts DetailMUHAMMAD LUQMAN HAKIMI MOHD ZAMRINo ratings yet

- HLG 600 R Spec ReportDocument4 pagesHLG 600 R Spec ReportJohnNo ratings yet

- Equivalents and Measurements TacioDocument16 pagesEquivalents and Measurements TacioRichell SorianoNo ratings yet

- GEM214E-Engineering Measurements Final Exam 20-21Document2 pagesGEM214E-Engineering Measurements Final Exam 20-21Deniz BüyüksuNo ratings yet

- Assignment 4Document4 pagesAssignment 4ShabihNo ratings yet

- Stabila 196-2 Elettronica ENDocument22 pagesStabila 196-2 Elettronica ENJohn WalesNo ratings yet

- Unit 1 Progress Check MCQDocument32 pagesUnit 1 Progress Check MCQshrishjainNo ratings yet

- Aich Le M3 4Document22 pagesAich Le M3 4El CamotitoNo ratings yet