Professional Documents

Culture Documents

SFH 2430 - en

SFH 2430 - en

Uploaded by

smokeiiotOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SFH 2430 - en

SFH 2430 - en

Uploaded by

smokeiiotCopyright:

Available Formats

www.osram-os.

com

Produktdatenblatt | Version 1.1

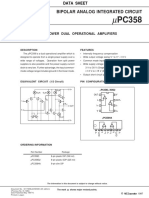

SFH 2430

SFH 2430

DIL SMT Ambient Light Sensor

Silicon Photodiode with Vλ Characteristic

Applications

—Ambient Light Sensors —Health Monitoring (Heart Rate Monitoring,

Pulse Oximetry)

Features:

—Package: clear epoxy

—Qualifications: The product qualification test plan is based on the guidelines of AEC-Q101-REV-C,

Stress Test Qualification for Automotive Grade Discrete Semiconductors.

—ESD: 2 kV acc. to ANSI/ESDA/JEDEC JS-001 (HBM, Class 2)

—Spectral sensitivity adapted to human eye sensitivity (Vλ)

—Low temperature coefficient of spectral sensitivity

—High linearity

—DIL plastic package with high packing density

Ordering Information

Type

Photocurrent 1)

Ev = 1000 lx; Std. Light A; VR = 5 V

Photocurrent

typ.

Ev = 1000 lx; Std. Light A; VR = 5 V

Ordering Code

IP IP

SFH 2430-Z ≥ 5.6 µA 6.3 µA Q65110A2673

1 Version 1.4 | 2021-06-08

SFH 2430

Maximum Ratings

TA = 25 °C

Parameter Symbol Values

Operating Temperature Top min. -40 °C

max. 100 °C

Storage temperature Tstg min. -40 °C

max. 100 °C

Reverse voltage VR max. 6V

Total power dissipation Ptot max. 150 mW

ESD withstand voltage VESD max. 2 kV

acc. to ANSI/ESDA/JEDEC JS-001 (HBM, Class 2)

2 Version 1.4 | 2021-06-08

SFH 2430

Characteristics

TA = 25 °C

Parameter Symbol Values

Spectral sensitivity S min. 5 nA/lx

VR = 5 V; Std. Light A; T = 2856 K typ. 6.3 nA/lx

Wavelength of max sensitivity λS max typ. 570 nm

Spectral range of sensitivity λ10% typ. 400 ... 900 nm

Radiant sensitive area A typ. 7.02 mm²

Dimensions of active chip area LxW typ. 2.65 x 2.65

mm x mm

Half angle φ typ. 60 °

Dark current IR typ. 0.1 nA

VR = 5 V max. 5 nA

Spectral sensitivity of the chip Sλ typ. 0.17 A / W

λ = 550 nm

Short-circuit current ISC typ. 6.1 µA

Ev = 1000 lx; Std. Light A; VR = 0 V

Rise time tr typ. 200 µs

VR = 5 V; RL = 50 Ω; λ = 550 nm

Fall time tf typ. 200 µs

VR = 5 V; RL = 50 Ω; λ = 550 nm

Forward voltage VF typ. 1.2 V

IF = 100 mA; E = 0

Capacitance C0 typ. 1000 pF

VR = 0 V; f = 1 MHz; E = 0

3 Version 1.4 | 2021-06-08

SFH 2430

Relative Spectral Sensitivity 2), 3)

Srel = f (λ)

OHF02387

100

Srel %

80

70

60

50

40

30

20

10

0

400 500 600 700 800 900 nm 1100

λ

Directional Characteristics 2), 3)

Srel = f (φ)

40 30 20 10 0 OHF01402

ϕ

1.0

50

0.8

60

0.6

70 0.4

80 0.2

0

90

100

1.0 0.8 0.6 0.4 0 20 40 60 80 100 120

4 Version 1.4 | 2021-06-08

SFH 2430

Dark Current 2), 3)

IR = f (VR); E = 0

OHF02390

10 0

nA

IR

5

10 -1

10 -2

0 1 2 3 4 5 V 6

VR

Capacitance 2), 3)

C = f (VR); f = 1MHz; E = 0; TA = 25°C

OHF02388

1200

pF

C

800

600

400

200

0 -2

10 5 10-1 5 100 V 101

VR

5 Version 1.4 | 2021-06-08

SFH 2430

Photocurrent

IP,rel = f (TA); Ev = 1000 lx; VR = 5 V

OHF05719

1.15

IP

I P (25 ˚C)

1.05

1.00

0.95

0.90

0.85

0.80

-40 -20 0 20 40 60 ˚C 100

TA

Power Consumption

Ptot = f (TA)

OHF05583

160

mW

Ptot

TA TS

120

100

80

60

40

TA temp. ambient

20

TS temp. solder point

0

0 25 50 75 ˚C 100

TA

6 Version 1.4 | 2021-06-08

SFH 2430

Dimensional Drawing 4)

Chip position

0.45 (0.018)

0.32 (0.013)

1.2 (0.047)

1.1 (0.043)

1.1 (0.043)

(0...0.004)

0.9 (0.035)

0...0.1

0.2 (0.008)

0.1 (0.004)

˚

0...5

6.7 (0.264)

6.2 (0.244)

4.5 (0.177)

4.3 (0.169) 1.4 (0.055)

1.0 (0.039)

4.0 (0.157)

3.7 (0.146)

1.7 (0.067)

1.5 (0.059)

0.9 (0.035)

0.7 (0.028)

Photosensitive area = A Cathode lead

GEOY6599

Further Information:

Approximate Weight: 44.0 mg

Package marking: Cathode

7 Version 1.4 | 2021-06-08

SFH 2430

Recommended Solder Pad 4)

8 Version 1.4 | 2021-06-08

SFH 2430

Reflow Soldering Profile

Product complies to MSL Level 4 acc. to JEDEC J-STD-020E

OHA04525

300

˚C

T 250

240 ˚C Tp 245 ˚C

217 ˚C tP

200

tL

150

tS

100

50

25 ˚C

0

0 50 100 150 200 250 s 300

t

Profile Feature Symbol Pb-Free (SnAgCu) Assembly Unit

Minimum Recommendation Maximum

Ramp-up rate to preheat*) 2 3 K/s

25 °C to 150 °C

Time tS tS 60 100 120 s

TSmin to TSmax

Ramp-up rate to peak*) 2 3 K/s

TSmax to TP

Liquidus temperature TL 217 °C

Time above liquidus temperature tL 80 100 s

Peak temperature TP 245 260 °C

Time within 5 °C of the specified peak tP 10 20 30 s

temperature TP - 5 K

Ramp-down rate* 3 6 K/s

TP to 100 °C

Time 480 s

25 °C to TP

All temperatures refer to the center of the package, measured on the top of the component

* slope calculation DT/Dt: Dt max. 5 s; fulfillment for the whole T-range

9 Version 1.4 | 2021-06-08

SFH 2430

Taping 4)

10 Version 1.4 | 2021-06-08

SFH 2430

Tape and Reel 5)

Reel Dimensions

A W Nmin W1 W2 max Pieces per PU

180 mm 12 + 0.3 / - 0.1 mm 60 mm 12.4 + 2 mm 18.4 mm 1500

11 Version 1.4 | 2021-06-08

SFH 2430

Barcode-Product-Label (BPL)

Dry Packing Process and Materials 4)

Moisture-sensitive label or print

N s E RS

L

E

re

V

E

tiv

If

e

la ared ag

fr

in pa

L

hu

ck

an

m

id

k,

bl r co

ba

e

de

e be

sela

ity

30

l

˚C

).

(R

/6

R

H

0%

.

Barcode label

TIO

<

_

in IV O % k

IT T of

nta

90 to rs

S C < d ea s ). rs

N U ou

U coSEND d te (p on ,

or de H rs

iti ou

an bjec ng

ou rs

Ais bUagRMEICO ˚C co 72 H

si nd 5 H ou

˚C su es te 48

CThIS co ± e H

y da e 24 6

T E 40 be oc

or ˚C tim e

S < ill pr). ith or tim

O w nt ct 23 w tim e

M TO

at fa lo or

s at le ˚C at at e. al F lo or tim

P th th va l tic F lo or

O on s ui be if: read

ur F lo

m ce eq la lo

w ed

id

en l 4 5 F

vi g, n oc ve l

24 or de be in pr is 5a

de , e nt whe Le ve l 6

te

g: , w

r

co

se ou ke e Le ve l

da Le ve

ba ed flo

ba e m % ba al st

ur e

en re r ur e Le

ed e e tim re> 10 fo se oi st ur e

al op se fo M oi st ur

se is as or . is 33 k, M oi st

k, lo H bed

in g ph , -0 an M oi

e r- an in F R ng ar D bl M

ba

lif is po If bl ith % ki r C. S

T (if r

lf th va p. w 10 ba to et J- ea r ks

he r w, m <

_ m Y ea rs

S te ed iredicat d, EC 1 Y ee

1.

fte

A flody

nt

d

at

qu In no ire D > 1 W Hou

ou e 4 8

2. re

bo M re reity is qu/JE e

to es id 2b re C : tim e 16

a) S tim

ic is IP ed loor tim e

b) ev Humor e or

en F

D 2a king nc te F

lo or tim

a) op lo or

3. b) ba re da e F lo

If fe

al l 1 2 F

re tim ve l

4. se d l 2a

Le ve 3

ag an e Le ve l

B e ur e Le ve

at st ur e

D Le

oi st ur e

M oi st ur

M oi st

M oi

M

M

RA

OS

Humidity indicator

Barcode label

Do not eat.

Avoid metal contact.

Discard if circles overrun.

bag opening.

Please check the HIC immidiately after

check dot WET

Comparator

bake units

examine units, if necessary 15%

If wet,

bake units

examine units, if necessary 10%

If wet,

change desiccant

parts still adequately dry. 5%

If wet,

MIL-I-8835

Humidity Indicator

Desiccant

AM

OSR

OHA00539

Moisture-sensitive product is packed in a dry bag containing desiccant and a humidity card according JEDEC-STD-033.

12 Version 1.4 | 2021-06-08

SFH 2430

Notes

The evaluation of eye safety occurs according to the standard IEC 62471:2006 (photo biological safety of

lamps and lamp systems). Within the risk grouping system of this IEC standard, the device specified in this

data sheet fall into the class exempt group (exposure time 10000 s). Under real circumstances (for expo-

sure time, conditions of the eye pupils, observation distance), it is assumed that no endangerment to the

eye exists from these devices. As a matter of principle, however, it should be mentioned that intense light

sources have a high secondary exposure potential due to their blinding effect. When looking at bright light

sources (e.g. headlights), temporary reduction in visual acuity and afterimages can occur, leading to irrita-

tion, annoyance, visual impairment, and even accidents, depending on the situation.

Subcomponents of this device contain, in addition to other substances, metal filled materials including silver.

Metal filled materials can be affected by environments that contain traces of aggressive substances. There-

fore, we recommend that customers minimize device exposure to aggressive substances during storage,

production, and use. Devices that showed visible discoloration when tested using the described tests above

did show no performance deviations within failure limits during the stated test duration. Respective failure

limits are described in the IEC60810.

For further application related information please visit www.osram-os.com/appnotes

13 Version 1.4 | 2021-06-08

SFH 2430

Disclaimer

Attention please!

The information describes the type of component and shall not be considered as assured characteristics.

Terms of delivery and rights to change design reserved. Due to technical requirements components may

contain dangerous substances.

For information on the types in question please contact our Sales Organization.

If printed or downloaded, please find the latest version on the OSRAM OS website.

Packing

Please use the recycling operators known to you. We can also help you – get in touch with your nearest

sales office. By agreement we will take packing material back, if it is sorted. You must bear the costs of

transport. For packing material that is returned to us unsorted or which we are not obliged to accept, we

shall have to invoice you for any costs incurred.

Product and functional safety devices/applications or medical devices/applications

OSRAM OS components are not developed, constructed or tested for the application as safety relevant

component or for the application in medical devices.

OSRAM OS products are not qualified at module and system level for such application.

In case buyer – or customer supplied by buyer – considers using OSRAM OS components in product safety

devices/applications or medical devices/applications, buyer and/or customer has to inform the local sales

partner of OSRAM OS immediately and OSRAM OS and buyer and /or customer will analyze and coordi-

nate the customer-specific request between OSRAM OS and buyer and/or customer.

14 Version 1.4 | 2021-06-08

SFH 2430

Glossary

1)

Photocurrent: The photocurrent values are measured (by irradiating the devices with a homogenous

light source and applying a voltage to the device) with a tolerance of ±11 %.

2)

Typical Values: Due to the special conditions of the manufacturing processes of semiconductor devic-

es, the typical data or calculated correlations of technical parameters can only reflect statistical figures.

These do not necessarily correspond to the actual parameters of each single product, which could dif-

fer from the typical data and calculated correlations or the typical characteristic line. If requested, e.g.

because of technical improvements, these typ. data will be changed without any further notice.

3)

Testing temperature: TA = 25°C (unless otherwise specified)

4)

Tolerance of Measure: Unless otherwise noted in drawing, tolerances are specified with ±0.1 and

dimensions are specified in mm.

5)

Tape and Reel: All dimensions and tolerances are specified acc. IEC 60286-3 and specified in mm.

15 Version 1.4 | 2021-06-08

SFH 2430

Revision History

Version Date Change

1.4 2021-06-08 Schematic Transportation Box

Dimensions of Transportation Box

16 Version 1.4 | 2021-06-08

SFH 2430

Published by OSRAM Opto Semiconductors GmbH

Leibnizstraße 4, D-93055 Regensburg

www.osram-os.com © All Rights Reserved.

17 Version 1.4 | 2021-06-08

You might also like

- IPC7093NB SIPADssd 2Document6 pagesIPC7093NB SIPADssd 2Lamjed WhibiNo ratings yet

- DIL SMT Ambient Light Sensor: Produktdatenblatt - Version 1.1Document16 pagesDIL SMT Ambient Light Sensor: Produktdatenblatt - Version 1.1Lucy Herney Canchimbo GarciaNo ratings yet

- Chipled: Produktdatenblatt - Version 1.1Document16 pagesChipled: Produktdatenblatt - Version 1.1Amir MasoodNo ratings yet

- DataSheet SFH 2200 - ENDocument17 pagesDataSheet SFH 2200 - ENMostafa IbrahimNo ratings yet

- SFH 2505 - enDocument19 pagesSFH 2505 - enbarisNo ratings yet

- SFH 235 Fa - enDocument15 pagesSFH 235 Fa - enbarisNo ratings yet

- SFH 203 - enDocument15 pagesSFH 203 - enbarisNo ratings yet

- Smart DIL: Produktdatenblatt - Version 1.1Document17 pagesSmart DIL: Produktdatenblatt - Version 1.1khalid000No ratings yet

- Metal Can TO39: Produktdatenblatt - Version 1.1Document13 pagesMetal Can TO39: Produktdatenblatt - Version 1.1abc bNo ratings yet

- BPW 34 S - enDocument17 pagesBPW 34 S - enRajesh KumarNo ratings yet

- SFH 213 - enDocument15 pagesSFH 213 - ennyolczas.aronNo ratings yet

- Silicon Photodiode with Vλ Characteristic: FeaturesDocument12 pagesSilicon Photodiode with Vλ Characteristic: FeaturesLucy Herney Canchimbo GarciaNo ratings yet

- BPW 21 - enDocument13 pagesBPW 21 - enMichael MitchellNo ratings yet

- SFH 300 - enDocument16 pagesSFH 300 - enShreyash SoniNo ratings yet

- Reflective Interrupter: Produktdatenblatt - Version 1.1Document17 pagesReflective Interrupter: Produktdatenblatt - Version 1.1Antoine DODANENo ratings yet

- Silicon PIN Photodiode: FeaturesDocument8 pagesSilicon PIN Photodiode: FeaturesGogu GogomanuNo ratings yet

- BPX+65 enDocument14 pagesBPX+65 enLeandro SafraNo ratings yet

- SFH 229 - en PDFDocument15 pagesSFH 229 - en PDFbarisNo ratings yet

- OSRAM SFH 309 DatasheetDocument16 pagesOSRAM SFH 309 DatasheetbarisNo ratings yet

- Oslon P1616: Produktdatenblatt - Version 1.1Document16 pagesOslon P1616: Produktdatenblatt - Version 1.1Samuel SchwiderkeNo ratings yet

- SFH 313 Fa - enDocument16 pagesSFH 313 Fa - enHo PhuNo ratings yet

- SFH 309 Fa - enDocument14 pagesSFH 309 Fa - enJairo FernandezNo ratings yet

- Chip LED 0805: Produktdatenblatt - Version 1.1Document21 pagesChip LED 0805: Produktdatenblatt - Version 1.1maxmoron600No ratings yet

- LR Y8sf - enDocument22 pagesLR Y8sf - enCarlos MarcialNo ratings yet

- Chipled 0603: Produktdatenblatt - Version 1.1Document21 pagesChipled 0603: Produktdatenblatt - Version 1.1VictorNo ratings yet

- SFH 213 DatasheetDocument9 pagesSFH 213 DatasheetLeunamezNo ratings yet

- SFH 4547 - enDocument16 pagesSFH 4547 - enMultiverse GamerNo ratings yet

- OSLON Black FlatDocument24 pagesOSLON Black FlatHasanErkelNo ratings yet

- Led5r05 600 LL503VC2Z V1 4if 3547Document7 pagesLed5r05 600 LL503VC2Z V1 4if 3547Tomi OzzyNo ratings yet

- KW H2l531.te - en 2Document24 pagesKW H2l531.te - en 2fredtranNo ratings yet

- Kw2 Hil532.Tk enDocument25 pagesKw2 Hil532.Tk enPiero PorielliNo ratings yet

- Gy CSHPM1.23 - enDocument21 pagesGy CSHPM1.23 - enzebusNo ratings yet

- Produktdatenblatt - Version 1.1: Only One Bin Within One Packing Unit (Variation Less Than 2:1)Document14 pagesProduktdatenblatt - Version 1.1: Only One Bin Within One Packing Unit (Variation Less Than 2:1)Manikanta Sai KumarNo ratings yet

- SFH 229 FaDocument9 pagesSFH 229 Fam.j.viana.200815No ratings yet

- GW CSSRM3.HW - enDocument23 pagesGW CSSRM3.HW - enalutu paluNo ratings yet

- SFH 4350 - enDocument14 pagesSFH 4350 - enOzel Ders YasarNo ratings yet

- Description: Si PhotodiodeDocument4 pagesDescription: Si PhotodiodebobbbNo ratings yet

- Gw+pusta1.pm enDocument26 pagesGw+pusta1.pm enMohammed AliNo ratings yet

- 1N4001/L-1N4007/L: Vishay Lite-On Power SemiconductorDocument4 pages1N4001/L-1N4007/L: Vishay Lite-On Power SemiconductorxhlNo ratings yet

- BPV10NFDocument5 pagesBPV10NFהליכות ג'יין נהריהNo ratings yet

- Isolated Two Wire Transmitter For RTD: Datexel@datexel - It WWW - Datexel.itDocument2 pagesIsolated Two Wire Transmitter For RTD: Datexel@datexel - It WWW - Datexel.itEduardoNo ratings yet

- SFH 310 PDFDocument10 pagesSFH 310 PDFNelsonNo ratings yet

- Ly E67f - enDocument22 pagesLy E67f - enAndrey PolupanNo ratings yet

- Circuito EL357N Optoacoplador PDFDocument11 pagesCircuito EL357N Optoacoplador PDFcastellano_rNo ratings yet

- SRF0905A Series - Line Filter: FeaturesDocument4 pagesSRF0905A Series - Line Filter: FeaturesIbai BiNo ratings yet

- Silicon PIN Photodiode: FeaturesDocument8 pagesSilicon PIN Photodiode: FeaturesEzequiel AriasNo ratings yet

- SPL Ul90at08 enDocument13 pagesSPL Ul90at08 enkarenNo ratings yet

- AV01 0715EN0 DatasheetDocument6 pagesAV01 0715EN0 DatasheetMightyelectronics EquipmentsNo ratings yet

- Ly+etsf enDocument22 pagesLy+etsf enAndrey PolupanNo ratings yet

- GW Pllra1.Pm: Osconiq C 2424Document24 pagesGW Pllra1.Pm: Osconiq C 2424xeisteexNo ratings yet

- LedspiroDocument20 pagesLedspirorogeriocorrea601No ratings yet

- Infrared Light Emitting Diode OP280: FeaturesDocument3 pagesInfrared Light Emitting Diode OP280: FeaturesGhozali Suhariyanto HadiNo ratings yet

- Infrared Emitter (850 NM) : FeaturesDocument10 pagesInfrared Emitter (850 NM) : FeaturesDaniel ThomasNo ratings yet

- El3h7 GDocument11 pagesEl3h7 GAthiwa RuantoNo ratings yet

- Osram SFH 7015 - enDocument20 pagesOsram SFH 7015 - enromumarNo ratings yet

- GP PSLM31.14 - enDocument22 pagesGP PSLM31.14 - enzebusNo ratings yet

- SPL PL90 - 3 - enDocument10 pagesSPL PL90 - 3 - enEUNo ratings yet

- SFH 4546 - enDocument14 pagesSFH 4546 - enOzel Ders YasarNo ratings yet

- Siemens SRD 00514Document4 pagesSiemens SRD 00514accessmodyfierNo ratings yet

- GH CSBRM4.24: Oslon SquareDocument22 pagesGH CSBRM4.24: Oslon SquareguciNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- MC34675Document24 pagesMC34675John MurdochNo ratings yet

- c358c Dual OpampDocument12 pagesc358c Dual OpampPhil IdorNo ratings yet

- DS58 - Rev B Gen2 SMD 2835 1W 9V Data SheetDocument19 pagesDS58 - Rev B Gen2 SMD 2835 1W 9V Data Sheetkhawar mukhtarNo ratings yet

- Pk2n 3lxe RXDocument19 pagesPk2n 3lxe RXBucur BaleanuNo ratings yet

- PCF85163Document43 pagesPCF85163achuthkumarNo ratings yet

- How Do You Assemble A Flex PCBDocument29 pagesHow Do You Assemble A Flex PCBjackNo ratings yet

- PCB Design Hand BookDocument30 pagesPCB Design Hand BookDeepak Srinivasan75% (4)

- Bga Reballing SmtaDocument18 pagesBga Reballing SmtaAvs ElectronNo ratings yet

- What You Always Wanted To Know About Wave Soldering But Were Afraid To AskDocument43 pagesWhat You Always Wanted To Know About Wave Soldering But Were Afraid To Asksmtdrkd100% (4)

- Alpha CVP390 PDFDocument7 pagesAlpha CVP390 PDFSergio MoyaNo ratings yet

- HS1101LF - Relative Humidity Sensor: DescriptionDocument6 pagesHS1101LF - Relative Humidity Sensor: DescriptionManuel_DreamNo ratings yet

- What Is Pin in Paste (PiP) Soldering TechnologyDocument22 pagesWhat Is Pin in Paste (PiP) Soldering TechnologyjackNo ratings yet

- 15001WR 04 (20151007)Document74 pages15001WR 04 (20151007)Enzo AscañoNo ratings yet

- Solder Paste SC 170: Physical PropertiesDocument2 pagesSolder Paste SC 170: Physical PropertiesluismcmcNo ratings yet

- Paper For Effect of Flux Systems On Electrochemical Migration of Lead Free Assembly - Wei1Document7 pagesPaper For Effect of Flux Systems On Electrochemical Migration of Lead Free Assembly - Wei1Zetocha MilanNo ratings yet

- A Review of Mechanical Properties of Lead-Free Solders For Electronic PackagingDocument18 pagesA Review of Mechanical Properties of Lead-Free Solders For Electronic Packagingeid elsayedNo ratings yet

- Asus h110m-Cs RGDocument12 pagesAsus h110m-Cs RGinfomais.jlcNo ratings yet

- EPC9126xx QSGDocument8 pagesEPC9126xx QSGمهدیار میرحسین خانیNo ratings yet

- Conn Header P# 5.103908.1Document98 pagesConn Header P# 5.103908.1SCRIBD DOCSNo ratings yet

- UM1983 User Manual: VL6180X Proximity, Gesture and Ambient Light Sensing (ALS)Document39 pagesUM1983 User Manual: VL6180X Proximity, Gesture and Ambient Light Sensing (ALS)lucianobuglioniNo ratings yet

- Lm823 Wifi 802.11 B/G/N Module With Ipex Receptical: Host Controller Interface (Hci) Via Usb InterfaceDocument12 pagesLm823 Wifi 802.11 B/G/N Module With Ipex Receptical: Host Controller Interface (Hci) Via Usb InterfaceFelipe SoffiattiNo ratings yet

- Cliff NotesDocument8 pagesCliff NotesAnas ShoaibNo ratings yet

- ESP32-WROOM-32 Datasheet: Espressif SystemsDocument25 pagesESP32-WROOM-32 Datasheet: Espressif SystemsEllyakin JesseNo ratings yet

- 3014 LED PLW3014CA Series: Product DatasheetDocument14 pages3014 LED PLW3014CA Series: Product DatasheetfaberjetNo ratings yet

- An 353Document10 pagesAn 353Lê Đình TiếnNo ratings yet

- Advantages of Solid-State Relays Over Electro Mechanical RelaysDocument10 pagesAdvantages of Solid-State Relays Over Electro Mechanical RelaysnsadnanNo ratings yet

- MOC3021Document10 pagesMOC3021RamonNo ratings yet

- Agm 12864D2 801 PDFDocument17 pagesAgm 12864D2 801 PDFestevaomoraesNo ratings yet