Professional Documents

Culture Documents

A.L BH#1 D3

A.L BH#1 D3

Uploaded by

ISHTIAQ NOORCopyright:

Available Formats

You might also like

- Filter MediaDocument51 pagesFilter Mediavnil100% (1)

- Specific Gravity 20mmDocument4 pagesSpecific Gravity 20mmIsaiahogedaNo ratings yet

- Boiler DataDocument28 pagesBoiler DataMonique ThomasNo ratings yet

- Property of FRP Chart 1 PDFDocument1 pageProperty of FRP Chart 1 PDFKurt FinkNo ratings yet

- Ball Mill OptimizationDocument82 pagesBall Mill OptimizationRashek_119588% (16)

- The California Bearing Ratio (CBR) (1/1) : (3) - Penetration (1) - DensityDocument8 pagesThe California Bearing Ratio (CBR) (1/1) : (3) - Penetration (1) - Densityabdallah abdurhman aliNo ratings yet

- Kandis Ex PalasDocument113 pagesKandis Ex PalasBm X BreakerNo ratings yet

- Specipic Gravity Test: SNI 03-1969-1990 & SNI 03-1970-1990Document113 pagesSpecipic Gravity Test: SNI 03-1969-1990 & SNI 03-1970-1990Bm X BreakerNo ratings yet

- Grain Size Distribution: Job No. Sample Size Client Sample Type Location Delivery Date SourceDocument14 pagesGrain Size Distribution: Job No. Sample Size Client Sample Type Location Delivery Date SourceDarmadiNo ratings yet

- Civ T Qac 00134 ProctorDocument6 pagesCiv T Qac 00134 ProctorIsaiahogedaNo ratings yet

- CBR TestDocument7 pagesCBR Testjaffna100% (1)

- Gatch Quality TestDocument7 pagesGatch Quality TestMansoor AliNo ratings yet

- Bridges-2 - 1Document99 pagesBridges-2 - 1Kwame AsamoaNo ratings yet

- Embankment Quality TestsDocument10 pagesEmbankment Quality TestsMansoor AliNo ratings yet

- Compaction TestDocument9 pagesCompaction TestFaisal SardarNo ratings yet

- ESP Lesson 7 (Industrial Applications For Fabric Filters)Document24 pagesESP Lesson 7 (Industrial Applications For Fabric Filters)jkaunoNo ratings yet

- Dgar 1Document22 pagesDgar 1Moses KaswaNo ratings yet

- Data Uji TanahDocument22 pagesData Uji TanahPrieta Aghi MeiliaNo ratings yet

- ConcreteDocument169 pagesConcretesabareesan09No ratings yet

- ABU CHAPTER 4 AND 5Document20 pagesABU CHAPTER 4 AND 5Engr Edozie JoshuaNo ratings yet

- Ministry of Transportation - Field Services, PavingDocument12 pagesMinistry of Transportation - Field Services, PavingukruegerNo ratings yet

- PVC SpecDocument2 pagesPVC SpecMuhammad Noor FizuanNo ratings yet

- Lab_ReportDocument6 pagesLab_Reportmaryali416No ratings yet

- Plastic Concrete TestDocument8 pagesPlastic Concrete TestSlan ClanNo ratings yet

- SDBC With FillerDocument8 pagesSDBC With Fillerer_kenedyNo ratings yet

- Laboratorio 1Document29 pagesLaboratorio 1Omar Martinez RetamozoNo ratings yet

- MDD SoilDocument4 pagesMDD SoilDaljeet SidhuNo ratings yet

- Courage Transport PracDocument11 pagesCourage Transport Prackundayi shavaNo ratings yet

- Jayamix RM Specification (Standard Raw Material)Document6 pagesJayamix RM Specification (Standard Raw Material)Afip PullahNo ratings yet

- LS-628 R23 PDFDocument7 pagesLS-628 R23 PDFqwerysqlNo ratings yet

- Soil Testing ReportDocument12 pagesSoil Testing ReportEinstein JeboneNo ratings yet

- Mix DesignDocument32 pagesMix DesignRiLha HaNumNo ratings yet

- Plastic Concrete Compression Strength and Elasticity Modulus Changes During TimeDocument8 pagesPlastic Concrete Compression Strength and Elasticity Modulus Changes During TimeKhlif NadaNo ratings yet

- MDD, Omc (VH) - GCSDocument4 pagesMDD, Omc (VH) - GCSDaniel KariukiNo ratings yet

- California Bearing Ratio Test Report: AASHTO T-193Document4 pagesCalifornia Bearing Ratio Test Report: AASHTO T-193tannuNo ratings yet

- U1 Dry Sieve AnalysisDocument9 pagesU1 Dry Sieve AnalysisFakeyha RashidNo ratings yet

- SDBC Without FillerDocument9 pagesSDBC Without Fillerer_kenedyNo ratings yet

- Sample Description: K17+180 Date: 2016.4.14 Sample Designation: K16-K18Document33 pagesSample Description: K17+180 Date: 2016.4.14 Sample Designation: K16-K18kwameNo ratings yet

- Use of Additive Materials in Sub Grade For Road ConstructionDocument6 pagesUse of Additive Materials in Sub Grade For Road Constructionseventhsensegroup100% (1)

- Slump Test: Sourse /location:: CC Pavement Grade of Concrete:: M30 Water Cement Ratio:: 0.45Document37 pagesSlump Test: Sourse /location:: CC Pavement Grade of Concrete:: M30 Water Cement Ratio:: 0.45ChManikumarNo ratings yet

- 2305 - 15 - Hasil Trial Embankment FilterDocument12 pages2305 - 15 - Hasil Trial Embankment FilterAngghy NaghaNo ratings yet

- Transpo Open EndedDocument38 pagesTranspo Open EndedInformation StudyNo ratings yet

- K0 413涵洞基底不合适材料试验资料Document33 pagesK0 413涵洞基底不合适材料试验资料kwameNo ratings yet

- Laboratory Manual FinalDocument57 pagesLaboratory Manual Finalrohit kumarNo ratings yet

- Laboratory WorksDocument32 pagesLaboratory WorksCliff Jude ZehnderNo ratings yet

- Desidn AopDocument73 pagesDesidn AopDavid LambertNo ratings yet

- California Bearing Ratio (CBR) TestDocument6 pagesCalifornia Bearing Ratio (CBR) TestgimanuNo ratings yet

- 130 KMDocument967 pages130 KMKwame AsamoaNo ratings yet

- Arba Minch University - Institute of Technology Civil &urban Engineering Department Final Examination, (1st Semester, AY 2013-14)Document4 pagesArba Minch University - Institute of Technology Civil &urban Engineering Department Final Examination, (1st Semester, AY 2013-14)Ashebir AsratNo ratings yet

- Syce Sem - Iv Mini ProjectDocument37 pagesSyce Sem - Iv Mini ProjectAmey KadulkarNo ratings yet

- GONDA SUB-STATION (400/220/132kV) : Flakiness & Elongation Index (Is 2386, Part 1)Document6 pagesGONDA SUB-STATION (400/220/132kV) : Flakiness & Elongation Index (Is 2386, Part 1)Aamir Anwar100% (1)

- A Ready Reckoner For Quantity Surveyors: ObjectiveDocument105 pagesA Ready Reckoner For Quantity Surveyors: ObjectiveanaszkNo ratings yet

- Hoja de Calculo FP Borrador - 2Document14 pagesHoja de Calculo FP Borrador - 22artNo ratings yet

- Strength of ConcreteDocument3 pagesStrength of ConcretelombangrurusNo ratings yet

- Gradation Hydrometer PI (BH AB1 AS1)Document10 pagesGradation Hydrometer PI (BH AB1 AS1)Kiran Chandra PrakashNo ratings yet

- Isokinetic Calibration Report Raw Mill Line 2Document89 pagesIsokinetic Calibration Report Raw Mill Line 2Muhammad AbrarNo ratings yet

- Plastic Limit Test - 004Document8 pagesPlastic Limit Test - 004funky_jebonNo ratings yet

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceFrom EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceNo ratings yet

- Roll-to-Roll Manufacturing: Process Elements and Recent AdvancesFrom EverandRoll-to-Roll Manufacturing: Process Elements and Recent AdvancesJehuda GreenerNo ratings yet

- Butler Pa Leo Magnetism BookDocument248 pagesButler Pa Leo Magnetism BookISHTIAQ NOORNo ratings yet

- Sufi PoetryDocument107 pagesSufi PoetryISHTIAQ NOOR100% (1)

- Solar SystemDocument105 pagesSolar Systemv155r100% (18)

- Islamic MedicineDocument5 pagesIslamic Medicinefarizah100% (2)

A.L BH#1 D3

A.L BH#1 D3

Uploaded by

ISHTIAQ NOOROriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A.L BH#1 D3

A.L BH#1 D3

Uploaded by

ISHTIAQ NOORCopyright:

Available Formats

MULTAN DEVELOPMENT AUTHORITY

CONTRACTOR: CH. ABDULLATIF & CO. CONSULTANT: ABM ENGINEERS:

SOUTHERN BYEPASS PHASE II MULTAN Sieve Analysis of Embankment & Sub Grade Material

Grain Size Analysis AASHTO-T-27

PROJECT: Sampling Date Testing Date Field Sample No. Lab. Sample No. Analyst.

Kind of Material LOCATION Original Sourse

Weight of Original Sample Weight of Oven Dry Weight of Washed Oven Dry Sieve Size

mm 75

63 50.0 37.5 25.0 19.0 12.5 9.5 4.75 2.36 2.00 1.18 0.60 0.425 0.3 0.18 0.15 0.075

Gms Gms Gms

Cum. Wt.Retained Cum. Retained

Grms %

1042.9

Date () Cum. Passing

%

Wt. Retained

Grms

Specification

%

Remarks

(alt.) 3''

2 1/2" 2" 1 1/2'' 1" 3/4 " 1/2 " 3/8 " No. 4 No. 8 No. 10 No. 16 No. 30 No. 40 No. 50 No. 80 No. 100 No. 200

0.0 10.4

0.0 10.4

0.0 1.0

100.0 99.0

66.7

77.2

7.4

92.6

135.6 Oven Dry wt. -4 # Sieve ( Gms) Sieve Size Passing %

212.8 No.10

20.4 No.40

79.6 No.200

Calculations

CONTRACTOR:

Cumulative Percent Retained = Cumulative mass Retained / Dry Mass Before Wash Percent Passing = 100 - Cumulative Percent Retained

CONSULTANT:

CONSULTANT:

LAB TECHNICIAN

MATERIAL INSPECTOR

MATERIAL ENGINEER

MULTAN DEVELOPMENT AUTHORITY

CONTRACTOR: CH.ABDUL LATIF & CO. CONSULTANT: ABM ENGINEERS

SOUTHERN BYE PASS PHASE II MULTAN

Soils Classification /Atterburg Limits

MRD Test Method 208 -209 - 210 (Adaptation of AASHTO T 89 - 90 - 80) Project Kind of Material Location Quantity Represented

Sampling Date Testing Date Lab. Sample No.

Material Used:

Sieve Analysis

Sieve Size

Individual Wt. Retained Cumulative Wt. Retained

Cumulative Percent Retained

Percent Passing

3/4 in (19 mm) No.4 (4.75 mm) No.10 (2.00 mm) No. 40 (0.425 mm) No.200 (0.075 mm) Pan Wash Total

0 0 0.9 5.7 179.8

0 0 0.9 6.6 186.4

0 0 0 1 20

100 100 99.9 99.3 80.3

186.4 Original Wt. Gram

Dry Wt. Gram 946.3

LIQUID LIMIT TEST 32 25 32 24 A-2 A-3 27.70 18.50 53.43 46.15 48.72 40.70 4.71 5.45 21.02 22.20 22.41 24.56

Wash Dry Wt. Gram

Atterburg Limits (Liquid Limit & Plastic Limit )

Type of Test Number of Blows Trial No. Container Number Wt. of Container Wt. Wet Soil + Container Wt. Dry Soil + Container Wt. of Water Wt. of Dry Soil Water Content % 40 1 A-1 17.70 45.54 40.85 4.69 23.15 20.26 18 18 A-4 19.50 44.63 39.36 5.27 19.86 26.54 PLASTIC LIMIT TEST 1 A-5 22.20 34.96 32.85 2.11 10.65 19.85 2 A-6 20.20 33.66 31.45 2.21 11.25 19.65 3 A-7 24.00 35.93 33.99 1.94 9.99 19.40

g g g g g

Avg.

30.00 29.00 28.00 27.00 26.00 25.00 24.00 23.00 22.00 21.00 20.00 19.00 18.00 17.00

23.44

19.63

Water Content %

10

20

25

30

40

50

60

70

80

90

100

No. of Blows

Liquid Limit (L.L) Plasticity Index (P.I)

CONTRACTOR LL =

24.40 4.77

P.I = L.L - P.L

Plastic Limit (P.L) Classification Group

CONSULTANT

P.L =

19.63

A-4

CONSULTANT

LAB TECHNICIAN

MATERIALS INSPECTOR

MATERIAL ENGINEER

MULTAN DEVELOPMENT AUTHORITY

CONTRACTOR: NAZIR & COMPANY CONSULTANT: ABM CONSULTANT

FATIMA JINNAH TOWN PHASE 1 VEHARI ROAD MULTAN

California Bearing Ratio

MRD Test Method 213 (Adaptation of ASTM D 1883 - AASHOT 193) Page 1 Of 2 Road Name Description: Location Materials

Surcharge Weight Used(kg) Test No. Can No.

A B C D E F Mass. Wet Soil + Can. Mass Dry Soil + Can. Mass Of Water. A-B Mass Can. Mass Dry Soil . B-D Moisture Content C/E X 100

Standard Load (Stresses) Kg / Cm2

FATIMA JINNAH TOWN SUB GRADE MATERIAL B-BLOCK SUB GRADE MATERIAL

4.54 1

g g g g g % A5 647.6 581.9 65.7 48 533.9 12.30

Field Sample No. Date Of Sampling Date Tested Quant. Rep. Analyst: Rate of penetration mm/Minute 1.27

2/1/2010

Molding Moisture Content (ASTM D 2216)

2

A9 727.8 655.2 72.6 70.1 585.1 12.40

Density Determination

3

B4 621.4 558 63.4 47.1 510.9 12.40

Test No.

Blows Per Lift

Test No. Mold Volume Mass. Sample + Mold . Mass Mold . Mass Sample . Unit Wet Mass. Percent Moisture Unit Dry Mass. 2

cm g g g g/cm 3 % 3 g/cm

1

2128.0 10997 7090 3907 1.836 12.30 1.635

2

2109.0 11191 6950 4241 2.011 12.4 1.789

3

2124.0 11496 6940 4556 2.145 12.40 1.908

10

Molded

Total Load Kg Unit Load Kg / Cm 2 0

30

Tested

Corrected Load Kg / Cm 2

65

Tested

Corrected Load Kg / Cm 2

Penetration

Per Min. 0

Molded

Total Load Kg Unit Load Kg / Cm 2 0

Molded

Total Load Kg Unit Load Kg / Cm 2 0

Tested

Corrected Load Kg / Cm 2

CBR

%

CBR

%

CBR

%

mm 0 0.64 1.27 1.90 2.54 3.81 5.08 7.62

0.5 1 1.5 2 3 4 6

70.35

105.53

0.7 1.3 1.7 2.2 2.9 3.3 3.9

1.2 2.2 2.9 3.7 4.9 5.6 6.6

5.3 5.3

1.8 3.0 4.2 5.1 6.3 7.5 9.1

3.0 5.1 7.1 8.7 10.7 12.7 15.4 25

12.3 12.1

2.7 4.3 5.6 6.8 8.4 9.9 12.0

4.6 7.3 9.5 11.4 14.2 16.8 20.3

16.2 15.9

Swell Reading

Date Moldend Test No. Mold No. Final Height . Initial Height . Difference . Sample Length . mm mm mm mm 1 1

0.42 0.000 0.42 116.43 0.36

2 2

0.34 0.000 0.34 116.43 0.29 1.899 12.4 30 1.789 12.1 1.804

3 3

0.21 0.000 0.21 116.43 0.18 g/cm3

Unit Load (Stress) kg / cm2

20

15

10

Percent Swell %

PROCTOR MODIFIED

MAX DRY DENSITY

OPTIMUM MOISTURE CONTENT

%

65 1.908 15.9 g/cm3 %

Blows Per Lift No. Dry Density g/cm . Soaked C.B.R. %

95 % of Max. Dry Density C.B.R At 95% of Max Dry Density

3

10 1.635 5.3

0 0 1.27 2.54 3.81 5.08 6.35 7.62 8.89

Penetration mm

12.8

Contractor:

Consultant:

Lab Technician

Material Inspector

Material Engineer

MULTAN DEVELOPMENT AUTHORITY

CONTRACTOR: NAZIR & COMPANY CONSULTANT: ABM CONSULTANTS:

FATIMA JINNAH TOWN PHASE 1 VEHARI ROAD MULTAN

California Bearing Ratio

MRD Test Method 213 (Adaptation of ASTM D 1883 - AASHOT 193) Page 2 Of 2 Description: SUB GRADE MATERIAL LOCATION: B-BLOCK

18 16 14 12 Soaked CBR % 10 8 6 4 2 0 1.600

1.650

1.700

1.750

1.800

1.850

1.900

1.950

2.000

Dry Density g/cc

MAX DRY DENSITY

1.915 11.9 30 1.877 12 65 1.980 16

g/cm 3

g/cm

PROCTOR MODIFIED

OPTIMUM MOISTURE CONTENT

BLOWS PER LAYER No. DRY DENSITY AS MOLDED g/cm 3 SOAKED C.B.R. % 95 % of Max. Dry Density C.B.R At 93.0% of Max Dry Density C.B.R At 95% of Max Dry Density

CONTRACTOR:

10 1.635 5

1.819 11.2 12.8

CONSULTANT:

% %

Lab Technician

Material Inspector

Material Engineer

ROVEMENT&WIDENING OF NATIONAL HIGHWAY N-5 BAHAWAL POUR CHOWK (929+

CONTRACTOR:

CH:ABDUL LATIF &CO

CONSULTANT:

ABM ENGINEERS

SOUTHREN BYPASS PHASE II VEHARI ROAD TO BAHAWALPUR CHOWK MULTAN

Moisture-Density Relationship of Soils

MRDTM 212 (ASTM D 698 - 1557 - AASHO T 99 - T 180)

Project Description Of Sample LOCATION: LAYER: Analyst. A B C D E F G H I J K L M N Mold No. Formula Wt. Compacted Wet soil + Mold (gm) Wt. Mold (gm) Volume of Mold (Cm 3 ) Wt. Compacted Wet soil (gm)

3

Sampling Date Testing Date Field Sample No. Lab. Sample No.

1

8382 4724 2118 3658 1.727 A-1 36.0 336.9 322.6 14.3 286.6 5.0 1.645

2

8755 4724 2118 4031 1.903 A-2 35.5 302.3 285.3 17.0 249.8 6.8 1.782

3

9072 4724 2118 4348 2.053 A-3 34.0 313.2 290.6 22.6 256.6 8.8 1.887

4

9237 4724 2118 4513 2.131 A-4 34.5 302.5 275.5 27.0 241 11.2 1.916

5

9110 4724 2118 4386 2.071 A-4 36.2 308.1 274.9 33.2 238.7 13.9 1.818

B-C

Wet Density (gm/Cm ) E/D Container No. Wt. of Container Wt. Wet Soil + Container (gm) Wt. Dry Soil + Container (gm) Wt of Water (gm) I-J Wt. of Dry Soil (gm) J-H Water Content % ( K / L )*100 Dry Density (g/cc) F / ( 1+ ( M/100 ) ) OPIMUM MOISTURE CONTENT % 3 MAXIMUM DRY DENSITY gm/Cm

11.3 1.917

Moisture-Density Relationship 1.990

1.930

Dry Density gm/cm3

1.870

1.809

1.749

1.689

1.628 0 1 2 3 4 5 6 7 8 9 Moisture Content % 10 11 12 13 14 15

Remraks :

CONTRACTOR:

CONSULTANT:

LAB TECHNICIAN

MATERIALS INSPECTOR

MATERIAL ENGINEER

MULTAN DEVELOPMENT AUTHORITY

CONTRACTOR: CH:ABDUL LATIF &CO CONSULTANT: ABM CONSULTANT

SOUTHERN BYEPASS PHASE II MULTAN

California Bearing Ratio

MRD Test Method 213 (Adaptation of ASTM D 1883 - AASHOT 193) Page 1 Of 2 Road Name Description: Location Materials Field Sample No. Date Of Sampling Date Tested Quant. Rep. Analyst:

Molding Moisture Content (ASTM D 2216)

Test No. Can No.

A B C D E F Mass. Wet Soil + Can. Mass Dry Soil + Can. Mass Of Water. A-B Mass Can. Mass Dry Soil . B-D Moisture Content C/E X 100

Standard Load (Stresses) Kg / Cm2

Density Determination

3

B4 686.3 631.1 55.2 68 563.1 9.80

1

g g g g g % A5 740.2 680.4 59.8 70.1 610.3 9.80

2

A9 638.0 586.9 51.1 65 521.9 9.80

Test No.

Blows Per Lift

Test No. Mold Volume Mass. Sample + Mold . Mass Mold . Mass Sample . Unit Wet Mass. Percent Moisture Unit Dry Mass. 2

cm g g g g/cm 3 % 3 g/cm

1

2124.0 10969 6510 4459 2.099 9.80 1.912

2

2128.0 11310 7090 4220 1.983 9.8 1.806

3

2109.0 11344 6950 4394 2.084 9.80 1.898

10

Molded

Total Load Kg Unit Load Kg / Cm 2 0

30

Tested

Corrected Load Kg / Cm 2

65

Tested

Corrected Load Kg / Cm 2

Penetration

Per Min. 0

Molded

Total Load Kg Unit Load Kg / Cm 2 0

Molded

Total Load Kg Unit Load Kg / Cm 2 0

Tested

Corrected Load Kg / Cm 2

CBR

%

CBR

%

CBR

%

mm 0 0.64 1.27 1.90 2.54 3.81 5.08 7.62

0.5 1 1.5 2 3 4 6

70.35

105.53

1.0 1.3 1.7 2.1 2.8 3.2 3.8

1.7 2.2 2.8 3.6 4.7 5.3 6.5

5.2 5.1

1.4 3.0 4.2 5.0 6.3 7.3 8.9

2.4 5.0 7.1 8.4 10.7 12.4 15.0 25

12.0 11.7

2.4 3.9 5.3 6.6 8.0 9.7 11.7

4.1 6.6 9.0 11.2 13.5 16.4 19.8

15.9 15.5

Swell Reading

Date Moldend Test No. Mold No. Final Height . Initial Height . Difference . Sample Length . mm mm mm mm 1 1

0.45 0.000 0.45 116.43 0.39

2 2

0.36 0.000 0.36 116.43 0.31 1.909 9.8 30 1.806 11.7 1.814

3 3

0.28 0.000 0.28 116.43 0.24 g/cm3

Unit Load (Stress) kg / cm2

20

15

10

Percent Swell %

PROCTOR MODIFIED

MAX DRY DENSITY

OPTIMUM MOISTURE CONTENT

%

65 1.898 15.5 g/cm3 %

Blows Per Lift No. Dry Density g/cm . Soaked C.B.R. %

95 % of Max. Dry Density C.B.R At 95% of Max Dry Density

3

10 1.912 5.1

0 0 1.27 2.54 3.81 5.08 6.35 7.62 8.89

Penetration mm

12.2

Contractor:

Consultant:

Lab Technician

Material Inspector

Material Engineer

MULTAN DEVELOPMENT AUTHORITY

CONTRACTOR: CH. CONSTRUCTON COMPANY CONSULTANT: ABM CONSULTANTS:

SOUTHERN BYEPASS MULTAN

California Bearing Ratio

MRD Test Method 213 (Adaptation of ASTM D 1883 - AASHOT 193) Page 2 Of 2 Description: Embankment 4th Layer LOCATION: 3+175 TO 3+500 Full Width

35.0 30.0 25.0 Soaked CBR % 20.0 15.0 10.0 5.0 0.0 1.650

1.700

1.750

1.800 Dry Density g/cc

1.850

1.900

1.950

MAX DRY DENSITY

1.909 9.8 30 1.806 11.7 65 1.898 15.5

g/cm 3

g/cm

PROCTOR MODIFIED

OPTIMUM MOISTURE CONTENT

BLOWS PER LAYER No. DRY DENSITY AS MOLDED g/cm 3 SOAKED C.B.R. % 95 % of Max. Dry Density C.B.R At 93.0% of Max Dry Density C.B.R At 95% of Max Dry Density

CONTRACTOR:

10 1.912 5.1

1.814 9.6 12.2

CONSULTANT:

% %

Lab Technician

Material Inspector

Material Engineer

MULTAN DEVELOPMENT AUTHORITY

CONTRACTOR:

CHOUDHARY CONSTRUCTION CO.

CONSULTANT:

ABM ENGINEERS

SOUTHERN BYEPASS PHASE 1 MULTAN

Moisture-Density Relationship of Soils

MRDTM 212 (ASTM D 698 - 1557 - AASHO T 99 - T 180)

Project Description Of Sample LOCATION: LAYER: Analyst. A B C D E F G H I J K L M N

Sothern ByePass Multan Embankment 4th Layer 3+175 to 3+500 Full Width 4th Layer

Sampling Date Testing Date Field Sample No. Lab. Sample No.

Mold No. Formula Wt. Compacted Wet soil + Mold (gm) Wt. Mold (gm) Volume of Mold (Cm 3 ) Wt. Compacted Wet soil (gm) B-C

1

9144 5376 2135 3768 1.765 A-1 36.2 314.4 304.5 9.9 268.3 3.7 1.702

2

9438 5376 2135 4062 1.903 A-2 34.5 372.2 353.1 19.1 318.6 6.0 1.795

3

9695 5376 2135 4319 2.023 A-3 35.0 446.3 416.2 30.1 381.2 7.9 1.875

4

9851 5376 2135 4475 2.096 A-4 35.0 362.3 333.1 29.2 298.1 9.8 1.909

5

9798 5376 2135 4422 2.071 A-4 35.4 394.5 357.2 37.3 321.8 11.6 1.856

Wet Density (gm/Cm 3 ) E/D Container No. Wt. of Container Wt. Wet Soil + Container (gm) Wt. Dry Soil + Container (gm) Wt of Water (gm) I-J Wt. of Dry Soil (gm) J-H Water Content % ( K / L )*100 Dry Density (g/cc) F / ( 1+ ( M/100 ) ) OPTIMUM MOISTURE CONTENT % MAXIMUM DRY DENSITY gm/Cm 3

9.8 1.909

Moisture-Density Relationship

1.950

1.900

Dry Density gm/cm3

1.850

1.800

1.750

1.700

1.650 0 1 2 3 4 5 6 7 8 9 10 11 12 13

Moisture Content %

Remraks :

CONTRACTOR:

CONSULTANT:

LAB TECHNICIAN

MATERIALS INSPECTOR

MATERIAL ENGINEER

MULTAN DEVELOPMENT AUTHORITY

CONTRACTOR: CH. CONSTRUCTION COMPANY CONSULTANT: ABM ENGINEERS

SOUTHERN BYE PASS MULTAN

Soils Classification /Atterburg Limits

MRD Test Method 208 -209 - 210 (Adaptation of AASHTO T 89 - 90 - 80) Project Kind of Material Location Quantity Represented SOUTHERN BYE PASS MULTAN Embankment 4th Layer 3+175 to 3+500 Full Width

Sampling Date Testing Date Lab. Sample No.

Material Used:

Embankment

Sieve Analysis

Sieve Size

Individual Wt. Retained Cumulative Wt. Retained

Cumulative Percent Retained

Percent Passing

3/4 in (19 mm) No.4 (4.75 mm) No.10 (2.00 mm) No. 40 (0.425 mm) No.200 (0.075 mm) Pan Wash Total

0 0 0.9 5.7 179.8

0 0 0.9 6.6 186.4

0 0 0 1 20

100 100 99.9 99.3 80.3

186.4 Original Wt. Gram

Dry Wt. Gram 946.3

LIQUID LIMIT TEST 32 24 2 3 A-2 A-3 17.90 27.70 42.80 64.32 38.06 56.91 4.74 7.41 20.16 29.21 23.51 25.36

Wash Dry Wt. Gram

Atterburg Limits (Liquid Limit & Plastic Limit )

Type of Test Number of Blows Trial No. Container Number Wt. of Container Wt. Wet Soil + Container Wt. Dry Soil + Container Wt. of Water Wt. of Dry Soil Water Content % 40 1 A-1 22.40 50.53 45.59 4.94 23.19 21.29 16 4 A-4 19.50 47.91 41.79 6.12 22.29 27.45 PLASTIC LIMIT TEST 1 A-5 22.20 35.73 33.46 2.27 11.26 20.16 2 A-6 16.80 28.83 26.80 2.03 10.00 20.25 3 A-7 17.00 30.87 28.48 2.39 11.48 20.81

g g g g g

Avg.

30.00 29.00

24.80

20.41

Water Content %

28.00 27.00 26.00 25.00 24.00 23.00 22.00 21.00 20.00 19.00

10

20

25

30

40

50

60

70

80

90

100

No. of Blows

Liquid Limit (L.L) Plasticity Index (P.I)

CONTRACTOR LL =

24.20 3.79

P.I = L.L - P.L

Plastic Limit (P.L) Classification Group

CONSULTANT

P.L =

20.41

A-4

CONSULTANT

LAB TECHNICIAN

MATERIALS INSPECTOR

MATERIAL ENGINEER

MULTAN DEVELOPMENT AUTHORITY

CONTRACTOR: CH.CONSTRUCTION COMPANY CONSULTANT: ABM ENGINEERS:

SOUTHERN BYEPASS MULTAN Sieve Analysis of Embankment Material

Grain Size Analysis AASHTO-T-27

PROJECT:

Kind of Material LOCATION Original Sourse

Southern ByePass EMBANKMENT 4 TH LAYER 3+175 TO 3+500 Full Width

Embankmant

Sampling Date Testing Date Field Sample No. Lab. Sample No. Analyst.

Weight of Original Sample Weight of Oven Dry Weight of Washed Oven Dry Sieve Size

mm 75

63 50.0 37.5 25.0 19.0 12.5 9.5 4.75 2.36 2.00 1.18 0.60 0.425 0.3 0.18 0.15 0.075

Gms Gms Gms

Cum. Wt.Retained Cum. Retained

Grms %

971.6

Date () Cum. Passing

%

Wt. Retained

Grms

Specification

%

Remarks

(alt.) 3''

2 1/2" 2" 1 1/2'' 1" 3/4 " 1/2 " 3/8 " No. 4 No. 8 No. 10 No. 16 No. 30 No. 40 No. 50 No. 80 No. 100 No. 200

0 0 0 0 131 0 0 76 0.0 7.8

0 0 0 0 131 0 0 36 0.0 7.8

34.4 48 60 0.0 13.5 0.0 99.7 3.7 0.0 0.8

65.6 52.0 40.4 100.0 86.5 100.0 0.3 96.3 100.0 99.2

-3.9

3.9

0.4

99.6

177.8 Oven Dry wt. -4 # Sieve ( Gms) Sieve Size Passing %

181.7 No.10

18.7 No.40

81.3 No.200

Calculations

CONTRACTOR:

Cumulative Percent Retained = Cumulative mass Retained / Dry Mass Before Wash Percent Passing = 100 - Cumulative Percent Retained

CONSULTANT:

CONSULTANT:

LAB TECHNICIAN

MATERIAL INSPECTOR

MATERIAL ENGINEER

MULTAN DEVELOPMENT AUTHORITY

CONTRACTOR: CH.CONSTRUCTION COMPANY CONSULTANT: ABM CONSULTANT

SOUTHERN BYEPASS PHASE 1 MULTAN

California Bearing Ratio

MRD Test Method 213 (Adaptation of ASTM D 1883 - AASHOT 193) Page 1 Of 2 Road Name Description: Location Materials

Surcharge Weight Used(kg) Test No. Can No.

A B C D E F Mass. Wet Soil + Can. Mass Dry Soil + Can. Mass Of Water. A-B Mass Can. Mass Dry Soil . B-D Moisture Content C/E X 100

Standard Load (Stresses) Kg / Cm2

SOUTHERN BYEPASS MULTAN SUB GRADE MATERIAL 1+550 to 2+600 L/S Sub Grade 1st Layer

4.54 1

g g g g g % A5 624.3 571.0 53.3 48 523.0 10.20

Field Sample No. Date Of Sampling Date Tested Quant. Rep. Analyst: Rate of penetration mm/Minute 1.27

Molding Moisture Content (ASTM D 2216)

2

A9 638.2 584 54.2 47.1 536.9 10.10

Density Determination

3

B4 683.1 626.4 56.7 65 561.4 10.10

Test No.

Blows Per Lift

Test No. Mold Volume Mass. Sample + Mold . Mass Mold . Mass Sample . Unit Wet Mass. Percent Moisture Unit Dry Mass. 2

cm g g g g/cm 3 % 3 g/cm

1

2128.0 11155 7090 4065 1.910 10.20 1.734

2

2109.0 11198 6950 4248 2.014 10.1 1.829

3

2124.0 11457 6940 4517 2.127 10.10 1.932

10

Molded

Total Load Kg Unit Load Kg / Cm 2 0

30

Tested

Corrected Load Kg / Cm 2

65

Tested

Corrected Load Kg / Cm 2

Penetration

Per Min. 0

Molded

Total Load Kg Unit Load Kg / Cm 2 0

Molded

Total Load Kg Unit Load Kg / Cm 2 0

Tested

Corrected Load Kg / Cm 2

CBR

%

CBR

%

CBR

%

mm 0 0.64 1.27 1.90 2.54 3.81 5.08 7.62

0.5 1 1.5 2 3 4 6

70.35

105.53

1.0 1.6 2.0 2.4 3.1 3.7 4.7

1.8 2.7 3.4 4.0 5.2 6.3 7.9

5.7 6.0

2.0 3.5 4.5 5.6 7.1 8.7 10.9

3.4 5.9 7.6 9.4 12.0 14.7 18.5 25

13.4 14.0

2.8 4.5 6.0 7.4 9.8 11.6 14.5

4.7 7.6 10.2 12.5 16.6 19.6 24.6

17.8 18.6

Swell Reading

Date Moldend Test No. Mold No. Final Height . Initial Height . Difference . Sample Length . mm mm mm mm 1 1

0.00 0.000 0.00 116.43 0.00

2 2

0.00 0.000 0.00 116.43 0.00 1.931 10.1 30 1.829 14.0 1.834

3 3

0.00 0.000 0 116.43 0.00 g/cm3

Unit Load (Stress) kg / cm2

20

15

10

Percent Swell %

PROCTOR MODIFIED

MAX DRY DENSITY

OPTIMUM MOISTURE CONTENT

%

65 1.932 18.6 g/cm3 %

Blows Per Lift No. Dry Density g/cm . Soaked C.B.R. %

95 % of Max. Dry Density C.B.R At 95% of Max Dry Density

3

10 1.734 6.0

0 0 1.27 2.54 3.81 5.08 6.35 7.62 8.89

Penetration mm

14.2

Contractor:

Consultant:

Lab Technician

Material Inspector

Material Engineer

MULTAN DEVELOPMENT AUTHORITY

CONTRACTOR: CH. CONSTRUCTON COMPANY CONSULTANT: ABM CONSULTANTS:

SOUTHERN BYEPASS MULTAN

California Bearing Ratio

MRD Test Method 213 (Adaptation of ASTM D 1883 - AASHOT 193) Page 2 Of 2 Description: Sub Grade 1st Layer LOCATION: 1+550 TO 2+600 L/S

20.0 18.0 16.0 14.0 Soaked CBR % 12.0 10.0 8.0 6.0 4.0 2.0 0.0 1.650

1.700

1.750

1.800 Dry Density g/cc

1.850

1.900

1.950

MAX DRY DENSITY

1.931 10.1 30 1.829 14.0 65 1.932 18.6

g/cm 3

g/cm

PROCTOR MODIFIED

OPTIMUM MOISTURE CONTENT

BLOWS PER LAYER No. DRY DENSITY AS MOLDED g/cm 3 SOAKED C.B.R. % 95 % of Max. Dry Density C.B.R At 93.0% of Max Dry Density C.B.R At 95% of Max Dry Density

CONTRACTOR:

10 1.734 6.0

1.834 11.6 14.2

CONSULTANT:

% %

Lab Technician

Material Inspector

Material Engineer

MULTAN DEVELOPMENT AUTHORITY

CONTRACTOR:

CHOUDHARY CONSTRUCTION CO.

CONSULTANT:

ABM ENGINEERS

SOUTHERN BYEPASS PHASE 1 MULTAN

Moisture-Density Relationship of Soils

MRDTM 212 (ASTM D 698 - 1557 - AASHO T 99 - T 180)

Project Description Of Sample LOCATION: LAYER: Analyst. A B C D E F G H I J K L M N

Sothern ByePass Multan SUB GRADE MATERIAL 1+550 to 2+600 L/S Sub Grade 1st Layer

Sampling Date Testing Date Field Sample No. Lab. Sample No.

Mold No. Formula Wt. Compacted Wet soil + Mold (gm) Wt. Mold (gm) Volume of Mold (Cm 3 ) Wt. Compacted Wet soil (gm) B-C

1

9149 5376 2135 3773 1.767 A-1 35.4 366.3 353.9 12.4 318.5 3.9 1.701

2

9463 5376 2135 4087 1.914 A-2 35.0 381.9 361.3 20.6 326.3 6.3 1.801

3

9722 5376 2135 4346 2.036 A-3 35.0 412.1 384.2 27.9 349.2 8.0 1.885

4

9915 5376 2135 4539 2.126 A-4 36.2 378.1 346.7 31.4 310.5 10.1 1.931

5

9834 5376 2135 4458 2.088 A-4 41.1 397.1 360.1 37.0 319 11.6 1.871

Wet Density (gm/Cm 3 ) E/D Container No. Wt. of Container Wt. Wet Soil + Container (gm) Wt. Dry Soil + Container (gm) Wt of Water (gm) I-J Wt. of Dry Soil (gm) J-H Water Content % ( K / L )*100 Dry Density (g/cc) F / ( 1+ ( M/100 ) ) OPTIMUM MOISTURE CONTENT % MAXIMUM DRY DENSITY gm/Cm 3

10.1 1.931

Moisture-Density Relationship

1.950

1.900

Dry Density gm/cm3

1.850

1.800

1.750

1.700

1.650 0 1 2 3 4 5 6 7 8 9 10 11 12 13

Moisture Content %

Remraks :

CONTRACTOR:

CONSULTANT:

LAB TECHNICIAN

MATERIALS INSPECTOR

MATERIAL ENGINEER

MULTAN DEVELOPMENT AUTHORITY

CONTRACTOR: NAZIR & COMPANY CONSULTANT: ABM ENGINEERS

FATIMA JINNAH TOWN PHASE 1 VEHARI ROAD MULTAN

Soils Classification /Atterburg Limits

MRD Test Method 208 -209 - 210 (Adaptation of AASHTO T 89 - 90 - 80) Project Kind of Material Location Quantity Represented FATIMA JINNAH TOWN PHASE 1 SUB GRADE MATERIAL B-BLOCK

Sampling Date Testing Date Lab. Sample No.

1/1/2010

Material Used:

SUB GRADE

Sieve Analysis

Sieve Size

Individual Wt. Retained Cumulative Wt. Retained

Cumulative Percent Retained

Percent Passing

3/4 in (19 mm) No.4 (4.75 mm) No.10 (2.00 mm) No. 40 (0.425 mm) No.200 (0.075 mm) Pan Wash Total

0 0 0.9 5.7 179.8

0 0 0.9 6.6 186.4

0 0 0 1 20

100 100 99.9 99.3 80.3

186.4 Original Wt. Gram

Dry Wt. Gram 946.3

LIQUID LIMIT TEST 33 25 2 3 A-2 A-3 17.00 16.80 52.19 56.28 45.34 48.06 6.85 8.22 28.34 31.26 24.16 26.29

Wash Dry Wt. Gram

Atterburg Limits (Liquid Limit & Plastic Limit )

Type of Test Number of Blows Trial No. Container Number Wt. of Container Wt. Wet Soil + Container Wt. Dry Soil + Container Wt. of Water Wt. of Dry Soil Water Content % 41 1 A-1 27.70 59.74 53.89 5.85 26.19 22.35 17 4 A-4 20.20 53.06 45.84 7.22 25.64 28.16 PLASTIC LIMIT TEST 1 A-5 19.50 33.12 30.76 2.36 11.26 20.95 2 A-6 22.40 34.48 32.40 2.08 10.00 20.81 3 A-7 17.90 31.78 29.38 2.40 11.48 20.93

g g g g g

Avg.

30.00 29.00

24.80

20.90

Water Content %

28.00 27.00 26.00 25.00 24.00 23.00 22.00 21.00 20.00 19.00

10

20

25

30

40

50

60

70

80

90

100

No. of Blows

Liquid Limit (L.L) Plasticity Index (P.I)

CONTRACTOR LL =

26.00 5.10

P.I = L.L - P.L

Plastic Limit (P.L) Classification Group

CONSULTANT

P.L =

20.90

A-4

CONSULTANT

LAB TECHNICIAN

MATERIALS INSPECTOR

MATERIAL ENGINEER

MULTAN DEVELOPMENT AUTHORITY

CONTRACTOR: NAZIR & COMPANY CONSULTANT: ABM ENGINEERS:

FATIMA JINNAH TOWN PHASE 1 VEHARI ROAD MULTAN Sieve Analysis of Sub Grade Material

Grain Size Analysis AASHTO-T-27

PROJECT:

Kind of Material LOCATION Original Sourse

FATIMA JINNAH TOWN SUB GRADE MAERIAL B-BLOCK

SUB GRADE MATERIAL

Sampling Date Testing Date 01/01/2010 Field Sample No. Lab. Sample No. Analyst.

Weight of Original Sample Weight of Oven Dry Weight of Washed Oven Dry Sieve Size

mm 75

63 50.0 37.5 25.0 19.0 12.5 9.5 4.75 2.36 2.00 1.18 0.60 0.425 0.3 0.18 0.15 0.075

Gms Gms Gms

Cum. Wt.Retained Cum. Retained

Grms %

1193.6

Date () Cum. Passing

%

Wt. Retained

Grms

Specification

%

Remarks

(alt.) 3''

2 1/2" 2" 1 1/2'' 1" 3/4 " 1/2 " 3/8 " No. 4 No. 8 No. 10 No. 16 No. 30 No. 40 No. 50 No. 80 No. 100 No. 200

0 0 0 0 161 0 0 7.2 9.5

0 0 0 0 161 0 0 0 0.0 9.5

34.4 48 60 0.0 13.5 0.0 99.7 0.0 0.0 0.8

65.6 52.0 40.4 100.0 86.5 100.0 0.3 100.0 100.0 99.2

81.2

90.7

7.6

92.4

37.0 Oven Dry wt. -4 # Sieve ( Gms) Sieve Size Passing %

127.7 No.10

10.7 No.40

89.3 No.200

Calculations

CONTRACTOR:

Cumulative Percent Retained = Cumulative mass Retained / Dry Mass Before Wash Percent Passing = 100 - Cumulative Percent Retained

CONSULTANT:

CONSULTANT:

LAB TECHNICIAN

MATERIAL INSPECTOR

MATERIAL ENGINEER

MULTAN DEVELOPMENT AUTHORITY

CONTRACTOR:

CHOUDHARY CONSTRUCTION CO.

CONSULTANT:

ABM ENGINEERS

SOUTHERN BYEPASS PHASE 1 MULTAN

Moisture-Density Relationship of Soils

MRDTM 212 (ASTM D 698 - 1557 - AASHO T 99 - T 180)

Project Description Of Sample LOCATION: LAYER: Analyst. A B C D E F G H I J K L M N

Sothern ByePass Multan SUB BASE MATERIAL 1+550 to 2+600 L/S Sub Grade 1st Layer

Sampling Date Testing Date Field Sample No. Lab. Sample No.

Mold No. Formula Wt. Compacted Wet soil + Mold (gm) Wt. Mold (gm) Volume of Mold (Cm 3 ) Wt. Compacted Wet soil (gm) B-C

1

9149 5376 2135 3773 1.767 A-1 35.4 366.3 353.9 12.4 318.5 3.9 1.701

2

9463 5376 2135 4087 1.914 A-2 35.0 381.9 361.3 20.6 326.3 6.3 1.801

3

9722 5376 2135 4346 2.036 A-3 35.0 412.1 384.2 27.9 349.2 8.0 1.885

4

9915 5376 2135 4539 2.126 A-4 36.2 378.1 346.7 31.4 310.5 10.1 1.931

5

9834 5376 2135 4458 2.088 A-4 41.1 397.1 360.1 37.0 319 11.6 1.871

Wet Density (gm/Cm 3 ) E/D Container No. Wt. of Container Wt. Wet Soil + Container (gm) Wt. Dry Soil + Container (gm) Wt of Water (gm) I-J Wt. of Dry Soil (gm) J-H Water Content % ( K / L )*100 Dry Density (g/cc) F / ( 1+ ( M/100 ) ) OPTIMUM MOISTURE CONTENT % MAXIMUM DRY DENSITY gm/Cm 3

10.1 1.931

Moisture-Density Relationship

1.950

1.900

Dry Density gm/cm3

1.850

1.800

1.750

1.700

1.650 0 1 2 3 4 5 6 7 8 9 10 11 12 13

Moisture Content %

Remraks :

CONTRACTOR:

CONSULTANT:

LAB TECHNICIAN

MATERIALS INSPECTOR

MATERIAL ENGINEER

MULTAN DEVELOPMENT AUTHORITY

CONTRACTOR:

CH.ABDUL LATIF & CO.

CONSULTANT:

ABM ENGINEERS

SOUTHERN BYEPASS PART:II MULTAN

Moisture-Density Relationship of Soils

MRDTM 212 (ASTM D 698 - 1557 - AASHO T 99 - T 180)

Project Description Of Sample Analyst. A B C D E F G H I J K L M N Mold No. Formula Wt. Compacted Wet soil + Mold (gm) Wt. Mold (gm) Volume of Mold (Cm 3 ) Wt. Compacted Wet soil (gm) B-C

Sampling Date Testing Date Field Sample No. Lab. Sample No.

1

9190 4836 2118 4354 2.056 A-1 48.0 573.9 558.6 15.3 510.6 3.0 1.996

2

9502 4836 2118 4666 2.203 A-2 65.0 613.4 591.3 22.1 526.3 4.2 2.114

3

9702 4836 2118 4866 2.298 A-3 47.1 639.6 610.3 29.3 563.2 5.2 2.184

4

9904 4836 2118 5068 2.393 A-4 62.4 643.1 607.7 35.4 545.3 6.5 2.247

5

9729 4836 2118 4893 2.310 A-1 70.1 619.5 580.7 38.8 510.6 7.6 2.147

Wet Density (gm/Cm 3 ) E/D Container No. Wt. of Container Wt. Wet Soil + Container (gm) Wt. Dry Soil + Container (gm) Wt of Water (gm) I-J Wt. of Dry Soil (gm) J-H Water Content % ( K / L )*100 Dry Density (g/cc) F / ( 1+ ( M/100 ) ) OPTIMUM MOISTURE CONTENT % MAXIMUM DRY DENSITY gm/Cm 3

6.6 2.248

Moisture-Density Relationship

2.300

2.250

Dry Density gm/cm3

2.200

2.150

2.100

2.050

2.000

1.950

0 1 2 3 4 5 6 7 8

Moisture Content %

Remraks :

CONTRACTOR:

CONSULTANT:

LAB TECNICIAN

MATERIALS INSPECTOR

MATERIAL ENGINEER

MULTAN DEVELOPMENT AUTHORITY

CONTRACTOR: CH.CONSTRUCTION COMPANY CONSULTANT: ABM CONSULTANT

SOUTHERN BYEPASS PHASE 1 MULTAN

California Bearing Ratio

MRD Test Method 213 (Adaptation of ASTM D 1883 - AASHOT 193) Page 1 Of 2 Road Name Description: Location Materials

Surcharge Weight Used(kg) Test No. Can No.

A B C D E F Mass. Wet Soil + Can. Mass Dry Soil + Can. Mass Of Water. A-B Mass Can. Mass Dry Soil . B-D Moisture Content C/E X 100

Standard Load (Stresses) Kg / Cm2

SOUTHERN BYEPASS MULTAN SUB BASE MATERIAL 0+175 to 1+250 L/S Sub Base 1st Layer

4.54 1

g g g g g % A5 674.5 639.6 34.9 76 563.6 6.20

Field Sample No. Date Of Sampling Date Tested Quant. Rep. Analyst: Rate of penetration mm/Minute 1.27

Molding Moisture Content (ASTM D 2216)

2

A9 594.5 563.6 30.9 65 498.6 6.20

Density Determination

3

B4 608.1 576.8 31.3 64 512.8 6.10

Test No.

Blows Per Lift

Test No. Mold Volume Mass. Sample + Mold . Mass Mold . Mass Sample . Unit Wet Mass. Percent Moisture Unit Dry Mass. 2

cm g g g g/cm 3 % 3 g/cm

1

2109.0 11466 6950 4516 2.141 6.20 2.016

2

2124.0 11690 6940 4750 2.236 6.2 2.106

3

2128.0 12162 7090 5072 2.383 6.10 2.246

10

Molded

Total Load Kg Unit Load Kg / Cm 2 0

30

Tested

Corrected Load Kg / Cm 2

65

Tested

Corrected Load Kg / Cm 2

Penetration

Per Min. 0

Molded

Total Load Kg Unit Load Kg / Cm 2 0

Molded

Total Load Kg Unit Load Kg / Cm 2 0

Tested

Corrected Load Kg / Cm 2

CBR

%

CBR

%

CBR

%

mm 0 0.64 1.27 1.90 2.54 3.81 5.08 7.62

0.5 1 1.5 2 3 4 6

70.35

105.53

4.4 7.3 10.0 12.3 15.6 18.2 22.0

3.1 5.1 6960.0 8594.7 10.9 12.6 15.3

12217.0 12.0

11.0 17.9 24.3 28.6 35.6 42.1 51.0

7.7 12.5 16.9 19.9 24.8 29.3 35.5 10000

28.3 27.8

14.2 23.1 31.2 37.8 47.2 55.6 67.3

9.9 16.1 21.7 26.3 32.9 38.7 46.8

37.4 36.7

Swell Reading

Date Moldend Test No. Mold No. Final Height . Initial Height . Difference . Sample Length . mm mm mm mm 1 1

0.4 0.000 0.40 116.43 0.34

2 2

0.32 0.000 0.32 116.43 0.27 2.233 6.0 30 2.106 27.8 2.188

3 3

0.21 0.000 0.21 116.43 0.18 g/cm3

Unit Load (Stress) kg / cm2

8000

6000

4000

Percent Swell %

PROCTOR MODIFIED

2000

MAX DRY DENSITY

OPTIMUM MOISTURE CONTENT

%

65 2.246 36.7 g/cm3 %

0

0 1.27 2.54 3.81 5.08 6.35 7.62 8.89

Blows Per Lift No. Dry Density g/cm 3 . Soaked C.B.R. %

98 % of Max. Dry Density C.B.R At 98% of Max Dry Density

10 2.016 12.0

-2000

Penetration mm

#REF!

Contractor:

Consultant:

Lab Technician

Material Inspector

Material Engineer

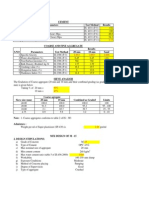

AN ASSOCIATES GEOTECHNICAL &SOIL TESTING LABORATORY

ATTERBURG'S LIMITS

PROJECT:

Sub-soil Investigation of Plot of Capt. Arshad M.Nasir.

BH # Sample Depth : Sampling Date:

1 03 ft 05/10/2011 08/10/2011

LOCATION: Plot #61,ST# Jinnah Blved,Sector#A,PH#II DHA Islamabad.

946.3

Type of Test Number of Blows Trial No. Container Number Wt. of Container Wt. Wet Soil + Container Wt. Dry Soil + Container Wt. of Water Wt. of Dry Soil Water Content % g g g g g 35 1 4 9.00 16.23 14.62 1.61 5.62 28.65

Testing Date :

Atterburg Limits (Liquid Limit & Plastic Limit )

LIQUID LIMIT TEST 26 2 5 13.70 23.60 21.25 2.35 7.55 31.13 17 3 6 12.50 20.85 18.74 2.11 6.24 33.81 1 A4 5.00 12.50 11.07 1.43 6.07 23.56 2 A2 5.50 17.20 14.88 2.32 9.38 24.73 3 A3 6.00 15.80 13.99 1.81 7.99 22.65 PLASTIC LIMIT TEST

Avg.

31.20

23.65

35.00

Water Content %

34.00

33.00

32.00

31.00

31.13

30.00

29.00

28.00

20

25

30

40

50

60

70

80

90

10

100

No. of Blows

Liquid Limit (L.L) Plasticity Index (P.I)

LL =

31.20 7.55

P.I = L.L - P.L

Plastic Limit (P.L) Classification Group

P.L =

23.65 CL-ML

TESTED BY:---------------------------

CHECKED BY:---------------------------

You might also like

- Filter MediaDocument51 pagesFilter Mediavnil100% (1)

- Specific Gravity 20mmDocument4 pagesSpecific Gravity 20mmIsaiahogedaNo ratings yet

- Boiler DataDocument28 pagesBoiler DataMonique ThomasNo ratings yet

- Property of FRP Chart 1 PDFDocument1 pageProperty of FRP Chart 1 PDFKurt FinkNo ratings yet

- Ball Mill OptimizationDocument82 pagesBall Mill OptimizationRashek_119588% (16)

- The California Bearing Ratio (CBR) (1/1) : (3) - Penetration (1) - DensityDocument8 pagesThe California Bearing Ratio (CBR) (1/1) : (3) - Penetration (1) - Densityabdallah abdurhman aliNo ratings yet

- Kandis Ex PalasDocument113 pagesKandis Ex PalasBm X BreakerNo ratings yet

- Specipic Gravity Test: SNI 03-1969-1990 & SNI 03-1970-1990Document113 pagesSpecipic Gravity Test: SNI 03-1969-1990 & SNI 03-1970-1990Bm X BreakerNo ratings yet

- Grain Size Distribution: Job No. Sample Size Client Sample Type Location Delivery Date SourceDocument14 pagesGrain Size Distribution: Job No. Sample Size Client Sample Type Location Delivery Date SourceDarmadiNo ratings yet

- Civ T Qac 00134 ProctorDocument6 pagesCiv T Qac 00134 ProctorIsaiahogedaNo ratings yet

- CBR TestDocument7 pagesCBR Testjaffna100% (1)

- Gatch Quality TestDocument7 pagesGatch Quality TestMansoor AliNo ratings yet

- Bridges-2 - 1Document99 pagesBridges-2 - 1Kwame AsamoaNo ratings yet

- Embankment Quality TestsDocument10 pagesEmbankment Quality TestsMansoor AliNo ratings yet

- Compaction TestDocument9 pagesCompaction TestFaisal SardarNo ratings yet

- ESP Lesson 7 (Industrial Applications For Fabric Filters)Document24 pagesESP Lesson 7 (Industrial Applications For Fabric Filters)jkaunoNo ratings yet

- Dgar 1Document22 pagesDgar 1Moses KaswaNo ratings yet

- Data Uji TanahDocument22 pagesData Uji TanahPrieta Aghi MeiliaNo ratings yet

- ConcreteDocument169 pagesConcretesabareesan09No ratings yet

- ABU CHAPTER 4 AND 5Document20 pagesABU CHAPTER 4 AND 5Engr Edozie JoshuaNo ratings yet

- Ministry of Transportation - Field Services, PavingDocument12 pagesMinistry of Transportation - Field Services, PavingukruegerNo ratings yet

- PVC SpecDocument2 pagesPVC SpecMuhammad Noor FizuanNo ratings yet

- Lab_ReportDocument6 pagesLab_Reportmaryali416No ratings yet

- Plastic Concrete TestDocument8 pagesPlastic Concrete TestSlan ClanNo ratings yet

- SDBC With FillerDocument8 pagesSDBC With Fillerer_kenedyNo ratings yet

- Laboratorio 1Document29 pagesLaboratorio 1Omar Martinez RetamozoNo ratings yet

- MDD SoilDocument4 pagesMDD SoilDaljeet SidhuNo ratings yet

- Courage Transport PracDocument11 pagesCourage Transport Prackundayi shavaNo ratings yet

- Jayamix RM Specification (Standard Raw Material)Document6 pagesJayamix RM Specification (Standard Raw Material)Afip PullahNo ratings yet

- LS-628 R23 PDFDocument7 pagesLS-628 R23 PDFqwerysqlNo ratings yet

- Soil Testing ReportDocument12 pagesSoil Testing ReportEinstein JeboneNo ratings yet

- Mix DesignDocument32 pagesMix DesignRiLha HaNumNo ratings yet

- Plastic Concrete Compression Strength and Elasticity Modulus Changes During TimeDocument8 pagesPlastic Concrete Compression Strength and Elasticity Modulus Changes During TimeKhlif NadaNo ratings yet

- MDD, Omc (VH) - GCSDocument4 pagesMDD, Omc (VH) - GCSDaniel KariukiNo ratings yet

- California Bearing Ratio Test Report: AASHTO T-193Document4 pagesCalifornia Bearing Ratio Test Report: AASHTO T-193tannuNo ratings yet

- U1 Dry Sieve AnalysisDocument9 pagesU1 Dry Sieve AnalysisFakeyha RashidNo ratings yet

- SDBC Without FillerDocument9 pagesSDBC Without Fillerer_kenedyNo ratings yet

- Sample Description: K17+180 Date: 2016.4.14 Sample Designation: K16-K18Document33 pagesSample Description: K17+180 Date: 2016.4.14 Sample Designation: K16-K18kwameNo ratings yet

- Use of Additive Materials in Sub Grade For Road ConstructionDocument6 pagesUse of Additive Materials in Sub Grade For Road Constructionseventhsensegroup100% (1)

- Slump Test: Sourse /location:: CC Pavement Grade of Concrete:: M30 Water Cement Ratio:: 0.45Document37 pagesSlump Test: Sourse /location:: CC Pavement Grade of Concrete:: M30 Water Cement Ratio:: 0.45ChManikumarNo ratings yet

- 2305 - 15 - Hasil Trial Embankment FilterDocument12 pages2305 - 15 - Hasil Trial Embankment FilterAngghy NaghaNo ratings yet

- Transpo Open EndedDocument38 pagesTranspo Open EndedInformation StudyNo ratings yet

- K0 413涵洞基底不合适材料试验资料Document33 pagesK0 413涵洞基底不合适材料试验资料kwameNo ratings yet

- Laboratory Manual FinalDocument57 pagesLaboratory Manual Finalrohit kumarNo ratings yet

- Laboratory WorksDocument32 pagesLaboratory WorksCliff Jude ZehnderNo ratings yet

- Desidn AopDocument73 pagesDesidn AopDavid LambertNo ratings yet

- California Bearing Ratio (CBR) TestDocument6 pagesCalifornia Bearing Ratio (CBR) TestgimanuNo ratings yet

- 130 KMDocument967 pages130 KMKwame AsamoaNo ratings yet

- Arba Minch University - Institute of Technology Civil &urban Engineering Department Final Examination, (1st Semester, AY 2013-14)Document4 pagesArba Minch University - Institute of Technology Civil &urban Engineering Department Final Examination, (1st Semester, AY 2013-14)Ashebir AsratNo ratings yet

- Syce Sem - Iv Mini ProjectDocument37 pagesSyce Sem - Iv Mini ProjectAmey KadulkarNo ratings yet

- GONDA SUB-STATION (400/220/132kV) : Flakiness & Elongation Index (Is 2386, Part 1)Document6 pagesGONDA SUB-STATION (400/220/132kV) : Flakiness & Elongation Index (Is 2386, Part 1)Aamir Anwar100% (1)

- A Ready Reckoner For Quantity Surveyors: ObjectiveDocument105 pagesA Ready Reckoner For Quantity Surveyors: ObjectiveanaszkNo ratings yet

- Hoja de Calculo FP Borrador - 2Document14 pagesHoja de Calculo FP Borrador - 22artNo ratings yet

- Strength of ConcreteDocument3 pagesStrength of ConcretelombangrurusNo ratings yet

- Gradation Hydrometer PI (BH AB1 AS1)Document10 pagesGradation Hydrometer PI (BH AB1 AS1)Kiran Chandra PrakashNo ratings yet

- Isokinetic Calibration Report Raw Mill Line 2Document89 pagesIsokinetic Calibration Report Raw Mill Line 2Muhammad AbrarNo ratings yet

- Plastic Limit Test - 004Document8 pagesPlastic Limit Test - 004funky_jebonNo ratings yet

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceFrom EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceNo ratings yet

- Roll-to-Roll Manufacturing: Process Elements and Recent AdvancesFrom EverandRoll-to-Roll Manufacturing: Process Elements and Recent AdvancesJehuda GreenerNo ratings yet

- Butler Pa Leo Magnetism BookDocument248 pagesButler Pa Leo Magnetism BookISHTIAQ NOORNo ratings yet

- Sufi PoetryDocument107 pagesSufi PoetryISHTIAQ NOOR100% (1)

- Solar SystemDocument105 pagesSolar Systemv155r100% (18)

- Islamic MedicineDocument5 pagesIslamic Medicinefarizah100% (2)