Professional Documents

Culture Documents

Ultrosound

Ultrosound

Uploaded by

devanarayan2000Copyright:

Available Formats

You might also like

- CT Calculation & BEF Report ICADocument24 pagesCT Calculation & BEF Report ICALim EugeneNo ratings yet

- Lab 1Document11 pagesLab 1Amar DixitNo ratings yet

- Laser Doppler Vibrometry and Modal TestingDocument17 pagesLaser Doppler Vibrometry and Modal TestingNanda KurniaNo ratings yet

- Laser-Based Optical Facility For Determination of Refractive Index of LiquidsDocument10 pagesLaser-Based Optical Facility For Determination of Refractive Index of LiquidsBABYNISHA N MNo ratings yet

- A Novel Technique For Measuring The Pulsewidth of Nanosecond Laser PulsesDocument4 pagesA Novel Technique For Measuring The Pulsewidth of Nanosecond Laser PulsesGindra WinaldiNo ratings yet

- Mass Loading EffectDocument4 pagesMass Loading EffectGrudge stanleyNo ratings yet

- 2005-Laser Doppler Velocimetry Based On The Photoacoustic Effect in A CO2 LaserDocument4 pages2005-Laser Doppler Velocimetry Based On The Photoacoustic Effect in A CO2 LaserAndrés Oswaldo Rivera HérnandezNo ratings yet

- Study On Partial Discharge Fault Diagnosis of High Voltage Switchboard Based On Ultrasound DetectionDocument8 pagesStudy On Partial Discharge Fault Diagnosis of High Voltage Switchboard Based On Ultrasound DetectionAM KANo ratings yet

- Acoustic Wave Propegation in Pressure Sense LinesDocument4 pagesAcoustic Wave Propegation in Pressure Sense Linestw2skgfcmhwtgh2pw04No ratings yet

- Radiometry Lab 1Document8 pagesRadiometry Lab 1CyrilNo ratings yet

- Signal and Image Processing of Optical Coherence Tomography at 1310 NM Wavelength For Non Biological SamplesDocument11 pagesSignal and Image Processing of Optical Coherence Tomography at 1310 NM Wavelength For Non Biological SamplesSusilawati ESNo ratings yet

- Non Destructive TestingDocument10 pagesNon Destructive Testingcheikh ahmedNo ratings yet

- Dynamic Light Scattering: Applications To Food Systems: D. G. Dalgleish and F. R. Hallett#Document13 pagesDynamic Light Scattering: Applications To Food Systems: D. G. Dalgleish and F. R. Hallett#Javier carretero mendozaNo ratings yet

- A Project Report On Ultrasonic RANGE FINDER Using Micrcontroller ATmel 89C2051Document56 pagesA Project Report On Ultrasonic RANGE FINDER Using Micrcontroller ATmel 89C2051Nishit Chittora47% (15)

- Honey ExpDocument13 pagesHoney ExpMohammad Fazail BangashNo ratings yet

- Microcontroller Based Visible Light Spectrometer: Keshav Dhikale, Abhijeet Shimpi, Rushikesh Raut D.A.GhogareDocument4 pagesMicrocontroller Based Visible Light Spectrometer: Keshav Dhikale, Abhijeet Shimpi, Rushikesh Raut D.A.GhogareAnthropology BooksNo ratings yet

- Acoustic LidarDocument4 pagesAcoustic LidardrphysicsNo ratings yet

- Kellnerova - 2011 - Comparison of Wavelet Analysis With Velocity Derivatives For Detection of ShearDocument11 pagesKellnerova - 2011 - Comparison of Wavelet Analysis With Velocity Derivatives For Detection of Sheardoutor manelNo ratings yet

- Thaw Tar Thein Zan Kai-Juan Wong Hock-Beng Lim Andrew J. Whittle Bu-Sung LeeDocument5 pagesThaw Tar Thein Zan Kai-Juan Wong Hock-Beng Lim Andrew J. Whittle Bu-Sung LeeBrenner Biasi SilvaNo ratings yet

- Richter 1997Document10 pagesRichter 1997KazuoNo ratings yet

- The Laser Torsional Vibrometer: A Step Forward in Rotating Machinery DiagnosticsDocument20 pagesThe Laser Torsional Vibrometer: A Step Forward in Rotating Machinery DiagnosticsNini CortesNo ratings yet

- N - 1431 - PHY Practical2Document7 pagesN - 1431 - PHY Practical2Swarup DevdeNo ratings yet

- Average Power Meter For Laser RadiationDocument6 pagesAverage Power Meter For Laser Radiationoscar_sm77No ratings yet

- Engineering Physics WriteupDocument5 pagesEngineering Physics WriteupShrey JhaNo ratings yet

- Refractive Index Sprial Increase DistanceDocument6 pagesRefractive Index Sprial Increase DistanceShams AliNo ratings yet

- Ultrasonic Sensor-09Document10 pagesUltrasonic Sensor-09Ayesha NaseemNo ratings yet

- RSRMDocument30 pagesRSRMKevin RiosNo ratings yet

- Costes 1988Document14 pagesCostes 1988Akella Surya Prakasa DeekshithNo ratings yet

- AEI405Document27 pagesAEI405api-26787131No ratings yet

- 2-Crystal DetectorDocument5 pages2-Crystal DetectorSaransh MaheshwariNo ratings yet

- 1 5 11 PDFDocument3 pages1 5 11 PDFAfshaNo ratings yet

- Venkataraman EE816 NotebookDocument32 pagesVenkataraman EE816 NotebookRintuMathunniNo ratings yet

- Journal of Quantitative Spectroscopy & Radiative Transfer: Andre Hollstein, J Urgen FischerDocument13 pagesJournal of Quantitative Spectroscopy & Radiative Transfer: Andre Hollstein, J Urgen FischerFelicia CarbunaruNo ratings yet

- A Design of An Acousto-Optical SpectrometerDocument4 pagesA Design of An Acousto-Optical Spectrometeranasrl2006No ratings yet

- A Scintillator Based Halo-Detector For Beam Position MonitoringDocument3 pagesA Scintillator Based Halo-Detector For Beam Position MonitoringSean Captain HonestlagoNo ratings yet

- A Functional Form For Liquid Scintillator Pulse ShapesDocument14 pagesA Functional Form For Liquid Scintillator Pulse ShapesfraNo ratings yet

- 2017 JINST - 001T - 0617 (Fast and Simple Glass)Document12 pages2017 JINST - 001T - 0617 (Fast and Simple Glass)Marina VildanovaNo ratings yet

- Comparison of TOF, FMCW and Phase-Shift Laser Range-Finding Methods by Simulation and MeasurementDocument9 pagesComparison of TOF, FMCW and Phase-Shift Laser Range-Finding Methods by Simulation and Measurementdogukan duranNo ratings yet

- Frequency Detection in Vortex Flowmeter For Low Reynolds Number Using Piezoelectric Sensor and Installation EffectsDocument9 pagesFrequency Detection in Vortex Flowmeter For Low Reynolds Number Using Piezoelectric Sensor and Installation EffectsBurak YalımNo ratings yet

- Direct Measurement of Cold Neutron Moderator Spectra: Article in PressDocument5 pagesDirect Measurement of Cold Neutron Moderator Spectra: Article in PressPaul AsturbiarisNo ratings yet

- 2021-OL-single Shot Interferometric Measurement of Cavitation Bubble Dynamics PDFDocument4 pages2021-OL-single Shot Interferometric Measurement of Cavitation Bubble Dynamics PDFzyxNo ratings yet

- Sensors and Actuators A: PhysicalDocument8 pagesSensors and Actuators A: PhysicalElectronic BoyNo ratings yet

- RevSciInstrum 82 115001Document4 pagesRevSciInstrum 82 115001Kevin LiuNo ratings yet

- Mastromarino 2021 Meas. Sci. Technol. 32 125305Document12 pagesMastromarino 2021 Meas. Sci. Technol. 32 125305manishNo ratings yet

- Particle-In-Cell Simulation of A Novel High Power Terahertz Vacuum Electron DeviceDocument6 pagesParticle-In-Cell Simulation of A Novel High Power Terahertz Vacuum Electron Deviceharun hakshiNo ratings yet

- Ultra 7Document7 pagesUltra 7Raj RajNo ratings yet

- Vibrational Spectroscopy: An Integrated ExperimentDocument21 pagesVibrational Spectroscopy: An Integrated ExperimentJonathanNo ratings yet

- Ultrasonic InterferometerDocument6 pagesUltrasonic Interferometeramathya45No ratings yet

- Venu SPIE3 2008 BaccaratDocument10 pagesVenu SPIE3 2008 Baccaratsoma_venuNo ratings yet

- Lab 1 Visit To KCREDocument5 pagesLab 1 Visit To KCRESuyog BhattaraiNo ratings yet

- Electricity & MagnetismDocument17 pagesElectricity & MagnetismAnadélys BenoitNo ratings yet

- Galaxies 10 00046Document16 pagesGalaxies 10 00046tosta ricaNo ratings yet

- 3-D Finite Element Modeling of Nanostructure Enhanced SAW SensorDocument6 pages3-D Finite Element Modeling of Nanostructure Enhanced SAW SensornitinsriniwasNo ratings yet

- B - 2001 - 308-310 - 942 - ZnSe-Cr - IR PL - Excitation MechanizmDocument3 pagesB - 2001 - 308-310 - 942 - ZnSe-Cr - IR PL - Excitation MechanizmAlexanderNo ratings yet

- DC-readout of A Signal-Recycled Gravitational Wave DetectorDocument11 pagesDC-readout of A Signal-Recycled Gravitational Wave DetectorArtyomNo ratings yet

- Microwave SensorDocument25 pagesMicrowave Sensorshek sonsonNo ratings yet

- aaaNIM Paper Draft2Document16 pagesaaaNIM Paper Draft2Yemi AdetayoNo ratings yet

- Ultrasonic InterferometerDocument11 pagesUltrasonic InterferometerramsheydjNo ratings yet

- Paper Velocimeter SPIE RS07Document12 pagesPaper Velocimeter SPIE RS07Mounika ReddyNo ratings yet

- Laser Metrology in Fluid Mechanics: Granulometry, Temperature and Concentration MeasurementsFrom EverandLaser Metrology in Fluid Mechanics: Granulometry, Temperature and Concentration MeasurementsNo ratings yet

- Estimation of No-Load Losses in Distribution Transformer Design Finite Element Analysis Techniques in Transformer DesignDocument7 pagesEstimation of No-Load Losses in Distribution Transformer Design Finite Element Analysis Techniques in Transformer DesignJorge EnriqueNo ratings yet

- Measuring Paved Surface Frictional Properties Using The Dynamic Friction TesterDocument5 pagesMeasuring Paved Surface Frictional Properties Using The Dynamic Friction TesterEric GozzerNo ratings yet

- Total StationDocument15 pagesTotal StationDream zone EngineeringNo ratings yet

- Extra Problems On Chapter 3Document32 pagesExtra Problems On Chapter 3unicorn angelNo ratings yet

- Power Supply SDR-480-24Document3 pagesPower Supply SDR-480-24sarah sahraouiNo ratings yet

- Experimental Values of Thermal Conductivity of Selected Fruits AND VegetablesDocument4 pagesExperimental Values of Thermal Conductivity of Selected Fruits AND VegetablesSergio David Vargas GarzonNo ratings yet

- Environmental Conditions and Environmental LoadsDocument22 pagesEnvironmental Conditions and Environmental LoadsrublasterNo ratings yet

- Military Institute of Science & TechnologyDocument3 pagesMilitary Institute of Science & Technologyahmed rifatNo ratings yet

- Solar Refrigeration Using Peltier ModuleDocument5 pagesSolar Refrigeration Using Peltier ModulePrachurjya BaruahNo ratings yet

- (SSLC) Constants and ConversionsDocument4 pages(SSLC) Constants and ConversionsJamilaWeinPerilloQuintanaNo ratings yet

- Endress-Hauser Prothermo NMT81 enDocument3 pagesEndress-Hauser Prothermo NMT81 enYayan SuhendiNo ratings yet

- 9702 As Physics 12Document317 pages9702 As Physics 12Vinod RNo ratings yet

- Viscosity Measurements On Gaseous Sulfur Hexafluoride (Wilhelm2005)Document11 pagesViscosity Measurements On Gaseous Sulfur Hexafluoride (Wilhelm2005)daegerteNo ratings yet

- MCAT Physics Question PracticeDocument3 pagesMCAT Physics Question PracticeThao NguyenNo ratings yet

- Wiring Ac Doorstrike ButterflymxDocument1 pageWiring Ac Doorstrike ButterflymxadenijisegunNo ratings yet

- NEET 2023 Question Paper F3Document44 pagesNEET 2023 Question Paper F3simantkaushik18No ratings yet

- B.SC Physics - 2019-2020Document90 pagesB.SC Physics - 2019-2020Babitha DhanaNo ratings yet

- Dual Nature of Radiation & Matter - 2022Document4 pagesDual Nature of Radiation & Matter - 20221128.Sakshi MauryaNo ratings yet

- VanillinDocument17 pagesVanillinMuneebNo ratings yet

- NTi Audio Impedance Testing of Evacuation SystemsDocument9 pagesNTi Audio Impedance Testing of Evacuation SystemsSuperhypoNo ratings yet

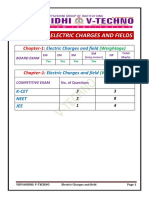

- Electric Charges & Fields. Full Notes21Document15 pagesElectric Charges & Fields. Full Notes21DHANUSH PATEL .MNo ratings yet

- TEST B MCQsDocument83 pagesTEST B MCQsMaanat Hemant BhadaniNo ratings yet

- QUIZ Chemistry SlidesDocument206 pagesQUIZ Chemistry SlidesVAIBHAV VAIBHAVNo ratings yet

- Turbine Flow MeterDocument3 pagesTurbine Flow MeterJatin RamboNo ratings yet

- Q4 - Science 10 - Week 2Document8 pagesQ4 - Science 10 - Week 2Rayza CatrizNo ratings yet

- AC와 DC RMS 의미Document2 pagesAC와 DC RMS 의미stormstoneNo ratings yet

- ClassificationDocument7 pagesClassificationj9048191078No ratings yet

- PHY01 LabReport4-GROUP4Document11 pagesPHY01 LabReport4-GROUP4okNo ratings yet

- Turbine Meter TrainingDocument77 pagesTurbine Meter TrainingJazielNo ratings yet

Ultrosound

Ultrosound

Uploaded by

devanarayan2000Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ultrosound

Ultrosound

Uploaded by

devanarayan2000Copyright:

Available Formats

Measurement of Ultrasonic Wave Velocity in a Liquid

Devanarayan Saljith (IMS21055)1

1

IISER TVM

(Dated: August 30, 2023)

This report presents the experimental setup and procedure for measuring the velocity of ultrasonic

waves in a liquid using the interference of ultrasonic waves and laser diffraction. The experiment

involves various components including piezoelectric crystals, lasers, detectors, and liquid-filled glass

tanks. The aim of the experiment is to determine the velocity of ultrasonic waves in the liquid and

related properties such as bulk modulus and compressibility. The report outlines the theoretical

background, experimental setup, observations, and measurements.

PACS numbers:

I. INTRODUCTION III. OBSERVATIONS AND MEASUREMENTS

Ultrasonic waves have significant applications in var- A. Diffraction Pattern

ious fields, including material characterization and non-

destructive testing. This experiment aims to measure the

velocity of ultrasonic waves in a liquid using the interfer- Adjust the frequency of the oscillator until a clear

ence pattern produced by the interaction of ultrasonic fringe pattern appears on both sides of the central bright

waves and a diode laser. The interference pattern allows spot. Using the micrometer-driven stage, move the de-

us to extract valuable information about the properties tector along the diffraction pattern and record the read-

of the medium, including its velocity, bulk modulus, and ings of the micrometer and the corresponding detector

compressibility. output.

II. EXPERIMENTAL SETUP

• Wavelength of laser,λ = 650nm

The experimental setup consists of a glass tank filled

with the liquid under investigation, a piezoelectric crystal

connected to an RF oscillator, a diode laser, a translation • Least count of the micrometer = 0.01mm

stage with a detector, and various optical components for

laser alignment and diffraction pattern observation.

• Distance between the crystal and the detector,L =

1145mm

A. Procedure

1. Fix the laser mount on the optical rail and properly

place the laser on the mount. • Frequency of the crystal,v =3.15 MHz

2. Fill the glass tank with the liquid and position it

on the tank holder. Micrometer reading (mm) Detector Output (uA)

8.35 0.7

3. Mount the piezoelectric crystal on a holder and im- 6.02 10.1

merse it fully in the liquid. Connect it to the RF 4.85 49.5

oscillator. 2.57 8.9

1.36 0.5

4. Attach the translation stage with the detector to

the rail. Adjust the laser spot to fall onto the de-

tector stage.

5. Align the crystal and laser for a parallel beam con-

figuration and set up the kinematic setup for stand-

ing wave generation. B. Analysis

6. Ensure there are no air bubbles around the crystal

and that the laser beam hits the pinhole detector

accurately. Plotting from data:

2

Distance Vs detector current

60

50

Detector Output (uA

40

30

20

10

0

−6 −4 −2 0 2 4 6

Distance(mm)

From the collected data, calculate the distance from

the central bright spot to the n-th order spot (D)

and the angle of ultrasonic diffraction (θ). Use FIG. 1: Image

these values to calculate the wavelength of the laser

in the liquid medium (Λ).

relevant formulas, we successfully determined the

From Graph

velocity of ultrasonic waves in the liquid. This ap-

order(n) D (m) θ = tan−1 (D/L) Λ = nλsin(θ) V=(v)Λ(m/s)

proach provides insights into the bulk modulus and

2(L) -0.00349 -0.174 0.000428 1348.4 compressibility of the liquid, making it a valuable

1(L) -0.00228 -0.114 0.000326 1026.9 technique for material characterization.

1(R) 0.00117 0.0585 0.000633 1993.95

2(R) 0.0035 0.17 0.000438 1379.7

Mean velocity = 1436.82 m/s

The Bulk modulus β(pV2 ) = 2.058x109 P a

The Compressibility κ(1/β) = 4.85x10−10 P a−1

IV. RESULTS

Using the calculated values of wavelength, you can

determine the velocity of ultrasonic waves in the

liquid using the formula ν = Λf , where f is the

frequency of the crystal oscillator.

Mean velocity = 1436.82 m/s

The Bulk modulus β(pV2 ) = 2.058x109 P a

The Compressibility κ(1/β) =

4.85x10−10 P a−1

V. CONCLUSION

This experiment demonstrated the measurement of

ultrasonic wave velocity in a liquid using the in-

terference of ultrasonic waves and laser diffraction.

By analyzing the diffraction pattern and applying

Measurement of Ultrasonic Wave Velocity in a Immiscible Liquid

Devanarayan Saljith (IMS21055)1

1

IISER TVM

(Dated: August 30, 2023)

This report presents the experimental setup and procedure for measuring the velocity of ultrasonic

waves in a liquid using the interference of ultrasonic waves and laser diffraction. The experiment

involves various components including piezoelectric crystals, lasers, detectors, and liquid-filled glass

tanks, Two immiscible liquids. The aim of the experiment is to determine the velocity of ultrasonic

waves in the 2 liquids and related properties such as bulk modulus and compressibility. The report

outlines the theoretical background, experimental setup, observations, and measurements.

PACS numbers:

I. INTRODUCTION III. OBSERVATIONS AND MEASUREMENTS

Ultrasonic waves have significant applications in var- A. Diffraction Pattern

ious fields, including material characterization and non-

destructive testing. This experiment aims to measure the Adjust the frequency of the oscillator until a clear

velocity of ultrasonic waves in a liquid using the interfer- fringe pattern appears on both sides of the central bright

ence pattern produced by the interaction of ultrasonic spot. Using the micrometer-driven stage, move the de-

waves and a diode laser. The interference pattern allows tector along the diffraction pattern and record the read-

us to extract valuable information about the properties ings of the micrometer and the corresponding detector

of the medium, including its velocity, bulk modulus, and output.

compressibility.

B. Analysis

II. EXPERIMENTAL SETUP

Changing the liqiud means that thr velocity also varies

The experimental setup consists of a glass tank filled in the medium, and as the frequency remains constant,

with the liquid under investigation, a piezoelectric crystal the wavelength varies. We tried replacing the water

connected to an RF oscillator, a diode laser, a translation medium oil and then air,both of which admitted a higher

stage with a detector, and various optical components for speed through them, thus enabling a larger wavelength

laser alignment and diffraction pattern observation. and varying the pattern to a wider one, which was not

captured in the screen placed, probably because the pat-

tern itself collapsed. The placement of oil over water and

A. Procedure then laser beam through it also yielded the same result.

1. Fix the laser mount on the optical rail and properly

place the laser on the mount. IV. INFERENCE

2. Fill the glass tank with the liquid and position it The result could be explained on the basis of the col-

on the tank holder. lapse of the diffraction pattern. When there is an im-

3. Mount the piezoelectric crystal on a holder and im- miscible oil water layer formed, there is a reduction in

merse it fully in the liquid. Connect it to the RF the intensity f the laser beam that is entering water thus

oscillator. removing the pattern was observed. This is a very useful

technique to calculate the velocity of sound in a medium

4. Attach the translation stage with the detector to and thus the bulk modulus and compressibility.

the rail. Adjust the laser spot to fall onto the de-

tector stage.

5. Align the crystal and laser for a parallel beam con-

figuration and set up the kinematic setup for stand-

ing wave generation.

6. Ensure there are no air bubbles around the crystal

and that the laser beam hits the pinhole detector

accurately.

You might also like

- CT Calculation & BEF Report ICADocument24 pagesCT Calculation & BEF Report ICALim EugeneNo ratings yet

- Lab 1Document11 pagesLab 1Amar DixitNo ratings yet

- Laser Doppler Vibrometry and Modal TestingDocument17 pagesLaser Doppler Vibrometry and Modal TestingNanda KurniaNo ratings yet

- Laser-Based Optical Facility For Determination of Refractive Index of LiquidsDocument10 pagesLaser-Based Optical Facility For Determination of Refractive Index of LiquidsBABYNISHA N MNo ratings yet

- A Novel Technique For Measuring The Pulsewidth of Nanosecond Laser PulsesDocument4 pagesA Novel Technique For Measuring The Pulsewidth of Nanosecond Laser PulsesGindra WinaldiNo ratings yet

- Mass Loading EffectDocument4 pagesMass Loading EffectGrudge stanleyNo ratings yet

- 2005-Laser Doppler Velocimetry Based On The Photoacoustic Effect in A CO2 LaserDocument4 pages2005-Laser Doppler Velocimetry Based On The Photoacoustic Effect in A CO2 LaserAndrés Oswaldo Rivera HérnandezNo ratings yet

- Study On Partial Discharge Fault Diagnosis of High Voltage Switchboard Based On Ultrasound DetectionDocument8 pagesStudy On Partial Discharge Fault Diagnosis of High Voltage Switchboard Based On Ultrasound DetectionAM KANo ratings yet

- Acoustic Wave Propegation in Pressure Sense LinesDocument4 pagesAcoustic Wave Propegation in Pressure Sense Linestw2skgfcmhwtgh2pw04No ratings yet

- Radiometry Lab 1Document8 pagesRadiometry Lab 1CyrilNo ratings yet

- Signal and Image Processing of Optical Coherence Tomography at 1310 NM Wavelength For Non Biological SamplesDocument11 pagesSignal and Image Processing of Optical Coherence Tomography at 1310 NM Wavelength For Non Biological SamplesSusilawati ESNo ratings yet

- Non Destructive TestingDocument10 pagesNon Destructive Testingcheikh ahmedNo ratings yet

- Dynamic Light Scattering: Applications To Food Systems: D. G. Dalgleish and F. R. Hallett#Document13 pagesDynamic Light Scattering: Applications To Food Systems: D. G. Dalgleish and F. R. Hallett#Javier carretero mendozaNo ratings yet

- A Project Report On Ultrasonic RANGE FINDER Using Micrcontroller ATmel 89C2051Document56 pagesA Project Report On Ultrasonic RANGE FINDER Using Micrcontroller ATmel 89C2051Nishit Chittora47% (15)

- Honey ExpDocument13 pagesHoney ExpMohammad Fazail BangashNo ratings yet

- Microcontroller Based Visible Light Spectrometer: Keshav Dhikale, Abhijeet Shimpi, Rushikesh Raut D.A.GhogareDocument4 pagesMicrocontroller Based Visible Light Spectrometer: Keshav Dhikale, Abhijeet Shimpi, Rushikesh Raut D.A.GhogareAnthropology BooksNo ratings yet

- Acoustic LidarDocument4 pagesAcoustic LidardrphysicsNo ratings yet

- Kellnerova - 2011 - Comparison of Wavelet Analysis With Velocity Derivatives For Detection of ShearDocument11 pagesKellnerova - 2011 - Comparison of Wavelet Analysis With Velocity Derivatives For Detection of Sheardoutor manelNo ratings yet

- Thaw Tar Thein Zan Kai-Juan Wong Hock-Beng Lim Andrew J. Whittle Bu-Sung LeeDocument5 pagesThaw Tar Thein Zan Kai-Juan Wong Hock-Beng Lim Andrew J. Whittle Bu-Sung LeeBrenner Biasi SilvaNo ratings yet

- Richter 1997Document10 pagesRichter 1997KazuoNo ratings yet

- The Laser Torsional Vibrometer: A Step Forward in Rotating Machinery DiagnosticsDocument20 pagesThe Laser Torsional Vibrometer: A Step Forward in Rotating Machinery DiagnosticsNini CortesNo ratings yet

- N - 1431 - PHY Practical2Document7 pagesN - 1431 - PHY Practical2Swarup DevdeNo ratings yet

- Average Power Meter For Laser RadiationDocument6 pagesAverage Power Meter For Laser Radiationoscar_sm77No ratings yet

- Engineering Physics WriteupDocument5 pagesEngineering Physics WriteupShrey JhaNo ratings yet

- Refractive Index Sprial Increase DistanceDocument6 pagesRefractive Index Sprial Increase DistanceShams AliNo ratings yet

- Ultrasonic Sensor-09Document10 pagesUltrasonic Sensor-09Ayesha NaseemNo ratings yet

- RSRMDocument30 pagesRSRMKevin RiosNo ratings yet

- Costes 1988Document14 pagesCostes 1988Akella Surya Prakasa DeekshithNo ratings yet

- AEI405Document27 pagesAEI405api-26787131No ratings yet

- 2-Crystal DetectorDocument5 pages2-Crystal DetectorSaransh MaheshwariNo ratings yet

- 1 5 11 PDFDocument3 pages1 5 11 PDFAfshaNo ratings yet

- Venkataraman EE816 NotebookDocument32 pagesVenkataraman EE816 NotebookRintuMathunniNo ratings yet

- Journal of Quantitative Spectroscopy & Radiative Transfer: Andre Hollstein, J Urgen FischerDocument13 pagesJournal of Quantitative Spectroscopy & Radiative Transfer: Andre Hollstein, J Urgen FischerFelicia CarbunaruNo ratings yet

- A Design of An Acousto-Optical SpectrometerDocument4 pagesA Design of An Acousto-Optical Spectrometeranasrl2006No ratings yet

- A Scintillator Based Halo-Detector For Beam Position MonitoringDocument3 pagesA Scintillator Based Halo-Detector For Beam Position MonitoringSean Captain HonestlagoNo ratings yet

- A Functional Form For Liquid Scintillator Pulse ShapesDocument14 pagesA Functional Form For Liquid Scintillator Pulse ShapesfraNo ratings yet

- 2017 JINST - 001T - 0617 (Fast and Simple Glass)Document12 pages2017 JINST - 001T - 0617 (Fast and Simple Glass)Marina VildanovaNo ratings yet

- Comparison of TOF, FMCW and Phase-Shift Laser Range-Finding Methods by Simulation and MeasurementDocument9 pagesComparison of TOF, FMCW and Phase-Shift Laser Range-Finding Methods by Simulation and Measurementdogukan duranNo ratings yet

- Frequency Detection in Vortex Flowmeter For Low Reynolds Number Using Piezoelectric Sensor and Installation EffectsDocument9 pagesFrequency Detection in Vortex Flowmeter For Low Reynolds Number Using Piezoelectric Sensor and Installation EffectsBurak YalımNo ratings yet

- Direct Measurement of Cold Neutron Moderator Spectra: Article in PressDocument5 pagesDirect Measurement of Cold Neutron Moderator Spectra: Article in PressPaul AsturbiarisNo ratings yet

- 2021-OL-single Shot Interferometric Measurement of Cavitation Bubble Dynamics PDFDocument4 pages2021-OL-single Shot Interferometric Measurement of Cavitation Bubble Dynamics PDFzyxNo ratings yet

- Sensors and Actuators A: PhysicalDocument8 pagesSensors and Actuators A: PhysicalElectronic BoyNo ratings yet

- RevSciInstrum 82 115001Document4 pagesRevSciInstrum 82 115001Kevin LiuNo ratings yet

- Mastromarino 2021 Meas. Sci. Technol. 32 125305Document12 pagesMastromarino 2021 Meas. Sci. Technol. 32 125305manishNo ratings yet

- Particle-In-Cell Simulation of A Novel High Power Terahertz Vacuum Electron DeviceDocument6 pagesParticle-In-Cell Simulation of A Novel High Power Terahertz Vacuum Electron Deviceharun hakshiNo ratings yet

- Ultra 7Document7 pagesUltra 7Raj RajNo ratings yet

- Vibrational Spectroscopy: An Integrated ExperimentDocument21 pagesVibrational Spectroscopy: An Integrated ExperimentJonathanNo ratings yet

- Ultrasonic InterferometerDocument6 pagesUltrasonic Interferometeramathya45No ratings yet

- Venu SPIE3 2008 BaccaratDocument10 pagesVenu SPIE3 2008 Baccaratsoma_venuNo ratings yet

- Lab 1 Visit To KCREDocument5 pagesLab 1 Visit To KCRESuyog BhattaraiNo ratings yet

- Electricity & MagnetismDocument17 pagesElectricity & MagnetismAnadélys BenoitNo ratings yet

- Galaxies 10 00046Document16 pagesGalaxies 10 00046tosta ricaNo ratings yet

- 3-D Finite Element Modeling of Nanostructure Enhanced SAW SensorDocument6 pages3-D Finite Element Modeling of Nanostructure Enhanced SAW SensornitinsriniwasNo ratings yet

- B - 2001 - 308-310 - 942 - ZnSe-Cr - IR PL - Excitation MechanizmDocument3 pagesB - 2001 - 308-310 - 942 - ZnSe-Cr - IR PL - Excitation MechanizmAlexanderNo ratings yet

- DC-readout of A Signal-Recycled Gravitational Wave DetectorDocument11 pagesDC-readout of A Signal-Recycled Gravitational Wave DetectorArtyomNo ratings yet

- Microwave SensorDocument25 pagesMicrowave Sensorshek sonsonNo ratings yet

- aaaNIM Paper Draft2Document16 pagesaaaNIM Paper Draft2Yemi AdetayoNo ratings yet

- Ultrasonic InterferometerDocument11 pagesUltrasonic InterferometerramsheydjNo ratings yet

- Paper Velocimeter SPIE RS07Document12 pagesPaper Velocimeter SPIE RS07Mounika ReddyNo ratings yet

- Laser Metrology in Fluid Mechanics: Granulometry, Temperature and Concentration MeasurementsFrom EverandLaser Metrology in Fluid Mechanics: Granulometry, Temperature and Concentration MeasurementsNo ratings yet

- Estimation of No-Load Losses in Distribution Transformer Design Finite Element Analysis Techniques in Transformer DesignDocument7 pagesEstimation of No-Load Losses in Distribution Transformer Design Finite Element Analysis Techniques in Transformer DesignJorge EnriqueNo ratings yet

- Measuring Paved Surface Frictional Properties Using The Dynamic Friction TesterDocument5 pagesMeasuring Paved Surface Frictional Properties Using The Dynamic Friction TesterEric GozzerNo ratings yet

- Total StationDocument15 pagesTotal StationDream zone EngineeringNo ratings yet

- Extra Problems On Chapter 3Document32 pagesExtra Problems On Chapter 3unicorn angelNo ratings yet

- Power Supply SDR-480-24Document3 pagesPower Supply SDR-480-24sarah sahraouiNo ratings yet

- Experimental Values of Thermal Conductivity of Selected Fruits AND VegetablesDocument4 pagesExperimental Values of Thermal Conductivity of Selected Fruits AND VegetablesSergio David Vargas GarzonNo ratings yet

- Environmental Conditions and Environmental LoadsDocument22 pagesEnvironmental Conditions and Environmental LoadsrublasterNo ratings yet

- Military Institute of Science & TechnologyDocument3 pagesMilitary Institute of Science & Technologyahmed rifatNo ratings yet

- Solar Refrigeration Using Peltier ModuleDocument5 pagesSolar Refrigeration Using Peltier ModulePrachurjya BaruahNo ratings yet

- (SSLC) Constants and ConversionsDocument4 pages(SSLC) Constants and ConversionsJamilaWeinPerilloQuintanaNo ratings yet

- Endress-Hauser Prothermo NMT81 enDocument3 pagesEndress-Hauser Prothermo NMT81 enYayan SuhendiNo ratings yet

- 9702 As Physics 12Document317 pages9702 As Physics 12Vinod RNo ratings yet

- Viscosity Measurements On Gaseous Sulfur Hexafluoride (Wilhelm2005)Document11 pagesViscosity Measurements On Gaseous Sulfur Hexafluoride (Wilhelm2005)daegerteNo ratings yet

- MCAT Physics Question PracticeDocument3 pagesMCAT Physics Question PracticeThao NguyenNo ratings yet

- Wiring Ac Doorstrike ButterflymxDocument1 pageWiring Ac Doorstrike ButterflymxadenijisegunNo ratings yet

- NEET 2023 Question Paper F3Document44 pagesNEET 2023 Question Paper F3simantkaushik18No ratings yet

- B.SC Physics - 2019-2020Document90 pagesB.SC Physics - 2019-2020Babitha DhanaNo ratings yet

- Dual Nature of Radiation & Matter - 2022Document4 pagesDual Nature of Radiation & Matter - 20221128.Sakshi MauryaNo ratings yet

- VanillinDocument17 pagesVanillinMuneebNo ratings yet

- NTi Audio Impedance Testing of Evacuation SystemsDocument9 pagesNTi Audio Impedance Testing of Evacuation SystemsSuperhypoNo ratings yet

- Electric Charges & Fields. Full Notes21Document15 pagesElectric Charges & Fields. Full Notes21DHANUSH PATEL .MNo ratings yet

- TEST B MCQsDocument83 pagesTEST B MCQsMaanat Hemant BhadaniNo ratings yet

- QUIZ Chemistry SlidesDocument206 pagesQUIZ Chemistry SlidesVAIBHAV VAIBHAVNo ratings yet

- Turbine Flow MeterDocument3 pagesTurbine Flow MeterJatin RamboNo ratings yet

- Q4 - Science 10 - Week 2Document8 pagesQ4 - Science 10 - Week 2Rayza CatrizNo ratings yet

- AC와 DC RMS 의미Document2 pagesAC와 DC RMS 의미stormstoneNo ratings yet

- ClassificationDocument7 pagesClassificationj9048191078No ratings yet

- PHY01 LabReport4-GROUP4Document11 pagesPHY01 LabReport4-GROUP4okNo ratings yet

- Turbine Meter TrainingDocument77 pagesTurbine Meter TrainingJazielNo ratings yet