Professional Documents

Culture Documents

DSE BC2410Ei Installation Instructions

DSE BC2410Ei Installation Instructions

Uploaded by

thaiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DSE BC2410Ei Installation Instructions

DSE BC2410Ei Installation Instructions

Uploaded by

thaiCopyright:

Available Formats

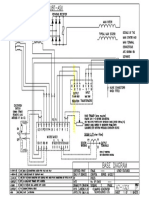

TYPICAL WIRING DIAGRAM DEEP SEA ELECTRONICS 053-251

ISSUE 2

NOTE: A larger version of the Typical Wiring Diagram is available in the product’s operator DSE BC2410Ei Installation Instructions

manual, refer to DSE Publication: 057-316 DSE BC2410Ei Operator Manual available from

www.deepseaelectronics.com for more information. INSTALLATION

The battery charger is wall mounted via four holes at the rear of the enclosure. Dimension and

mounting details are given overleaf. The battery charger is designed as a fit-and-forget device

therefore, is permanently connected to the supply and the load, with no requirement to disable the

charger during heavy load, such as engine cranking, or when in parallel with a charge alternator.

MODEL BC2410Ei BATTERY SUITABILITY

NOTE: With factory default settings, the battery charger produces 0 V until it is connected

to a battery. Once connected it automatically configures to 12 V or 24 V operation.

The battery charger is factory set by DSE to suit Lead Acid batteries and automatically switches

between 12 V or 24 V operation by measuring the battery voltage when connected. The battery

charger can be adjusted to suit many battery types and has the option of fixing the output voltage

range and characteristics using the Configuration Suite PC Software.

Care must be taken to ensure the batteries connected to the charger are of the correct technology to

suit the setting of the charger.

INDICATIONS

The Battery Charger features an LCD display and depending on the variant, additional voltage and

current meters may be fitted.

BOOST MODE

Boost mode is operated automatically or by activation of the digital input (if configured to perform this

function). This raises the battery charger voltage to the boost voltage setting.

ACCESSING THE FRONT PANEL EDITOR

• The Front Panel Editor (FPE) is accessed by pressing and holding the (✓) button for 10

seconds.

• Press the (up) or (down) button to cycle through the Adjustable Parameters listed

overleaf.

• Press the (✓) button to edit a parameter when it is being viewed on the screen. The value

flashes to show edit mode is in progress.

• Press the (+) or (-) button to change the parameter to the required value.

DANGER OF DEATH: LIVE PARTS exist within the enclosure. The enclosure cover must • Press the (✓) button to save the currently selected value. The value ceases flashing to show

not be removed when connected to an AC supply editing is complete.

• Press and hold the (✓) button to exit the editor

Deep Sea Electronics Ltd. Deep Sea Electronics Inc.

Tel:+44 (0)1723 890099 Tel: +1 (815) 316 8706

Email: support@deepseaelectronics.com Email: usasupport@deepseaelectronics.com NOTE: When the editor is left inactive for the duration of the LCD Page Timer, it is

Web: www.deepseaelectronics.com Web: www.deepseaelectronics.com automatically exited to ensure security.

NOTE: Comprehensive module configuration is possible using the DSE Configuration Suite

PC Software, refer to DSE publication 057-315 DSE BC2410Ei Configuration Suite PC Software

Manual available from www.deepseaelectronics.com.

ADJUSTABLE PARAMETERS DIMENSIONS AND MOUNTING

Index Parameter Value

100 Contrast 0%

101 Temperature Units °C, °F

102 Backlight Brightness 0%

103 Backlight and LCD Power save Timeout 0s

104 Enable Alarm Popup Screen Enable, Disable

105 Home Page Configuration 0 to 9 (Home Page List)

106 Home Page Timeout 0s

107 Sleep Mode Timeout 0s

108 Enable Engineering Page Enable, Disable

109 Deep Sleep Mode Timout 0s

Parameter 105 – Home Page Configuration has the following possible selections:

Value Home Page List

0 Analogue Meters

1 Output Voltage And Current

2 Output Power And Battery Charger Temperature

3 Battery Sensed Voltage And Battery Temperature (when enabled)

4 Mains AC Voltage And Frequency

5 Battery Charger Model And Charger Software Version

6 Control Page

7 Alarms Page

8 Engineering Page 1

9 Engineering Page 2

REQUIREMENTS FOR UL CERTIFICATION

WARNING!: More than one live circuit exists, see diagram overleaf for further information.

Parameter Comment

Screw Terminal

4.4 lb-in (0.4 Nm) Parameter Comment

Tightening Torque

Conductors • Terminals suitable for connection of conductor size 20 AWG - 13 AWG Cabinet Type Custom cabinet for indoor use only

(2.0 mm² to 2.5 mm²). Overall Size 170 mm X 305 mm X 116.6 mm (6.69 ” X 12.0 ” X 4.59 ”)

• Conductor protection must be provided in accordance with NFPA 70, Perimeter Distance for

100 mm (3.9 ”)

Article 240. Ventalation

• Low voltage circuits (35 V or less) must be supplied from the engine Material Sheet steel enclosure of all-round solid construction

starting battery or an isolated secondary circuit. Surface Finish Powder-coated black

• The communication, sensor, and/or battery derived circuit conductors Protection Category IP20, NEMA 1

shall be separated and secured to maintain at least ¼” (6 mm) Unboxed Weight 2.16 kg (4 lb 12 oz)

separation from the generator and mains connected circuit conductors Boxed Weight 2.34 kg (5 lb 2 oz)

unless all conductors are rated 600 V or greater. Base mounted to a vertical surface with connection terminals to the

Mounting Type

Communication Circuits Must be connected to communication circuits of UL Listed equipment bottom.

Mounting • Suitable for use in type 1 Enclosure Type rating with surrounding air Diameter 7 mm (0.276 ”), 63.5 mm X 291 mm (2.5 ” x 11.46 ”)

Mounting Holes

temperature -22 ºF to +131 ºF (-30 ºC to +55 ºC) centres

• Suitable for pollution degree 3 environments when voltage sensing Cable Entry Cutout Diameter 20 mm (0.78 ”)

inputs do not exceed 300 V. When used to monitor voltages over 300 V Operating Temperature -30 C to +55 C (-22 F to +131 F)

device to be installed in an unventilated or filtered ventilation enclosure Operating Temperature (With -30 C to +80 C (-22 F to +176 F)

to maintain a pollution degree 2 environment. Derate To Output)

Operating Temperature -22 F to +131 F (-30 C to +55 C)

Storage Temperature -40 ºF to +176 ºF (-40 ºC to +80 ºC)

You might also like

- Seca - 703 & 704 Service ManualDocument28 pagesSeca - 703 & 704 Service ManualWaseem Almuhtaseb100% (3)

- User Manual Configuration With Web Interface Controller CSU 502Document12 pagesUser Manual Configuration With Web Interface Controller CSU 502moumen Boughrara0% (1)

- Introduction to the simulation of power plants for EBSILON®Professional Version 15From EverandIntroduction to the simulation of power plants for EBSILON®Professional Version 15No ratings yet

- User Manual: Configuration With Web Interface Controller CSU 502Document10 pagesUser Manual: Configuration With Web Interface Controller CSU 502moumen BoughraraNo ratings yet

- Galaxy Dimension Installation Manual 1.0Document306 pagesGalaxy Dimension Installation Manual 1.0thailannaNo ratings yet

- Products IntroductionDocument34 pagesProducts IntroductionRichard RongNo ratings yet

- 056-054 DSE8x10 in Fixed Export (Base Load)Document4 pages056-054 DSE8x10 in Fixed Export (Base Load)hariana100% (1)

- DSE2610 Installation Instructions ManualDocument2 pagesDSE2610 Installation Instructions ManualEdson Da Rosa MachadoNo ratings yet

- GW PV Master User Manual-EnDocument21 pagesGW PV Master User Manual-EnEdison Joel Mullo TarcoNo ratings yet

- HA470631U200Document2 pagesHA470631U200Hayden LovettNo ratings yet

- Change Log:: GX Lte 4GDocument3 pagesChange Log:: GX Lte 4GDefiant OverlandNo ratings yet

- ssp3117b-1 1-3k SORODocument32 pagesssp3117b-1 1-3k SOROPaul Abi Najem100% (2)

- Victron SmartLithiumDocument2 pagesVictron SmartLithiumClifford ChiparaushaNo ratings yet

- DVR2000E Training - SECT #6 (Paralleling Set-Up)Document39 pagesDVR2000E Training - SECT #6 (Paralleling Set-Up)Anonymous uEt1sNhU7lNo ratings yet

- Motionplus™ Edc: Encoder Digital Controller Getting Started ManualDocument11 pagesMotionplus™ Edc: Encoder Digital Controller Getting Started Manualgamelab1964No ratings yet

- Configuring Voltage and Frequency Droop Settings in The DSEDocument3 pagesConfiguring Voltage and Frequency Droop Settings in The DSEasanlwin228No ratings yet

- 056-123 Simulation Injection TestingDocument6 pages056-123 Simulation Injection TestingRoxanneNo ratings yet

- T Rec Y.1541 201112 I!!pdf eDocument24 pagesT Rec Y.1541 201112 I!!pdf eSwapnil NageNo ratings yet

- 056-054 7510 in Fixed ExportDocument2 pages056-054 7510 in Fixed ExportYasser JaviNo ratings yet

- Manual Mastervolt Magic 12 12-20Document20 pagesManual Mastervolt Magic 12 12-20sandroterraNo ratings yet

- DSE8003 MKII Installation InstructionsDocument2 pagesDSE8003 MKII Installation InstructionsYacine DaliNo ratings yet

- 650 Series AC Drive: Frame 1, 2 & 3Document70 pages650 Series AC Drive: Frame 1, 2 & 3Darwin DuqueNo ratings yet

- Typical Wiring Diagram: Function ActionDocument2 pagesTypical Wiring Diagram: Function ActionMH..2023No ratings yet

- Product Change Notice 8610 MKII PH 6 Jan 20V2Document2 pagesProduct Change Notice 8610 MKII PH 6 Jan 20V2Nuc LeusNo ratings yet

- Fangpusun bmv700Document19 pagesFangpusun bmv700ingenieriaNo ratings yet

- ADD 103 Series PTI2045ADocument4 pagesADD 103 Series PTI2045ALeonardo LimbergerNo ratings yet

- HA470631U100Document2 pagesHA470631U100Hayden LovettNo ratings yet

- Seca717,757 - Service ManualDocument17 pagesSeca717,757 - Service ManualSergio PérezNo ratings yet

- Seca 728 Service ManualDocument19 pagesSeca 728 Service Manualperla_canto_1100% (1)

- Strength TesterDocument9 pagesStrength TesterAnonymous TYGiADNo ratings yet

- Venus OS v3.00 - Generator Start - Stop Improvements, ESS Peak Shaving - Victron EnergyDocument1 pageVenus OS v3.00 - Generator Start - Stop Improvements, ESS Peak Shaving - Victron EnergyMendrika RAZAFINDRABENo ratings yet

- Manson HCS-3202 Alimentatore 0 60V 0 5ADocument20 pagesManson HCS-3202 Alimentatore 0 60V 0 5Apaolo.defalcoNo ratings yet

- Ap Genstart CeDocument2 pagesAp Genstart CeHamza HafidiNo ratings yet

- DSEG8600 Installation InstructionsDocument6 pagesDSEG8600 Installation Instructionsvuvantieu802No ratings yet

- Evc 6Document2 pagesEvc 6David Roper0% (1)

- Acer LCD Monitor: User's GuideDocument33 pagesAcer LCD Monitor: User's GuidetvlodekNo ratings yet

- Installer Starter GuideDocument9 pagesInstaller Starter GuideJaokNo ratings yet

- Depth - Speed - Tension - Data Recorder Zone 2 - Safe Area WaterproofDocument2 pagesDepth - Speed - Tension - Data Recorder Zone 2 - Safe Area WaterproofmarcioNo ratings yet

- Strain Gage Measurement With AI-208 Using DASYLab and LabVIEWDocument14 pagesStrain Gage Measurement With AI-208 Using DASYLab and LabVIEWueidaqNo ratings yet

- Monitor TV: Owner'S ManualDocument36 pagesMonitor TV: Owner'S ManualStemplarsNo ratings yet

- Typical Wiring Diagram: Deep Sea ElectronicsDocument2 pagesTypical Wiring Diagram: Deep Sea ElectronicsBERANGER DAVESNE DJOMALIA SIEWENo ratings yet

- DSE2541 Installation Instructions PDFDocument2 pagesDSE2541 Installation Instructions PDFDEYNERNo ratings yet

- DSE2541 Installation Instructions PDFDocument2 pagesDSE2541 Installation Instructions PDFBERANGER DAVESNE DJOMALIA SIEWENo ratings yet

- CYC Ride Control App User Guide For Website 06012023Document12 pagesCYC Ride Control App User Guide For Website 06012023naimadnbNo ratings yet

- Deep Sea Controller KnowledgeDocument86 pagesDeep Sea Controller Knowledgeasanlwin228No ratings yet

- Manual PVMASTERDocument16 pagesManual PVMASTERNicolasAndresBerriosLunaNo ratings yet

- Goodwe 5048ES With BYD B-BOX (2.5-10) Installation GuideDocument13 pagesGoodwe 5048ES With BYD B-BOX (2.5-10) Installation GuideMeraj HasanNo ratings yet

- 808 PC Software InterfaceDocument2 pages808 PC Software InterfaceJohn GarnetNo ratings yet

- Victronconnect - Ve - Bus Configuration Guide: 1. WarningDocument17 pagesVictronconnect - Ve - Bus Configuration Guide: 1. WarningamooooosNo ratings yet

- Off-Grid User ManualDocument32 pagesOff-Grid User Manualowais mirNo ratings yet

- Manual Axpert MAXDocument9 pagesManual Axpert MAXJohn WNSNo ratings yet

- Diesel Control ECU Operator ManualDocument21 pagesDiesel Control ECU Operator ManualThug LabNo ratings yet

- EC2-711 Condenser Controller: MountingDocument4 pagesEC2-711 Condenser Controller: MountingNikolas ChionasNo ratings yet

- Lab 6Document6 pagesLab 6hareesh.makesuNo ratings yet

- E Catalog sk8550 1Document2 pagesE Catalog sk8550 1sgwestdepotNo ratings yet

- HA470679U200Document2 pagesHA470679U200Hayden LovettNo ratings yet

- Seca 374,375,376 - Service ManualDocument19 pagesSeca 374,375,376 - Service ManualmurifuNo ratings yet

- Manual Prensa GilsonDocument27 pagesManual Prensa GilsonAlvaro GuillermoNo ratings yet

- Pi044f-311-Td-En 3PDocument10 pagesPi044f-311-Td-En 3PthaiNo ratings yet

- Acostix Manual 3nd EditionDocument48 pagesAcostix Manual 3nd EditionthaiNo ratings yet

- FR0624300 Kta 50-G8Document4 pagesFR0624300 Kta 50-G8thaiNo ratings yet

- 06 - Power SuiteDocument29 pages06 - Power SuitethaiNo ratings yet

- Engine Diag - CumminsDocument19 pagesEngine Diag - CumminsthaiNo ratings yet

- Mx341 Automatic Voltage Regulator (Avr)Document4 pagesMx341 Automatic Voltage Regulator (Avr)Agus GunawanNo ratings yet

- Stamford MX321 Avr enDocument1 pageStamford MX321 Avr enthaiNo ratings yet

- A7-1321 - Rev - F AVR321 PDFDocument1 pageA7-1321 - Rev - F AVR321 PDFthaiNo ratings yet

- MX321 Wiring - Selco Interface PDFDocument1 pageMX321 Wiring - Selco Interface PDFthaiNo ratings yet

- Tech Tip Sauer Danfoss ControllerDocument37 pagesTech Tip Sauer Danfoss ControllerSantos C Pech Dzul100% (1)

- J212 PDFDocument7 pagesJ212 PDFRicky CoxNo ratings yet

- Mastering Cross-Platform Development With Xamarin - Sample ChapterDocument32 pagesMastering Cross-Platform Development With Xamarin - Sample ChapterPackt PublishingNo ratings yet

- 2.5.5 Packet Tracer Configure Initial Switch SettingsDocument5 pages2.5.5 Packet Tracer Configure Initial Switch SettingsjamesNo ratings yet

- SAP Installation ABAPDocument45 pagesSAP Installation ABAPSurut ShahNo ratings yet

- Custome Raspberry Pi ImageDocument4 pagesCustome Raspberry Pi ImagegejibNo ratings yet

- SumanPattukumarS7Yrs - Senioer Java Dev - ChennaiDocument4 pagesSumanPattukumarS7Yrs - Senioer Java Dev - ChennaiLohika AccountNo ratings yet

- Hardware, Software and The 7 Components of It Infrastructure 1. Computer Hardware PlatformsDocument2 pagesHardware, Software and The 7 Components of It Infrastructure 1. Computer Hardware PlatformsAmirul NorisNo ratings yet

- Signal Chain Benchmarking - A Demonstration of Optimized Performance of C2000™ Real-Time Control MCUDocument18 pagesSignal Chain Benchmarking - A Demonstration of Optimized Performance of C2000™ Real-Time Control MCUMauro Andre PagliosaNo ratings yet

- SuperCollider Tutorial by Nick CollinsDocument6 pagesSuperCollider Tutorial by Nick CollinsGiorgio BossoNo ratings yet

- RAN16.0 Capacity Monitoring Guide (BSC6900-Based) (01) (PDF) - ENDocument69 pagesRAN16.0 Capacity Monitoring Guide (BSC6900-Based) (01) (PDF) - ENoshwa_ishNo ratings yet

- Th-F6a F7e SMDocument74 pagesTh-F6a F7e SMAZQAR_TNo ratings yet

- Catchlogs - 2023-11-12 at 03-39-34 - 7.54.0 - .JavaDocument34 pagesCatchlogs - 2023-11-12 at 03-39-34 - 7.54.0 - .Javadedyirawan0758No ratings yet

- A Systematic Mapping Study of Software Development With GithubDocument20 pagesA Systematic Mapping Study of Software Development With GithubJaime SayagoNo ratings yet

- Lecture Slides 3 Point of Sales (POS) SystemDocument31 pagesLecture Slides 3 Point of Sales (POS) SystemAlice LowNo ratings yet

- BCP Lab ManualDocument65 pagesBCP Lab Manualferoz pathanNo ratings yet

- QT ExcerptDocument31 pagesQT ExcerptMohammad Mohsen AmiriNo ratings yet

- LAB NO 4: - Basic Router Configuration: 1. ObjectiveDocument9 pagesLAB NO 4: - Basic Router Configuration: 1. ObjectiveMujtaba HassanNo ratings yet

- QS WIFI S03 Switch Module User ManualDocument2 pagesQS WIFI S03 Switch Module User ManualTecsys Tecnologia a su alcanceNo ratings yet

- Command Reference: Optima/Econo DMC-2xxx SeriesDocument263 pagesCommand Reference: Optima/Econo DMC-2xxx SeriesAnimesh GhoshNo ratings yet

- Key Features: UsabilityDocument2 pagesKey Features: UsabilityFaustino Barrera SánchezNo ratings yet

- Bad Graphics On Your PS4 - Here Is How To Fix ItDocument6 pagesBad Graphics On Your PS4 - Here Is How To Fix Itlance laguertaNo ratings yet

- This Set of VLSI Multiple Choice QuestionsDocument20 pagesThis Set of VLSI Multiple Choice QuestionsSujith Mrinal100% (3)

- PIC16F877 Microcontroller TutorialDocument37 pagesPIC16F877 Microcontroller Tutorialmc_prayer100% (4)

- Frontier Error Codes PDFDocument2 pagesFrontier Error Codes PDFKing100% (1)

- 17 - Interfaces QuizDocument6 pages17 - Interfaces QuizsikandarbatchaNo ratings yet

- RTU - ASCII Master Test Software - Simply Modbus SoftwareDocument4 pagesRTU - ASCII Master Test Software - Simply Modbus SoftwareSaber LeffiNo ratings yet

- h7113 Vplex Architecture Deployment PDFDocument17 pagesh7113 Vplex Architecture Deployment PDFAbhishek PubbisettyNo ratings yet

- 63662ENDocument102 pages63662ENtan duyNo ratings yet