Professional Documents

Culture Documents

Peixe Fresco

Peixe Fresco

Uploaded by

Matheus SantosOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Peixe Fresco

Peixe Fresco

Uploaded by

Matheus SantosCopyright:

Available Formats

ORIGINAL RESEARCH

published: 21 June 2021

doi: 10.3389/fnut.2021.677884

Application of Interactive and

Intelligent Packaging for Fresh Fish

Shelf-Life Monitoring

Saber Ibrahim 1,2*, Hager Fahmy 3 and Shimaa Salah 3

1

Packaging Materials Department, National Research Centre, Giza, Egypt, 2 Nanomaterials Investigation Lab., Central

Laboratory Network, National Research Centre, Giza, Egypt, 3 Department of Advertising, Printing, and Publishing, Faculty of

Applied Arts, Benha University, Benha, Egypt

Smart packaging, also known as intelligent packaging, is responsive to external stimuli,

moisture, light, oxygen, heat, pH, and bacterial growth. It has evolved from extensive

applications in food safety, bacterial response, and medical packaging. Interactive

packaging has a scientific basis for additional information about food products because

these codes give all required data. This work deals with a combination of frontline food

sciences, smart and interactive packaging that are applicable for future production of

nutrition packages through smart detection of food spooling. Additionally, it verifies the

best degree of food safety and population demands as the third generation of packaging

Edited by:

technology. High qualified duplex laminated package with a nano-encapsulated pH

Golfo Moatsou,

Agricultural University of monitoring label for fresh fish was printed. The interactive Quick Response code icon

Athens, Greece was combined in a designed package with important information about cooking, smart

Reviewed by: packaging, and fish quality. Therefore, particle size, zeta potential, and surface area

Oladipupo Odunayo Olatunde,

Prince of Songkla University, Thailand

are measured for a nanoencapsulated indicator which exhibits 74.4 nm, 23.6 mV, and

Theofania Tsironi, 88.9 m2 /g, respectively: overall migration, water vapor, and oxygen permeability. The

Agricultural University of

properties of printing for 11 color spots are evaluated by x-rite before and after the cold

Athens, Greece

storage period without any detectable changes in the rate of color change (1E). The

*Correspondence:

Saber Ibrahim bacterial count of the tested sample is examined by counting the microbial colonies in the

sa.ibrahim@nrc.sci.eg; agar plate media. There is good agreement between microbial count and smart indicator

msa.nrc@gmail.com

color change as an effective direct detection tool for sustainable food quality and safety.

Specialty section: Keywords: smart packaging, food quality, interactive package, shelf life, Nile perch

This article was submitted to

Nutrition and Food Science

Technology,

a section of the journal

INTRODUCTION

Frontiers in Nutrition

Human health has been influenced by the quality of foods and their types. The demands

Received: 08 March 2021 of high food quality products with improved quality and shelf life are on the rise globally.

Accepted: 25 May 2021

For that, packaging materials play a vital role in saving the food quality, especially the third

Published: 21 June 2021

generation of packaging that indicates the spoiling metabolism of food throughout using smart,

Citation: responsive materials.

Ibrahim S, Fahmy H and Salah S

In addition, Packaging functions can be classified into the following protection, communication,

(2021) Application of Interactive and

Intelligent Packaging for Fresh Fish

containment, and convenience (1). The second generation of packaging involves reducing the

Shelf-Life Monitoring. environmental footprint of pre-packaged foods (2). Whereas, the third-generation smart packaging

Front. Nutr. 8:677884. can adequately screen the quality of fish products and represent data once changes in food quality

doi: 10.3389/fnut.2021.677884 occur and caution of potential issues (3). These issues are intended for developing the interest as

Frontiers in Nutrition | www.frontiersin.org 1 June 2021 | Volume 8 | Article 677884

Ibrahim et al. Smart Packaging for Food Safety

safer foods with a long shelf life of usability to assure sanitation, novel nanoencapsulated pH indicator as a color response

detectability, and quality (4). The powerful monitoring of the label. The reverse printing is performed and applied on

packaged food status gives data to the nature of the bundled food polyester/polyethylene duplex laminated structure material (PET

during transportation and storage (5). 12/ PE 40 micron) using a polyurethane adhesive. The microbial

Spontaneously, the interactive packaging design based on population was followed over 288 h and compared with label

Quick Response code (QR) adds another dimension to clarify color transformation as a direct tool for food quality by bacterial

the utilization of smart packaging plus checking the product population detection. Combining multidiscipline frontier

shelf life. In this kind of interactive smart packaging, a shrewd sciences, nanotechnology, smart packaging, and interactive

outsider gadget, for example, a smartphone, is allocated to packages has been enhanced for food quality detection to one of

examine a coding framework to perceive pictures (6–8) and its abundance food types. The fresh fish filet was kept in storage for

site, which gives data like the item smart packaging and “fresh over 12 days at 4◦ C with follow-up from microbial growth and

check indicator.” pH response using a validation indicator.

Freshness indicators could give quick product quality data

because of microbial development or synthetic changes inside EXPERIMENTAL

a food product (9). Encapsulation of responsive materials is

the most effective technique and easily applied in industrial Materials

production (10). Oxygen, nitrogen, carbon dioxide, moisture, The interactive package design was constructed in the Adobe

and pH sensors were applied with polymers as supporting Illustrator CC 2018 program in cyan, magenta, yellow, and

materials (11). Following the metabolism process of packaged black (CMYK) colors with spot colors. Processing machine

food has great attention to evaluating nutrient quality and photopolymer flexo-plate ESKO was used to produce the

avoiding poisoning accidents (12). This process can be detected flexo photopolymer plate thickness 1.14 mm, Germany. The

by determining gas evolved or pH change with sensory character interactive package was printed on flexographic machine supplier

as color, smell, and forms. The color change of the pH sensor is Bobst 8 color 2019, Germany. The reverse printing was applied

the easiest and cheapest way to use for food quality control (13). on polyester/polyethylene duplex laminated structure material

Recently, many research groups deal with pH indicator response (PET 12 µm/PE 40 µm) with polyurethane solvent-less adhesive.

with one or more materials through conventional methods, The rate of color change 1E was measured with X-Rite exact,

limiting the sensitivity of measurement (13, 14). The novel Pantone, the USA for the printed packages.

nanomaterials research field is still in the first step to applying Lactic acid, stannous octanoates, and methyl red are

pH sensors as a label. Microbial growth is the key factor in the purchased from Sigma-Aldrich, Germany. Additionally,

metabolism of food to be spoiled with pH change (15, 16). chloroform, acetone, and ethanol were distilled and kept over

Moreover, microbiological quality might be resolved visually calcium hydrate until used. Nile perch fishes were purchased

through responses between microbial development metabolites from the Egyptian food market (Cairo) and were prepared

and incorporated indicators and pointers inside the package as a filet with direct packaging in a printed duplex smart

(17). Most of the freshness indicators depend on the color and interactive package. The nutrient agar (Lab M Limited,

change of the marker/indicator tag for the presence of microbial Heywood, Lancashire BL9JJ, United Kingdom) was used, and

metabolites created during the developing microorganisms. All the potato dextrose agar (Ponadisa, Laboratories Conda S.A,

these signs are referring to how the food is still new or not (18). Madrid, Spain) was purchased.

Freshness indicators can likewise be utilized to gauge the rest

of the timeframe of realistic usability of perishable items (19). Synthesis of Nanoencapsulated

Although the use of QR codes in the packaging products has been According to our previous work, with little modification, the

applied already, the integration of “interactivity” and “smartness” synthesis of polylactic acid and encapsulation reaction of methyl

into a similar packaging design is a significant additional worth red occurred with little modification (25). Methyl red was

and new trend in the showcasing advantage (20, 21). Thus, dissolved in ethanol (0.05 mol. L−1 ). The 20 ml of methyl

interactive QR to detect smart monitoring of shelf life of fresh red solutions was mixed with (0.21 mol) lactic acid monomer.

fish-based products is an innovative value. It can provide a new The mixture was charged in a three-neck round bottom flask

dimension in packaging quality, saving product waste, righteous connected with vacuum and nitrogen inlets. The reaction flask

monitoring of the product shelf life, and better communication was immersed in a temperature-controlled water bath during

with the customers (22). Therefore, the research problem is nitrogen purge for 1 h with stirring 800 rpm. The temperature

about the inability of the consumer to evaluate the chemical, was raised gradually up to 75◦ C. The polymerization initiator

biological, and physical processes, leading him to throw the 2.1 × 10−2 mol of stannous octanoates was added dropwise

product if any slight change appeared. However, it is still usable over 15 min. The reaction was continued for 10 h under vacuum.

and consequences unintended waste of the product (23). On After that, the reaction was immersed in an ice bath, and

the contrary, it could lead to using the expired product, with a the prepared methyl red/polymer was precipitated in acetone

false expiration date of the product which causes poisoning and through a dropwise separation funnel. The precipitate was dried

deaths (24). under vacuum at 50◦ C for 24 h. After dying, the indicator circle

This paper, a smart and interactive package as the third was cast in a circle Teflon plate and drying in a vacuum oven at

generation of packaging, was designed and printed with a 40◦ C for 24 h.

Frontiers in Nutrition | www.frontiersin.org 2 June 2021 | Volume 8 | Article 677884

Ibrahim et al. Smart Packaging for Food Safety

Smart Packaging Film Formation Microbiological Evaluations

The prepared polymer/methyl red nanoencapsulation was The microbial infection of the tested sample was examined

dissolved in chloroform with solid content 20 wt% and mixed by counting the microbial colonies in the agar plate media

for 30 min over a magnetic stirrer. Then, PLA/pH indicator (CFU agar plate method). Mixed sample with sterilized bi-

solution was purged with nitrogen for 30 min and immersed distilled water (0.1 g/ml w/v) and then transferred aseptically

in a sonication bath for 10 min to remove any air bubble. to a stomacher bag and shaking for 4 h at 180 rpm. Serial

The solution was cast in a Teflon Petri dish and dried in dilutions (10−2 –10−6 ) were performed, and dilutions were

a vacuum oven overnight at 40◦ C. The film was cut into plated in duplicate. The spread plate and pour plate methods

small round pieces to be used as indicator pads. All pads enumerated total aerobic bacteria (at 37◦ C for 2 days). In

were attached to the inner side of the duplex package film comparison, yeasts and molds (at 28◦ C for 3 days) were

by pressing under a mechanical hydrolytic piston at 80◦ C for performed on the nutrient agar (Lab M Limited, Heywood,

2 min. Lancashire BL9JJ, United Kingdom) and the potato dextrose agar

(Ponadisa, Laboratories Conda S.A, Madrid, Spain), respectively.

The microbial colonies were counted and expressed as CFU/g of

Measurements and Analysis the tested sample (27).

Investigation of Smart Nanoencapsulated Polymer

Composite

The mean diameter and zeta potential of the nanoencapsulated

RESULTS AND DISCUSSION

particles were determined at 170 and 18◦ , respectively, by Investigation of Smart Nanoencapsulated

dynamic light scattering (DLS) (NICOMP 380 ZLS, PSS, The particle size test is one of the high considered measurements

Santa Barbara, CA, USA). Nitrogen adsorption-desorption to evaluate the efficiency of the preparation method to fulfill

measurements were carried out at 77.35 K on a Nova Touch the target materials properties. DLS examined nanoencapsulated

LX4 Quantachrome Instruments, Florida, USA, to determine the

Brunauer–Emmett–Teller (BET) surface area. All samples were

kept dry in a desiccator until testing. Samples were cooled with

liquid nitrogen and analyzed by measuring the volume of gas

(N2 ) adsorbed at specific pressures. The pore volume was taken

from the adsorption branch of the isotherm at P/Po = 0.995,

assuming complete surface saturation.

Water vapor transmission rate (WVTR) was performed using

GBI W303 (B) Water Vapor Permeability Analyzer (Labthink

Instruments Co. Ltd., Jinan, China) via the cup method. The

water vapor permeability was measured as the amount of water

vapor passes through the tested film. Also, WVTR was measured

as the mass of water vapor transmitted throughout a unit area in

a unit time under controlled conditions of temperature (38◦ C)

and (90% relative humidity, RH) according to the following

standards (ASTM E96, ISO 2528, ASTM D1653, TAPPI T464,

DIN 53122-1, JIS Z0208). Also, the oxygen transmission rate

(OTR) under conditions (23◦ C and 50% RH) was measured by

N530 Gas Permeability Analyzer (Labthink Instruments Co. Ltd.,

Jinan, China) according to the following Standards ISO2556-

2001, GB/T1038-2000, ASTM D1434-82(2003).

Overall Migration Test

Many international regulations have been legalized regarding

the migration of specific substances such as heavy metals,

degradation products, and additives. These materials could have

bad taste, odors, or suspected harmful effects on consumers.

The OM simulants and conditions as detailed in the European

Union (EU) Regulation are categorized in Nr. 10/2011 (The

PIM), Simulant A, Simulant B, Simulant D2. All samples were

compared with a blank sample (Millipore water with resistivity

18.5 M) as a reference. The OM is expressed as the amount

in milligrams of material lost from one decimeter square surface FIGURE 1 | (A) The particle size distribution and zeta potential measurement

for nanoencapsulated smart polymer composites. (B) Illustrated the relation of

(mg/dm2 ). OM results were calculated according to (EN 1186-5- pH value with the color change of smart package label.

single side contact in cell test) (26).

Frontiers in Nutrition | www.frontiersin.org 3 June 2021 | Volume 8 | Article 677884

Ibrahim et al. Smart Packaging for Food Safety

smart food responsive composite to investigate the particle size average zeta potential is 23.9 mV which indicated good dispersion

distribution as shown in Figure 1. The average particle size of with nice stabilization of nanoencapsulated particle. These results

nanocomposite smart materials was 70 nm with a range of 10– can strongly recommend nanoencapsulated smart, responsive

500 nm. The polydispersity index (PDI) was indicated to narrow polymer to form homogenized smart polymer film by simple

particle size variation 0.21 as a unimodal bell shape of particle casting techniques.

diameter homogenized distribution. On the other hand, adsorption/desorption isotherm

Zeta potential measurement was calculated as an average value measurements give a high surface area of 88.9 m2 /g with

for a sequence of measurements, as shown in Figure 1. The an excellent correlation coefficient of 0.996 as a first-order fitting

FIGURE 2 | (A) The designed interactive package and (B) the color spot on the package.

Frontiers in Nutrition | www.frontiersin.org 4 June 2021 | Volume 8 | Article 677884

Ibrahim et al. Smart Packaging for Food Safety

relationship which indicated good efficiency and accuracy of All measurements are within the permissible limits according to

calculated BET value. Overall, there is a high degree of agreement ISO 12647-6. The colors of the printing package were not affected

between particle size and surface area measurements as indirect through cool storage as customer demand. This is verified the aim

proportional relationships (28). of reverse printing technology to protect the color of the printing

area (30).

Smart Interactive Design and Printing

Properties Evolution of Packaging Film

The contrast color was used in an interactive design to attract Oxygen and Water Vapor Permeability

consumer attention, as shown in Figure 2A. The transparent The barrier properties of laminated packaging film were

part at the top of the design has shown the fresh fish products. evaluated against oxygen gas and water vapor at 23◦ C as

Nanoencapsulated indicator film was combined with a package permeability for the film sector. According to Robertson (29),

in eye fish design to detect the color change. QR code was applied the transmission of gases through a packaging material can occur

in the interactive package to represent the product website via through two mechanisms: pore effect and solubility-diffusion

smartphone with product information. effect. In the first case, the gases cross the material by passing

Additionally, polyester (PET)/polyethylene (PE) film was

reversely printed through the flexographic process and laminated

as a high barrier interactive package with excellent durability,

TABLE 2 | The overall migration from polyester-/polyethylene-laminated duplex

environmental stability, and mechanical flexibility characters of packaging film.

used nitrocellulose inks (2). The PET film has known properties

as thermal stability, tensile resistance strength, and excellent gas Method EN-1186-5 EN-1186-5 EN-1186-5 EN-1186-4

and moisture barrier properties. Moreover, PE film contributes as (simulant A) (simulant B) (simulant C) (simulant D2 )

mg/dm2 mg/dm2 mg/dm2 mg/dm2

an inner package welder and barrier layer between printed inks

and fish filets as inert protecting layers (29). Replicates

The rate change of colors (1E) for the printed package before 1 0.3 0.6 1.1 0.0

and after cool storage for 12 days at 4◦ C. Eleven color spots were 2 0.2 0.7 1.3 0.0

selected to be measured with X-Rite, as shown in Figure 2B, and 3 0.4 0.8 1.4 0.0

the results were inserted in Table 1. Mean result 0.3 0.7 1.3 0.0

Differences in 1E (11.10–10.29) for color spots before and

Limit 10.0 10.0 10.0 10.0

after cool storage were tiny. The higher and lower values of 11.10

and 10.29 were related to color 2 (orange) and color 4 (red). Bold values are the average of results and the limit of measurement.

TABLE 1 | Measurement of 11 color spots on the package before and after cooling storage.

REF# TEST* 1E REF# TEST 1E REF# TEST 1E REF# TEST 1E

Color Color Color Color

L 74.27 −0.51 0.41 49.30 0.56 1.10 39.08 0.63 0.58 35.69 0.34 0.29

A −3.24 0.06 33.13 −0.66 47.22 0.21 58.49 0.27

B −7.12 −0.21 38.78 −2.36 28.32 −0.22 30.24 0.08

Color Color Color Color

L 54.42 0.45 0.67 63.75 0.42 0.37 46.93 0.80 0.79 19.54 0.74 0.52

A 16.82 0.73 −12.95 0.12 0.36 0.08 7.30 −0.33

B 38.42 −0.04 −20.70 −0.14 −22.87 0.79 −38.58 0.42

Color Color Color

L 43.87 43.87 0.59 37.96 0.11 0.41 51.27 0.28 0.28

A −51.58 1.45 −30.35 0.51 25.26 −0.06

B 7.35 −0.83 0.51 −0.82 6.32 −0.08

# Referencesample before cooling storage printed film.

*Tested sample after cooling storage printed film.

Frontiers in Nutrition | www.frontiersin.org 5 June 2021 | Volume 8 | Article 677884

Ibrahim et al. Smart Packaging for Food Safety

through small pinholes or ruptures in the structure. While, in food, and the external layer must be suitable for printing

the second case, the concentration difference between the two product information.

sides of the packaging material and the solubility of gases in the The migration of low molecular weight polymer or chemical

corresponding material determines the level of transmission (31). additives substances from the bulk polymers laminated film has

The oxygen transmission rate (OTR) shows excellent barrier been studied according to the EU Regulation Nr. 10/2011. The

property with low oxygen gas permeability with a range of stimulants were selected carefully to represent the different food

0.047–0.252 mL m m−2 day−1 Pa−1 at a humidity of 50%. natures. As shown in Table 2, the duplex laminated PE/PET

In addition, the water vapor transmission rate was exhibited packaging film shows acceptable migration limits. The OM from

high barrier properties for water vapors as a successful anti- the package was ranged from 0.3 up to 1.3 mg/dm2 with limits of

moisture packaging film. The measured values are 0.351–2.072 g accepted level up to 10 mg/dm2 , as shown in Table 1.

m m−2 s−1 Pa−1 at water vapor saturation of 80%. The water

permeability in this study is lower than PE and PET films in the Microbiological Evaluations

literature which can be discussed to increase the hydrophobicity The microbial action of different microbes mainly causes spoilage

of the laminated film with an adhesive layer between the two of fresh and lightly preserved fish products. Therefore, fish

films (32). products can be spoiled due to the growth of aerobic bacteria,

yeasts, and molds. Although the spoilage of fresh fish is well-

OM Test of Food Package understood, the spoilage of cool preserved fish products still lacks

Laminated polymer films are materials consisting of multiple knowledge. The production of trimethylamine (TMA) with off-

layers of different polymers types. These materials are ubiquitous odor detection was used as qualitative measurements of microbial

in daily life, with substantial food and pharmaceutical packaging spoilage activity (33). On average, cells of Photobacterium

containing laminates. A common requirement of food packaging phosphoreum are found in spoiled packed cod suggesting

is that the internal layer must appropriate for contacting this organism could be responsible for spoilage (34). A high

concentration of Shewanella putrefaciens is required in producing

detectable off-odors and concluded up this organism without

importance for spoilage of packed cod (35).

The microbial population of bacteria and fungi were

illustrated in Figure 3. The microbial growth was increased with

geometric propagation up to 10−7 and 10−8 after 10 and 12 days,

FIGURE 3 | Microbial population over 12 days for cooling fresh fish filet. FIGURE 5 | The smart packages during the storage period of fresh fish filet.

FIGURE 4 | Petri dish photos of microbial activity assay of fresh cooling fish filet with different concentrations (µg/mL) over different incubation time 48, 144, 240, and

288 h.

Frontiers in Nutrition | www.frontiersin.org 6 June 2021 | Volume 8 | Article 677884

Ibrahim et al. Smart Packaging for Food Safety

respectively. As a rule, fish spoil more rapidly than meat under to evaluate fresh fish quality tools. This research-based one

chill conditions (36). The pH of mammalian muscle, around combined multidiscipline science, packaging design as an

5.6, is lower than that of fish (6.2–6.5), contributing to the long interactive package, nanomaterials stabilization in polymer

storage life of meat. For these reasons, the detection of microbial matrix through encapsulation process, and microbial evaluation

growth in fish is highly recommended. for food quality until spoiling. Package design was successfully

The microbial growth after 48 h. was not detected. After printed and combined with a nanopolymer-encapsulated methyl

that, the population of bacterial and fungal colonies appeared red indicator label. The interactive design provided additional

from 96 h until 288 h, as shown in Figure 4. The metabolite of value to the user as it facilitated the monitoring of the fresh

microbial activity is directly related to change in pH value, which fish shelf-life. Microbial population study was concluded with

acts as a spoiling indication with smart packages, as shown in the superb microbial growth detection of packaged fresh fish in

Figure 5. pH change until 10−7 and 10−8 dilution. Also, the microbial

The color of the nanoencapsulated indicator in the smart growth for bacteria, molds, and fungi was directly related to pH

package was changed from yellow to red over six color degrees, change due to the metabolism process for fresh fish filets. Overall,

as presented in Figure 5. The pH value was increased in direct effective microbial spoiling metabolism was well directly detected

proportion with microbial population that gives an accurate through a smart and interactive package with nanoencapsulated

determination of the food quality over the storage period to avoid color change pH sensors from yellow to red as an efficient

any harmful or poisoning accident. motoring tool to verify the validity of fresh fish to use or discard.

Overall, the initial microbial population was determined

immediately after fish packaging with time intervals (for each DATA AVAILABILITY STATEMENT

48 h). The total aerobic bacteria, the total yeast, and molds were

reached the lower value even after 96 h, which became neglected The original contributions presented in the study are included

compared with the unpackaged sample. After 6 days of storage, in the article/supplementary material, further inquiries can be

yeasts, molds, and total aerobic bacteria counts were initially directed to the corresponding author.

increased. It was observed that the total yeast and molds were

remarkably lower than that observed in the total aerobic bacteria AUTHOR CONTRIBUTIONS

along with the storage time. Indeed, the packaging of fresh

fish in the smart package showed the highest preserved against All authors listed have made a substantial, direct and intellectual

microbial population via reducing the total aerobic bacteria and contribution to the work, and approved it for publication.

the total level of yeast and molds over 6 days of storage at 4◦ C.

ACKNOWLEDGMENTS

CONCLUSION The authors are thankful for the nanomaterial investigation

laboratory, Central Lab. Network, National Research Centre

Excellent microbial growth detection was monitored through a for technical support and materials investigation. The duplex

developed nanoencapsulation technique for pH sensor materials package was printed in Rotographia Co., Egypt.

REFERENCES 7. Narang S, Jain V, Roy S. Effect of QR Codes on Consumer Attitudes.

J Mob Mark (2012). p. 52–64. Available online at: http://eds.b.

1. Ho CHL, Rodrigues ET. Intelligent packaging. Innov Food Packag. (2005) ebscohost.com/abstract?site=eds&scope=site&jrnl=19391161&asa=

3:138–55. doi: 10.1016/B978-012311632-1/50041-3 Y&AN=79962979&h=3F5x84O7h9iBHmy2WshgN0NDAob%2Brbs8v

2. Guillard V, Gaucel S, Fornaciari C, Angellier-Coussy H, Buche P, Gontard %2FugEHcOZiqBWj47I250djSJiH9K5PRhY%2F3nfoIIDVvSU0l7zoIAmQ

N. The next generation of sustainable food packaging to preserve our %3D%3D&crl=c&resultLocal=ErrCrlNoResults&resultNs=Ehost&

environment in a circular economy context. Front Nutr. (2018) 5:121. crlhashurl=login (accessed January 10, 2021).

doi: 10.3389/fnut.2018.00121 8. Okazaki S, Navarro-Bailón MÁ, Molina-Castillo FJ. Privacy concerns

3. Wu D, Zhang M, Chen H, Bhandari B. Freshness monitoring technology of in quick response code mobile promotion: the role of social anxiety

fish products in intelligent packaging. Crit Rev Food Sci Nutr. (2020) 61:1–14. and situational involvement. Int J Electron Commer. (2012) 16:91–120.

doi: 10.1080/10408398.2020.1757615 doi: 10.2753/JEC1086-4415160404

4. Biji KB, Ravishankar CN, Mohan CO, Srinivasa Gopal TK. Smart packaging 9. Özogul F, Polat A, Özogul Y. The effects of modified atmosphere

systems for food applications: a review. J Food Sci Technol. (2015) 52:6125–35. packaging and vacuum packaging on chemical, sensory and microbiological

doi: 10.1007/s13197-015-1766-7 changes of sardines (Sardina pilchardus). Food Chem. (2004) 85:49–57.

5. Gauglitz JM, Aceves CM, Aksenov AA, Aleti G, Almaliti J, Bouslimani doi: 10.1016/j.foodchem.2003.05.006

A, et al. Untargeted mass spectrometry-based metabolomics approach 10. Nedovic V, Kalusevic A, Manojlovic V, Levic S, Bugarski B. An

unveils molecular changes in raw and processed foods and beverages. overview of encapsulation technologies for food applications.

Food Chem. (2020) 302:125290. doi: 10.1016/j.foodchem.2019. Procedia Food Sci. (2011) 1:1806–15. doi: 10.1016/j.profoo.2011.

125290 09.265

6. Butler P. Smart and Interactive Packaging Developments for Enhanced 11. Bibi F, Guillaume C, Gontard N, Sorli B. Wheat gluten, a bio-

Communication at the Packaging/User Interface. Trends Packag. Food, polymer to monitor carbon dioxide in food packaging: electric and

Beverages Other Fast-Moving Consum. Emerald, FL: Goods, Elsevier Inc. dielectric characterization. Sens Actuators B Chem. (2017) 250:76–84.

(2013). p. 261–87. doi: 10.1016/j.snb.2017.03.164

Frontiers in Nutrition | www.frontiersin.org 7 June 2021 | Volume 8 | Article 677884

Ibrahim et al. Smart Packaging for Food Safety

12. Coelho PM, Corona B, ten Klooster R, Worrell E. Sustainability of reusable 26. Bhunia K, Sablani SS, Tang J, Rasco B. Migration of chemical compounds

packaging-Current situation and trends. Resour Conserv Recycl X. (2020) from packaging polymers during microwave, conventional heat

6:100037. doi: 10.1016/j.rcrx.2020.100037 treatment, and storage. Compr Rev Food Sci Food Saf. (2013) 12:523–45.

13. Puligundla P, Jung J, Ko S. Carbon dioxide sensors for intelligent doi: 10.1111/1541-4337.12028

food packaging applications. Food Control. (2012) 25:328–33. 27. Zhang H, Wu J, Guo X. Effects of antimicrobial and antioxidant activities of

doi: 10.1016/j.foodcont.2011.10.043 spice extracts on raw chicken meat quality. Food Sci Hum Wellness. (2016)

14. Xu K, Lu Y, Takei K. Multifunctional skin-inspired flexible sensor 5:39–48. doi: 10.1016/j.fshw.2015.11.003

systems for wearable electronics. Adv Mater Technol. (2019) 4:1–25. 28. Goodrich JD, Winter WT. α-Chitin nanocrystals prepared from shrimp

doi: 10.1002/admt.201800628 shells and their specific surface area measurement. Biomacromolecules. (2007)

15. Putnik P, Roohinejad S, Greiner R, Granato D, Bekhit AEDA, Bursać 8:252–7. doi: 10.1021/bm0603589

Kovačević D. Prediction and modeling of microbial growth in minimally 29. Ghoshal G. Recent trends in active, smart, and intelligent

processed fresh-cut apples packaged in a modified atmosphere: a review. Food packaging for food products. Food Packag Preserv. (2018) 343–74.

Control. (2017) 80:411–9. doi: 10.1016/j.foodcont.2017.05.018 doi: 10.1016/B978-0-12-811516-9.00010-5

16. Li Z, Rui J, Li X, Li J, Dong L, Huang Q, et al. Bacterial community succession 30. Rundh B. The multi-faceted dimension of packaging: marketing

and metabolite changes during doubanjiang-meju fermentation, a Chinese logistic or marketing tool? Br Food J. (2005) 107:670–84.

traditional fermented broad bean (Vicia faba L.) paste. Food Chem. (2017) doi: 10.1108/00070700510615053

218:534–42. doi: 10.1016/j.foodchem.2016.09.104 31. Siracusa V. Food packaging permeability behaviour: a report. Int J Polym Sci.

17. Vanderroost M, Ragaert P, Devlieghere F, De Meulenaer B. Intelligent food (2012) 2012:1–11. doi: 10.1155/2012/302029

packaging: the next generation. Trends Food Sci Technol. (2014) 39:47–62. 32. Kester JJ, Fennema O. An edible film of lipids and cellulose ethers: barrier

doi: 10.1016/j.tifs.2014.06.009 properties to moisture vapor transmission and structural evaluation. J Food

18. Rhim JW, Kim YT. Biopolymer-based composite packaging Sci. (1989) 54:1383–9. doi: 10.1111/j.1365-2621.1989.tb05118.x

materials with nanoparticles. Innov Food Packag. (2013) 16:413–42. 33. Odeyemi OA, Burke CM, Bolch CJS, Stanley R. Evaluation of spoilage

doi: 10.1016/B978-0-12-394601-0.00017-5 potential and volatile metabolites production by Shewanella baltica isolated

19. Kuswandi B, Maryska C, Jayus, Abdullah A, Heng LY. Real time on-package from modified atmosphere packaged live mussels. Food Res Int. (2018)

freshness indicator for guavas packaging. J Food Meas Charact. (2013) 7:29– 103:415–25. doi: 10.1016/j.foodres.2017.10.068

39. doi: 10.1007/s11694-013-9136-5 34. Dehghani S, Hosseini SV, Regenstein JM. Edible films and coatings

20. Kerry JP, O’Grady MN, Hogan SA. Past, current and potential utilisation of in seafood preservation: a review. Food Chem. (2018) 240:505–13.

active and intelligent packaging systems for meat and muscle-based products: doi: 10.1016/j.foodchem.2017.07.034

a review. Meat Sci. (2006) 74:113–30. doi: 10.1016/j.meatsci.2006.04.024 35. Odeyemi OA, Burke CM, Bolch CCJ, Stanley R. Seafood spoilage

21. Llana-Ruiz-Cabello M, Pichardo S, Maisanaba S, Puerto M, Prieto AI, microbiota and associated volatile organic compounds at different storage

Gutiérrez-Praena D, et al. In vitro toxicological evaluation of essential oils and temperatures and packaging conditions. Int J Food Microbiol. (2018) 280:87–

their main compounds used in active food packaging: a review. Food Chem 99. doi: 10.1016/j.ijfoodmicro.2017.12.029

Toxicol. (2015) 81:9–27. doi: 10.1016/j.fct.2015.03.030 36. Peck MW, Webb MD, Goodburn KE. Assessment of the risk of botulism from

22. Gutierrez MM, Meleddu M, Piga A. Food losses, shelf life extension chilled, vacuum/modified atmosphere packed fresh beef, lamb and pork held

and environmental impact of a packaged cheesecake: a life cycle at 3◦ C-8◦ C. Food Microbiol. (2020) 91:103544. doi: 10.1016/j.fm.2020.103544

assessment. Food Res Int. (2017) 91:124–32. doi: 10.1016/j.foodres.2016.

11.031 Conflict of Interest: The authors declare that the research was conducted in the

23. Poyatos-Racionero E, Ros-Lis JV, Vivancos J-L, Martínez-Máñez R. Recent absence of any commercial or financial relationships that could be construed as a

advances on intelligent packaging as tools to reduce food waste. J Clean Prod. potential conflict of interest.

(2018) 172:3398–409. doi: 10.1016/j.jclepro.2017.11.075

24. Sohail A, Turner MS, Prabawati EK, Coombes AGA, Bhandari B. Evaluation Copyright © 2021 Ibrahim, Fahmy and Salah. This is an open-access article

of Lactobacillus rhamnosus GG and Lactobacillus acidophilus NCFM distributed under the terms of the Creative Commons Attribution License (CC BY).

encapsulated using a novel impinging aerosol method in fruit food products. The use, distribution or reproduction in other forums is permitted, provided the

Int J Food Microbiol. (2012) 157:162–6. doi: 10.1016/j.ijfoodmicro.2012.04.025 original author(s) and the copyright owner(s) are credited and that the original

25. Ibrahim S, El-Khawas KM. Development of eco-environmental nano- publication in this journal is cited, in accordance with accepted academic practice.

emulsified active coated packaging material. J King Saud Univ Sci. (2019) No use, distribution or reproduction is permitted which does not comply with these

31:1485–90. doi: 10.1016/j.jksus.2019.09.010 terms.

Frontiers in Nutrition | www.frontiersin.org 8 June 2021 | Volume 8 | Article 677884

You might also like

- HACCP Multiple Choice QuestionsDocument7 pagesHACCP Multiple Choice Questionsaloke ganguly92% (12)

- Work Immersion Parent Consent FormDocument2 pagesWork Immersion Parent Consent FormJohnArgielLaurenteVictor88% (8)

- Function, Structure, Operation of Engine Null (4JK1)Document36 pagesFunction, Structure, Operation of Engine Null (4JK1)jonathan100% (3)

- Eng 3050 User Test MemoDocument6 pagesEng 3050 User Test Memoapi-273155668100% (1)

- Active and Intelligent Packaging-The Indication of Quality and Safety PDFDocument25 pagesActive and Intelligent Packaging-The Indication of Quality and Safety PDFNguyễn Đình Như NguyệnNo ratings yet

- Bill Bartmann - Self Esteem WorkbookDocument46 pagesBill Bartmann - Self Esteem WorkbookMihai Vinatoru100% (5)

- Journal of Agriculture and Food Research: Neha Chausali, Jyoti Saxena, Ram PrasadDocument14 pagesJournal of Agriculture and Food Research: Neha Chausali, Jyoti Saxena, Ram PrasadLeonardo PohtsNo ratings yet

- Food Packaging and Shelf Life: Abdus Sobhan, Kasiviswanathan Muthukumarappan, Lin WeiDocument12 pagesFood Packaging and Shelf Life: Abdus Sobhan, Kasiviswanathan Muthukumarappan, Lin Weiedwar tinocoNo ratings yet

- 1 s2.0 S0023643823012628 MainDocument12 pages1 s2.0 S0023643823012628 MainRIDHO IKSANNo ratings yet

- Comp Rev Food Sci Food Safe - 2021 - Omerovi - Antimicrobial Nanoparticles and Biodegradable Polymer Composites For ActiveDocument28 pagesComp Rev Food Sci Food Safe - 2021 - Omerovi - Antimicrobial Nanoparticles and Biodegradable Polymer Composites For ActiveMahmoud BelabbassiNo ratings yet

- Development of Organic-Inorganic Hybrid Antimicrobial Materials by Mechanical Force and Application For Active PackagingDocument10 pagesDevelopment of Organic-Inorganic Hybrid Antimicrobial Materials by Mechanical Force and Application For Active Packagingabbas413No ratings yet

- Smart and Active Food Packaging Insights in NovelDocument26 pagesSmart and Active Food Packaging Insights in NovelMary MaryamNo ratings yet

- Películas y Recubrimientos A Base de Proteínas para Aplicaciones de La Industria AlimentariaDocument24 pagesPelículas y Recubrimientos A Base de Proteínas para Aplicaciones de La Industria AlimentariaDeisy Paola Correa CardenasNo ratings yet

- Protein-Based Films: Advances in The Development of Biomaterials Applicable To Food PackagingDocument16 pagesProtein-Based Films: Advances in The Development of Biomaterials Applicable To Food PackagingVeronica HernandezNo ratings yet

- Plastik Biodegradable Dengan Indikator Warna Dari Ekstrak Daun Dan Buah Tanaman Pucuk Merah (Syzygium Oleana) Sebagai Smart PackagingDocument21 pagesPlastik Biodegradable Dengan Indikator Warna Dari Ekstrak Daun Dan Buah Tanaman Pucuk Merah (Syzygium Oleana) Sebagai Smart Packagingajengpuspita10No ratings yet

- Trends and Prospects in Sustainable Food Packaging MaterialsDocument4 pagesTrends and Prospects in Sustainable Food Packaging MaterialsCsaba AndrásNo ratings yet

- Microbial Assessment of Selected, LocallyDocument9 pagesMicrobial Assessment of Selected, LocallyOnyekachiNo ratings yet

- Recent Trends in Nanotechnology Based Applications in Food MicrobiologyDocument12 pagesRecent Trends in Nanotechnology Based Applications in Food MicrobiologyKatherin sylviaNo ratings yet

- Nanotechnology in Food PreservationDocument8 pagesNanotechnology in Food PreservationSardaneta SweetNo ratings yet

- Application of Nanotechnology in Food Packaging: September 2016Document8 pagesApplication of Nanotechnology in Food Packaging: September 2016Mumtahin Ul KousarNo ratings yet

- Màng FilmDocument52 pagesMàng FilmTrangNo ratings yet

- Review Article - Nanomaterial in Food PackagingDocument16 pagesReview Article - Nanomaterial in Food PackagingMateriálová Technnologia ExternistiNo ratings yet

- A Review On Active Packaging For Quality and Safety of Fo - 2022 - Food PackaginDocument12 pagesA Review On Active Packaging For Quality and Safety of Fo - 2022 - Food Packaginfernanda santosNo ratings yet

- Cellulose Nanofiber Based PH Indicator Integrated With Resazuri - 2023 - Food BiDocument10 pagesCellulose Nanofiber Based PH Indicator Integrated With Resazuri - 2023 - Food BimarciaNo ratings yet

- Jurnal Indikator Alami 5Document16 pagesJurnal Indikator Alami 5Alvando SiahaanNo ratings yet

- 2023 Antifungal Edible Coatings For Fruits Based On Zein and Chitosan NanowhiskersDocument15 pages2023 Antifungal Edible Coatings For Fruits Based On Zein and Chitosan NanowhiskersEliton Medeiros Candido de MacêdoNo ratings yet

- Nanotechnology For The Food and Bioprocessing IndustriesDocument9 pagesNanotechnology For The Food and Bioprocessing IndustriesvikashvermaiitkgpNo ratings yet

- Development of Smart Bilayer AlginateAgar Film Containing-CompressedDocument18 pagesDevelopment of Smart Bilayer AlginateAgar Film Containing-Compresseddavisazalea3No ratings yet

- Trends in Food Science & Technology: S. Kalpana, S.R. Priyadarshini, M. Maria Leena, J.A. Moses, C. Anandharamakrishnan TDocument13 pagesTrends in Food Science & Technology: S. Kalpana, S.R. Priyadarshini, M. Maria Leena, J.A. Moses, C. Anandharamakrishnan TAnutza PopescuNo ratings yet

- Nano TechnologyDocument4 pagesNano TechnologyTäð Œvê MîðNo ratings yet

- 41863-Article Text-215041-2-10-20230515Document10 pages41863-Article Text-215041-2-10-20230515InangNo ratings yet

- Role of Nanotechnology in Food Industry-May 30 22Document2 pagesRole of Nanotechnology in Food Industry-May 30 22waqasNo ratings yet

- Foto Pengawetan ApelDocument8 pagesFoto Pengawetan ApelheraNo ratings yet

- Sensors 21 02148 v2 1Document24 pagesSensors 21 02148 v2 1quimicosorioNo ratings yet

- Biopolymer-Based Functional Films For Packaging Applications - A ReviewDocument20 pagesBiopolymer-Based Functional Films For Packaging Applications - A ReviewDeidra CadeNo ratings yet

- Foods 11 02228Document16 pagesFoods 11 02228Varshita KothariNo ratings yet

- Application of Innovative Technologies For Improved Food Quality and SafetyDocument83 pagesApplication of Innovative Technologies For Improved Food Quality and SafetyIsha GargNo ratings yet

- Food Bioengineering - 2023 - Thirupathi Vasuki - Smart Packaging An Overview of Concepts and Applications in Various FoodDocument17 pagesFood Bioengineering - 2023 - Thirupathi Vasuki - Smart Packaging An Overview of Concepts and Applications in Various FooddepsondualityNo ratings yet

- 10 1016@j Foodres 2019 108927Document104 pages10 1016@j Foodres 2019 108927SiddharthBhasneyNo ratings yet

- 1 s2.0 S0141813021015932 MainDocument9 pages1 s2.0 S0141813021015932 MainAna Claudia AlmeidaNo ratings yet

- Salchichas Bacteira Celullose PDFDocument64 pagesSalchichas Bacteira Celullose PDFLuis ChavezArroyoNo ratings yet

- Esfaf 438Document6 pagesEsfaf 438Pew PewNo ratings yet

- A Comprehensive Review of Polysaccharide-Based Bionanocomposites For Food Packaging Applications (2022)Document13 pagesA Comprehensive Review of Polysaccharide-Based Bionanocomposites For Food Packaging Applications (2022)Mahmoud BelabbassiNo ratings yet

- OSU NanoAgDocument2 pagesOSU NanoAgJason FromerNo ratings yet

- International Journal of Biological Macromolecules: Clitoria Ternatea Anthocyanin-Rich Extract To Preserve and MonitorDocument12 pagesInternational Journal of Biological Macromolecules: Clitoria Ternatea Anthocyanin-Rich Extract To Preserve and MonitorLộc Trần TuấnNo ratings yet

- Neme Et Al. 2021 - Application of Nanotechnology in Agriculture, Postharvest Loss Reduction and FoodDocument12 pagesNeme Et Al. 2021 - Application of Nanotechnology in Agriculture, Postharvest Loss Reduction and FoodYosafat KurniadiNo ratings yet

- Advanced Biomaterials For Sustainable Applications in The FoodDocument11 pagesAdvanced Biomaterials For Sustainable Applications in The FoodMảnhGhépNo ratings yet

- Antimicrobial Nanomaterials For Food PackagingDocument31 pagesAntimicrobial Nanomaterials For Food PackagingMary MaryamNo ratings yet

- Jurnal PackagingDocument6 pagesJurnal PackagingFarah Insan SalsabilaNo ratings yet

- Foods 12 03159Document29 pagesFoods 12 03159Rafael AraujoNo ratings yet

- Prasetiyo 2020 EFFECTS OF CHITOSAN COATING ON THE PHYSICAL, MECHANICAL AND ANTIMICROBIAL PROPERTIES OF FOOD PACKAGING PAPERDocument7 pagesPrasetiyo 2020 EFFECTS OF CHITOSAN COATING ON THE PHYSICAL, MECHANICAL AND ANTIMICROBIAL PROPERTIES OF FOOD PACKAGING PAPERAndri WigunaNo ratings yet

- Penerapan Teknologi Nanokomposit Pada Kemasan Pangan: Roswita Puji Lestari, Mohamad Ali Fulazzaky, Aji JumionoDocument8 pagesPenerapan Teknologi Nanokomposit Pada Kemasan Pangan: Roswita Puji Lestari, Mohamad Ali Fulazzaky, Aji Jumionoeva agustinaNo ratings yet

- The Rise of Nanotechnology Food Processing and Packaging 2s4wzauyDocument13 pagesThe Rise of Nanotechnology Food Processing and Packaging 2s4wzauyadhyNo ratings yet

- Fishintendedforhumanconsumption fromDNAbarcodingtoanext generationsequencingNGS BasedapproachDocument8 pagesFishintendedforhumanconsumption fromDNAbarcodingtoanext generationsequencingNGS BasedapproachIBTISAAM MushtaqNo ratings yet

- Recent Developments in Intelligent Packaging For Enhancing Food Quality and SafetyDocument42 pagesRecent Developments in Intelligent Packaging For Enhancing Food Quality and SafetyAndrew KapraunNo ratings yet

- Applsci 13 08436Document18 pagesApplsci 13 08436TOmmy QuantoNo ratings yet

- Pengemasa. Aktif KemasanDocument7 pagesPengemasa. Aktif KemasanGalni karangoraNo ratings yet

- Implementation of Food Safety On Frozen ShrimpDocument7 pagesImplementation of Food Safety On Frozen Shrimp12CH1-13 ĐỖ HOÀNG PHÚCNo ratings yet

- Pfe ReviewDocument10 pagesPfe ReviewFatiha El badraouiNo ratings yet

- Survival Spoilage and Pathogenic Microorgs On Carrdboard-Plastic Packaging Materialsli, 2017Document10 pagesSurvival Spoilage and Pathogenic Microorgs On Carrdboard-Plastic Packaging Materialsli, 2017chetanaNo ratings yet

- 1 s2.0 S0959652623013276 MainDocument11 pages1 s2.0 S0959652623013276 MainWilliam Rolando Miranda ZamoraNo ratings yet

- Active and Intelligent Packaging in Meat IndustryDocument12 pagesActive and Intelligent Packaging in Meat IndustryAncuţa-IonelaPartin100% (1)

- Development of On Package Indicator Sensor For Real-Time Monitoring of Meat QualityDocument5 pagesDevelopment of On Package Indicator Sensor For Real-Time Monitoring of Meat QualityFarah Yume Yasumi100% (1)

- 1 s2.0 S0023643822000470 MainDocument8 pages1 s2.0 S0023643822000470 Maintaha242004No ratings yet

- Un Cisic E-Bulliten 5Document3 pagesUn Cisic E-Bulliten 5taha_basit2441No ratings yet

- NIC Components NSRN SeriesDocument5 pagesNIC Components NSRN SeriesNICCompNo ratings yet

- Emotional WellnessDocument3 pagesEmotional Wellnesspaula_evangelista_3100% (1)

- Population and EmploymentDocument16 pagesPopulation and EmploymentAbdullah NukhbatNo ratings yet

- Self-Healing DNA Nanostructures - American Chemical SocietyDocument3 pagesSelf-Healing DNA Nanostructures - American Chemical Societydanutzza90No ratings yet

- JS1034-XX-F06-0001. A1Document107 pagesJS1034-XX-F06-0001. A1Pawan Gosavi100% (1)

- Bare Copper Conductor Soft Drawn1Document1 pageBare Copper Conductor Soft Drawn1Ian de GaliciaNo ratings yet

- PDFDocument7 pagesPDFNupur SaxenaNo ratings yet

- C882 Bond Strength of Epoxy-Resin Systems Used With ConcreteDocument3 pagesC882 Bond Strength of Epoxy-Resin Systems Used With ConcreteHassan MokhtarNo ratings yet

- 10 Minutes On Global Talent MobilityDocument8 pages10 Minutes On Global Talent MobilityRamona Paula100% (1)

- Senate Bill 897v8 NC FY 2010-11 Budget As RatifiedDocument189 pagesSenate Bill 897v8 NC FY 2010-11 Budget As RatifiedBobby CogginsNo ratings yet

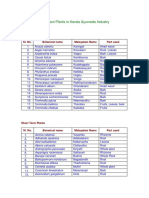

- Important Plants in Kerala Ayurveda Industry: Tree CropsDocument2 pagesImportant Plants in Kerala Ayurveda Industry: Tree Cropsajeez86No ratings yet

- Research Paper About E-Waste: Kolehiyo NG Lungsod NG Lipa Marawoy, Lipa City College of Teacher EducationDocument10 pagesResearch Paper About E-Waste: Kolehiyo NG Lungsod NG Lipa Marawoy, Lipa City College of Teacher EducationAlexa Ylarie Mei FetalcoNo ratings yet

- Ercoli 2020Document47 pagesErcoli 2020Miguel Angel Cabrera DiazNo ratings yet

- Birth AsphyxiaDocument12 pagesBirth Asphyxiaannu panchalNo ratings yet

- Sunflower Production (Final) PPT - Compressed PDFDocument27 pagesSunflower Production (Final) PPT - Compressed PDFMarijenLeaño88% (8)

- Digital - Accelerator (1) Julho 2011Document21 pagesDigital - Accelerator (1) Julho 2011kleibertNo ratings yet

- Terms and Conditions - DXB Grade EK.04Document1 pageTerms and Conditions - DXB Grade EK.04SylajNo ratings yet

- Kingdoms Shortlisting PDFDocument28 pagesKingdoms Shortlisting PDFNoman KhanNo ratings yet

- Chapter 1 PPT 2 (Container and Closures)Document15 pagesChapter 1 PPT 2 (Container and Closures)Shumaila Qadir100% (2)

- Academic Answers For Practice Test 2 Listening Section 1: Answer KeysDocument7 pagesAcademic Answers For Practice Test 2 Listening Section 1: Answer KeysVinda EkabudiningsihNo ratings yet

- Soal Uts Kelas 9 MtsDocument5 pagesSoal Uts Kelas 9 Mtsindah sNo ratings yet

- Performance Chemicals For Enhanced Oil RecoveryDocument6 pagesPerformance Chemicals For Enhanced Oil RecoveryMiguel MartinezNo ratings yet

- Photosynthesis PDFDocument22 pagesPhotosynthesis PDFbhaskar rayNo ratings yet

- Format For Computation of Income Under Income Tax ActDocument3 pagesFormat For Computation of Income Under Income Tax ActAakash67% (3)