Professional Documents

Culture Documents

MOS of Fabrication and Welding of F27B01 Stainless Steel Laterals

MOS of Fabrication and Welding of F27B01 Stainless Steel Laterals

Uploaded by

tinzarmoeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MOS of Fabrication and Welding of F27B01 Stainless Steel Laterals

MOS of Fabrication and Welding of F27B01 Stainless Steel Laterals

Uploaded by

tinzarmoeCopyright:

Available Formats

Pelican

(S96029)

Work Method Statement of Fabrication

and Welding of F27B01 Stainless Steel

Laterals Spools (PCW, CPCW, OFA,

EMSH)

Ref. no: S96029-ESS-F27B01-SMT-0012-

Prepared by: WMS-0002

(Signature)

Revision: 00

Name: Dickson

Contact no.: 9271 8128 Date: 4 May 2022

Company: Exyte Services Singapore Pte Ltd

Page 1 of 8

Method Statement Title:

Work Method Statement of Fabrication and Welding of F27B01

Stainless Steel Laterals Spools (PCW, CPCW, OFA, EMSH)

Exyte

Contractor Package / Package/

QA / QC EHS Construction

Site Site

Manager Manager Manager

Supervisor Engineer

Exyte

Goh Ann

Name Services James Ho

Kee

Pte Ltd

Signature

Date

Revision 2.0 Revision Date: 4/5/2022

Pelican

(S96029)

Work Method Statement of Fabrication

and Welding of F27B01 Stainless Steel

Laterals Spools (PCW, CPCW, OFA,

EMSH)

Ref. no: S96029-ESS-F27B01-SMT-0012-

Prepared by: WMS-0002

(Signature)

Revision: 00

Name: Dickson

Contact no.: 9271 8128 Date: 4 May 2022

Company: Exyte Services Singapore Pte Ltd

Page 2 of 8

1.0 Scope of Work

To fabricate stainless steel pipes/ laterals by cut and weld the stainless steel pipe based on

drawing

2.0 Resources

2.1 Materials

All materials used on site will be of approved type and they are as below:-

No Type / Brand Name Description of Materials

1 YC Inox Pipes

2 Sow Long Industrial Co. Ltd Ball Valves

3 Kao Jung Fittings

4 Yih Tai Fittings

5 DKB Pipes

2.2 Machinery and Equipment

No Type / Model Quantity

1 Band Saw 5

2 Hand Grinder 20

3 Danox TIG Water-cooled Welding 10

Machine

4 Danox TIG Air-cooled Welding 5

Machine

Revision 2.0 Revision Date: 4/5/2022

Pelican

(S96029)

Work Method Statement of Fabrication

and Welding of F27B01 Stainless Steel

Laterals Spools (PCW, CPCW, OFA,

EMSH)

Ref. no: S96029-ESS-F27B01-SMT-0012-

Prepared by: WMS-0002

(Signature)

Revision: 00

Name: Dickson

Contact no.: 9271 8128 Date: 4 May 2022

Company: Exyte Services Singapore Pte Ltd

Page 3 of 8

2.3 Manpower involved / Plan

Trade Nos. Lead person Remarks

Welder 10 1

Pipe Fitter 5 1

QC 2 1

Revision 2.0 Revision Date: 4/5/2022

Pelican

(S96029)

Work Method Statement of Fabrication

and Welding of F27B01 Stainless Steel

Laterals Spools (PCW, CPCW, OFA,

EMSH)

Ref. no: S96029-ESS-F27B01-SMT-0012-

Prepared by: WMS-0002

(Signature)

Revision: 00

Name: Dickson

Contact no.: 9271 8128 Date: 4 May 2022

Company: Exyte Services Singapore Pte Ltd

Page 4 of 8

3.0 Work Methods

3.1 Mobilization / Site set up

Raw stainless steel pipes will be unloaded and shifted to the material prep area.

Pipes are taken and cut to size using the bandsaw placed in the material prep area

Cut pipes are then placed onto racks and moved to the Fit-up bays on the top half

Completed pipes will be shifted to the QC final inspection and packing bay to be

shifted out

Revision 2.0 Revision Date: 4/5/2022

Pelican

(S96029)

Work Method Statement of Fabrication

and Welding of F27B01 Stainless Steel

Laterals Spools (PCW, CPCW, OFA,

EMSH)

Ref. no: S96029-ESS-F27B01-SMT-0012-

Prepared by: WMS-0002

(Signature)

Revision: 00

Name: Dickson

Contact no.: 9271 8128 Date: 4 May 2022

Company: Exyte Services Singapore Pte Ltd

Page 5 of 8

3.2 Procedure

Use qualified welders for welding works.

Fillet welds are used for welding slip on flanges to pipe.

Welder must wear welding hand gloves and welding face shield

Pipe joints must be carefully prepared to ensure good results

Clean the weld edges or surfaces of all loose scale, slag, rust, paint, oil, and other foreign

matter

Ensure that the joint surfaces are smooth and uniform

Make the bevels by grinding or by beveling machine

When beveling, cut away as little metal as possible to allow for complete fusion and

penetration

Ensure bevels have an angle of 60° and a root gap of 2 - 3.5mm

Proper beveling reduces the amount of filler metal required which, in turn, reduces time

and expense. In addition, it also means less strain in the weld and a better job of design

and welding

Align the piping before welding and maintain it in alignment during the welding operation

The maximum alignment tolerance is 20 percent of the pipe thickness

Revision 2.0 Revision Date: 4/5/2022

Pelican

(S96029)

Work Method Statement of Fabrication

and Welding of F27B01 Stainless Steel

Laterals Spools (PCW, CPCW, OFA,

EMSH)

Ref. no: S96029-ESS-F27B01-SMT-0012-

Prepared by: WMS-0002

(Signature)

Revision: 00

Name: Dickson

Contact no.: 9271 8128 Date: 4 May 2022

Company: Exyte Services Singapore Pte Ltd

Page 6 of 8

To ensure proper initial alignment, you should use clamps or jigs as holding devices. A

piece of angle iron makes a good jig for a small-diameter pipe

While a section of channel or I-beam is more suitable for larger diameter pipe

QC to inspect dimensions and alignment of fitted pipe

Weld stainless steel pipes together based on approved WPS

Ensure proper purging with argon gas is in place prior to welding

After welding, QC to confirm dimensions and alignment of welded pipe

Acid pickling cleaning to be performed on the outer surface of the pipe with proper PPE

eg. rubber gloves.

Housekeeping should be carried out after completion of work activity

3.3 House Keeping

Keep all equipment back to their respective locations after use

Thorough sweeping of floor at individual stations after end of day

Revision 2.0 Revision Date: 4/5/2022

Pelican

(S96029)

Work Method Statement of Fabrication

and Welding of F27B01 Stainless Steel

Laterals Spools (PCW, CPCW, OFA,

EMSH)

Ref. no: S96029-ESS-F27B01-SMT-0012-

Prepared by: WMS-0002

(Signature)

Revision: 00

Name: Dickson

Contact no.: 9271 8128 Date: 4 May 2022

Company: Exyte Services Singapore Pte Ltd

Page 7 of 8

4.0 Attachments (Org chart, PE Design, Catalogues, etc)

Organizational Chart

5.0 Emergency Response (Emergency contact details)

S/n Name Designation Contact no.

1 Ng Aik Beng Workshop 1 Manager 9735 3806

2 Dickson Sie Asst. Workshop Manager 9271 8128

3 Mohammad Izran Bin Yusoff Workshop 1 Safety Coordinator 8693 0366

4 Mohammad Izran Bin Yusoff First Aider 8693 0366

5 Chong Kok Hoong Workshop 1 Supervisor 9126 2990

6 Lin Hantang ESR FSM 9113 1095

Singapore Civil Defense Force 995

Ambulance 995

Revision 2.0 Revision Date: 4/5/2022

Pelican

(S96029)

Work Method Statement of Fabrication

and Welding of F27B01 Stainless Steel

Laterals Spools (PCW, CPCW, OFA,

EMSH)

Ref. no: S96029-ESS-F27B01-SMT-0012-

Prepared by: WMS-0002

(Signature)

Revision: 00

Name: Dickson

Contact no.: 9271 8128 Date: 4 May 2022

Company: Exyte Services Singapore Pte Ltd

Page 8 of 8

5.1 Factory 1 Evacuation Plan

Points to take note:

1. General SWP should not be written as work procedure

2. Job Specific Sketches and pictures are to be included in the work steps

3. First submission to be a draft. After the first joint review / dicussion, all refernce documents are to be attached

4. Necessary drawings are to be attached

Revision 2.0 Revision Date: 4/5/2022

You might also like

- Work Method Statement For Constructing New RC Plinth & Top Up SlabDocument9 pagesWork Method Statement For Constructing New RC Plinth & Top Up SlabMohd Hafizi Azlan100% (1)

- Eddy Current (RFT) ProcedureDocument12 pagesEddy Current (RFT) ProcedureAnonymous gFcnQ4go83% (6)

- Method Statement Fabrication of Girder - Rev4Document49 pagesMethod Statement Fabrication of Girder - Rev4John Rom Cabadongga100% (1)

- ALLHAT Journal ClubDocument3 pagesALLHAT Journal ClubcvariableNo ratings yet

- MPS Bare Pipe EN 10219 - Kraken Australia Pty LTD Rev.0Document26 pagesMPS Bare Pipe EN 10219 - Kraken Australia Pty LTD Rev.0Alfian ImaduddinNo ratings yet

- Pipe Supports z4Document5 pagesPipe Supports z4alla malikNo ratings yet

- MS-TCC-2200-020-00001 - 6 Insul.Document96 pagesMS-TCC-2200-020-00001 - 6 Insul.ronald mirabelNo ratings yet

- Gre Pipe Technical Documents PDFDocument64 pagesGre Pipe Technical Documents PDFSunriseNo ratings yet

- Final 26 PicDocument9 pagesFinal 26 PicHaryy PrabowoNo ratings yet

- Steel Structure Erection SpecificationDocument3 pagesSteel Structure Erection SpecificationSallah OmranNo ratings yet

- 1 KU-TWK-40-IC-REQ-0015 - 0 - Material Requistion - Fibre Optic CableDocument8 pages1 KU-TWK-40-IC-REQ-0015 - 0 - Material Requistion - Fibre Optic CableFadi SabbaghNo ratings yet

- Required Information For Analysing The Potential Effect of Sheet Pile On Cathodic Protection of Existing Oil PipesDocument23 pagesRequired Information For Analysing The Potential Effect of Sheet Pile On Cathodic Protection of Existing Oil PipesmladenprNo ratings yet

- Forging SDocument93 pagesForging SrichardchiamNo ratings yet

- Laboratory Course Report: Mansoorp Syed 203219012Document44 pagesLaboratory Course Report: Mansoorp Syed 203219012Santosh YelagandulaNo ratings yet

- MAS Cable TrayDocument5 pagesMAS Cable TrayJofey SimonNo ratings yet

- E00804 Commercial Building For MRCB Technical OfferDocument8 pagesE00804 Commercial Building For MRCB Technical OfferkirubaNo ratings yet

- Concession RequestDocument1 pageConcession Requestmitendra singhNo ratings yet

- Structural Steel Design DetailsDocument7 pagesStructural Steel Design DetailsJanya AssociatesNo ratings yet

- WIR Steel PlatformDocument3 pagesWIR Steel PlatformDarren LiewNo ratings yet

- ONGC Suggested Vendor List PDFDocument70 pagesONGC Suggested Vendor List PDFmanishaNo ratings yet

- ONGC Suggested Vendor ListDocument70 pagesONGC Suggested Vendor Listajaykg0% (1)

- DM Fillerboard - HuntonDocument65 pagesDM Fillerboard - HuntonFahis V MNo ratings yet

- 60 41 Ab SPC 00002Document39 pages60 41 Ab SPC 00002Vineet RungtaNo ratings yet

- COE 0350-01-15 en TechRpt 0006 Nitrogen Plant Vessel Nozzle Load Assessments - RevA0Document80 pagesCOE 0350-01-15 en TechRpt 0006 Nitrogen Plant Vessel Nozzle Load Assessments - RevA0SbuZikalalaNo ratings yet

- DRP001 Ouf Gal Pro Q 000 064 S1Document26 pagesDRP001 Ouf Gal Pro Q 000 064 S1Rafat KhanNo ratings yet

- MPS ITP Bare Pipe - PT Sari Dumai Oleo (Signed SAP)Document30 pagesMPS ITP Bare Pipe - PT Sari Dumai Oleo (Signed SAP)Alfian ImaduddinNo ratings yet

- TS-MES-3203-CGC - Fittings - 13.03.2023Document321 pagesTS-MES-3203-CGC - Fittings - 13.03.2023energy8001No ratings yet

- GGG-SPC-PIP-0013 - Rev 02Document25 pagesGGG-SPC-PIP-0013 - Rev 02oleg safaniukNo ratings yet

- Structural Steel FabricationDocument14 pagesStructural Steel FabricationClarkFedele27No ratings yet

- Welding Procedure B69AWDocument2 pagesWelding Procedure B69AWMastram HatheshNo ratings yet

- DRP001 Ouf Gal Pro Q 000 063 S2Document66 pagesDRP001 Ouf Gal Pro Q 000 063 S2Rafat KhanNo ratings yet

- Bolted Flange and Gasket Joints Assembly ProcedureDocument9 pagesBolted Flange and Gasket Joints Assembly ProceduremohdNo ratings yet

- Brochure The Precast Concrete Product: BetonDocument9 pagesBrochure The Precast Concrete Product: BetonA Akbar HawardiNo ratings yet

- 26071-100-VSC-CV5-00009 - Method Statment of Sheet Pile 00ADocument13 pages26071-100-VSC-CV5-00009 - Method Statment of Sheet Pile 00ARezky BaskoroNo ratings yet

- CAS1969-2G00-31-110-001 - 2 Design Criteria For Electrical EngineeringDocument44 pagesCAS1969-2G00-31-110-001 - 2 Design Criteria For Electrical EngineeringAnindya ananda putriNo ratings yet

- MST-Structural Steel RepairDocument11 pagesMST-Structural Steel RepairDelta akathehuskyNo ratings yet

- Fabrication Procedure DMW-4820M00250-000120-19Document8 pagesFabrication Procedure DMW-4820M00250-000120-19mohd as shahiddin jafriNo ratings yet

- Spantech Technical Globe Valve PDFDocument3 pagesSpantech Technical Globe Valve PDFVijay - Spantech EngineersNo ratings yet

- Field Inspection Report: Item No Item Description QTY Fitup/Welding Report RequiredDocument2 pagesField Inspection Report: Item No Item Description QTY Fitup/Welding Report RequiredsivaNo ratings yet

- Ess-Byn-Hw-Sat-005-Report (R4-S2) - 7 Oct 22Document47 pagesEss-Byn-Hw-Sat-005-Report (R4-S2) - 7 Oct 22Mrbean BeanNo ratings yet

- CPP HT Pipeline ReportDocument301 pagesCPP HT Pipeline ReportAbdulkaderNo ratings yet

- Icf MD Spec 200 Rev 04 PDFDocument20 pagesIcf MD Spec 200 Rev 04 PDFUniversal LaboratoryNo ratings yet

- 50 Pies 00065 - BBDocument6 pages50 Pies 00065 - BBbsnegi111No ratings yet

- MS For Kerb Stone FixingDocument67 pagesMS For Kerb Stone FixingAdrian FrantescuNo ratings yet

- 772 Hest 0303Document4 pages772 Hest 0303yifei.zhuNo ratings yet

- TPS 8735Document114 pagesTPS 8735mech1kingNo ratings yet

- P105576-IC-IDF-204 - Rev01Document10 pagesP105576-IC-IDF-204 - Rev01bmanojkumar16No ratings yet

- UE-BHEL-054-MPP-04 Rev.03Document6 pagesUE-BHEL-054-MPP-04 Rev.03udayakarnaNo ratings yet

- Shop Fabrication Welding & Painting Procedure 22-07 Rev-2Document48 pagesShop Fabrication Welding & Painting Procedure 22-07 Rev-262239a658fb23fNo ratings yet

- APIC-X-XX-SP-PMG-EE-0490 - Ver2 (1) Lightning ProtectionDocument106 pagesAPIC-X-XX-SP-PMG-EE-0490 - Ver2 (1) Lightning Protectiondamienmoloney84No ratings yet

- Fabrication and Erection Piping Procedure. - VT PDFDocument19 pagesFabrication and Erection Piping Procedure. - VT PDFLeonardo ManurungNo ratings yet

- Al Asry Pre-Qualification DocumentDocument197 pagesAl Asry Pre-Qualification DocumentHASAN .100% (1)

- QAQC Procedure For Fabrication - Flare KOD Rev ADocument9 pagesQAQC Procedure For Fabrication - Flare KOD Rev ARajesh K Pillai100% (1)

- Spp-0401409-Gg-01!15!24-014 - Rev1 - Datasheet For Telecom and Fiber Optic CableDocument14 pagesSpp-0401409-Gg-01!15!24-014 - Rev1 - Datasheet For Telecom and Fiber Optic Cablechandrahai hrangkhawlNo ratings yet

- Wash Column - E1172-U81-PS-DS-101408 - B PDFDocument13 pagesWash Column - E1172-U81-PS-DS-101408 - B PDFrutujaNo ratings yet

- Machine Foundation Spreadsheet - MARS3 Pg. 1Document1 pageMachine Foundation Spreadsheet - MARS3 Pg. 1Setiadi Margono100% (2)

- DDDDocument7 pagesDDDmohd as shahiddin jafriNo ratings yet

- T-25-2018-00-Pe-Das-1048 - Rev-2 - Datasheet For Sight GlassDocument3 pagesT-25-2018-00-Pe-Das-1048 - Rev-2 - Datasheet For Sight Glassvinoj chandranNo ratings yet

- Renewables Certification Valid Certificates 2024-02-02Document70 pagesRenewables Certification Valid Certificates 2024-02-02anup.vyas1No ratings yet

- TP-WELLS-09073-DAS-A4-D1-L - Valve DSDocument21 pagesTP-WELLS-09073-DAS-A4-D1-L - Valve DSJessica RahmaNo ratings yet

- Manufacturing Technology for Aerospace Structural MaterialsFrom EverandManufacturing Technology for Aerospace Structural MaterialsRating: 5 out of 5 stars5/5 (2)

- MECH REC105 Cleaning Treatment ReportDocument4 pagesMECH REC105 Cleaning Treatment ReporttinzarmoeNo ratings yet

- JR WPS&PQR-02 GTAW (Auto) (2-6inch)Document11 pagesJR WPS&PQR-02 GTAW (Auto) (2-6inch)tinzarmoeNo ratings yet

- MECH REC120 Piping Inspection FormDocument1 pageMECH REC120 Piping Inspection FormtinzarmoeNo ratings yet

- MECH REC76 - Record of RepairsDocument2 pagesMECH REC76 - Record of RepairstinzarmoeNo ratings yet

- 1105 Welbrite SDS 20200307 New VersionDocument11 pages1105 Welbrite SDS 20200307 New VersiontinzarmoeNo ratings yet

- BNT Coc SampleDocument1 pageBNT Coc SampletinzarmoeNo ratings yet

- Ductwork Installation ChecklistDocument1 pageDuctwork Installation ChecklisttinzarmoeNo ratings yet

- Plastic Welding Machine Miniplast2IR Working Instructions Up To OD 110 MMDocument58 pagesPlastic Welding Machine Miniplast2IR Working Instructions Up To OD 110 MMtinzarmoeNo ratings yet

- 717ECO - UltraLoVoc DatasheetDocument2 pages717ECO - UltraLoVoc DatasheettinzarmoeNo ratings yet

- WT-002 (Method of Joining PVC)Document2 pagesWT-002 (Method of Joining PVC)tinzarmoeNo ratings yet

- WT-001 (Method of Joining PP & PE)Document2 pagesWT-001 (Method of Joining PP & PE)tinzarmoeNo ratings yet

- Exss-Stm-Hk-Mos-014 Nh4oh 25%, H2o2 30%, HCL 37%, HF 49%, H2so4 96% PTDocument5 pagesExss-Stm-Hk-Mos-014 Nh4oh 25%, H2o2 30%, HCL 37%, HF 49%, H2so4 96% PTtinzarmoeNo ratings yet

- Keppel Piping Hand BookDocument21 pagesKeppel Piping Hand BooktinzarmoeNo ratings yet

- Testing and Commissioning InterfaceDocument1 pageTesting and Commissioning InterfacetinzarmoeNo ratings yet

- Chem Mech Cleaning ReportDocument1 pageChem Mech Cleaning ReporttinzarmoeNo ratings yet

- Size Comparison SS Tube To PVDF PipeDocument1 pageSize Comparison SS Tube To PVDF PipetinzarmoeNo ratings yet

- Inspection Testing FormsDocument1 pageInspection Testing FormstinzarmoeNo ratings yet

- MECH REC50 - Non Conformity ReportDocument1 pageMECH REC50 - Non Conformity ReporttinzarmoeNo ratings yet

- AMY Filler Rod 2.4 CertDocument1 pageAMY Filler Rod 2.4 CerttinzarmoeNo ratings yet

- MECH REC93 - Equipment Receiving Inspection ReportDocument1 pageMECH REC93 - Equipment Receiving Inspection ReporttinzarmoeNo ratings yet

- Method Statement For Paint On Galv PipeDocument25 pagesMethod Statement For Paint On Galv PipetinzarmoeNo ratings yet

- MECH REC12 - Hydrant PIV Deluge Station InstallationDocument1 pageMECH REC12 - Hydrant PIV Deluge Station InstallationtinzarmoeNo ratings yet

- Painting ReportDocument4 pagesPainting ReporttinzarmoeNo ratings yet

- 1-MECH - Testpack Cover - FA2Document1 page1-MECH - Testpack Cover - FA2tinzarmoeNo ratings yet

- IPS Weld On Solvent Cementing BU Asia Master 15-12-2020 Minus ASTM 31.3Document39 pagesIPS Weld On Solvent Cementing BU Asia Master 15-12-2020 Minus ASTM 31.3tinzarmoeNo ratings yet

- ASME II Part C Rod & Filler 40Document1 pageASME II Part C Rod & Filler 40tinzarmoeNo ratings yet

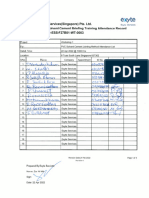

- Quality Control Briefing Training Attendance Reocord 18 MAY 2022Document3 pagesQuality Control Briefing Training Attendance Reocord 18 MAY 2022tinzarmoeNo ratings yet

- Equinix Piping STDDocument2 pagesEquinix Piping STDtinzarmoeNo ratings yet

- Uddin Sala & Sivakumar RT ReportsDocument6 pagesUddin Sala & Sivakumar RT ReportstinzarmoeNo ratings yet

- Grid Line f12-f13 PCWSR Visual Inspection Gf-f46Document17 pagesGrid Line f12-f13 PCWSR Visual Inspection Gf-f46tinzarmoeNo ratings yet

- 07 1108647827262 Process MGTDocument58 pages07 1108647827262 Process MGTHương PhạmNo ratings yet

- N-Channel Enhancement Mode MOSFET: Product SummaryDocument5 pagesN-Channel Enhancement Mode MOSFET: Product Summaryserrano.flia.coNo ratings yet

- Water Treatment ChemicalsDocument33 pagesWater Treatment ChemicalsMutasim Hasan MehranNo ratings yet

- Tools For Dowsing and HealingDocument11 pagesTools For Dowsing and Healingsvrmn100% (2)

- AssignmentDocument6 pagesAssignmentvikrantNo ratings yet

- Chandra NamaskarDocument8 pagesChandra NamaskarSwati Rohan JadhavNo ratings yet

- OPEC Energy Review - 2022 - Asif - Renewable and Non Renewable Energy Resources of Pakistan and Their Applicability UnderDocument30 pagesOPEC Energy Review - 2022 - Asif - Renewable and Non Renewable Energy Resources of Pakistan and Their Applicability UnderAsadullah MaharNo ratings yet

- 01 - Important Announcement For The Accepted ParticipantsDocument2 pages01 - Important Announcement For The Accepted ParticipantsMohammad Asif KabirNo ratings yet

- Soal Procedure Text 1Document8 pagesSoal Procedure Text 1Nina Sri AstutiNo ratings yet

- PP 7 B PS Oil Prices (H)Document4 pagesPP 7 B PS Oil Prices (H)Nimish PatankarNo ratings yet

- Bullying - Moral Theology ProjectDocument10 pagesBullying - Moral Theology ProjectJaira GayodNo ratings yet

- Alto Shaam 20-20ESI Combi OvenDocument4 pagesAlto Shaam 20-20ESI Combi Ovenwsfc-ebayNo ratings yet

- Chromatography 1Document24 pagesChromatography 1chaudhary TahiraliNo ratings yet

- BoreholesDocument41 pagesBoreholesDr.Binay Prakash Panigrahy50% (2)

- Jeppview For Windows: General Information General InformationDocument39 pagesJeppview For Windows: General Information General Informationbooba100% (1)

- Ansulite Afc3B-Fp29 3% Freeze-Protected AFFF Concentrate: DescriptionDocument2 pagesAnsulite Afc3B-Fp29 3% Freeze-Protected AFFF Concentrate: DescriptionDavid CubaNo ratings yet

- DEVIANT BEHAVIOR - SocpsychDocument16 pagesDEVIANT BEHAVIOR - SocpsychChristine PeñamanteNo ratings yet

- Adsorption of Acetic Acid On Charcoal SurfaceDocument3 pagesAdsorption of Acetic Acid On Charcoal SurfaceFrankyFan90% (10)

- Para Jumble PDF Set 1Document25 pagesPara Jumble PDF Set 1RajuNo ratings yet

- 7.0 Analysis 3: Case Study Concrete Over Pour On Decks Due To Steel Deflection (Structural Breath)Document12 pages7.0 Analysis 3: Case Study Concrete Over Pour On Decks Due To Steel Deflection (Structural Breath)Kiara Ticangan ArgelNo ratings yet

- Chapter 2Document7 pagesChapter 2Edita O PanuncioNo ratings yet

- Surgery KGMU Proff Chapterwise by Arif Naseem 2009-2021Document4 pagesSurgery KGMU Proff Chapterwise by Arif Naseem 2009-2021DR. PARDEEP SHARMANo ratings yet

- Proc - Installation For Solar HeaterDocument7 pagesProc - Installation For Solar HeaterMagesh ShankarNo ratings yet

- 1adulteration and Evaluation of Crude DrugsDocument23 pages1adulteration and Evaluation of Crude DrugsRamling PatrakarNo ratings yet

- Effectiveness of video assisted teaching on techniques of expressing and utilization of expressed breast milk, to establish exclusive breastfeeding among working lactating mothers in selected settings in Coimbatore.Document44 pagesEffectiveness of video assisted teaching on techniques of expressing and utilization of expressed breast milk, to establish exclusive breastfeeding among working lactating mothers in selected settings in Coimbatore.mohiiieNo ratings yet

- TLEDocument2 pagesTLEayesha teroNo ratings yet

- Impco 425 CarburetorDocument6 pagesImpco 425 Carburetors_boots100% (2)

- Organic Reactions 63 (2004) eDocument366 pagesOrganic Reactions 63 (2004) emarkiza07No ratings yet