Professional Documents

Culture Documents

Pa 12

Pa 12

Uploaded by

pava16230.meOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pa 12

Pa 12

Uploaded by

pava16230.meCopyright:

Available Formats

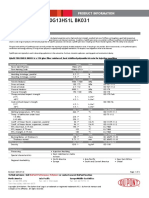

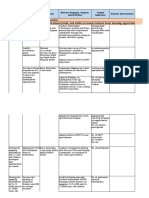

Technical Data Sheet

Badamid® PA12 H

>PA12<

Unreinforced, heat stabilized PA12 for injection moulding; Extrusion of cable sheeting

Properties Test Conditions Test Methods Units Dry as conditioned

moulded 23° C, 50% r.H.

Mechanical Properties

Modulus of Elasticity, tensile 23° C, 1 mm/Min ISO 527-1/2 MPa 1700 *

Yield Stress 1 23° C, 50 mm/Min ISO 527-1/2 MPa 47 *

Yield Strain 1 23° C, 50 mm/Min ISO 527-1/2 % 4 *

Nominal Stress at Break 1 23° C, 50 mm/Min ISO 527-1/2 % >200 *

Stress at Break 1 23° C, 5 mm/Min ISO 527-1/2 MPa - *

Strain at Break 1 23° C, 5 mm/Min ISO 527-1/2 % - *

Bending Strength 2 23° C ISO 178 MPa 60 -

Bending modul 23°C ISO 178 MPa 1 500 *

Charpy Impact Strength, unnotched 2 23° C ISO 179/1eU kJ/m2 - -

-30° C ISO 179/1eU kJ/m2 - -

Notched Charpy Impact Strength 2 23° C ISO 179/1eA kJ/m2 - -

-30° C ISO 179/1eA kJ/m2 - -

Izod notched Impact Strength 2 23° C ISO 180/1A kJ/m2 - -

-30° C ISO 180/1A kJ/m2 - -

Thermal Properties

Melting Temperature 3 10 K/Min ISO 3146 °C 180 *

Temperature of Deflection under Load 4 0.45 MPa ISO 75-1/2 °C 95 *

1.8 MPa ISO 75-1/2 °C 45 *

Coefficient of Linear Thermal Elongation 5 parallel direction DIN 53752 E-4/K 1,3 *

transverse direction DIN 53752 E-4/K - *

Maximum Service Temperature some hours - °C - *

20 000 h IEC 216 °C - *

50 % Decrease in Tensile

Strength or Yield Stress

Flammability 6 0.8 mm UL 94 Class - *

1.6 mm UL 94 Class - *

Glow Wire Test 0.75 mm / 1.6 mm GWIT IEC-60695-2-13 - *

0.75 mm / 1.6 mm GWFI IEC-60695-2-12 - *

Electric Properties

Relative Permittivity 7 1 MHz IEC 250 - - -

Dissipation Factor 7 1 MHz IEC 250 E-4 - -

Specific Volume Resistivity 7 - IEC 93 Ohm cm 10 15 -

Specific Surface Resistivity 7 - IEC 93 Ohm - -

Dielectric Strength 7 - IEC 243-1 kV/mm - -

Comparative Tracking Index - IEC 112 V - -

Other data

Water Absorption 23° C. Saturation ISO 62 % - *

Humidity Absorbent 23° C, 50% Humidity ISO 62 % 0,7 *

Density 23° C ISO 1183 g/ccm 1.02 *

Shore hardness - ISO 868 D-scala 77 *

Rockwell hardness - ISO 2039-2 R-scala 105 *

MFI 190°C/1kg ISO 1133 g/10min 9 *

LEGEND:

1

Test Specimen accordng to ISO 3167. Type A * not relevant These data are typical values and represent the state of our

2

Standard bar (80 x 10 x 4) mm - not tested knowledge at issue date. If not otherwise stated. the data is

3

Compound for moulding NB = No break related to uncoloured material. They must not be construed as

4

Standard bar (110 x 10 x 4) mm specification limits or as a guarantee for specific properties.

5

Specimen ( It is the liability of the processor to test the suitability of the material

6

Standard bar [125 x 13 x 0.8(1.6)] mm for a specific application.

7

Bar (80 x 80 x 1) mm

8

Specimen ( Issue date: 2011-05-20

Bada AG · Untere Strut 1 · D-77815 Bühl/Baden · Fon: +49 (0) 72 23-940 77-0 · Fax: +49 (0) 72 23-940 77-77 · info@bada.de · www.bada.de

You might also like

- BS 07273-1 2006 (En)Document18 pagesBS 07273-1 2006 (En)Emanuele MastrangeloNo ratings yet

- National Health Programmes in IndiaDocument33 pagesNational Health Programmes in IndiaNaveesh Vijay P K100% (3)

- The Gropes - Tom SharpeDocument73 pagesThe Gropes - Tom SharpeCrisMorillas100% (1)

- B70 S Natural S1: Badamid®Document2 pagesB70 S Natural S1: Badamid®hocineNo ratings yet

- Makrolon SF800 - en - 56979992 00009671 17283484Document3 pagesMakrolon SF800 - en - 56979992 00009671 17283484Shinichi SuzukiNo ratings yet

- Novodur P2MC: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesNovodur P2MC: Acrylonitrile Butadiene Styrene (ABS)heliocoelhojrNo ratings yet

- Makrolon LED2245 - en - 81038415 00003726 19218403Document4 pagesMakrolon LED2245 - en - 81038415 00003726 19218403dave judayaNo ratings yet

- Novodur H802: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesNovodur H802: Acrylonitrile Butadiene Styrene (ABS)Maribel GutierrezNo ratings yet

- LANXESS Durethan BKV35H2.0 901510 ISO ENDocument3 pagesLANXESS Durethan BKV35H2.0 901510 ISO ENcristinamss33No ratings yet

- Novodur P2H-ATDocument3 pagesNovodur P2H-ATavinashchauhan2695No ratings yet

- Makrolon Rx3440 - en - 87242367 05124840 21462211Document3 pagesMakrolon Rx3440 - en - 87242367 05124840 21462211MamdouhNo ratings yet

- Makrolon 3206 - en - 56817747 00003433 19231690Document4 pagesMakrolon 3206 - en - 56817747 00003433 19231690noto.sugiartoNo ratings yet

- Kynar Flex® 2800-20 ResinDocument5 pagesKynar Flex® 2800-20 ResinmohammedNo ratings yet

- Flow Elem. Makrolon 2467 - en - 56977450 00003066 15285551Document4 pagesFlow Elem. Makrolon 2467 - en - 56977450 00003066 15285551Guilherme Dos Santos SouzaNo ratings yet

- PBT - Lanxess Pocan B3235 000000Document3 pagesPBT - Lanxess Pocan B3235 000000armandoNo ratings yet

- TDS - TS002 - Durethan AKV30H3.0Document3 pagesTDS - TS002 - Durethan AKV30H3.0oberta.andrzejNo ratings yet

- Lanxess Durethan Bkv130h2.0 901510 Iso enDocument3 pagesLanxess Durethan Bkv130h2.0 901510 Iso enRICARDONo ratings yet

- Makrolon 2405: General Purpose Grades / Low Viscosity / High ProductivityDocument4 pagesMakrolon 2405: General Purpose Grades / Low Viscosity / High ProductivityagungNo ratings yet

- PC Makrolon 2458 - 2006Document4 pagesPC Makrolon 2458 - 2006countzeroaslNo ratings yet

- Lanxess - Pocan B7425Document3 pagesLanxess - Pocan B7425rihabNo ratings yet

- Elix ABS M220: Technical InformationDocument3 pagesElix ABS M220: Technical InformationDiegoTierradentroNo ratings yet

- LANXESS Durethan A30SFN31 000000 ISO ENDocument3 pagesLANXESS Durethan A30SFN31 000000 ISO ENNguyen Dinh VinhNo ratings yet

- Makrolon 6265 X - en - 83439336 05122261 16125443Document4 pagesMakrolon 6265 X - en - 83439336 05122261 16125443solar4meNo ratings yet

- Makrolon 6485 - en - 56978635 00009652 18539090Document4 pagesMakrolon 6485 - en - 56978635 00009652 18539090Lin DanNo ratings yet

- PA6-30GF LANXESS Durethan BKV130P 702214 ISO ENDocument2 pagesPA6-30GF LANXESS Durethan BKV130P 702214 ISO ENKalipse FerreiraNo ratings yet

- Makrolon 2407 - en - 56977361 00009645 19213223Document4 pagesMakrolon 2407 - en - 56977361 00009645 19213223vaibhav ShindeNo ratings yet

- Durethan B30S 000000: PA 6, Non-Reinforced, Injection Molding ISO Shortname: ISO 1874-PA 6, GR, 14-030Document3 pagesDurethan B30S 000000: PA 6, Non-Reinforced, Injection Molding ISO Shortname: ISO 1874-PA 6, GR, 14-030zoranNo ratings yet

- Makrolon 2405 ISO enDocument4 pagesMakrolon 2405 ISO enJuan Daniel Ledezma Alonso100% (1)

- Riteflex 640aDocument3 pagesRiteflex 640aazaleaemersonNo ratings yet

- Ficha Makrolon 2607 ISO enDocument4 pagesFicha Makrolon 2607 ISO enPatriciaNo ratings yet

- Durethan B30S 000000 ISO enDocument3 pagesDurethan B30S 000000 ISO enjujuplasticNo ratings yet

- Datasheet ZytelST801AHSBK010Document9 pagesDatasheet ZytelST801AHSBK010Alexandre GasparinNo ratings yet

- Makrolon AL2447 - en - 56978848 00009654 19215151 2Document4 pagesMakrolon AL2447 - en - 56978848 00009654 19215151 2optoyhamelNo ratings yet

- Makrolon 2407 - en - 86286874 00009645 19213223Document4 pagesMakrolon 2407 - en - 86286874 00009645 19213223fernandoincesaNo ratings yet

- Makrolon OD2015: Grades For / Optical Storage MediaDocument3 pagesMakrolon OD2015: Grades For / Optical Storage MediamarioNo ratings yet

- Makrolon 2858 ISO enDocument4 pagesMakrolon 2858 ISO enRushyanth KRNo ratings yet

- Makrolon® 1952: Flame Retardant Grades / Medium ViscosityDocument3 pagesMakrolon® 1952: Flame Retardant Grades / Medium ViscosityDiegoTierradentroNo ratings yet

- Styrolution TDS302200150418Document3 pagesStyrolution TDS302200150418erayNo ratings yet

- 202-Covestro Makrolon RX1805 Technical Data Sheet 03-12-2018Document3 pages202-Covestro Makrolon RX1805 Technical Data Sheet 03-12-2018obeckoneNo ratings yet

- Tds Carbon enDocument1 pageTds Carbon engegacolucNo ratings yet

- YEE70G30HSLNCDocument2 pagesYEE70G30HSLNCRanjan GnanaoliNo ratings yet

- Makrolon® ET3137: Grades / ExtrusionDocument4 pagesMakrolon® ET3137: Grades / ExtrusionDiegoTierradentroNo ratings yet

- Durethan BKV240 H20 XCP901510 ISOinternetDocument3 pagesDurethan BKV240 H20 XCP901510 ISOinternetshahin_723No ratings yet

- Elix ABS P2M-AT: Technical InformationDocument3 pagesElix ABS P2M-AT: Technical InformationDiegoTierradentroNo ratings yet

- Makrolon 6557 - TDSDocument4 pagesMakrolon 6557 - TDSCassianNo ratings yet

- Bayblend T85 XF ISO enDocument3 pagesBayblend T85 XF ISO enryanNo ratings yet

- Styro Lution Tds 401200140448Document3 pagesStyro Lution Tds 401200140448scribdNo ratings yet

- Zytel® 73G15L NC010-gbDocument12 pagesZytel® 73G15L NC010-gbzoxxxnNo ratings yet

- POLICARBONATO LEXAN™ Resin - 123R - Europe - Technical - Data - SheetDocument2 pagesPOLICARBONATO LEXAN™ Resin - 123R - Europe - Technical - Data - SheetscribdNo ratings yet

- Luran HH-120: Please SelectDocument3 pagesLuran HH-120: Please SelectDavid Costi da RosaNo ratings yet

- Ascend Vydyne® 47H BK03 TDS-enDocument4 pagesAscend Vydyne® 47H BK03 TDS-enShibu MohanNo ratings yet

- Makrolon 2607 - en - 56977671 00009617 18538954Document4 pagesMakrolon 2607 - en - 56977671 00009617 18538954MulyadiNo ratings yet

- SABIC® PP - 108MF97 - Global - Technical - Data - SheetDocument2 pagesSABIC® PP - 108MF97 - Global - Technical - Data - Sheetkhaloud.alkaabi98No ratings yet

- 5.0.aspa Axial Uv Antiestatica-1Document16 pages5.0.aspa Axial Uv Antiestatica-1Ventilación Minera S.A.SNo ratings yet

- TDS - TS004 - Durethan BKV30H2.0Document3 pagesTDS - TS004 - Durethan BKV30H2.0oberta.andrzejNo ratings yet

- Sabic PC 10 Mfi pc1003rDocument3 pagesSabic PC 10 Mfi pc1003rChu ChuNo ratings yet

- Nylon 6-BAYER DURATHAN BKV130-901510Document3 pagesNylon 6-BAYER DURATHAN BKV130-901510dcrypto2022No ratings yet

- Campus® Datasheet: Zytel® 70G30L Nc010 - Pa66-Gf30 Dupont Engineering PolymersDocument5 pagesCampus® Datasheet: Zytel® 70G30L Nc010 - Pa66-Gf30 Dupont Engineering PolymersVinayak ImadiNo ratings yet

- Zytel 70 G13 HS1 LBK031Document3 pagesZytel 70 G13 HS1 LBK031vikram goralNo ratings yet

- Sabic 1004RDocument3 pagesSabic 1004Rlcesaksham23No ratings yet

- Microwave Devices, Circuits and Subsystems for Communications EngineeringFrom EverandMicrowave Devices, Circuits and Subsystems for Communications EngineeringRating: 4 out of 5 stars4/5 (1)

- FA1 - Mole CalculationsDocument3 pagesFA1 - Mole CalculationsDenjiNo ratings yet

- VSMS Report-23223209Document8 pagesVSMS Report-23223209Joyal SanthoshNo ratings yet

- NIC Components NSRN SeriesDocument5 pagesNIC Components NSRN SeriesNICCompNo ratings yet

- Steelcrete PavementsDocument4 pagesSteelcrete Pavementsvinay rodeNo ratings yet

- Mimosa PudicaDocument4 pagesMimosa PudicaIna Guinar100% (1)

- CEUFast Infection Control and Barrier PrecautionsDocument90 pagesCEUFast Infection Control and Barrier PrecautionsMeg GalauranNo ratings yet

- Molar Volume of OxygenDocument5 pagesMolar Volume of OxygenGeorgeNo ratings yet

- Lecture 3: Polymeric Biomaterials. Part 2 - Advanced Techniques For Analysis of MacromoleculesDocument26 pagesLecture 3: Polymeric Biomaterials. Part 2 - Advanced Techniques For Analysis of MacromoleculesNurul FarhahNo ratings yet

- Panasonic KX-TG9581 - TG9582 2lineDocument100 pagesPanasonic KX-TG9581 - TG9582 2lineelpirata666No ratings yet

- Final ReferencesDocument8 pagesFinal ReferencesZyla KrisshaNo ratings yet

- MIT Technology Review 2021-0102Document92 pagesMIT Technology Review 2021-0102Amit SamantNo ratings yet

- RTL Critical Thinking Skills e LearningDocument50 pagesRTL Critical Thinking Skills e LearningElías Tamez100% (1)

- Activity Proposal Tree PlantingDocument1 pageActivity Proposal Tree PlantingJanet Floreno VillasanaNo ratings yet

- How To Grow A Truly Great BeardDocument3 pagesHow To Grow A Truly Great BeardWALEED HASSANNo ratings yet

- Total Supply Chain Management Cost Data CollectionDocument4 pagesTotal Supply Chain Management Cost Data CollectionSuhailNo ratings yet

- 2022 - Executive Order - BADAC - BDODocument3 pages2022 - Executive Order - BADAC - BDOromulo sigaNo ratings yet

- D10T-D11T To Compare PDFDocument44 pagesD10T-D11T To Compare PDFraulipaqNo ratings yet

- Iec61439 ImportanceDocument30 pagesIec61439 Importancearkupi100% (1)

- UntitledDocument175 pagesUntitledMark Edson AboyNo ratings yet

- Reactii Severe Transf RevDocument26 pagesReactii Severe Transf RevCapdemai OvidiuNo ratings yet

- Structural Steel DesignDocument8 pagesStructural Steel DesignNassim SabriNo ratings yet

- Bare Copper Conductor Soft Drawn1Document1 pageBare Copper Conductor Soft Drawn1Ian de GaliciaNo ratings yet

- Credit Analysis-Medlife: 1. Description of The LoanDocument20 pagesCredit Analysis-Medlife: 1. Description of The LoanAlexandraNo ratings yet

- JS1034-XX-F06-0001. A1Document107 pagesJS1034-XX-F06-0001. A1Pawan Gosavi100% (1)

- GE MAC 5000 ECG MantenimientoDocument160 pagesGE MAC 5000 ECG Mantenimientomoises100% (1)

- Narrative ReportDocument4 pagesNarrative ReportAlbert Bagasala AsidoNo ratings yet

- Bosch20182019 Catalog - Taps and DiesDocument8 pagesBosch20182019 Catalog - Taps and Diesrasim_m1146No ratings yet