Professional Documents

Culture Documents

Eco Bags System

Eco Bags System

Uploaded by

Nizam AnuarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Eco Bags System

Eco Bags System

Uploaded by

Nizam AnuarCopyright:

Available Formats

Method Statement

ECO BAGS SYSTEM

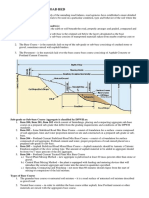

1. GENERAL

1.1 Delivery, Storage and Handling

a) Contactor shall check the material upon delivery to assure the proper

materials have been received.

b) Eco-Bags System shall store at temperatures above -20ºF

c) Contractor shall prevent excessive mud, wet cement, epoxy, and similar

materials (which may affix themselves to the gridwork) from coming in

contact with the materials.

1.2 Quality Assurance

a) Owner will supply soil testing and inspection services for quality control

testing during earthwork operation

2. FILLING MATERIAL PREPARATION

2.1 Wall, slopes and above High Waterline Applications

a) Freely draining native soils and granular materials cleaned of all debris,

roots, branches, stones in excess of 2” (50mm) diameter and other deleterious

materials. Remove soil contaminated with calcium chloride, toxic materials

and petroleum products.

b) Properties should include (by volume)

i. Approximate Organic Contect: 10 – 15%

ii. Granular Content: smaller than 50mm, larger than 20mm 60 – 70%

iii. Granular Content: larger than 0.05mm, smaller than 2mm 10 – 15%

iv. Clay and Silts 0 – 5%

c) Percolation shall be such that no standing water is visible 60 minutes after

at least 10 minutes of moderate to heavy rain or irrigation.

d)Organic additive materials should be a locally available commercial

compost product.

e) Mix all organic materials evenly through the material

2.2 Below Waterline Applications

a) Clean Granular material; 20mm gravel minimum particle size 2mm. pre

seeding bags is suggested for structures built below normal water levels.

2.3 Backfill

a) Material shall be site excavated soil when approved by the engineer unless

otherwise specified in the drawings. Unsuitable soil for backfill (heavy clays

or organic soils) shall not be used in the backfill or in the reinforced soil mass.

CSL soil centralab sdn. bhd.

Method Statement

3. ECO-BAGS SYSTEMS INSTALLATION

Step 1: Prepare Site

Remove all surface vegetation and debris (if any). This material should not be

used as backfill. Excavate site soils to accommodate the required Eco-Bags

length (Refer to project drawing)

Step 2: Excavate Base Trench

a) Refer to project drawings for specified depths and compaction for each wall

type and comply with requirements.

b) Excavate to depths shown on drawings allowing for specified number of

bags layers below grade over specified depth of compacted granular base

c) Prepare a stable, level platform and compact to 95% modified Proctor

Density.

Step 3: Reasonably Level Base

No footings are required, only a reasonably level base with compacted coarse-

grained sand, gravel, or crushed stone.

Step 4: Bag Fill and Close Bag

After bag filling, closed the bags with cable tie.

Step 5: Install base Course

Once the surface has been reasonably leveled, fill the base coarse bags and

begin placing them, starting at the lowest point of the wall. Level the bags

front to rear and side to side as best as possible.

After the base coarse units have been properly positioned, place and compact

soil backfill behind and in front of the bags to prevent shifting. Install the

entire length of the base course before starting succeeding course, if possible.

Step 6: Connector Base Course & Succeeding Courses

Place Connectors on tops of the bags toward the edges so that one Connector

spans two bags. Stagger succeeding courses so that the Connector pierces the

middle underside of the top Eco-Bag. Tamping the tops of the Eco-Bags will

help ensure that the Eco-bags are securely connected.

Step 7: Place Succeeding Courses

Succeeding courses will be set upon previous courses so that each top Eco-

Bag will be placed over two bottom Eco-Bags with one Connector sandwiched

between the upper and lower courses. This will create a running bond face

pattern. Continue placing Eco-Bags, drainage aggregate and reinforced

backfill. The weight from the top courses will drive the Connector into the

Eco-Bags, forming a positive connection between the Eco-Bags.

See diagram below:

CSL soil centralab sdn. bhd.

Method Statement

1) Place two Eco-Bags side by side

2) Place a Connector so that it spans the two Eco-Bags

3) Place the top Eco-Bags to drive in the Spikes

4) Repeat for the entire wall

Step 8: Drainage

Fill the drainage zone with inorganic free drainage granular material (open-

graded 9.5mm to 20mm). The drainage zone is the combined area of the Bags

units and or additional area behind the units. The width of the drainage zone

material should be approx 600mm measure from wall face to the back of the

trench. A drainage collection pipe is incorporated into the drainage zone at the

base to carry large

amount of water away from the system quickly.

The Eco-Bags Systems is water permeable and generally drainage system will

not be

required if adjacent soils are free drainage. Refer to the site drawing for

drainage

structures and comply with requirement.

Step 9: Repeats

Repeat the steps 6 – 8 until all course have been placed.

CSL soil centralab sdn. bhd.

You might also like

- Risk Assessment of Fire Hose Reel InstallationDocument9 pagesRisk Assessment of Fire Hose Reel Installationfidgety100% (2)

- Stabilised Base MethodologyDocument6 pagesStabilised Base MethodologyPanashe Chikomwe100% (1)

- Method Statement For VDFDocument7 pagesMethod Statement For VDFSagar Parab100% (2)

- DPWH Monitoring Guide For RoadsDocument19 pagesDPWH Monitoring Guide For RoadsChristian SesoNo ratings yet

- Guidelines of Septic Systems DesignDocument16 pagesGuidelines of Septic Systems DesignJowie100% (1)

- ISSB Water Tank Consruction Manual 120908 FINALDocument25 pagesISSB Water Tank Consruction Manual 120908 FINALPaul Kimera100% (2)

- 2 Constructing The Roadbed WTH Assignments PDFDocument4 pages2 Constructing The Roadbed WTH Assignments PDFAngelo John R. Javinez50% (2)

- ISO 9001-2015 Process Audit ChecklistDocument18 pagesISO 9001-2015 Process Audit Checklistprincess cipriano100% (7)

- HiPath Xpressions Compact V3.0 Installation Administration GuideDocument194 pagesHiPath Xpressions Compact V3.0 Installation Administration GuideenjoythedocsNo ratings yet

- Clearing, Grubbing and ExcavationDocument25 pagesClearing, Grubbing and ExcavationArah Louise ApostolNo ratings yet

- Clearing, Grubbing and ExcavationDocument11 pagesClearing, Grubbing and ExcavationArah Louise ApostolNo ratings yet

- Box Culvert, VUP & Minor BridgeDocument22 pagesBox Culvert, VUP & Minor BridgeĐărsĥąna RanasingheNo ratings yet

- ProctorDocument4 pagesProctorFatin HazwaniNo ratings yet

- ProctorDocument4 pagesProctorFatin HazwaniNo ratings yet

- BioCycle Waste Water Treatment SystemDocument12 pagesBioCycle Waste Water Treatment SystemDoug WeirNo ratings yet

- Constructing The Roadbed (BSCE3-EC1)Document6 pagesConstructing The Roadbed (BSCE3-EC1)Jayson J. PagalNo ratings yet

- Constructing The Roadbed (BSCE3-EC1)Document6 pagesConstructing The Roadbed (BSCE3-EC1)Jayson J. PagalNo ratings yet

- Ms-Draft 2Document22 pagesMs-Draft 2AlbertyNo ratings yet

- Section 02000: Milling, Hot Mix Asphalt and Patching Procedures: A. MillingDocument12 pagesSection 02000: Milling, Hot Mix Asphalt and Patching Procedures: A. MillingJojo DejucosNo ratings yet

- Tagupa, Mara Erna-ResearchworkDocument14 pagesTagupa, Mara Erna-ResearchworkMara Erna TagupaNo ratings yet

- Highway Engineering ReportDocument17 pagesHighway Engineering ReportJerick Magalang GallanoNo ratings yet

- Anchor TrenchDocument4 pagesAnchor TrenchAlbertyNo ratings yet

- Lab SandDocument4 pagesLab Sandshamsulaliff94No ratings yet

- Research Work 1Document14 pagesResearch Work 1Mara Erna TagupaNo ratings yet

- Arch. Karen G. FeliasDocument8 pagesArch. Karen G. FeliasKelly Manlangit Jr.No ratings yet

- Do 006 S2012 PDFDocument8 pagesDo 006 S2012 PDFWilliamNo ratings yet

- Unit 5BDocument28 pagesUnit 5BNaveen KumarNo ratings yet

- Division 2 SiteworkDocument3 pagesDivision 2 SiteworkMa Monica M. MuncadaNo ratings yet

- Stone ColumnDocument8 pagesStone ColumnBilal Ahmed BarbhuiyaNo ratings yet

- Minor Project On Compressed Earth BlocksDocument7 pagesMinor Project On Compressed Earth BlocksRajendra Singh Panwar100% (1)

- MS For ConstructionDocument33 pagesMS For ConstructionCokelatAnginNo ratings yet

- Pump STN m1Document99 pagesPump STN m1FiroshkhanEbrahimNo ratings yet

- How To Backfill Foundations and Trenches Backfill Is The Key To A Solid and Stable Grading Share Flip Pin EmailDocument4 pagesHow To Backfill Foundations and Trenches Backfill Is The Key To A Solid and Stable Grading Share Flip Pin Emailram_babu_59No ratings yet

- Earthwork ExcavationDocument24 pagesEarthwork ExcavationGabriella PrathapsonNo ratings yet

- Land PreprationDocument11 pagesLand PreprationMuhd Shahir SallehNo ratings yet

- Epoxy Fiberglass Pipe Wrap Directions: SnopsisDocument4 pagesEpoxy Fiberglass Pipe Wrap Directions: SnopsisdroidsNo ratings yet

- Appendix G3 Construction Method StatementDocument4 pagesAppendix G3 Construction Method StatementsotheaNo ratings yet

- Unit-3.1 Lakshmana NaikDocument51 pagesUnit-3.1 Lakshmana NaiknehamyaNo ratings yet

- Method of Statement For Interlocking Block and Curb StoneDocument4 pagesMethod of Statement For Interlocking Block and Curb StoneTAHER AMMAR100% (2)

- Guidelines For Decommissioning Abandonment) of Water WellsDocument4 pagesGuidelines For Decommissioning Abandonment) of Water WellsmikeromeoNo ratings yet

- 191aig026 - Const. MNGMTDocument10 pages191aig026 - Const. MNGMTkevinNo ratings yet

- MS Subgrade PreparationDocument5 pagesMS Subgrade PreparationAnduel SelamajNo ratings yet

- DCC1023 Civil Engiineering Materials: Name: Muhd Izzat Syahmi Akmal BinDocument8 pagesDCC1023 Civil Engiineering Materials: Name: Muhd Izzat Syahmi Akmal BinMiko ChanNo ratings yet

- Self-Healing Soft Grouts Form in Situ Bottom Barrier in Earthsaw Field DemoDocument5 pagesSelf-Healing Soft Grouts Form in Situ Bottom Barrier in Earthsaw Field DemoIan McGooNo ratings yet

- Method of StatementDocument17 pagesMethod of StatementhanyalramadyNo ratings yet

- Constructionandmaintenanceof Riverembankments (Levees) - GuidelinesDocument7 pagesConstructionandmaintenanceof Riverembankments (Levees) - GuidelinesSushil DhunganaNo ratings yet

- Geo Textile Tube DewateringDocument10 pagesGeo Textile Tube Dewateringadiapr15No ratings yet

- 1.1 A. B. C. D. 1.2 A. B. C. D. 1.3 A. B. C. 1.4 A. B. 1. 2. 3Document7 pages1.1 A. B. C. D. 1.2 A. B. C. D. 1.3 A. B. C. 1.4 A. B. 1. 2. 3tkm2004No ratings yet

- Method Statement For Installation of Soil Nails SK Kauluan, Ranau .Document9 pagesMethod Statement For Installation of Soil Nails SK Kauluan, Ranau .Asdia Aseffah FathiyaNo ratings yet

- January 20, 2021 CE 401 - CE31S6 Geotechnical Engineering 1 (Soil Mechanics) GROUP - (5 Members)Document5 pagesJanuary 20, 2021 CE 401 - CE31S6 Geotechnical Engineering 1 (Soil Mechanics) GROUP - (5 Members)Katy PerryNo ratings yet

- Work Method Statement For Implementing EscpDocument4 pagesWork Method Statement For Implementing EscpFaqrul AzwanNo ratings yet

- Concrete NotesDocument4 pagesConcrete NotesdaleemaNo ratings yet

- C. 7.4 - Construction MethodsDocument4 pagesC. 7.4 - Construction MethodsJhoycee MiclatNo ratings yet

- Construction and Design Criteria Earthen DamsDocument30 pagesConstruction and Design Criteria Earthen DamsAbhilash vishwakramaNo ratings yet

- Rip Rap Install 15 547e03aac1Document4 pagesRip Rap Install 15 547e03aac1Amanda CarinaNo ratings yet

- Rip Rap InstallDocument4 pagesRip Rap InstallAndrew ReidNo ratings yet

- Construction of RoadbedDocument34 pagesConstruction of RoadbedJohn Mark TaborNo ratings yet

- Appendix A. Technical Feasibility ChecklistDocument26 pagesAppendix A. Technical Feasibility ChecklistSasheen Dela CruzNo ratings yet

- Solid Waste Treatment ProcessDocument28 pagesSolid Waste Treatment ProcessRiddhiNo ratings yet

- Land Fill Design and Operation-Imp-Km3Document37 pagesLand Fill Design and Operation-Imp-Km3manoj kumar GNo ratings yet

- Blending of AggregateDocument7 pagesBlending of AggregateLakshan FonsekaNo ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Soil Investigation and Foundation DesignFrom EverandSoil Investigation and Foundation DesignRating: 4.5 out of 5 stars4.5/5 (9)

- Eco TubeDocument2 pagesEco TubeNizam AnuarNo ratings yet

- Crack Lines and Stone Pitching RepairDocument1 pageCrack Lines and Stone Pitching RepairNizam AnuarNo ratings yet

- MS Mill N Pave (13 Critical Location)Document16 pagesMS Mill N Pave (13 Critical Location)Nizam AnuarNo ratings yet

- MS Precast Drainage CulvertDocument30 pagesMS Precast Drainage CulvertNizam AnuarNo ratings yet

- Method of Statement of Roadline MarkingDocument6 pagesMethod of Statement of Roadline MarkingNizam AnuarNo ratings yet

- Introduction To CRMDocument20 pagesIntroduction To CRMflaviagonNo ratings yet

- K12 - CC - Catalog - 2013-2014 LouisianaDocument34 pagesK12 - CC - Catalog - 2013-2014 LouisianaElizabeth KahnNo ratings yet

- British Standard Cable Colours - Bs-Au7a by ColourDocument7 pagesBritish Standard Cable Colours - Bs-Au7a by Colourhagleyr5638100% (1)

- 1st Year Chemistry NotesDocument24 pages1st Year Chemistry NotesShasha Jain88% (8)

- Monday Tuesday Wednesday Thursday Friday: GRADES 1 To 12 Daily Lesson LogDocument7 pagesMonday Tuesday Wednesday Thursday Friday: GRADES 1 To 12 Daily Lesson LogKatrina Baldas Kew-isNo ratings yet

- Aspen Tree Art Lesson PlanDocument3 pagesAspen Tree Art Lesson Planapi-563439476No ratings yet

- Device InfoDocument8 pagesDevice InfoHarvey SucayreNo ratings yet

- Fundamentals Activities PrintDocument514 pagesFundamentals Activities PrintTOP NOTCHNo ratings yet

- Online Class: Students Preparedness in Coping Up With The New NormalDocument2 pagesOnline Class: Students Preparedness in Coping Up With The New NormalJoshua BernardoNo ratings yet

- ApomixisDocument3 pagesApomixisAnonymous yKjxyeLNo ratings yet

- Paper 5 Examiner's Script: 3 Minutes (5 Minutes For Groups of Three)Document5 pagesPaper 5 Examiner's Script: 3 Minutes (5 Minutes For Groups of Three)IsaMar NuñezNo ratings yet

- This Article Needs Additional Citations For VerificationDocument3 pagesThis Article Needs Additional Citations For Verificationsamina taneNo ratings yet

- Lovely Professional University, PunjabDocument6 pagesLovely Professional University, PunjabAlisha AgarwalNo ratings yet

- The Education of Albert Einstein: Clayton A. GearhartDocument23 pagesThe Education of Albert Einstein: Clayton A. GearhartJudith Banabatac OreganoNo ratings yet

- Unit3 OBDocument57 pagesUnit3 OBsiddhi vermaNo ratings yet

- Zener Tester: by MedhatkoDocument6 pagesZener Tester: by Medhatkosaran gulNo ratings yet

- Wallbox Supernova BrochureDocument8 pagesWallbox Supernova BrochuresaraNo ratings yet

- Deloitte NL Fsi Chatbots Adopting The Power of Conversational UxDocument24 pagesDeloitte NL Fsi Chatbots Adopting The Power of Conversational UxOliverNo ratings yet

- The Literary Formofthe QuranDocument10 pagesThe Literary Formofthe QuranTrina CanizoNo ratings yet

- Case StudiesDocument8 pagesCase StudiesGowtham RasamsettyNo ratings yet

- Marine Control Unit (Mcu)Document1 pageMarine Control Unit (Mcu)Oktay KESKİNKILIÇNo ratings yet

- Human Resource Management IN: Submitted To: Doc. Maryjane LubosDocument9 pagesHuman Resource Management IN: Submitted To: Doc. Maryjane LubosJanine padronesNo ratings yet

- LogarithmDocument2 pagesLogarithmSuryandaru Prasetyo JatiNo ratings yet

- Esip 2021-2024 LinabuisDocument107 pagesEsip 2021-2024 LinabuisJheryl Malapad Fortun-Guibelondo50% (2)

- PPCoN 2169-2000Document113 pagesPPCoN 2169-2000Minh Hong PhamNo ratings yet