Professional Documents

Culture Documents

CRAlloys MARTENSITIC STAINLESS STEELS

CRAlloys MARTENSITIC STAINLESS STEELS

Uploaded by

ganis supriadiCopyright:

Available Formats

You might also like

- Tessa Bailey - Find Her-Tessa Bailey (2019)Document58 pagesTessa Bailey - Find Her-Tessa Bailey (2019)Doğuş DereliköylüNo ratings yet

- Misinterpretation of TasawwufDocument260 pagesMisinterpretation of TasawwufSpirituality Should Be LivedNo ratings yet

- PQR & Welding Procedures Matrix PDFDocument1 pagePQR & Welding Procedures Matrix PDFsudeesh kumar100% (1)

- Din 1624Document2 pagesDin 1624avinashchauhan2695No ratings yet

- A Memorandum for the President of the Royal Audiencia and Chancery Court of the City and Kingdom of GranadaFrom EverandA Memorandum for the President of the Royal Audiencia and Chancery Court of the City and Kingdom of GranadaNo ratings yet

- CRAlloys DUPLEX STAINLESS STEELSDocument1 pageCRAlloys DUPLEX STAINLESS STEELSganis supriadiNo ratings yet

- Naval BrassDocument1 pageNaval BrassAugusto Gabriel Flores ManzanedaNo ratings yet

- Total Materia - Comparison ViewDocument4 pagesTotal Materia - Comparison ViewHarshad SharangdharNo ratings yet

- Technical Review: (Minimum Score Required 75%)Document4 pagesTechnical Review: (Minimum Score Required 75%)Deepak HoleNo ratings yet

- Product Catalog & Design Guide: Gas Discharge Tube (GDT) ProductsDocument76 pagesProduct Catalog & Design Guide: Gas Discharge Tube (GDT) ProductsSantiago BNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- RK 370ca PDFDocument1 pageRK 370ca PDFSetiawan Si GethokNo ratings yet

- Control Cable PPT - Converted - by - AbcdpdfDocument7 pagesControl Cable PPT - Converted - by - AbcdpdfManish ChandNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Product Specifications: Specifications For Continuous Cast ProductsDocument4 pagesProduct Specifications: Specifications For Continuous Cast ProductsvejanidbNo ratings yet

- 3827-E10-062 - Two Position Valve - DDocument4 pages3827-E10-062 - Two Position Valve - DMohamed Elsaid El ShallNo ratings yet

- Product Catalog & Design Guide: Gas Discharge Tube (GDT) ProductsDocument60 pagesProduct Catalog & Design Guide: Gas Discharge Tube (GDT) ProductsMisko PiskoNo ratings yet

- DZR BrassDocument1 pageDZR BrasssmrdojeNo ratings yet

- Hust WPS Gtaw - Smaw 6GDocument4 pagesHust WPS Gtaw - Smaw 6GtruongtrungplhdNo ratings yet

- Jig DW75 CNC2S 02Document1 pageJig DW75 CNC2S 02Luong LeNo ratings yet

- 104 13479 Mob02918 DSH 420 J 0018 - 1Document3 pages104 13479 Mob02918 DSH 420 J 0018 - 1Roberto Capcha SernaNo ratings yet

- Technical Evaluation Sheet: Kishan Forge, RajkotDocument3 pagesTechnical Evaluation Sheet: Kishan Forge, RajkotRajoo PrajapatiNo ratings yet

- 19-0070COM Operation CurveDocument1 page19-0070COM Operation CurveRichardJeffersonRoncalCotrinaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Serie 097 RTC CouplingsDocument4 pagesSerie 097 RTC CouplingsHIDRAFLUIDNo ratings yet

- 3827-E10-063 - Modulating Control Valve - EDocument6 pages3827-E10-063 - Modulating Control Valve - EMohamed Elsaid El ShallNo ratings yet

- Pump Protection Valve TDM087UVW-CS: Datasheet SA - TD.054133Document1 pagePump Protection Valve TDM087UVW-CS: Datasheet SA - TD.054133AhmadNo ratings yet

- Annex D Bs 5500 Design Reference Temperature Adjustment: R D S C HDocument13 pagesAnnex D Bs 5500 Design Reference Temperature Adjustment: R D S C Hduf fuNo ratings yet

- Cy3 - Te MeteringDocument22 pagesCy3 - Te MeteringSilpa Asti Nura100% (1)

- UTG - LPG - Tank (12) (Updated)Document1 pageUTG - LPG - Tank (12) (Updated)Ali TahirNo ratings yet

- MTC-SML (1) - 4500528257 I - Ii - Tubos GB - SCH 6MT - 210251 - 210291 - 210377Document3 pagesMTC-SML (1) - 4500528257 I - Ii - Tubos GB - SCH 6MT - 210251 - 210291 - 210377Saul Omar Fernandez RojasNo ratings yet

- Summary of Sub Grade Test Result.... 2Document8 pagesSummary of Sub Grade Test Result.... 2AshebirNo ratings yet

- Column List For NabeelDocument14 pagesColumn List For NabeelMuhammad NabeelNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Pot 5K Bourns 3362P-1-502LFDocument2 pagesPot 5K Bourns 3362P-1-502LFJoão Oliveira BentesNo ratings yet

- Wps - List For Piping Rev3Document2 pagesWps - List For Piping Rev3Ali MoosaviNo ratings yet

- Wps - List For Piping Rev3Document2 pagesWps - List For Piping Rev3Ali MoosaviNo ratings yet

- Final Enquiry List For ValvesDocument12 pagesFinal Enquiry List For ValvesnikhilNo ratings yet

- Sisco Wps 020 Rev 01Document15 pagesSisco Wps 020 Rev 01Asher ThomasNo ratings yet

- CoA - MTC - LOT 4525 - 4408Document1 pageCoA - MTC - LOT 4525 - 4408dipen royNo ratings yet

- WPS List For Piping: (Asme Section Ix)Document4 pagesWPS List For Piping: (Asme Section Ix)Ali MoosaviNo ratings yet

- Datasheet Motor VideoDocument1 pageDatasheet Motor VideoDocente Fede TecnologicoNo ratings yet

- 3.1.5. Perfil H 6x15Document1 page3.1.5. Perfil H 6x15benedicto soto mestanzaNo ratings yet

- Corte IPE220-IPE220Document7 pagesCorte IPE220-IPE220yonatandiazNo ratings yet

- Required Process Data Sheet StrainerDocument3 pagesRequired Process Data Sheet StrainersgjsevenpNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Cs15-3 Hea140 B Cw-S (Plated Stub)Document17 pagesCs15-3 Hea140 B Cw-S (Plated Stub)saravqwertyNo ratings yet

- Performance Curve - Service1 - Item 1Document1 pagePerformance Curve - Service1 - Item 1Fernando SanchezNo ratings yet

- WPS and PQR of GMAWDocument8 pagesWPS and PQR of GMAW魏利强No ratings yet

- Velosi Integrity & Safety Pakistan Pvt. LTD: Ultrasonic Examination A-Scan ReportDocument1 pageVelosi Integrity & Safety Pakistan Pvt. LTD: Ultrasonic Examination A-Scan ReportAli TahirNo ratings yet

- 3827-E10-066 - Knife Gate (On-Off) Control Valve - DDocument2 pages3827-E10-066 - Knife Gate (On-Off) Control Valve - DMohamed Elsaid El ShallNo ratings yet

- MTA Megacompact Technical Data Sheet v00Document1 pageMTA Megacompact Technical Data Sheet v00muhammetNo ratings yet

- (IAC) RNP B Rwy 02R: N/A N/ADocument2 pages(IAC) RNP B Rwy 02R: N/A N/Athiagoteles0No ratings yet

- Neyriz Grey Cement Co.: Date: 02.05.30Document1 pageNeyriz Grey Cement Co.: Date: 02.05.30alishahsavarNo ratings yet

- DXA Cross-Calibration WorkbookDocument5 pagesDXA Cross-Calibration WorkbookaaNo ratings yet

- Wps - Asme Ix - Gtaw - PipaDocument5 pagesWps - Asme Ix - Gtaw - PipaMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Welder Qualification Register SENBAL UPDATE (FCAW, SMAW & STRUCTURE) 261122Document4 pagesWelder Qualification Register SENBAL UPDATE (FCAW, SMAW & STRUCTURE) 261122R.A. AbriantoNo ratings yet

- Attention-Port Jacking Gearbox-Leg Chord 2-4-09-11-2020Document2 pagesAttention-Port Jacking Gearbox-Leg Chord 2-4-09-11-2020Sanju laaNo ratings yet

- Level TransmittorDocument1 pageLevel TransmittorAnonymous xfzNyyi4No ratings yet

- 12Cr12Mo 1Cr12MoDocument2 pages12Cr12Mo 1Cr12MoKashif MohiuddinNo ratings yet

- Unicima Nss23002 MTC 6534070332 of N.S. SteelDocument12 pagesUnicima Nss23002 MTC 6534070332 of N.S. Steelchua weichengNo ratings yet

- Canadian Living - November 2022Document102 pagesCanadian Living - November 2022ganis supriadiNo ratings yet

- Archaeology - November-December 2022Document74 pagesArchaeology - November-December 2022ganis supriadiNo ratings yet

- Business Sphere - October 2022Document70 pagesBusiness Sphere - October 2022ganis supriadiNo ratings yet

- Air & Space Forces - October 2022Document62 pagesAir & Space Forces - October 2022ganis supriadi100% (1)

- Adweek - October 10, 2022Document46 pagesAdweek - October 10, 2022ganis supriadiNo ratings yet

- Chemie Ingenieur Technik - 2021 - Pernica - Transient Thermal Stress Calculation of A Shell and Tube Condenser With FixedDocument8 pagesChemie Ingenieur Technik - 2021 - Pernica - Transient Thermal Stress Calculation of A Shell and Tube Condenser With Fixedganis supriadiNo ratings yet

- Technical Option SP-ME-ME-014 Mechanical Flotation Unit SpeciDocument6 pagesTechnical Option SP-ME-ME-014 Mechanical Flotation Unit Speciganis supriadiNo ratings yet

- Iso BN 8.8Document2 pagesIso BN 8.8ganis supriadiNo ratings yet

- Shell&TubeResults 215E009Document5 pagesShell&TubeResults 215E009ganis supriadiNo ratings yet

- Handling and Remediation of Duplex Austenitic and Nickel Based AlloysDocument1 pageHandling and Remediation of Duplex Austenitic and Nickel Based Alloysganis supriadiNo ratings yet

- Testing Requirements of API 5CRA - Rev2Document2 pagesTesting Requirements of API 5CRA - Rev2ganis supriadiNo ratings yet

- CRAlloys DUPLEX STAINLESS STEELSDocument1 pageCRAlloys DUPLEX STAINLESS STEELSganis supriadiNo ratings yet

- Cold Brew Recipe DownloadDocument21 pagesCold Brew Recipe Downloadganis supriadiNo ratings yet

- Specification For Smoke Bomb Test PDFDocument4 pagesSpecification For Smoke Bomb Test PDFganis supriadiNo ratings yet

- Solutions For Critical Saltwater Disposal Well ChallengesDocument3 pagesSolutions For Critical Saltwater Disposal Well Challengesganis supriadiNo ratings yet

- Cold Working Vs HotworkingDocument1 pageCold Working Vs Hotworkingganis supriadiNo ratings yet

- Envir Otect Power Cable Install ManualDocument49 pagesEnvir Otect Power Cable Install ManualRashi MrBRDNo ratings yet

- The Myth of PlutoDocument6 pagesThe Myth of PlutoZsuzsanna ZöldNo ratings yet

- Landini Mythos Training Manual 3659955m1Document905 pagesLandini Mythos Training Manual 3659955m1hms2024kftNo ratings yet

- Carlos Xuma - Dating Dynamics - Getting Men More Success With Women (2005)Document47 pagesCarlos Xuma - Dating Dynamics - Getting Men More Success With Women (2005)Retaliator StrikesbackNo ratings yet

- LDPDocument46 pagesLDPSoundradevi ArumugamNo ratings yet

- Biochar-Supported Reduced Graphene Oxide Composite For Adsorption and Coadsorption of Atrazine and Lead IonsDocument9 pagesBiochar-Supported Reduced Graphene Oxide Composite For Adsorption and Coadsorption of Atrazine and Lead IonsJuliana LuconiNo ratings yet

- Hydrodynamic Characteristics of The Kort-Nozzle Propeller by Different Turbulence ModelsDocument4 pagesHydrodynamic Characteristics of The Kort-Nozzle Propeller by Different Turbulence ModelstafocanNo ratings yet

- To Study Well Design Aspects in HPHT EnvironmentDocument40 pagesTo Study Well Design Aspects in HPHT Environmentnikhil_barshettiwat100% (1)

- Group 4 Physics1Document50 pagesGroup 4 Physics1cloud kumoishNo ratings yet

- Cable HDMI 10 MetrosDocument3 pagesCable HDMI 10 Metroschristian eduardoNo ratings yet

- Narrative Text - Infografis - KurmerDocument2 pagesNarrative Text - Infografis - KurmerCitra Arba RojunaNo ratings yet

- Forensic Syllabus@Document6 pagesForensic Syllabus@YocobSamandrewsNo ratings yet

- 03051Document2 pages03051JojolasNo ratings yet

- The Secrets of Ancient Rome's Buildings - History - Smithsonian Magazine PDFDocument2 pagesThe Secrets of Ancient Rome's Buildings - History - Smithsonian Magazine PDFMarlui Faith MaglambayanNo ratings yet

- MUSIC Quarter 3Document13 pagesMUSIC Quarter 3RaeNo ratings yet

- Objections Upon The Views of Ibn QudamaDocument4 pagesObjections Upon The Views of Ibn QudamaAHLUSSUNNAH WAL JAMAA"AH [ASHA:'IRAH & MATURIDIYAH]No ratings yet

- BD707/709/711 BD708/712: Complementary Silicon Power TransistorsDocument7 pagesBD707/709/711 BD708/712: Complementary Silicon Power TransistorsGheorghe DanielNo ratings yet

- Life On MarsDocument3 pagesLife On MarsSahar SmNo ratings yet

- ME542 4thDocument28 pagesME542 4thAhmed SalemNo ratings yet

- ALLEN-BRADLEY KINETIX 6200 SAFETY MANUAL PDF Download - ManuaLibDocument3 pagesALLEN-BRADLEY KINETIX 6200 SAFETY MANUAL PDF Download - ManuaLibticojfsNo ratings yet

- C21 - Curriculum Diploma in Mechanical EngineeringDocument118 pagesC21 - Curriculum Diploma in Mechanical EngineeringsathishkandulaNo ratings yet

- Test Bank For Chemistry 9th Edition Zumdahl Isbn 10 1133611095 Isbn 13 9781133611097Document17 pagesTest Bank For Chemistry 9th Edition Zumdahl Isbn 10 1133611095 Isbn 13 9781133611097Lynn Higgins100% (38)

- Libra AscendantDocument14 pagesLibra AscendantNarayana Remala100% (1)

- 1.8 Anchor Systems Indd 2009Document80 pages1.8 Anchor Systems Indd 2009ihpeter100% (1)

- Dit 24Document1 pageDit 24Abvolt IndiaNo ratings yet

- Yaesu FT-1802 Operating ManualDocument88 pagesYaesu FT-1802 Operating ManualYayok S. AnggoroNo ratings yet

- UBE-H-103 - Piping and Ducting MaterialDocument587 pagesUBE-H-103 - Piping and Ducting Materialjohn carterNo ratings yet

- Prepared by - Snehal ChintalaDocument78 pagesPrepared by - Snehal ChintalaSnehal ChintalaNo ratings yet

CRAlloys MARTENSITIC STAINLESS STEELS

CRAlloys MARTENSITIC STAINLESS STEELS

Uploaded by

ganis supriadiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CRAlloys MARTENSITIC STAINLESS STEELS

CRAlloys MARTENSITIC STAINLESS STEELS

Uploaded by

ganis supriadiCopyright:

Available Formats

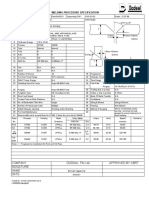

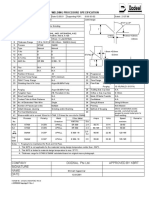

CRA GUIDE TO SELECTION OF STAINLESS STEELS

UNS Number

Trade Names

0.2% Yield Str. Tensile CVN Impact

Alloy Family

Alloy Family

Chemical Composition Elong. (%) Hardness NACE MR0175/ISO 15156

API Grade

Category

(ksi) Str. (ksi) (ft-lbs)

PREN

Alloy

Type

API

max. wt % or range, unless otherwise indicated long. at room temperature trans. at 14F (HRC) H2S Limits

C CR Ni Mo Cu Ti V W N min. max. min. min. min. max. Tables Sour Service Limits

13CR 0.15 12.0 12

function of wall

13 Chrome 5CT 13Cr L80 420 Mod S42000 to to 0.5 — 0.25 — — — — to 80 80 95 95 function of specimen size 23 A.19 H2S≤1.5 psi,ppH ≥3.5

thickness

13Cr L80 0.22 14.0 14

11.0 4.0 0.2 12

13CRM N/A 0.03 to to to — — — — — to

14.0 6.0 1.2 18 80 80 95 90 29 27

function of specimen size not recommended

N/A 95 95 110 105 29 28

Chrome 12.0 3.5 0.8 15 and strength for sour service

110 100 140 115 29/30 32

HP1 N/A 0.04 to to to — — — — — to

14.0 4.5 1.5 19

5CRA Group 1 11.5 4.5 1.5 0.01 16 80 80 95 90 29 27 H2S≤1.5 psi,ppH ≥3.5

13CRS function of specimen size

13-5-2 S41426 0.03 to to to — to 0.5 — — to 95 95 105 105 29 27 A.19 110 Gr. not recommended

CR13S and strength

Martensitic Stainless Steel

Martensitic Stainless Steel

PSL 1 & 2 13.5 6.5 3.0 0.5 23 110 110 140 115 29/30 32 for sour service

12 4.0 1.5 0.06 17 80 80 95 90 29 27 H2S≤1.5 psi,ppH ≥3.5

function of specimen size

S13CR S41425 0.05 to to to 0.03 — — — to to 95 95 105 105 29 28 A.18 110 Gr. not recommended

and strength for sour service

Super 13 15 7.0 2.0 0.12 22 110 110 140 115 29/30 32

Chrome 5CRA Group 1 11.5 4.5 1.5 0.1 16 80 80 95 90 29 27 1.5 psi H2S, pH3.5,

pH≥3.5,ClCl≤6

g/lg/l

function of specimen size

13-5-2 SCR13 S41427 0.03 to to to — 0.01 to — — to 95 95 105 105 29 29 A.21 110 Gr. not recommended

and strength for sour service

PSL 1 13.5 6.0 2.5 0.5 22 110 110 140 115 29/30 32

12.0 4.5 1.8 18 80 80 95 90 29 27

function of specimen size not recommended

HP2 N/A 0.04 to to to — — — — — to 95 95 105 105 29 28

and strength for sour service

14.0 5.5 2.5 22 110 110 140 115 29/30 32

0.08 14.0 1.0 0.3 15

15 Cr S42500 to to to to — — — — 0.2 to N/A 80 95 90 22 A.19 H2S≤1.5 psi,ppH≥3.5

0.2 16.0 2.0 0.7 18

15 Chrome N/A

14.0 6.0 1.8 20

UHP-15CR function of specimen size not recommended

N/A 0.04 to to to 1.5 — — — — to 125 125 150 135 37

Super 15Cr and strength for sour service

16.0 7.0 2.5 24

16.0 4.0 2.0 2.0 23

17CRS function of specimen size not recommended

17 Chrome N/A N/A 0.03 to to to to — 0.1 — — to 125 125 145 130 38

Super 17Cr and strength for sour service

18.0 5.5 3.0 3.0 28

5CRA Group 2 21.0 4.5 2.5 0.08 35 A.24

22 Chrome 22Cr 65 65 90 90 25% 26 H2S≤1.5 psi,TTemps≤450F

22-5-3 S31803 0.03 to to to — — — — to to (annealed)

Duplex 2205 75 75 100 90 25% function of 26

PSL 1 & 2 23.0 6.5 3.5 o.20 40

E-mail us at sales@cralloys.com

110 or

110call us 140

at (713) 827-8600

125 12% strength and 36 www.cralloys.com

5CRA Group 2 24.0 5.5 2.5 0.2 0.10 0.10 37 H2S≤0.3 psi

125 125 150 130 10% wall thickness 36 A.25

el

el

25 Chrome 25Cr 140 Gr. not recommended

You might also like

- Tessa Bailey - Find Her-Tessa Bailey (2019)Document58 pagesTessa Bailey - Find Her-Tessa Bailey (2019)Doğuş DereliköylüNo ratings yet

- Misinterpretation of TasawwufDocument260 pagesMisinterpretation of TasawwufSpirituality Should Be LivedNo ratings yet

- PQR & Welding Procedures Matrix PDFDocument1 pagePQR & Welding Procedures Matrix PDFsudeesh kumar100% (1)

- Din 1624Document2 pagesDin 1624avinashchauhan2695No ratings yet

- A Memorandum for the President of the Royal Audiencia and Chancery Court of the City and Kingdom of GranadaFrom EverandA Memorandum for the President of the Royal Audiencia and Chancery Court of the City and Kingdom of GranadaNo ratings yet

- CRAlloys DUPLEX STAINLESS STEELSDocument1 pageCRAlloys DUPLEX STAINLESS STEELSganis supriadiNo ratings yet

- Naval BrassDocument1 pageNaval BrassAugusto Gabriel Flores ManzanedaNo ratings yet

- Total Materia - Comparison ViewDocument4 pagesTotal Materia - Comparison ViewHarshad SharangdharNo ratings yet

- Technical Review: (Minimum Score Required 75%)Document4 pagesTechnical Review: (Minimum Score Required 75%)Deepak HoleNo ratings yet

- Product Catalog & Design Guide: Gas Discharge Tube (GDT) ProductsDocument76 pagesProduct Catalog & Design Guide: Gas Discharge Tube (GDT) ProductsSantiago BNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- RK 370ca PDFDocument1 pageRK 370ca PDFSetiawan Si GethokNo ratings yet

- Control Cable PPT - Converted - by - AbcdpdfDocument7 pagesControl Cable PPT - Converted - by - AbcdpdfManish ChandNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Product Specifications: Specifications For Continuous Cast ProductsDocument4 pagesProduct Specifications: Specifications For Continuous Cast ProductsvejanidbNo ratings yet

- 3827-E10-062 - Two Position Valve - DDocument4 pages3827-E10-062 - Two Position Valve - DMohamed Elsaid El ShallNo ratings yet

- Product Catalog & Design Guide: Gas Discharge Tube (GDT) ProductsDocument60 pagesProduct Catalog & Design Guide: Gas Discharge Tube (GDT) ProductsMisko PiskoNo ratings yet

- DZR BrassDocument1 pageDZR BrasssmrdojeNo ratings yet

- Hust WPS Gtaw - Smaw 6GDocument4 pagesHust WPS Gtaw - Smaw 6GtruongtrungplhdNo ratings yet

- Jig DW75 CNC2S 02Document1 pageJig DW75 CNC2S 02Luong LeNo ratings yet

- 104 13479 Mob02918 DSH 420 J 0018 - 1Document3 pages104 13479 Mob02918 DSH 420 J 0018 - 1Roberto Capcha SernaNo ratings yet

- Technical Evaluation Sheet: Kishan Forge, RajkotDocument3 pagesTechnical Evaluation Sheet: Kishan Forge, RajkotRajoo PrajapatiNo ratings yet

- 19-0070COM Operation CurveDocument1 page19-0070COM Operation CurveRichardJeffersonRoncalCotrinaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Serie 097 RTC CouplingsDocument4 pagesSerie 097 RTC CouplingsHIDRAFLUIDNo ratings yet

- 3827-E10-063 - Modulating Control Valve - EDocument6 pages3827-E10-063 - Modulating Control Valve - EMohamed Elsaid El ShallNo ratings yet

- Pump Protection Valve TDM087UVW-CS: Datasheet SA - TD.054133Document1 pagePump Protection Valve TDM087UVW-CS: Datasheet SA - TD.054133AhmadNo ratings yet

- Annex D Bs 5500 Design Reference Temperature Adjustment: R D S C HDocument13 pagesAnnex D Bs 5500 Design Reference Temperature Adjustment: R D S C Hduf fuNo ratings yet

- Cy3 - Te MeteringDocument22 pagesCy3 - Te MeteringSilpa Asti Nura100% (1)

- UTG - LPG - Tank (12) (Updated)Document1 pageUTG - LPG - Tank (12) (Updated)Ali TahirNo ratings yet

- MTC-SML (1) - 4500528257 I - Ii - Tubos GB - SCH 6MT - 210251 - 210291 - 210377Document3 pagesMTC-SML (1) - 4500528257 I - Ii - Tubos GB - SCH 6MT - 210251 - 210291 - 210377Saul Omar Fernandez RojasNo ratings yet

- Summary of Sub Grade Test Result.... 2Document8 pagesSummary of Sub Grade Test Result.... 2AshebirNo ratings yet

- Column List For NabeelDocument14 pagesColumn List For NabeelMuhammad NabeelNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Pot 5K Bourns 3362P-1-502LFDocument2 pagesPot 5K Bourns 3362P-1-502LFJoão Oliveira BentesNo ratings yet

- Wps - List For Piping Rev3Document2 pagesWps - List For Piping Rev3Ali MoosaviNo ratings yet

- Wps - List For Piping Rev3Document2 pagesWps - List For Piping Rev3Ali MoosaviNo ratings yet

- Final Enquiry List For ValvesDocument12 pagesFinal Enquiry List For ValvesnikhilNo ratings yet

- Sisco Wps 020 Rev 01Document15 pagesSisco Wps 020 Rev 01Asher ThomasNo ratings yet

- CoA - MTC - LOT 4525 - 4408Document1 pageCoA - MTC - LOT 4525 - 4408dipen royNo ratings yet

- WPS List For Piping: (Asme Section Ix)Document4 pagesWPS List For Piping: (Asme Section Ix)Ali MoosaviNo ratings yet

- Datasheet Motor VideoDocument1 pageDatasheet Motor VideoDocente Fede TecnologicoNo ratings yet

- 3.1.5. Perfil H 6x15Document1 page3.1.5. Perfil H 6x15benedicto soto mestanzaNo ratings yet

- Corte IPE220-IPE220Document7 pagesCorte IPE220-IPE220yonatandiazNo ratings yet

- Required Process Data Sheet StrainerDocument3 pagesRequired Process Data Sheet StrainersgjsevenpNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Cs15-3 Hea140 B Cw-S (Plated Stub)Document17 pagesCs15-3 Hea140 B Cw-S (Plated Stub)saravqwertyNo ratings yet

- Performance Curve - Service1 - Item 1Document1 pagePerformance Curve - Service1 - Item 1Fernando SanchezNo ratings yet

- WPS and PQR of GMAWDocument8 pagesWPS and PQR of GMAW魏利强No ratings yet

- Velosi Integrity & Safety Pakistan Pvt. LTD: Ultrasonic Examination A-Scan ReportDocument1 pageVelosi Integrity & Safety Pakistan Pvt. LTD: Ultrasonic Examination A-Scan ReportAli TahirNo ratings yet

- 3827-E10-066 - Knife Gate (On-Off) Control Valve - DDocument2 pages3827-E10-066 - Knife Gate (On-Off) Control Valve - DMohamed Elsaid El ShallNo ratings yet

- MTA Megacompact Technical Data Sheet v00Document1 pageMTA Megacompact Technical Data Sheet v00muhammetNo ratings yet

- (IAC) RNP B Rwy 02R: N/A N/ADocument2 pages(IAC) RNP B Rwy 02R: N/A N/Athiagoteles0No ratings yet

- Neyriz Grey Cement Co.: Date: 02.05.30Document1 pageNeyriz Grey Cement Co.: Date: 02.05.30alishahsavarNo ratings yet

- DXA Cross-Calibration WorkbookDocument5 pagesDXA Cross-Calibration WorkbookaaNo ratings yet

- Wps - Asme Ix - Gtaw - PipaDocument5 pagesWps - Asme Ix - Gtaw - PipaMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Welder Qualification Register SENBAL UPDATE (FCAW, SMAW & STRUCTURE) 261122Document4 pagesWelder Qualification Register SENBAL UPDATE (FCAW, SMAW & STRUCTURE) 261122R.A. AbriantoNo ratings yet

- Attention-Port Jacking Gearbox-Leg Chord 2-4-09-11-2020Document2 pagesAttention-Port Jacking Gearbox-Leg Chord 2-4-09-11-2020Sanju laaNo ratings yet

- Level TransmittorDocument1 pageLevel TransmittorAnonymous xfzNyyi4No ratings yet

- 12Cr12Mo 1Cr12MoDocument2 pages12Cr12Mo 1Cr12MoKashif MohiuddinNo ratings yet

- Unicima Nss23002 MTC 6534070332 of N.S. SteelDocument12 pagesUnicima Nss23002 MTC 6534070332 of N.S. Steelchua weichengNo ratings yet

- Canadian Living - November 2022Document102 pagesCanadian Living - November 2022ganis supriadiNo ratings yet

- Archaeology - November-December 2022Document74 pagesArchaeology - November-December 2022ganis supriadiNo ratings yet

- Business Sphere - October 2022Document70 pagesBusiness Sphere - October 2022ganis supriadiNo ratings yet

- Air & Space Forces - October 2022Document62 pagesAir & Space Forces - October 2022ganis supriadi100% (1)

- Adweek - October 10, 2022Document46 pagesAdweek - October 10, 2022ganis supriadiNo ratings yet

- Chemie Ingenieur Technik - 2021 - Pernica - Transient Thermal Stress Calculation of A Shell and Tube Condenser With FixedDocument8 pagesChemie Ingenieur Technik - 2021 - Pernica - Transient Thermal Stress Calculation of A Shell and Tube Condenser With Fixedganis supriadiNo ratings yet

- Technical Option SP-ME-ME-014 Mechanical Flotation Unit SpeciDocument6 pagesTechnical Option SP-ME-ME-014 Mechanical Flotation Unit Speciganis supriadiNo ratings yet

- Iso BN 8.8Document2 pagesIso BN 8.8ganis supriadiNo ratings yet

- Shell&TubeResults 215E009Document5 pagesShell&TubeResults 215E009ganis supriadiNo ratings yet

- Handling and Remediation of Duplex Austenitic and Nickel Based AlloysDocument1 pageHandling and Remediation of Duplex Austenitic and Nickel Based Alloysganis supriadiNo ratings yet

- Testing Requirements of API 5CRA - Rev2Document2 pagesTesting Requirements of API 5CRA - Rev2ganis supriadiNo ratings yet

- CRAlloys DUPLEX STAINLESS STEELSDocument1 pageCRAlloys DUPLEX STAINLESS STEELSganis supriadiNo ratings yet

- Cold Brew Recipe DownloadDocument21 pagesCold Brew Recipe Downloadganis supriadiNo ratings yet

- Specification For Smoke Bomb Test PDFDocument4 pagesSpecification For Smoke Bomb Test PDFganis supriadiNo ratings yet

- Solutions For Critical Saltwater Disposal Well ChallengesDocument3 pagesSolutions For Critical Saltwater Disposal Well Challengesganis supriadiNo ratings yet

- Cold Working Vs HotworkingDocument1 pageCold Working Vs Hotworkingganis supriadiNo ratings yet

- Envir Otect Power Cable Install ManualDocument49 pagesEnvir Otect Power Cable Install ManualRashi MrBRDNo ratings yet

- The Myth of PlutoDocument6 pagesThe Myth of PlutoZsuzsanna ZöldNo ratings yet

- Landini Mythos Training Manual 3659955m1Document905 pagesLandini Mythos Training Manual 3659955m1hms2024kftNo ratings yet

- Carlos Xuma - Dating Dynamics - Getting Men More Success With Women (2005)Document47 pagesCarlos Xuma - Dating Dynamics - Getting Men More Success With Women (2005)Retaliator StrikesbackNo ratings yet

- LDPDocument46 pagesLDPSoundradevi ArumugamNo ratings yet

- Biochar-Supported Reduced Graphene Oxide Composite For Adsorption and Coadsorption of Atrazine and Lead IonsDocument9 pagesBiochar-Supported Reduced Graphene Oxide Composite For Adsorption and Coadsorption of Atrazine and Lead IonsJuliana LuconiNo ratings yet

- Hydrodynamic Characteristics of The Kort-Nozzle Propeller by Different Turbulence ModelsDocument4 pagesHydrodynamic Characteristics of The Kort-Nozzle Propeller by Different Turbulence ModelstafocanNo ratings yet

- To Study Well Design Aspects in HPHT EnvironmentDocument40 pagesTo Study Well Design Aspects in HPHT Environmentnikhil_barshettiwat100% (1)

- Group 4 Physics1Document50 pagesGroup 4 Physics1cloud kumoishNo ratings yet

- Cable HDMI 10 MetrosDocument3 pagesCable HDMI 10 Metroschristian eduardoNo ratings yet

- Narrative Text - Infografis - KurmerDocument2 pagesNarrative Text - Infografis - KurmerCitra Arba RojunaNo ratings yet

- Forensic Syllabus@Document6 pagesForensic Syllabus@YocobSamandrewsNo ratings yet

- 03051Document2 pages03051JojolasNo ratings yet

- The Secrets of Ancient Rome's Buildings - History - Smithsonian Magazine PDFDocument2 pagesThe Secrets of Ancient Rome's Buildings - History - Smithsonian Magazine PDFMarlui Faith MaglambayanNo ratings yet

- MUSIC Quarter 3Document13 pagesMUSIC Quarter 3RaeNo ratings yet

- Objections Upon The Views of Ibn QudamaDocument4 pagesObjections Upon The Views of Ibn QudamaAHLUSSUNNAH WAL JAMAA"AH [ASHA:'IRAH & MATURIDIYAH]No ratings yet

- BD707/709/711 BD708/712: Complementary Silicon Power TransistorsDocument7 pagesBD707/709/711 BD708/712: Complementary Silicon Power TransistorsGheorghe DanielNo ratings yet

- Life On MarsDocument3 pagesLife On MarsSahar SmNo ratings yet

- ME542 4thDocument28 pagesME542 4thAhmed SalemNo ratings yet

- ALLEN-BRADLEY KINETIX 6200 SAFETY MANUAL PDF Download - ManuaLibDocument3 pagesALLEN-BRADLEY KINETIX 6200 SAFETY MANUAL PDF Download - ManuaLibticojfsNo ratings yet

- C21 - Curriculum Diploma in Mechanical EngineeringDocument118 pagesC21 - Curriculum Diploma in Mechanical EngineeringsathishkandulaNo ratings yet

- Test Bank For Chemistry 9th Edition Zumdahl Isbn 10 1133611095 Isbn 13 9781133611097Document17 pagesTest Bank For Chemistry 9th Edition Zumdahl Isbn 10 1133611095 Isbn 13 9781133611097Lynn Higgins100% (38)

- Libra AscendantDocument14 pagesLibra AscendantNarayana Remala100% (1)

- 1.8 Anchor Systems Indd 2009Document80 pages1.8 Anchor Systems Indd 2009ihpeter100% (1)

- Dit 24Document1 pageDit 24Abvolt IndiaNo ratings yet

- Yaesu FT-1802 Operating ManualDocument88 pagesYaesu FT-1802 Operating ManualYayok S. AnggoroNo ratings yet

- UBE-H-103 - Piping and Ducting MaterialDocument587 pagesUBE-H-103 - Piping and Ducting Materialjohn carterNo ratings yet

- Prepared by - Snehal ChintalaDocument78 pagesPrepared by - Snehal ChintalaSnehal ChintalaNo ratings yet