Professional Documents

Culture Documents

APPENDIX A.1 - Ojas Infra - Chichester SS - MV Cable TDS

APPENDIX A.1 - Ojas Infra - Chichester SS - MV Cable TDS

Uploaded by

Sanjay GadhaveOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

APPENDIX A.1 - Ojas Infra - Chichester SS - MV Cable TDS

APPENDIX A.1 - Ojas Infra - Chichester SS - MV Cable TDS

Uploaded by

Sanjay GadhaveCopyright:

Available Formats

Technical

Technical Data Sheet

Data Sheet-

UGL Bannerton Solar project/1446

Item 2, 19/33(36kV) 1Core 500mm2 CU/TR-XLPE/CWS (3.1kA/S)/PVC/Nylon/HDPE to AS/NZS 1429.1,

Direct burial compatible

Type of material Thickness (mm) Approx.

Construction Diameter

Material Nom. avg. Min. (mm)

Minimum number of

Conductor Copper, stranded compacted to AS1125 26.6

wires in conductor: 53

Conductor screen Semi-conductive compound Triple 0.5 0.3 28.2

Insulation TR-XLPE Extrusion 8 7.1 44.2

Insulation screen Semi-conductive compound 0.8 0.6 45.8

Metallic screen(3.1ka) Annealed copper wire 36/0.85mm 47.5

Binder Non-hygroscopic tape 0.2 - 48.1

Inner sheath PVC 5V-90, Orange 1.1 0.68 50.3

Anti-termite layer Nylon 12 0.5 0.2 51.3

Outer sheath HDPE, Black with min. 2.5% carbon black 1.5 1.0 54.3

Approx. weight of completed cable (kg/km) 6120.00

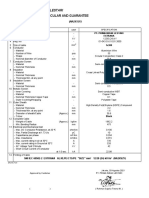

Cable Drawing

Page 3 of 6 Ojas Infrastructure Pty Ltd

Technical

Technical Data Sheet

Data Sheet-

UGL Bannerton Solar project/1446

1.Rated current carrying capacity (A) based on the standard conditions:

⚫ Ambient Air Temperature 40℃ Soil Temperature 25℃

⚫ Depth of Laying 800mm Soil thermal Resistivity1.2℃.m/W

In air 40℃ In ground 25℃

Solid Bond Solid Bond Solid Bond Solid Bond Solid Bond

803 600 637 574 682

2. Conductor DC resistance @ 20℃ 0.0366ohm/km

3. Conductor operating temperature: -25℃~90℃

4. Emergency conductor temperature: 105℃

5. Short circuit temperature: 250℃ for 5 sec.

6. Minimum bending radius(mm) During installation(1410mm) Installed(1000mm)

7. Maximum allowable pulling tension 35KN

8. Conductor AC Resistance @ 50Hz/90˚C (Ω/1000m) 0.0499

9. Inductive Reactance @ 50Hz (Ω/1000m) 0.111

10. Zero Sequence Resistance @ 20˚C (Ω/1000m) 0.302

11. Zero Sequence Reactance @ 50Hz (Ω/1000m) 0.0531

12. Conductor to Screen Capacitance (uF/1000m) 0.297

13. Maximum Dielectric Stress (kV/mm) 2.93

14. Minimum Insulation resistance at 20℃ 40000GΩ/m

15. Charging Current per phase (A/1000m) 1.77

16. Rated short circuit capacity- Screens & conductor 3.1kA/1s &71.5KA/1s

17. Material mechanical characteristics

17.1 INSULATION (Material: TR-XLPE):

a) Before ageing

- Tensile strength & Elongation at rupture: Min. 12.5 MPa & Min. 200%

b) After ageing (135±3℃, 168h)

- Tensile strength & Elongation at rupture: Min. 75% of unaged value & Min. 75% of unaged value

17.2 INNER SHEATH (Material: PVC 5V-90)

a) Before ageing

- Tensile strength & Elongation at rupture: Min. 12.5 MPa & Min. 150%

b) After ageing (504h at 115±2℃)

- Tensile strength & Elongation at rupture: Min. 75% of unaged value & Min. 65% of unaged value

17.3 OUTER SHEATH (Material: HDPE)

a) Before ageing

- Tensile strength & Elongation at rupture: Min. 22.0 MPa & Min. 400%

b) After ageing (336h at 110±3℃)

- Elongation at rupture: Min. 300%

c) Carbon black content: Min. 2.5%

18. Drum length TBA

19. Gross weight per drum TBA

20. Drum size (FDxBDxIWxEWxSH) TBA

Page 4 of 6 Ojas Infrastructure Pty Ltd

Technical

Technical Data Sheet

Data Sheet-

UGL Bannerton Solar project/1446

Item 3, 6.35/11(12kV) 1C630mm2 CU/TR-XLPE/CWS (3.1kA/S)/PVC/AWA/PVC/Nylon/HDPE to AS/NZS

1429.1, Direct burial compatible

Type of material Thickness (mm) Approx.

Construction Diameter

Material Nom. avg. Min. (mm)

Minimum number of

Conductor Copper, stranded compacted to AS1125 30.5

wires in conductor: 53

Conductor screen Semi-conductive compound Triple 0.5 0.3 32.4

Insulation TR-XLPE Extrusion 3.4 2.96 39.2

Insulation screen Semi-conductive compound 0.8 0.6 40.8

Metallic screen(3.1ka) Annealed copper wire 36/0.85mm 42.5

Binder Non-hygroscopic tape 0.2 - 43.1

PVC Bedding PVC 1.4 0.92 45.9

Armoured Aluminium wire armoured 2.5mm 50.9

Inner sheath PVC 5V-90, Orange 1.0 0.6 53.7

Anti-termite layer Nylon 12 0.5 0.2 54.7

Outer sheath HDPE, Black with min. 2.5% carbon black 1.6 1.08 57.9

Approx. weight of completed cable (kg/km) 7953.00

Cable Drawing

Page 5 of 6 Ojas Infrastructure Pty Ltd

Technical

Technical Data Sheet

Data Sheet-

UGL Bannerton Solar project/1446

1.Rated current carrying capacity (A) based on the standard conditions:

⚫ Ambient Air Temperature 40℃ Soil Temperature 25℃

⚫ Depth of Laying 800mm Soil thermal Resistivity1.2℃.m/W

In air 40℃ In ground 25℃

Solid Bond Solid Bond Solid Bond Solid Bond Solid Bond

911 672 697 619 759

2. Conductor DC resistance @ 20℃ 0.0283ohm/km

3. Conductor operating temperature: -25℃~90℃

4. Emergency conductor temperature: 105℃

5. Short circuit temperature: 250℃ for 5 sec.

6. Minimum bending radius(mm) During installation(1600mm) Installed(1070mm)

7. Maximum allowable pulling tension 44KN

8. Conductor AC Resistance @ 50Hz/90˚C (Ω/1000m) 0.0403

9. Inductive Reactance @ 50Hz (Ω/1000m) 0.108

10. Zero Sequence Resistance @ 20˚C (Ω/1000m) 0.294

11. Zero Sequence Reactance @ 50Hz (Ω/1000m) 0.0504

12. Conductor to Screen Capacitance (uF/1000m) 0.329

13. Maximum Dielectric Stress (kV/mm) 2.86

14. Minimum Insulation resistance at 20℃ 40000GΩ/m

15. Charging Current per phase (A/1000m) 1.96

16. Rated short circuit capacity- Screens & conductor 3.1kA/1s &90.0KA/1s

17. Material mechanical characteristics

17.1 INSULATION (Material: TR-XLPE):

a) Before ageing

- Tensile strength & Elongation at rupture: Min. 12.5 MPa & Min. 200%

b) After ageing (135±3℃, 168h)

- Tensile strength & Elongation at rupture: Min. 75% of unaged value & Min. 75% of unaged value

17.2 INNER SHEATH (Material: PVC 5V-90)

a) Before ageing

- Tensile strength & Elongation at rupture: Min. 12.5 MPa & Min. 150%

b) After ageing (504h at 115±2℃)

- Tensile strength & Elongation at rupture: Min. 75% of unaged value & Min. 65% of unaged value

17.3 OUTER SHEATH (Material: HDPE)

a) Before ageing

- Tensile strength & Elongation at rupture: Min. 22.0 MPa & Min. 400%

b) After ageing (336h at 110±3℃)

- Elongation at rupture: Min. 300%

c) Carbon black content: Min. 2.5%

18. Drum length TBA

19. Gross weight per drum TBA

20. Drum size (FDxBDxIWxEWxSH) TBA

Page 6 of 6 Ojas Infrastructure Pty Ltd

You might also like

- Understanding Greek Vases PDFDocument172 pagesUnderstanding Greek Vases PDFSaymon Almeida100% (9)

- MV Cables Data Sheet - SampleDocument5 pagesMV Cables Data Sheet - SampleAvoor KhanNo ratings yet

- PO1541 - Ojas Infra - GSF MV TDS-v1.1Document16 pagesPO1541 - Ojas Infra - GSF MV TDS-v1.1Sanjay GadhaveNo ratings yet

- NA2XS (F) 2Y 12-20 KV 1x400Document2 pagesNA2XS (F) 2Y 12-20 KV 1x400plavi10No ratings yet

- PO1541 - Ojas Infra - GSF DC TDS-v1.1Document7 pagesPO1541 - Ojas Infra - GSF DC TDS-v1.1Sanjay GadhaveNo ratings yet

- A2XS (FL) 2Y 1x 500RM - 50 110kV IEC 60840Document3 pagesA2XS (FL) 2Y 1x 500RM - 50 110kV IEC 60840Anonymous LNdiNQNo ratings yet

- TDS 1x300 11kV CTS+LEADDocument2 pagesTDS 1x300 11kV CTS+LEADNabeelNo ratings yet

- Technical Spec NA2XSEYBY 3x300mm2Document2 pagesTechnical Spec NA2XSEYBY 3x300mm2Suyanto Âñd Fámïly100% (1)

- RC - Local1x120mm CU XLPE CUT AWA PVC20kV (TD) - 20230131122332.677 - XDocument2 pagesRC - Local1x120mm CU XLPE CUT AWA PVC20kV (TD) - 20230131122332.677 - XAnonymous wx4I4YQONo ratings yet

- RC - Local 4x70mm SCU-XLPE-PVC 1 KV (TD)Document2 pagesRC - Local 4x70mm SCU-XLPE-PVC 1 KV (TD)HaikalNo ratings yet

- Technical Specification-33KV 1X500 SQ - MM XLPE CableDocument5 pagesTechnical Specification-33KV 1X500 SQ - MM XLPE Cableনাঈমুর রহমানNo ratings yet

- 3x240 MM CU-XLPE-CUT-SWA-PVC 11 KV (TD)Document2 pages3x240 MM CU-XLPE-CUT-SWA-PVC 11 KV (TD)HaikalNo ratings yet

- 3x240 MM CU-XLPE-CUT-SWA-PVC 11 KV (TD) 2Document2 pages3x240 MM CU-XLPE-CUT-SWA-PVC 11 KV (TD) 2HaikalNo ratings yet

- 3x240 MM CU-XLPE-CUT-SWA-PVC 11 KV (TD) 2Document2 pages3x240 MM CU-XLPE-CUT-SWA-PVC 11 KV (TD) 2HaikalNo ratings yet

- 3x120 MM CU-XLPE-CUT-SWA-PVC 15 KV (TD)Document2 pages3x120 MM CU-XLPE-CUT-SWA-PVC 15 KV (TD)HaikalNo ratings yet

- Product Specification Epm38031: Rhz1 19/33Kv 1X630Kcu+H50Document2 pagesProduct Specification Epm38031: Rhz1 19/33Kv 1X630Kcu+H50JFREY1504No ratings yet

- Loose Tube, Outdoor Aerial (Fig8) FO Cable 4-12-24 SM Tech Spec MLT Dry Core Dry Core SJDocument5 pagesLoose Tube, Outdoor Aerial (Fig8) FO Cable 4-12-24 SM Tech Spec MLT Dry Core Dry Core SJPetyo GeorgievNo ratings yet

- Technical Submittal For MV - Cable Data SheetsDocument4 pagesTechnical Submittal For MV - Cable Data SheetskhaledelgamalNo ratings yet

- IEC 36kv NA2XSEY YJLV 3C (1C150) EES CABLE SPECIFICATIONDocument7 pagesIEC 36kv NA2XSEY YJLV 3C (1C150) EES CABLE SPECIFICATIONmedazzNo ratings yet

- TDS 3x150 11kV CTS+LEADDocument2 pagesTDS 3x150 11kV CTS+LEADNabeelNo ratings yet

- TPG NA2XS2Y 1x300 mm2 20KVDocument2 pagesTPG NA2XS2Y 1x300 mm2 20KVtees220510No ratings yet

- Technical Data Sheets & Cross Sectional Details of 33kV XLPE CablesDocument4 pagesTechnical Data Sheets & Cross Sectional Details of 33kV XLPE CablesRamaKrishna ANo ratings yet

- 1C 630 MM (2xHSYRa2Y) 18 30 (36) KV CABLESDocument6 pages1C 630 MM (2xHSYRa2Y) 18 30 (36) KV CABLESanamulk-1No ratings yet

- 33 KV 3 Core Aluminium XLPE CableDocument3 pages33 KV 3 Core Aluminium XLPE CableSai KumarNo ratings yet

- BCC 23120008Document2 pagesBCC 23120008abdulkawi alasharyNo ratings yet

- 300 RM 31.5 Ka 1sec SpecificationDocument4 pages300 RM 31.5 Ka 1sec SpecificationAbdullah Al AsikNo ratings yet

- 79 2X (ST) YRY TiMF 5x3x1.5 BK 300-500V HelukableDocument1 page79 2X (ST) YRY TiMF 5x3x1.5 BK 300-500V HelukableSittiporn TamngamNo ratings yet

- SG-SP-M-006 - Cable Datasheet - 200629 - Cat-ADocument14 pagesSG-SP-M-006 - Cable Datasheet - 200629 - Cat-AanamulkabirNo ratings yet

- (N) 2XSEHRGbH (N2XSEOHROH) 3x120-70 MM 12-20 KV IEC 14.10.2020Document1 page(N) 2XSEHRGbH (N2XSEOHROH) 3x120-70 MM 12-20 KV IEC 14.10.2020Marco Cordova RicraNo ratings yet

- 4x10mm NCU-XLPE-PVC 1 KV (TD)Document2 pages4x10mm NCU-XLPE-PVC 1 KV (TD)nadeem UddinNo ratings yet

- Fuse Modular Terminal Block - DT 6/2,5-DREHSILED 24 (5X20) - 3034251Document18 pagesFuse Modular Terminal Block - DT 6/2,5-DREHSILED 24 (5X20) - 3034251Ade Y SaputraNo ratings yet

- Pgvac4036 51Document3 pagesPgvac4036 51aidin.ashtariNo ratings yet

- Spec - AAAC CAIRO DARIEN OPGWDocument4 pagesSpec - AAAC CAIRO DARIEN OPGWErnesto Antonio Astorga FloresNo ratings yet

- Instrumentation Cable: ApplicationDocument2 pagesInstrumentation Cable: Applicationbakien-canNo ratings yet

- RRU AISG Cable Assembly SpecificationDocument9 pagesRRU AISG Cable Assembly SpecificationBayu AndriantoNo ratings yet

- GEN GP 208 5143 SRNo A1 141010 PDFDocument4 pagesGEN GP 208 5143 SRNo A1 141010 PDFdamlanNo ratings yet

- 9844 - Techdata RS 485Document2 pages9844 - Techdata RS 485Anonymous zMWvcTNo ratings yet

- Datos CableDocument3 pagesDatos CablePablo Briceño NavarroNo ratings yet

- ZTT MV Power Cable Rev A 20181228Document5 pagesZTT MV Power Cable Rev A 20181228Jean Pierre GoossensNo ratings yet

- Technology Department Technical Data Sheet Low Voltage Power CableDocument2 pagesTechnology Department Technical Data Sheet Low Voltage Power CableMuhammad ShahidNo ratings yet

- 3107A TechdataDocument2 pages3107A TechdataComercial FirenoNo ratings yet

- NA2XS (F) 2Y 26-45 KV 1x120Document2 pagesNA2XS (F) 2Y 26-45 KV 1x120plavi10No ratings yet

- Universal Cable (M) Berhad: Schedule of Technical ParticularsDocument1 pageUniversal Cable (M) Berhad: Schedule of Technical Particularsmohd darusNo ratings yet

- XLPE Cu 115kV, 300mm2 1-Core, CuXLPECWS (31.5ka) APL HDPE Data SheetDocument2 pagesXLPE Cu 115kV, 300mm2 1-Core, CuXLPECWS (31.5ka) APL HDPE Data SheetJean CarlosNo ratings yet

- (CS29) Ultra Low Loss Double Shielded CableDocument2 pages(CS29) Ultra Low Loss Double Shielded CableDavid E. I. GallardoNo ratings yet

- CS29 CableDocument2 pagesCS29 Cablegrilleflapper.00No ratings yet

- N10P 1.5en50288 Isos PDFDocument2 pagesN10P 1.5en50288 Isos PDFRijo RajanNo ratings yet

- N10P 1.5en50288 IsosDocument2 pagesN10P 1.5en50288 IsosRijo RajanNo ratings yet

- 3x1.5 RM Flexible-FRDocument1 page3x1.5 RM Flexible-FRAnonymous ntMNpvNo ratings yet

- Nexans 10px 0.75mm2 MGT Xlpe Isos LSZH Swa LSZHDocument2 pagesNexans 10px 0.75mm2 MGT Xlpe Isos LSZH Swa LSZHRijo RajanNo ratings yet

- TECHNICAL SPECIFICATION - POWER FRC CABLE-Hyundai Engineering - WP-1 LINE Project - LSAG 25NOV2022Document6 pagesTECHNICAL SPECIFICATION - POWER FRC CABLE-Hyundai Engineering - WP-1 LINE Project - LSAG 25NOV2022nnNo ratings yet

- 0.6-1kV HFCO 4C (23.08.18) - N.C - CAT ADocument6 pages0.6-1kV HFCO 4C (23.08.18) - N.C - CAT AQuang LuongNo ratings yet

- DS - (Q-0456-R2) Agrawal Machinery Stroes - LT Screen & InstDocument3 pagesDS - (Q-0456-R2) Agrawal Machinery Stroes - LT Screen & InstAppzNo ratings yet

- Freedm B2 Breakout Tight Buffer Indoor/ Outdoor Cable (2.4 MM)Document4 pagesFreedm B2 Breakout Tight Buffer Indoor/ Outdoor Cable (2.4 MM)Franklin CabreraNo ratings yet

- Nextractc1 6KNDocument5 pagesNextractc1 6KNgeorgeta.dumitrache50No ratings yet

- Li# 1 - 3c X 70 + 35mm2 Swa Fr-3 BahraDocument2 pagesLi# 1 - 3c X 70 + 35mm2 Swa Fr-3 BahraMuhammad ShahidNo ratings yet

- 9843 Techdata-1388896Document3 pages9843 Techdata-1388896Marco ApellidoNo ratings yet

- Cable 2744652Document3 pagesCable 2744652Alicia AltamiranoNo ratings yet

- 33 KV Single Core Copper XLPE CableDocument3 pages33 KV Single Core Copper XLPE CableSai KumarNo ratings yet

- Data Sheet For LT XLPE Cable: S.No Particulars 3.5 X 50Document2 pagesData Sheet For LT XLPE Cable: S.No Particulars 3.5 X 50AteebNo ratings yet

- Automated Optical Inspection: Advancements in Computer Vision TechnologyFrom EverandAutomated Optical Inspection: Advancements in Computer Vision TechnologyNo ratings yet

- Principles and Interpretation of CardiotocographyDocument9 pagesPrinciples and Interpretation of CardiotocographyCKNo ratings yet

- Eerc 07 01Document73 pagesEerc 07 01Hugo BobadillaNo ratings yet

- Uk Erik Common Rail Nozzle Catalogue 2014 PDFDocument13 pagesUk Erik Common Rail Nozzle Catalogue 2014 PDFjeferson de castro souzaNo ratings yet

- Un Român, Aeronaut În Polonia, La Începutul Secolului Al Xix - Lea: Iordache CuparencuDocument26 pagesUn Român, Aeronaut În Polonia, La Începutul Secolului Al Xix - Lea: Iordache CuparencuCodrin Codrin100% (1)

- Radha BurnierDocument1 pageRadha BurnierarpitaNo ratings yet

- Bersa Arms 2011 CatalogDocument16 pagesBersa Arms 2011 CatalogAmmoLand Shooting Sports News100% (1)

- Mvc2 ManualDocument49 pagesMvc2 ManualMICHELLE ALEXANDRA SOTOMAYOR MONTECINOSNo ratings yet

- 7 Principles of An EagleDocument2 pages7 Principles of An EagleDhruti BotadraNo ratings yet

- RM RM RM RM RM: 3684nwxci 3684wxci Aspire 5583wxmi Aspire 5573A Wxmi Aspire 5054nwxmiDocument1 pageRM RM RM RM RM: 3684nwxci 3684wxci Aspire 5583wxmi Aspire 5573A Wxmi Aspire 5054nwxmialexcus1539No ratings yet

- Tishk International University: ApixabanDocument4 pagesTishk International University: ApixabanDyar MzafarNo ratings yet

- Classified: Your Local MarketplaceDocument4 pagesClassified: Your Local MarketplaceDigital MediaNo ratings yet

- Integrated Circuits Applications Laboratory: Lab ManualDocument72 pagesIntegrated Circuits Applications Laboratory: Lab ManualRajkumar RajNo ratings yet

- Fire Pump Field Acceptance TestDocument23 pagesFire Pump Field Acceptance Testwalitedison100% (1)

- Ocean Acidification - Yet Another Wobbly Pillar of Climate AlarmismDocument6 pagesOcean Acidification - Yet Another Wobbly Pillar of Climate AlarmismcaioNo ratings yet

- Annotated BibliographyDocument15 pagesAnnotated Bibliographyapi-190312542No ratings yet

- Camouflage Matt EnamelsDocument3 pagesCamouflage Matt EnamelsIqra AngelsNo ratings yet

- Solar Street LightDocument26 pagesSolar Street LightAr Abhinav SrivastavNo ratings yet

- Cleanupdrive Project ProposalDocument13 pagesCleanupdrive Project ProposalAllyn Chabill AlmiranteNo ratings yet

- Extended Sample Invoice 0001Document1 pageExtended Sample Invoice 0001importvalleNo ratings yet

- LG 26lc51-c 26lc7r Chassis Lp78a SMDocument30 pagesLG 26lc51-c 26lc7r Chassis Lp78a SMВМалиновNo ratings yet

- Nuclear Power Gcse CourseworkDocument8 pagesNuclear Power Gcse Courseworkbcqneexy100% (2)

- Chapter 1 - CONCEPT OF PLANT BIOTECH AGT 566Document33 pagesChapter 1 - CONCEPT OF PLANT BIOTECH AGT 566Xwag 12No ratings yet

- Bridge Axi AhbDocument22 pagesBridge Axi Ahbkrishnaav100% (1)

- Euro Currency MarketDocument33 pagesEuro Currency Marketsfkokane83% (6)

- BVR F15.fr - enDocument25 pagesBVR F15.fr - endundun92100% (1)

- Chromosome Mapping by Conjugation ExperimentsDocument26 pagesChromosome Mapping by Conjugation ExperimentskittyngameNo ratings yet

- ICT 1105 Assignment 2Document23 pagesICT 1105 Assignment 2Rachel NgNo ratings yet

- Control Panel ETV 0551Document40 pagesControl Panel ETV 0551Thillainathan So ThanabhalanNo ratings yet

- Schrack Accessories Industrial Power Relay RT: General Purpose RelaysDocument6 pagesSchrack Accessories Industrial Power Relay RT: General Purpose RelaysUlfran MedinaNo ratings yet