Professional Documents

Culture Documents

181-Article Text-292-1-10-20200406

181-Article Text-292-1-10-20200406

Uploaded by

Nhi NguyễnCopyright:

Available Formats

You might also like

- Computer Vision Solution ManualDocument110 pagesComputer Vision Solution ManualChoi SeongJun100% (3)

- Signals and Systems 2Nd Edition Oppenheim Solutions Manual Full Chapter PDFDocument67 pagesSignals and Systems 2Nd Edition Oppenheim Solutions Manual Full Chapter PDFnettleshrill.gpkga100% (14)

- Okuma - Osp - E100m - E10m - Alarm Erros List - ME37005R4E100MAlarm883220150816 PDFDocument588 pagesOkuma - Osp - E100m - E10m - Alarm Erros List - ME37005R4E100MAlarm883220150816 PDFAntonioCanestriJúnior100% (3)

- Huvitz CAB-4000 Manual Utilizare PDFDocument89 pagesHuvitz CAB-4000 Manual Utilizare PDFPetrica DascaluNo ratings yet

- Composite Boiler AalborgDocument2 pagesComposite Boiler Aalborghpss77100% (1)

- A Neural-Network Approach For Semiconductor Wafer Post-Sawing InspectionDocument7 pagesA Neural-Network Approach For Semiconductor Wafer Post-Sawing InspectionMohd Nurfirdaus Mohd ShamsuriNo ratings yet

- Ijres V9i5p101Document10 pagesIjres V9i5p101AutoDZNo ratings yet

- Wang 2018Document8 pagesWang 2018Gabriel MessiasNo ratings yet

- A Multilayered Neural Network ControllerDocument5 pagesA Multilayered Neural Network ControllerAditya AgarwalNo ratings yet

- The Evaluation of Grinding Process Using ArtificiaDocument8 pagesThe Evaluation of Grinding Process Using ArtificiaAlex vilcaNo ratings yet

- Modelling 05 00009Document27 pagesModelling 05 00009TnsORTYNo ratings yet

- 2012 - Stochastic Gradient Descent Inspired Training Technique For A CMOS Nano Memristive Trainable Threshold Gate ArrayDocument10 pages2012 - Stochastic Gradient Descent Inspired Training Technique For A CMOS Nano Memristive Trainable Threshold Gate Arrayfromthedepth@gmail.comNo ratings yet

- Prediction of Strength Characteristics of Fly Ash Concrete Using Artificial Neural NetworkingDocument14 pagesPrediction of Strength Characteristics of Fly Ash Concrete Using Artificial Neural NetworkingKeerthiNo ratings yet

- PR Oof: Memristor Models For Machine LearningDocument23 pagesPR Oof: Memristor Models For Machine LearningtestNo ratings yet

- PAxC A Probabilistic-Oriented Approximate Computing Methodology For ANNsDocument4 pagesPAxC A Probabilistic-Oriented Approximate Computing Methodology For ANNsHan Yan100% (1)

- Amaitik WESIC2003 PaperDocument8 pagesAmaitik WESIC2003 PaperSalehNo ratings yet

- Control of Batch Reactors Using Neural Networks Chemical Engineering and Processing, 31 (1992) 113 - 180Document8 pagesControl of Batch Reactors Using Neural Networks Chemical Engineering and Processing, 31 (1992) 113 - 180eeeeNo ratings yet

- Zounemat Kermani2008 PDFDocument9 pagesZounemat Kermani2008 PDFJosue MarshallNo ratings yet

- Forecasting The Production of Fully-Mechanised Coal Face by Meta-Synthetic AI MethodDocument4 pagesForecasting The Production of Fully-Mechanised Coal Face by Meta-Synthetic AI Methodazimi32No ratings yet

- Water Saturation and Porosity Prediction Using Back-Propagation Artificial Neural Network (Bpann) From Well Log DataDocument8 pagesWater Saturation and Porosity Prediction Using Back-Propagation Artificial Neural Network (Bpann) From Well Log DataArega GenetieNo ratings yet

- Deep Physical Neural Networks Trained With Backpropagation: ArticleDocument11 pagesDeep Physical Neural Networks Trained With Backpropagation: ArticleManh Hoang VanNo ratings yet

- Deep Physical Neural Networks Trained With Backpropagation. Nature 2022, P L McmohanDocument11 pagesDeep Physical Neural Networks Trained With Backpropagation. Nature 2022, P L McmohanmahadimasnadNo ratings yet

- (Polish Maritime Research) Application of Artificial Neural Networks To Assessment of Ship Manoeuvrability QualitiesDocument7 pages(Polish Maritime Research) Application of Artificial Neural Networks To Assessment of Ship Manoeuvrability Qualitiesjwpaprk1No ratings yet

- Paper Modular Neural NetworkDocument11 pagesPaper Modular Neural NetworkQunalNo ratings yet

- Sensors 22 08845Document16 pagesSensors 22 08845John CarterNo ratings yet

- A Pneumonia Detection Method Based On ImprovedDocument6 pagesA Pneumonia Detection Method Based On ImprovedAmílcar CáceresNo ratings yet

- Low-Loss Photonic Reservoir Computing With Multimode Photonic Integrated CircuitsDocument10 pagesLow-Loss Photonic Reservoir Computing With Multimode Photonic Integrated CircuitsprajneshNo ratings yet

- PDF 154051 80482Document7 pagesPDF 154051 80482Hani BenguesmiaNo ratings yet

- Optimum Architecture of Neural Networks Lane Following SystemDocument6 pagesOptimum Architecture of Neural Networks Lane Following SystemJ.No ratings yet

- Neural Control2 PDFDocument5 pagesNeural Control2 PDFsuryaNo ratings yet

- Neural Network Seminar ReportDocument17 pagesNeural Network Seminar ReportJainendra SinghNo ratings yet

- Ijaest: Use of Artificial Bee Colony (ABC) Algorithm in Artificial Neural Network SynthesisDocument10 pagesIjaest: Use of Artificial Bee Colony (ABC) Algorithm in Artificial Neural Network Synthesisz1111234No ratings yet

- Curriculum ExitsDocument8 pagesCurriculum ExitsmayethmosteraNo ratings yet

- ECBC Efficient Convolution Via Blocked ColumnizingDocument13 pagesECBC Efficient Convolution Via Blocked ColumnizingTuhin KarakNo ratings yet

- Temporal Neural Network A Rchitecture For Online LearningDocument13 pagesTemporal Neural Network A Rchitecture For Online LearninghelbakouryNo ratings yet

- Downstream Team3Document22 pagesDownstream Team3Priyanka PanigrahiNo ratings yet

- 1995 Dornier PDFDocument11 pages1995 Dornier PDFnevenkanikNo ratings yet

- Common Work Ows For Computing Material Properties Using Different Quantum EnginesDocument12 pagesCommon Work Ows For Computing Material Properties Using Different Quantum EnginesRonaldo PaxDeorumNo ratings yet

- 3.4 Examples of Mathematical Models: - Part I: IntroductionDocument10 pages3.4 Examples of Mathematical Models: - Part I: IntroductionCamila TorresNo ratings yet

- Implementation of Deep Neural Network Using VLSI BDocument8 pagesImplementation of Deep Neural Network Using VLSI BKhang Truong NguyenNo ratings yet

- Artificial Intelligence in Pharma-Ceutical Product Formulation: Neural ComputingDocument10 pagesArtificial Intelligence in Pharma-Ceutical Product Formulation: Neural ComputingHimanshu PanchalNo ratings yet

- Highly-Accurate Machine Fault Diagnosis Using Deep Transfer LearningDocument9 pagesHighly-Accurate Machine Fault Diagnosis Using Deep Transfer LearningJaime100% (1)

- Gunaratna 2010Document4 pagesGunaratna 2010SebastianNo ratings yet

- Intelligent Web Caching Using Neurocomputing and Particle Swarm Optimization AlgorithmDocument6 pagesIntelligent Web Caching Using Neurocomputing and Particle Swarm Optimization AlgorithmHny Henny HennyNo ratings yet

- Use of Influence Diagrams and Neural Networks in Modeling Semiconductor Manufacturing ProcessesDocument7 pagesUse of Influence Diagrams and Neural Networks in Modeling Semiconductor Manufacturing ProcessesarqonexusNo ratings yet

- Can Neural Networks Be Easily Interpreted in Software Cost Estimation?Document6 pagesCan Neural Networks Be Easily Interpreted in Software Cost Estimation?jagannath_singhNo ratings yet

- Neural Network Technique in The Study of Selected Chemical Engineering Unit Operations Data Using MatlabDocument8 pagesNeural Network Technique in The Study of Selected Chemical Engineering Unit Operations Data Using MatlabSepribo BraideNo ratings yet

- 1 s2.0 S0263224120302050 MainDocument12 pages1 s2.0 S0263224120302050 MainCristian BastiasNo ratings yet

- Neural Network Methodology Process Fault Diagnosis: A ForDocument10 pagesNeural Network Methodology Process Fault Diagnosis: A ForyokonoraNo ratings yet

- Neural Network Approaches To Image Compression: Robert D. Dony, Student, IEEE Simon Haykin, Fellow, IEEEDocument16 pagesNeural Network Approaches To Image Compression: Robert D. Dony, Student, IEEE Simon Haykin, Fellow, IEEEdanakibreNo ratings yet

- Model Transferability From ImageNet To Lithography HotspotDocument9 pagesModel Transferability From ImageNet To Lithography Hotspotameed shahNo ratings yet

- Feasibility Study On The Use of Dynamic Neural Networks (DNN'S) For Modeling A Variable Displacement Load Sensing PumpDocument8 pagesFeasibility Study On The Use of Dynamic Neural Networks (DNN'S) For Modeling A Variable Displacement Load Sensing PumpTuan AnhNo ratings yet

- Micromaquinas para MecatronicaDocument12 pagesMicromaquinas para Mecatronicaraul pocoriNo ratings yet

- Introduction To Neural Networks For InteDocument5 pagesIntroduction To Neural Networks For InteJohn ReeseNo ratings yet

- BackprpDocument6 pagesBackprpAnay ChowdharyNo ratings yet

- 1 s2.0 S0020025521002693 MainDocument16 pages1 s2.0 S0020025521002693 MainAPRAJITA SRIVASTAVANo ratings yet

- RM Assign1Document7 pagesRM Assign1Sushant BhargavaNo ratings yet

- Neural Network Technique in The Study of Selected Chemical Engineering Unit Operations Data Using MATLABDocument7 pagesNeural Network Technique in The Study of Selected Chemical Engineering Unit Operations Data Using MATLABInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Neuromorphic Dreaming: A Pathway To Efficient Learning in Artificial AgentsDocument16 pagesNeuromorphic Dreaming: A Pathway To Efficient Learning in Artificial AgentsvoltNo ratings yet

- Comparison of Neural Network Architectures For Machinery Fault DiagnosisDocument10 pagesComparison of Neural Network Architectures For Machinery Fault DiagnosiselshafeiNo ratings yet

- Adsorption Enthalpies in Zeolites. High-Accuracy, Machine LearningDocument3 pagesAdsorption Enthalpies in Zeolites. High-Accuracy, Machine LearningLUIS EDUARDO RAMOS FUENTESNo ratings yet

- Neural Network EnsemblesDocument9 pagesNeural Network EnsembleskronalizedNo ratings yet

- Constructing Online Testable CircuitsDocument9 pagesConstructing Online Testable CircuitsNandita RajasekaranNo ratings yet

- Deep Learning with Python: A Comprehensive Guide to Deep Learning with PythonFrom EverandDeep Learning with Python: A Comprehensive Guide to Deep Learning with PythonNo ratings yet

- Embedded Deep Learning: Algorithms, Architectures and Circuits for Always-on Neural Network ProcessingFrom EverandEmbedded Deep Learning: Algorithms, Architectures and Circuits for Always-on Neural Network ProcessingNo ratings yet

- WPS Format For Asme Ix - Wps - Gtaw Fcaw GmawDocument1 pageWPS Format For Asme Ix - Wps - Gtaw Fcaw GmawThe Welding Inspections CommunityNo ratings yet

- NCP1002Document14 pagesNCP1002Ailton De JesusNo ratings yet

- Assembling Field Vane Shear Test ApparatusDocument17 pagesAssembling Field Vane Shear Test ApparatusSanjay MuthekarNo ratings yet

- Floating Point MultiplierDocument35 pagesFloating Point Multiplierbindu_ankuNo ratings yet

- WSC1 ST Year NSQFFinalDocument187 pagesWSC1 ST Year NSQFFinalVadnala ArunNo ratings yet

- Service Manual: EPSON Stylus C58/C59/ME 2 EPSON Stylus C79/D78 EPSON Stylus C90/C91/C92/D92Document100 pagesService Manual: EPSON Stylus C58/C59/ME 2 EPSON Stylus C79/D78 EPSON Stylus C90/C91/C92/D92Wilfredo PérezNo ratings yet

- Sewing Technology enDocument54 pagesSewing Technology enWibowo Abi TigabeNo ratings yet

- Model-Based Testing at Spotify: Kristian KarlDocument26 pagesModel-Based Testing at Spotify: Kristian Karlmr.sharma11No ratings yet

- Mastering ArpeggiosDocument58 pagesMastering Arpeggiospeterd87No ratings yet

- Qos Command Reference, Cisco Ios Release 15.2 (2) E (Catalyst 2960-X Switch)Document120 pagesQos Command Reference, Cisco Ios Release 15.2 (2) E (Catalyst 2960-X Switch)AHOUALAKOUNNo ratings yet

- Flat Plate Boundary Layer CornellDocument39 pagesFlat Plate Boundary Layer CornellsidyantNo ratings yet

- Articulo de Revision Unidad IIIDocument17 pagesArticulo de Revision Unidad IIIYeiru Azael RatmareNo ratings yet

- ARMY TM 5-822-7 Air Force Afm 88-6, Chap. 8Document55 pagesARMY TM 5-822-7 Air Force Afm 88-6, Chap. 8PDHLibraryNo ratings yet

- CyberAces Module1-Windows 1 InstallingWindowsDocument40 pagesCyberAces Module1-Windows 1 InstallingWindowsAbiodun AmusatNo ratings yet

- Onur 447 Spring15 Lecture1 Intro AfterlectureDocument88 pagesOnur 447 Spring15 Lecture1 Intro AfterlecturekaanpNo ratings yet

- Case Study 1. Developing HYSYS Material Stream: 1.1. Component and Fluid List SelectionDocument7 pagesCase Study 1. Developing HYSYS Material Stream: 1.1. Component and Fluid List SelectionChakravarthy BharathNo ratings yet

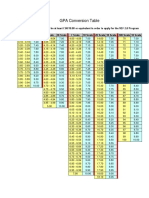

- VEF GPA Conversion TableDocument2 pagesVEF GPA Conversion TableMinh Khôi AnNo ratings yet

- About Ansys: Finite Element AnalysisDocument2 pagesAbout Ansys: Finite Element Analysissuffiya abdulNo ratings yet

- FutureDocument37 pagesFutureBT20EEE052 KhushalNo ratings yet

- Mirror Maze: InputDocument2 pagesMirror Maze: InputHello misterNo ratings yet

- Grout 214 TRDocument3 pagesGrout 214 TRbarouniamineNo ratings yet

- R R X R YtDocument9 pagesR R X R YtAthiyo MartinNo ratings yet

- LegTech ReviewerDocument9 pagesLegTech ReviewerMaris Cay0% (1)

- Phrases and ClausesDocument11 pagesPhrases and ClausesChepie Creencia33% (3)

- 2024 Bss Chemistry P IIDocument8 pages2024 Bss Chemistry P IIbarotathomas1234No ratings yet

181-Article Text-292-1-10-20200406

181-Article Text-292-1-10-20200406

Uploaded by

Nhi NguyễnOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

181-Article Text-292-1-10-20200406

181-Article Text-292-1-10-20200406

Uploaded by

Nhi NguyễnCopyright:

Available Formats

Machine Translated by Google

PETROLEUM EXPLORATION & PRODUCTION

PETROVIETNAM JOURNAL

Volume 6/2019, p. 48 -

57 ISSN-0866-854X

An applied machine learning approach to production forecast for

basement formation - Bach Ho field

Tran Dang Tu1 , Nguyen The Duc1, Le Quang Duyen2 , Pham Truong Giang1 , Le Vu Quan1 Le Quoc Trung1 Tran

, ,

Xuan Quy1 ,Pham Chi Duc1

1 Vietnam Petroleum Institute

2 Ha Noi University of Mining and Geology

Email: tutd@vpi.pvn.vn

Summary

Oil production forecast is a major challenge in the oil and gas industry. Simulation model and prediction results play an important role in field

operation and management. Currently, production forecast problems are resolved mainly by using pure traditional prediction methods. Generally,

production forecast by dynamic simulations does not provide reliable results in case where a lot of uncertain parameters remains when the dynamic

model is constructed.

In fact, in Vietnam, the dynamic models of fractured reservoirs give unreliable results and differ with actual performance. It is a challenge to

build and design reasonable production plans for fractured granite reservoirs in Vietnam. In order to replace the disadvantages of simulation model

by different methods, a growing trend of research in the world is predictive tools by using machine learning algorithms.

The paper introduces the applicability of machine learning through the artificial neural network to predict oil production for basement formation

- Bach Ho field. The research results show that Artificial Neural Network (ANN) model has improved the ability to predict production with high

accuracy.

Key words: Artificial Neural Network, machine learning, oil production, reservoir management, Bach Ho field.

1. Introduction

Machine learning (ML) is the scientific study of algo

rithms and statistical models that computer systems use

to effectively perform a specific task without using explicit

instructions, evaluating on models and inference instead.

It is seen as a subset of artificial intelligence. Machine

learning algorithms build a mathematical model of sample

Figure 1. Basic physical elements of a biological neuron [1].

data, known as “training data”, in order to make

predictions or decisions without being explicitly

programmed to per form the task [2, 3]. Machine learning

is closely related to computational statistics, which

focuses on making predic tions using computers. The

study of mathematical optimi sation delivers methods,

theory and application domains to the field of machine

learning. Data mining is a field of study within machine

learning and focuses on explor atory data analysis

through unsupervised learning. In its application across

business problems, machine learning is also referred to as predictive analytics [4].

Date of receipt: 20/2/2019. Date of review and editing: February 20 - April 1, 2019.

Date of approval: 3/6/2019. Figure 2. Representation of neurons in ANN [1].

48 PETROVIETNAM - JOURNAL VOL 6/2019

Machine Translated by Google

PETROVIETNAM

One of the most popular machine learning methods - the output layer back, through the hidden layers, to the

ANN is employed for this purpose. In computer science, input layer. This process is repeated until the connection

ANN is formed of computer architecture, inspired by bio weights produce an output which is with a tolerance of the

logical neural networks (the central nervous systems of desired output [2].

animals, particularly, the brain) and used to estimate or

The selection of an optimum architecture of a model

approximate functions that can depend on a large number

is a difficult task requiring a procedure of trial and error [5].

of inputs and are generally unknown. ANN is gener ally

Thus, several networks with various numbers of hid den

presented as systems of connected “neurons” which can

units, training algorithms, and activation functions are

compute values from inputs and are capable of machine

attempted and the generalization error is estimated for

learning or pattern recognition, thanks to their adaptive

each. The network with the minimum estimated gen

nature. Figures 1 and 2 show the basic biological neuron eralisation error is chosen.

structure and representation of artificial neuron.

3. Production data of basement formation of Bach Ho

2. Neural networks

field

The most popular ANN model is the multi-layer per

The basement formation of Bach Ho field has produced

ceptron (MLP) architecture trained using the feedforward

commercially since 1988. Based on the well test results of

backpropagation algorithm. The MLP architecture is com

wells 2, 401, 401, and 417, which were the first exploration,

posed of at least three layers vector and the last layer

appraisal, and production wells, the initial reservoir pres

sub sists of the output vector. The intermediate layers,

sure was 417atm at 3,650m TVDSS. In the first production

called hidden layers, represent neural pathways and

stage, reservoir drive mechanisms were rock or

modify the input data through several weighted connections.

compaction drive and solution gas without water drive and

There are three major phases to network training with water injection supply. After several years of production

backpropagation. During the initial phase, the input vec the res ervoir pressure decreased significantly to 280atm.

tor is presented to a network, which is activated via the Pressure maintenance by water injection was initiated in

forward pass. This generates a difference (error) between 1993 when a few production wells were converted to

the input of the network (error backward pass). During injection wells and connected with the water injection system. As of M

70000 500

Prediction

Training data interval Interval 450

60000

400

50000

350

300

40000

NOP,Reservoir

pressure

(at)

Beginning of 250

water ooding

30000

Production

Injection

day),

day)

(m3/

(ton/

rate

rate

200

150

20000

100

10000

50

0 0

0 50 100 150 200 250 300 350 400

Time (Months)

FLPR_Family FOPR_Family FWIR FOPR_Pred FLPR_Pred FPR_FUL NOP FPR_Pred

Figure 3. Reservoir oil production from September 1988 to May 2018.

PETROVIETNAM - JOURNAL VOL 6/2019 49

Machine Translated by Google

PETROLEUM EXPLORATION & PRODUCTION

2018, the total reservoir achieved a cumulative oil mum error. The testing set used 47 data months (16.5%)

production of 180 million tons, accounting for 86% of to fine-tune the network model. It is not applied for training

Vietsovpet ro's oil production, with an average oil rate of ing and validation process, only used to identify optimal

6,000 tons per day, and an average water cut of 60% [6]. network architecture, to select a suitable network model

and assess their performance.

4. Network architecture

- ANN network architecture

Neuron architecture is composed of five inputs and

The best results were obtained from ANN sub model

three outputs. The inputs are the average field oil

sisting of 2 hidden layers and 50 neurons for each one.

production rate (FOPR) at time t, the average field liquid

The node in the hidden and output layers is activated

production rate (FLPR) at time t, the average reservoir

through Sigmoid function and trained by the Backpropagation

pressure (FPR) at time t, the average water injection rate

Neural Network algorithm (BPNN).

(FWIR) at time t+1 and the number of production wells (NP)

at time t+1. The outputs are the average field oil production 4.2. Long-term production prediction

rate (FOPR) at time t+1, the average field liquid production

- Data pre-processing

rate (FLPR) at time t+1, the average reservoir pressure

(FPR) at time t+1. The selection of an optimum neural The first set used 236 data months (from May 1993 to

network architecture can be achieved using a trial and er December 2012) to build a network model. The second set

ror approach. Figure 3 shows the oil production rate from used 60 data months (from January 2013 to Decem ber

September 1988 to May 2018. 2017) to predict oil production rate, liquid production rate,

and reservoir pressure. The training set used 160 data

4.1. Short-term production prediction months (67%) to calculate gradient and update the net

work weights and biases. The validation set used 38 data

- Data pre-processing

months (16.5%) to evaluate the quality of the training

Normally, an accurate network model can be achieved process. Training can be stopped when the performance

without adequate data. Therefore, before training model, of the model on the validation dataset provides a mini

production data have to guarantee high reliability to avoid mum error. The testing set used 38 data months (16.5%)

peculiar answers from trained network model. However, to fine-tune the network model. It is not applied for training

depending on the problem, there may be special features ing and validation process, only used to identify optimal

from the data that are able to test its quality. One way to network architecture, to select a suitable network model

check the quality is to view the graphical representations and assess their performance.

of the data in question, in the hope of selecting a reason

- ANN network architecture

able subset while eliminating portions. As presented in

Figure 3, the oil field production rate is time dependent The best results were obtained from ANN sub model

and was split into two sets. The first set (from May 1993 to sisting of 1 hidden layer and 60 neurons for each one. The

December 2016) used 284 data months to build the network node in the hidden and output layers is activated through

model. The second set (from January 2017 to May 2018) Sigmoid function and trained by the Backpropagation

used 15 data months to predict the average oil production Neural Network algorithm (BPNN)

rate, liquid production rate, and reservoir pressure.

5. Assessing and comparing the production prediction

results of ANN model and those of the dynamic simu

To avoid overfitting or underfitting results and im prove lation model

the generalization of the network model, the first set was

5.1. Evaluating short-term production prediction results

subdivided randomly into three parts: training, validation, from the ANN model

and testing. The training set used 190 data months (67%)

to compute the gradient and update the network weights The statistic method is used to assess the accuracy of

and biases. The validation set used 47 data months (16.5%) the ANN model in the training, validation, and testing

to evaluate the quality of the training process. Training can process (Table 1) through the average absolute error (AE)

be stopped when the performance of the model on the and average relative error (ARE) of three parameters: oil

validation dataset provides a mini production rate , liquid production rate, and reservoir pressure:

50 PETROVIETNAM - JOURNAL VOL 6/2019

Machine Translated by Google

PETROVIETNAM

- Training sets:

Data_Training

st + AE: 526 tons/day, 637 tons/day, 6at;

40000 350

35000 300 + ARE: 3.11%, 3.13%, 2.47%;

30000

250

25000 - Validation set:

200 Reservoir

pressure

(at)

20000

150

+ AE: 998 tons/day, 1112 tons/day, 6.67at;

Production

day)

(ton/

rate

15000

100

10000

5000 50 + ARE: 5.51%, 5.26%, 2.76%;

00 50 100 150 200 250 0 300 - Testing sets:

Time (Months)

H_Data_Train FOPR H_Data_Train Liquid M_Data_Train FLPR + AE: 1157 tons/day, 1165 tons/day, 6.12at;

M_Data_Train FOPR H_Data_Train FPR M_Data_Train FPR

+ ARE: 6.46%, 5.54%, 2.5%.

Figure 4. Performance of short-term prediction training set. The errors are in the allowable limit. The results

of training, validation and testing processes are

described in Figures 4, 5 and 6.

Data_Validation

1stDataset To study the robustness and accuracy of the

40000 350

network approach, with respect to predicting oil

35000 300

reservoir production, the second dataset was used to

30000

250

predict the reservoir oil production. The predict ed

25000

200

Production

day)

(ton/

rate

20000

Reservoir

pressure

(at)

reservoir oil rate values agree with the historical values

150

15000 indicating the training network can serve as a practical

100 robust reservoir production management tool (Figure

10000

5000 50 7). The network provides reservoir oil rates with an

0 average AE of 255 tons/day and av erage ARE of

0 50 100 150 200 250 0 300

4.82%, as illustrated in Table 1.

Time (Months)

H_Data_Validation FOPR H_Data_Validation FLPR

5.2. Evaluating long-term production prediction

M_Data_Validation FOPR H_Data_Validation FPR

results from the ANN model

M_Data_Validation F:PR M_Data_Validation FPR

The statistic method is used to assess the accu

Figure 5. Performance of short-term prediction validation set. racy of ANN model in the training, validation, and

testing processes (Table 1) through the average ab

solute error (AE) and average relative error (ARE) of

Data_Testing three parameters: oil production rate, liquid production

1stDataset

40000 350 rate, and reservoir pressure:

35000 300

- Training sets:

30000 250

25000

200 Reservoir

pressure

(at)

+ AE: 553 tons/day, 644 tons/day, 5.25at;

Production

day)

(ton/

rate

20000

150 + ARE: 2.79%, 2.78%, 2.1%;

15000

100

10000 - Validation set:

5000 50

+ AE: 1001 tons/day, 1025 tons/day, 6.34at;

0

0 50 100 150 200 250 0 300

+ ARE: 4.91%, 4.4%, 2.52%;

Time (Months)

H_Data_Testing FOPR H_Data_Testing FLPR - Testing sets:

M_Data_Testing FOPR H_Data_Testing FPR

M_Data_Testing FLPR M_Data_Testing FPR + AE: 1215 tons/day, 1261 tons/day, 7.69at;

+ ARE: 5.6%, 5.43%, 3.13%.

Figure 6. Performance of short-term prediction testing set.

PETROVIETNAM - JOURNAL VOL 6/2019 51

52 PETROVIETNAM - JOURNAL VOL 6/2019

DATABASE

II DATABASE

I

Standard

deviation Standard

deviation Standard

deviation Standard

deviation

Maximum Minimum Maximum Minimum Maximum Minimum Maximum Minimum

Average Average Average Average

35367 10015 1980 35478 19469 35959 10034 19523 FOPR

5848 4692 5280 4525 4669 9973 4521

350

H

34801 19523 34648 19558 34902 19421 FOPR

5538 4951 5277 4900 9794 4901 9649 4765 9914 ANN

173

Table

1.

Statistical

analysis

of

network

model

accuracy

for

short-

term

production

prediction

434.59 111.78 254.50

30.54 7271 1281 1157 5407 2496

995 998 485 526 AE1

6 15 4

20.56 23.20 17.84 ARE1

8.71 0.56 2.13 4.82 0.11 4.98 6.46 0.23 4.92 5.51 0.01 2.79 3.11 (%)

12097 11095 36778 22216 37204 22289 37452 22410

9464 9464 8765 9438 8772 9081 8815 FLPR

726 VALIDATION

PREDICTION

TESTING

TRAINING

H

11041 10615 36267 22250 36382 22270 36707 22273

9947 9947 8531 9902 8411 9719 8656 ANN FLPR

312

1637 6883 1218 1165 5480 1020 1112 2765 AE2

504 573 522 637

66 65 20 ten

13.54 18.88 20.22 14.81 ARE2

0.63 4.13 5.00 0.19 4.72 5.54 0.14 4.45 5.26 0.04 2.63 3.13 (%)

234 206 220 306 217 246 305 211 245 309 210 245 FPR

7 27 28 26 H

ANN

237 216 228 298 218 247 299 216 247 298 216 245 FPR

7 25 26 25

24.78 10.38 26.70 27.86 33.11

0.35 8.68 0.02 6.47 6.12 0.16 7.08 6.67 0.08 5.37 6.00 AE3

11.83 10.18 12.69 15.62 ARE3

0.15 4.15 4.83 0.01 2.59 2.50 0.06 3.02 2.76 0.03 2.23 2.47 (%)

PETROLEUM EXPLORATION & PRODUCTION

Machine Translated by Google

Machine Translated by Google

PETROVIETNAM

Data_Prediction FOPR nd Data_Validation

2 Dataset 1 stDataset

7000

40000 350

6000 35000 300

5000 30000 250

day)

(ton/

rate

Oil

4000 25000

200

3000 20000 Reservoir

pressure

(at)

Production

day)

(ton/

rate

150

15000

2000 100

10000

1000 50

5000

0 284 286 288 290 292 294 296 298 300 302 00 50 100 150 200 0 250

Time (Months) Time (Months)

Data_Predicted FOPR H_Data_Prediction FOPR

H_Data_Validation FOPR H_Data_Validation FLPR

M_Data_Validation FOPR H_Data_Validation FPR

M_Data_Validation FLPR M_Data_Validation FPR

Data_Prediction FLPR nd Figure 9. Performance of long-term prediction validation set.

2 Dataset

13000

12000 Data_Testing

11000 1stDataset

10000 40000 350

Liquid

day)

(ton/

rate

9000 35000 300

8000 30000 250

7000

25000

6000 200

20000

5000 Production

day)

(ton/

rate

150

Reservoir

pressure

(at)

4000 15000

280 285 290 295 300 305 100

10000

Time (Months) 5000 50

Data_Predicted FLPR H_Data_Prediction FLPR

00 50 100 150 200 0 250

Time (Months)

H_Data_Testing FOPR H_Data_Testing FLPR

Data_Prediction FPR M_Data_Testing FOPR H_Data_Testing FPR

2 nd

Dataset

250 M_Data_Testing FLPR M_Data_Testing FPR

200 Figure 10. Performance of long-term prediction testing set.

150

Reservoir

pressure

(at)

The errors are in the allowable limit. The results of

100

training, validation and testing processes are described in

50

Figures 8, 9, and 10.

0 284 286 288 290 292 294 296 298 300 302 To study the robustness and accuracy of the network

Time (Months)

Data_Predicted FPR H_Data_Prediction FPR approach, the second dataset was used to predict the res

ervoir oil production. The predicted reservoir oil rate val

Figure 7. Prediction of average oil production rate, liquid production rate and reservoir

pressure (from January 2017 to April 2018).

ues agree with the historical values indicating the training

network can serve as a practical robust reservoir utility

tion management tool (Figure 11). The network provides

Data_Training

1stDataset reservoir oil rates with an average AE of 698 tons/day and

40000 350

35000 300 average ARE of 12.61%, as illustrated in Table 2.

30000 250

25000 200 5.3. Comparing the production prediction results of

20000

Reservoir

pressure

(at)

150

15000 ANN model and dynamic simulation model results in

Production

day)

(ton/

rate

100

10000

5000

50 the short term and in the long term

00 50 100 150 200 0 250

Time (Months)

- Comparing the results of short-term production

H_Data_Train FOPR H_Data_Train FLPR M_Data_Train FLPR prediction and those of long-term production prediction

M_Data_Train FOPR H_Data_train FPR M_Data_Train FPR

From Figures 12 and 13, it is obvious that short term

Figure 8. Performance of long-term prediction training set. oil production prediction of ANN model (284 data

PETROVIETNAM - JOURNAL VOL June 2019 53

54 PETROVIETNAM - JOURNAL VOL 6/2019

DATASET

II DATASET

I

Standard

deviation Standard

deviation Standard

deviation Standard

deviation

Maximum Minimum Maximum Minimum Maximum Minimum Maximum Minimum

Average Average Average Average

34899 22563 22430 22430 35959 22342 FOPR

7031 4521 5405 8935 8236 7083 8729 6864 8365

630

H

Table

2.

Statistical

analysis

of

network

model

accuracy

for

long-

term

production

prediction

35255 22753 22633 22633 35569 22302 FOPR

7697 4419 5238 8453 8300 6852 8666 6498 8571 ANN

863

2628.28

559.05 697.84

16.73 5887 1307 1215 1001 1001 3941

844 478 553 AE1

30 58 6

52.67 10.08 12.61 23.91 16.11 ARE1

0.26 0.27 5.68 5.60 4.91 0.18 3.97 4.91 0.06 2.45 2.79 (%)

PREDICTION VALIDATION

TRAINING

TESTING

FLPR_Family

14553 11302 36778 14021 24779 24633 13167 24633 37452 12650 24599

9081 1369 7804 8149 7820

13755

2758 11281 11899

1254 36052 14080 24796

1261 24668

1025 13137 24668

1025 36606

3693 12748 24498

7367 7644 7475 ANN FLPR

638

5963 1216 AE2

761 794 551 644

95 twelfth

9 9

25.71 11.44 27.26 13.62 ARE2

0.08 7.29 0.38 5.53 5.43 4.40 0.08 3.45 4.40 0.04 2.45 2.78 (%)

240 206 222 306 212 250 250 217 250 309 211 250 FPR

7 27 27 27 H

ANN

278 224 241 303 224 251 252 222 252 304 223 249 PR

15 26 27 26

66.92 16.88 19.60 42.64 34.37

0.00 0.25 9.02 7.69 6.34 0.24 5.01 6.34 0.02 5.41 5.25 AE3

31.73 20.11 12.94 ARE3

0.00 7.90 8.94 0.11 3.89 3.13 2.52 0.11 1.95 2.52 0.01 2.14 2.10 (%)

PETROLEUM EXPLORATION & PRODUCTION

Machine Translated by Google

Machine Translated by Google

PETROVIETNAM

Data_Prediction FOPR

Data_Prediction FOPR nd

2 Dataset FOPR nd

Data_Prediction Data_Prediction FOPR

9000 2 Dataset nd

2 Dataset 2nd Dataset

9000 9000

8000

9000

8000 8000

7000

8000

7000 7000

6000

7000

6000 6000

day)

(ton/

rate

Oil

5000

6000

5000 5000

4000

day)

(ton/

rate

Oil

day)5000

(ton/

rate

Oil

day)

(ton/

rate

Oil

4000 4000

3000

4000

3000 3000

2000

3000

2000

1000

2000 2000

1000

0 1000

1000 246 256 266 246 256 266 276 286 296 306 286 296 306 286

0 276 266 296 306

236 0 236 236 246 256 Time (Months) 276

0 236 246 256 266 276 286 296 306

Time (Months) Time (Months)

Data_Predicted FOPR Time (Months)H_Data_Prediction FOPR

Data_Predicted FOPR H_Data_Prediction FOPR Data_Predicted FOPR H_Data_Prediction FOPR

Data_Predicted FOPR H_Data_Prediction FOPR

Figure 13. Long-term oil production rate prediction.

Data_Prediction FLPR

Data_Prediction FLPR

2 nd

Dataset FLPR nd

Data_Prediction

16000 2 Dataset Data_FOPR

16000 nd

2 Dataset

16000 10000

14000

14000 9000

14000

12000 8000

12000

12000 7000

day)

(ton/

rate

Oil

Liquid

day)

(ton/

rate

10000

10000 Liquid

Liquid

day)

(ton/

day)

(ton/

rate

rate

6000

10000

8000

8000 5000

8000

6000 4000

6000

6000

4000 3000

4000 246 256 266 276 286 256 266 276 286 296 2000

236 4000 246 296

236 236 246 Time

256 266 (Months)

276 286 296 1000

Time (Months)

Data_Predicted FLPR Time (Months)H_Data_Prediction FLPR

Data_Predicted FLPR H_Data_Prediction FLPR 0 230 240 250 260 270 280 290 300

Data_Predicted FLPR H_Data_Prediction FLPR

Time (Months)

FOPR_Actual FOPR_Simulation FOPR_ANN

Data_FPR

300 Data_FPR Figure 14. The results of oil production rate prediction.

300 Data_FPR

300

250

250

250 Data_FLPR

200

200 16000

200

150 15000

Reservoir

pressure

(at)

150 14000

150 13000

100

Reservoir

Reservoir

pressure

pressure

(at)

(at)

100 12000

100 11000

50 10000

50

9000

0 Liquid

day)

(ton/

rate

8000

50 0 230 260

240270 280250

290 300 0 230 240 250 260 270 280 290 300 Time 7000

(Months) 230 240 250 260 270 280 290 300 Time (Months) )

6000

5000

FPR _Actual

Time (Months)FPR _ANN 4000

FPR _Actual FPR _ANN FPR 3000

_Actual FPR _ANN Figure 11. 2000

Prediction of average oil production rate, liquid production rate and reservoir pressure

1000

(from January 2013 to December 2017).

0 230 240 250 260 270 280 290 300

Time (Months)

Data_Prediction FOPR

FLPR _Actual FLPR _Simulation FLPR _ANN

2nd Dataset

7000

Figure 15. The results of liquid production rate prediction.

6000

5000 months) gives better results than long-term oil

4000

day)

(ton/

rate

Oil

production prediction of ANN model (236 data months).

3000

2000 - Comparing the results of long-term production

1000 prediction of ANN model and dynamic simulation model

results

0 284 286 288 290 292 294 296 298 300 302

Time (Months) - In comparison with traditional prediction method,

Data_Predicted FOPR H_Data_Prediction FOPR the artificial neural network method can learn arithmetic

Figure 12. Short-term oil production rate prediction. problems which the in-out relationship is non-linear with

PETROVIETNAM - JOURNAL VOL 6/2019 55

Machine Translated by Google

PETROLEUM EXPLORATION & PRODUCTION

Data _FPR

400

350

300

250

Reservoir

pressure

(at)

200

150

100

50

0

230 240 250 260 270 280 290 300

Time (Months)

FPR_Actual FPR_Simulation FPR_ANN

Figure 16. The results of reservoir pressure prediction.

high accurate prediction, corresponding to production Observation: From the experimental results, the per

input data. The ANN method forecasts input data without form of the two models was evaluated, showing:

being based on the subjective experiment of professors.

- Dynamic simulation model:

After the training process, the ANN model will actively

determine weights for each input parameter and their The model is controlled by a constant value of liquid

relationship. yes, the results of the ANN model are more production rate (LPR) in the period from January 2013

trustworthy than the traditional prediction method. to December 2017. As a matter of fact, LPR did not

remain stable due to production operation (well shut-in,

- In the training set, the network will regulate input

facility maintenance, weather conditions…). The

parameters to satisfy mean squared error value, ANN's

qualification assump tion of production depends on

convergence ability depends on original arguments, so

experiment, simulator's subjective and field development

many sensitivity scenarios must be run to choose the

plan. On the other hand, the simulation oil production

best original arguments. On the other hand, the training

rate has high deviation compared with history at starting

in complicated networks becomes more difficult than

forecasting date, the model does not obtain reliability

shallow and narrow networks, in which case the

and neither does it capture geological complications,

optimisation is more likely to converge to some useless

rock property distribution, fracture network, and

local optima. Ideally, we would like to design a model of

hydrodynamic connec tivity of granite basement. Until

reasonable complexity but powerful representation for now, there is not a granite basement simulation method

the data we feed into it. Furthermore, to avoid overfitting

that is accurate, reliable and widely recognized.

the model, the size of the training data has also to be

considered in the design. Therefore, taking all these - ANN model:

concerns into account and after several trials on the

The parameters: oil production rate, liquid production

validation dataset, one layer of the hidden layer with the rate, and reservoir pressure are very close to the actual

proper number of neurons fits the best. data, the trend of results and actual production match

- Figures 14, 15 and 16 show comparison between closer than the dynamic model. however, the confine

the results of long-term production prediction of the ANN ment of the ANN model only applies to predict short term.

model and those of the dynamic simulation model.

56 PETROVIETNAM - JOURNAL VOL 6/2019

Machine Translated by Google

PETROVIETNAM

6. Conclusion and recommendation using machine learning. SPE Argentina Exploration and

Production of Unconventional Resources Symposium, Buenos

This research work aims to present a new approach to

Aires, Argentina. 1 - 3 June, 2016.

predict oil production rate based on the historical production

data. The results of methodology show prediction problem 2. Brian D. Ripley. Pattern recognition and neural networks.

generalization ability on the ANN model, become an effective Cambridge University Press. 1996.

implement to resolve variable problems in operation and 3. John R. Koza, Forrest H. Bennett, David Andre, Martin A.

management field production techniques. Keane. Automated design of both the topology and sizing of

The ANN model has many features: data learning possibility, analog electrical circuits using genetic programming. Springer.

adaptation, a decision with deficiency or noise data, which are a 1996: p. 151 - 170.

significant advantage compared with numeri cal simulation.

4. Jerome H. Friedman. Data mining and statistics: What's

the connection. Computing Science and Statistics.

- ANN application will be more effective when the first stages 1997.

such as training samples, extracting characteristics and pre-

5. Jeff Heaton. Introduction to neural networks for java (2nd

processing are well done;

edition). Heaton Research. 2008.

- ANN model postulates more time to train and

6. Tran Van Hoi, Nguyen Van Duc, Pham Xuan Son.

adjust network argument;

Oil exploration and development in the foundation rock of Bach

- As for the future work, other particularly different algorithms Ho mine: Documentation, facts and lessons learned. Vietsovpetro.

and input data effected to production prediction such as well 2018: pages 7 - 20.

bottom hole pressure, choke size, and gas lift rate will be

7. Yunan Li, Yifu Han. Decline curve analysis for production

integrated.

forecasting based on machine learning.

Acknowledgement SPE Symposium: Production Enhancement and Cost Optimization,

Kuala Lumpur, Malaysia. 7 - 8 November, 2017.

This work is supported by the Ministry of Industry and Trade

of Vietnam, project No. CNKK.001/19.

8. A. Mirzaei Paiaman, S. Salavati. The application of artificial

References

neural networks for the prediction of oil production flow rate.

Energy Sources, Part A: Recovery, utilization, and environmental

1. Q.Cao, R.Banerjee, S.Gupta, J.Li, W.Zhou, B.Jeyachandra.

effects. 2012; 34(19): p. 1834 - 1843.

Data driven production forecasting

PETROVIETNAM - JOURNAL VOL 6/2019 57

You might also like

- Computer Vision Solution ManualDocument110 pagesComputer Vision Solution ManualChoi SeongJun100% (3)

- Signals and Systems 2Nd Edition Oppenheim Solutions Manual Full Chapter PDFDocument67 pagesSignals and Systems 2Nd Edition Oppenheim Solutions Manual Full Chapter PDFnettleshrill.gpkga100% (14)

- Okuma - Osp - E100m - E10m - Alarm Erros List - ME37005R4E100MAlarm883220150816 PDFDocument588 pagesOkuma - Osp - E100m - E10m - Alarm Erros List - ME37005R4E100MAlarm883220150816 PDFAntonioCanestriJúnior100% (3)

- Huvitz CAB-4000 Manual Utilizare PDFDocument89 pagesHuvitz CAB-4000 Manual Utilizare PDFPetrica DascaluNo ratings yet

- Composite Boiler AalborgDocument2 pagesComposite Boiler Aalborghpss77100% (1)

- A Neural-Network Approach For Semiconductor Wafer Post-Sawing InspectionDocument7 pagesA Neural-Network Approach For Semiconductor Wafer Post-Sawing InspectionMohd Nurfirdaus Mohd ShamsuriNo ratings yet

- Ijres V9i5p101Document10 pagesIjres V9i5p101AutoDZNo ratings yet

- Wang 2018Document8 pagesWang 2018Gabriel MessiasNo ratings yet

- A Multilayered Neural Network ControllerDocument5 pagesA Multilayered Neural Network ControllerAditya AgarwalNo ratings yet

- The Evaluation of Grinding Process Using ArtificiaDocument8 pagesThe Evaluation of Grinding Process Using ArtificiaAlex vilcaNo ratings yet

- Modelling 05 00009Document27 pagesModelling 05 00009TnsORTYNo ratings yet

- 2012 - Stochastic Gradient Descent Inspired Training Technique For A CMOS Nano Memristive Trainable Threshold Gate ArrayDocument10 pages2012 - Stochastic Gradient Descent Inspired Training Technique For A CMOS Nano Memristive Trainable Threshold Gate Arrayfromthedepth@gmail.comNo ratings yet

- Prediction of Strength Characteristics of Fly Ash Concrete Using Artificial Neural NetworkingDocument14 pagesPrediction of Strength Characteristics of Fly Ash Concrete Using Artificial Neural NetworkingKeerthiNo ratings yet

- PR Oof: Memristor Models For Machine LearningDocument23 pagesPR Oof: Memristor Models For Machine LearningtestNo ratings yet

- PAxC A Probabilistic-Oriented Approximate Computing Methodology For ANNsDocument4 pagesPAxC A Probabilistic-Oriented Approximate Computing Methodology For ANNsHan Yan100% (1)

- Amaitik WESIC2003 PaperDocument8 pagesAmaitik WESIC2003 PaperSalehNo ratings yet

- Control of Batch Reactors Using Neural Networks Chemical Engineering and Processing, 31 (1992) 113 - 180Document8 pagesControl of Batch Reactors Using Neural Networks Chemical Engineering and Processing, 31 (1992) 113 - 180eeeeNo ratings yet

- Zounemat Kermani2008 PDFDocument9 pagesZounemat Kermani2008 PDFJosue MarshallNo ratings yet

- Forecasting The Production of Fully-Mechanised Coal Face by Meta-Synthetic AI MethodDocument4 pagesForecasting The Production of Fully-Mechanised Coal Face by Meta-Synthetic AI Methodazimi32No ratings yet

- Water Saturation and Porosity Prediction Using Back-Propagation Artificial Neural Network (Bpann) From Well Log DataDocument8 pagesWater Saturation and Porosity Prediction Using Back-Propagation Artificial Neural Network (Bpann) From Well Log DataArega GenetieNo ratings yet

- Deep Physical Neural Networks Trained With Backpropagation: ArticleDocument11 pagesDeep Physical Neural Networks Trained With Backpropagation: ArticleManh Hoang VanNo ratings yet

- Deep Physical Neural Networks Trained With Backpropagation. Nature 2022, P L McmohanDocument11 pagesDeep Physical Neural Networks Trained With Backpropagation. Nature 2022, P L McmohanmahadimasnadNo ratings yet

- (Polish Maritime Research) Application of Artificial Neural Networks To Assessment of Ship Manoeuvrability QualitiesDocument7 pages(Polish Maritime Research) Application of Artificial Neural Networks To Assessment of Ship Manoeuvrability Qualitiesjwpaprk1No ratings yet

- Paper Modular Neural NetworkDocument11 pagesPaper Modular Neural NetworkQunalNo ratings yet

- Sensors 22 08845Document16 pagesSensors 22 08845John CarterNo ratings yet

- A Pneumonia Detection Method Based On ImprovedDocument6 pagesA Pneumonia Detection Method Based On ImprovedAmílcar CáceresNo ratings yet

- Low-Loss Photonic Reservoir Computing With Multimode Photonic Integrated CircuitsDocument10 pagesLow-Loss Photonic Reservoir Computing With Multimode Photonic Integrated CircuitsprajneshNo ratings yet

- PDF 154051 80482Document7 pagesPDF 154051 80482Hani BenguesmiaNo ratings yet

- Optimum Architecture of Neural Networks Lane Following SystemDocument6 pagesOptimum Architecture of Neural Networks Lane Following SystemJ.No ratings yet

- Neural Control2 PDFDocument5 pagesNeural Control2 PDFsuryaNo ratings yet

- Neural Network Seminar ReportDocument17 pagesNeural Network Seminar ReportJainendra SinghNo ratings yet

- Ijaest: Use of Artificial Bee Colony (ABC) Algorithm in Artificial Neural Network SynthesisDocument10 pagesIjaest: Use of Artificial Bee Colony (ABC) Algorithm in Artificial Neural Network Synthesisz1111234No ratings yet

- Curriculum ExitsDocument8 pagesCurriculum ExitsmayethmosteraNo ratings yet

- ECBC Efficient Convolution Via Blocked ColumnizingDocument13 pagesECBC Efficient Convolution Via Blocked ColumnizingTuhin KarakNo ratings yet

- Temporal Neural Network A Rchitecture For Online LearningDocument13 pagesTemporal Neural Network A Rchitecture For Online LearninghelbakouryNo ratings yet

- Downstream Team3Document22 pagesDownstream Team3Priyanka PanigrahiNo ratings yet

- 1995 Dornier PDFDocument11 pages1995 Dornier PDFnevenkanikNo ratings yet

- Common Work Ows For Computing Material Properties Using Different Quantum EnginesDocument12 pagesCommon Work Ows For Computing Material Properties Using Different Quantum EnginesRonaldo PaxDeorumNo ratings yet

- 3.4 Examples of Mathematical Models: - Part I: IntroductionDocument10 pages3.4 Examples of Mathematical Models: - Part I: IntroductionCamila TorresNo ratings yet

- Implementation of Deep Neural Network Using VLSI BDocument8 pagesImplementation of Deep Neural Network Using VLSI BKhang Truong NguyenNo ratings yet

- Artificial Intelligence in Pharma-Ceutical Product Formulation: Neural ComputingDocument10 pagesArtificial Intelligence in Pharma-Ceutical Product Formulation: Neural ComputingHimanshu PanchalNo ratings yet

- Highly-Accurate Machine Fault Diagnosis Using Deep Transfer LearningDocument9 pagesHighly-Accurate Machine Fault Diagnosis Using Deep Transfer LearningJaime100% (1)

- Gunaratna 2010Document4 pagesGunaratna 2010SebastianNo ratings yet

- Intelligent Web Caching Using Neurocomputing and Particle Swarm Optimization AlgorithmDocument6 pagesIntelligent Web Caching Using Neurocomputing and Particle Swarm Optimization AlgorithmHny Henny HennyNo ratings yet

- Use of Influence Diagrams and Neural Networks in Modeling Semiconductor Manufacturing ProcessesDocument7 pagesUse of Influence Diagrams and Neural Networks in Modeling Semiconductor Manufacturing ProcessesarqonexusNo ratings yet

- Can Neural Networks Be Easily Interpreted in Software Cost Estimation?Document6 pagesCan Neural Networks Be Easily Interpreted in Software Cost Estimation?jagannath_singhNo ratings yet

- Neural Network Technique in The Study of Selected Chemical Engineering Unit Operations Data Using MatlabDocument8 pagesNeural Network Technique in The Study of Selected Chemical Engineering Unit Operations Data Using MatlabSepribo BraideNo ratings yet

- 1 s2.0 S0263224120302050 MainDocument12 pages1 s2.0 S0263224120302050 MainCristian BastiasNo ratings yet

- Neural Network Methodology Process Fault Diagnosis: A ForDocument10 pagesNeural Network Methodology Process Fault Diagnosis: A ForyokonoraNo ratings yet

- Neural Network Approaches To Image Compression: Robert D. Dony, Student, IEEE Simon Haykin, Fellow, IEEEDocument16 pagesNeural Network Approaches To Image Compression: Robert D. Dony, Student, IEEE Simon Haykin, Fellow, IEEEdanakibreNo ratings yet

- Model Transferability From ImageNet To Lithography HotspotDocument9 pagesModel Transferability From ImageNet To Lithography Hotspotameed shahNo ratings yet

- Feasibility Study On The Use of Dynamic Neural Networks (DNN'S) For Modeling A Variable Displacement Load Sensing PumpDocument8 pagesFeasibility Study On The Use of Dynamic Neural Networks (DNN'S) For Modeling A Variable Displacement Load Sensing PumpTuan AnhNo ratings yet

- Micromaquinas para MecatronicaDocument12 pagesMicromaquinas para Mecatronicaraul pocoriNo ratings yet

- Introduction To Neural Networks For InteDocument5 pagesIntroduction To Neural Networks For InteJohn ReeseNo ratings yet

- BackprpDocument6 pagesBackprpAnay ChowdharyNo ratings yet

- 1 s2.0 S0020025521002693 MainDocument16 pages1 s2.0 S0020025521002693 MainAPRAJITA SRIVASTAVANo ratings yet

- RM Assign1Document7 pagesRM Assign1Sushant BhargavaNo ratings yet

- Neural Network Technique in The Study of Selected Chemical Engineering Unit Operations Data Using MATLABDocument7 pagesNeural Network Technique in The Study of Selected Chemical Engineering Unit Operations Data Using MATLABInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Neuromorphic Dreaming: A Pathway To Efficient Learning in Artificial AgentsDocument16 pagesNeuromorphic Dreaming: A Pathway To Efficient Learning in Artificial AgentsvoltNo ratings yet

- Comparison of Neural Network Architectures For Machinery Fault DiagnosisDocument10 pagesComparison of Neural Network Architectures For Machinery Fault DiagnosiselshafeiNo ratings yet

- Adsorption Enthalpies in Zeolites. High-Accuracy, Machine LearningDocument3 pagesAdsorption Enthalpies in Zeolites. High-Accuracy, Machine LearningLUIS EDUARDO RAMOS FUENTESNo ratings yet

- Neural Network EnsemblesDocument9 pagesNeural Network EnsembleskronalizedNo ratings yet

- Constructing Online Testable CircuitsDocument9 pagesConstructing Online Testable CircuitsNandita RajasekaranNo ratings yet

- Deep Learning with Python: A Comprehensive Guide to Deep Learning with PythonFrom EverandDeep Learning with Python: A Comprehensive Guide to Deep Learning with PythonNo ratings yet

- Embedded Deep Learning: Algorithms, Architectures and Circuits for Always-on Neural Network ProcessingFrom EverandEmbedded Deep Learning: Algorithms, Architectures and Circuits for Always-on Neural Network ProcessingNo ratings yet

- WPS Format For Asme Ix - Wps - Gtaw Fcaw GmawDocument1 pageWPS Format For Asme Ix - Wps - Gtaw Fcaw GmawThe Welding Inspections CommunityNo ratings yet

- NCP1002Document14 pagesNCP1002Ailton De JesusNo ratings yet

- Assembling Field Vane Shear Test ApparatusDocument17 pagesAssembling Field Vane Shear Test ApparatusSanjay MuthekarNo ratings yet

- Floating Point MultiplierDocument35 pagesFloating Point Multiplierbindu_ankuNo ratings yet

- WSC1 ST Year NSQFFinalDocument187 pagesWSC1 ST Year NSQFFinalVadnala ArunNo ratings yet

- Service Manual: EPSON Stylus C58/C59/ME 2 EPSON Stylus C79/D78 EPSON Stylus C90/C91/C92/D92Document100 pagesService Manual: EPSON Stylus C58/C59/ME 2 EPSON Stylus C79/D78 EPSON Stylus C90/C91/C92/D92Wilfredo PérezNo ratings yet

- Sewing Technology enDocument54 pagesSewing Technology enWibowo Abi TigabeNo ratings yet

- Model-Based Testing at Spotify: Kristian KarlDocument26 pagesModel-Based Testing at Spotify: Kristian Karlmr.sharma11No ratings yet

- Mastering ArpeggiosDocument58 pagesMastering Arpeggiospeterd87No ratings yet

- Qos Command Reference, Cisco Ios Release 15.2 (2) E (Catalyst 2960-X Switch)Document120 pagesQos Command Reference, Cisco Ios Release 15.2 (2) E (Catalyst 2960-X Switch)AHOUALAKOUNNo ratings yet

- Flat Plate Boundary Layer CornellDocument39 pagesFlat Plate Boundary Layer CornellsidyantNo ratings yet

- Articulo de Revision Unidad IIIDocument17 pagesArticulo de Revision Unidad IIIYeiru Azael RatmareNo ratings yet

- ARMY TM 5-822-7 Air Force Afm 88-6, Chap. 8Document55 pagesARMY TM 5-822-7 Air Force Afm 88-6, Chap. 8PDHLibraryNo ratings yet

- CyberAces Module1-Windows 1 InstallingWindowsDocument40 pagesCyberAces Module1-Windows 1 InstallingWindowsAbiodun AmusatNo ratings yet

- Onur 447 Spring15 Lecture1 Intro AfterlectureDocument88 pagesOnur 447 Spring15 Lecture1 Intro AfterlecturekaanpNo ratings yet

- Case Study 1. Developing HYSYS Material Stream: 1.1. Component and Fluid List SelectionDocument7 pagesCase Study 1. Developing HYSYS Material Stream: 1.1. Component and Fluid List SelectionChakravarthy BharathNo ratings yet

- VEF GPA Conversion TableDocument2 pagesVEF GPA Conversion TableMinh Khôi AnNo ratings yet

- About Ansys: Finite Element AnalysisDocument2 pagesAbout Ansys: Finite Element Analysissuffiya abdulNo ratings yet

- FutureDocument37 pagesFutureBT20EEE052 KhushalNo ratings yet

- Mirror Maze: InputDocument2 pagesMirror Maze: InputHello misterNo ratings yet

- Grout 214 TRDocument3 pagesGrout 214 TRbarouniamineNo ratings yet

- R R X R YtDocument9 pagesR R X R YtAthiyo MartinNo ratings yet

- LegTech ReviewerDocument9 pagesLegTech ReviewerMaris Cay0% (1)

- Phrases and ClausesDocument11 pagesPhrases and ClausesChepie Creencia33% (3)

- 2024 Bss Chemistry P IIDocument8 pages2024 Bss Chemistry P IIbarotathomas1234No ratings yet