Professional Documents

Culture Documents

manual-ELB (TEDL) Operation Manual-Eng

manual-ELB (TEDL) Operation Manual-Eng

Uploaded by

Nuno PintoCopyright:

Available Formats

You might also like

- HKN-93 Series Manual de Servicio PDFDocument84 pagesHKN-93 Series Manual de Servicio PDFDiana Vega86% (7)

- NEC NP-V332X V332W V302H Service Manual (2nd Ed)Document343 pagesNEC NP-V332X V332W V302H Service Manual (2nd Ed)RandyCairo100% (2)

- Very Advanced Maternal Age, TOG-2021Document10 pagesVery Advanced Maternal Age, TOG-2021saeed hasan saeedNo ratings yet

- Jesus The Liberator - Jon SorbinoDocument321 pagesJesus The Liberator - Jon SorbinoavaMotivatorije94% (16)

- Gateway-and-Apple 1111Document5 pagesGateway-and-Apple 1111Khulan Tsetsegmaa100% (3)

- Mercruiser Service Manual #14 Alpha I Gen II Outdrives 1991-NewerDocument715 pagesMercruiser Service Manual #14 Alpha I Gen II Outdrives 1991-NewerM5Melo100% (10)

- vxBjICCrQ7eQYyAgq0O3cg - Debit Credit Rules ActivityDocument1 pagevxBjICCrQ7eQYyAgq0O3cg - Debit Credit Rules ActivityAlok PatilNo ratings yet

- Gymnastic Bodies Fundamentals GuideDocument17 pagesGymnastic Bodies Fundamentals GuideGianniNo ratings yet

- Lince: User'S and Installer'S ManualDocument15 pagesLince: User'S and Installer'S ManualDragos VidmichiNo ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Religion and Belief Systems in Australia Post 1945Document6 pagesReligion and Belief Systems in Australia Post 1945Jananee SundarakumarNo ratings yet

- Offshore Engineer-February 2015Document84 pagesOffshore Engineer-February 2015ilkerkozturk100% (2)

- Spotify Strategig Possining and Product Life Cycle Four Basic Stages.Document5 pagesSpotify Strategig Possining and Product Life Cycle Four Basic Stages.Jorge YeshayahuNo ratings yet

- Kasatha 5eDocument1 pageKasatha 5eBryce St. LouisNo ratings yet

- Tgs-Led: Taxiway Guidance Sign: Technical Specification & Operation ManualDocument26 pagesTgs-Led: Taxiway Guidance Sign: Technical Specification & Operation ManualJavier Eduardo Alzate BogotaNo ratings yet

- User'S Manual Operating & Maintenance: RGL-L: Runway Guard Light (Led)Document21 pagesUser'S Manual Operating & Maintenance: RGL-L: Runway Guard Light (Led)Javier Eduardo Alzate BogotaNo ratings yet

- NVC DCP551B Um CP SP 1032e 18Document220 pagesNVC DCP551B Um CP SP 1032e 18johnductamNo ratings yet

- Model DT450G Dust Monitor: User's ManualDocument41 pagesModel DT450G Dust Monitor: User's ManualzaffarNo ratings yet

- User's Manual: AQ2200 Series Modules Checking The Contents of The Package and Handling Precautions of The ModulesDocument10 pagesUser's Manual: AQ2200 Series Modules Checking The Contents of The Package and Handling Precautions of The Modulessagar_ovhalNo ratings yet

- Autonics CX Series - User ManualDocument87 pagesAutonics CX Series - User ManualEldglay da Silva DomingosNo ratings yet

- Manual de Uso Coagulador Bipolar BP-200Document20 pagesManual de Uso Coagulador Bipolar BP-200Clinica de Estudios Oftalmologicos PracticanteNo ratings yet

- Dell 2209WA Service Manual Rev 1.0Document85 pagesDell 2209WA Service Manual Rev 1.01133523568585No ratings yet

- Burner Controller User's Manual: Model AUR890Document66 pagesBurner Controller User's Manual: Model AUR890Edwin Salazar OrtizNo ratings yet

- AgilePID - User Manual - Ver10 - 20210113Document24 pagesAgilePID - User Manual - Ver10 - 20210113Raj GaneshNo ratings yet

- TK - EN - User ManualDocument125 pagesTK - EN - User ManualHector CamachoNo ratings yet

- Projector Manual 2550Document73 pagesProjector Manual 2550narozNo ratings yet

- Adb Uel-1-120Document41 pagesAdb Uel-1-120FranciscoVicenteNo ratings yet

- Manual de Utilizare Motor Automatizare Rulouri Motorline TUB25Document6 pagesManual de Utilizare Motor Automatizare Rulouri Motorline TUB25Daniel PanciuNo ratings yet

- Incubadora de Transporte DAVID TI-2000 Service ManualDocument99 pagesIncubadora de Transporte DAVID TI-2000 Service ManualDaniela GonzalezNo ratings yet

- VG User en 190129 WDocument126 pagesVG User en 190129 WaluiziojoseNo ratings yet

- Ir 202 ImDocument103 pagesIr 202 ImzaffarNo ratings yet

- TMU220 PrintersDocument18 pagesTMU220 PrintersAlmir PedrottiNo ratings yet

- XWEB300D/500D/500 EVO: Installation ManualDocument24 pagesXWEB300D/500D/500 EVO: Installation ManualHalilNo ratings yet

- Manual - Autonics Vision Sensor VGDocument124 pagesManual - Autonics Vision Sensor VGMuhammad Imam MuthahharNo ratings yet

- Autonics TK ManualDocument124 pagesAutonics TK ManualFathurrahman Yudhi NugrahaNo ratings yet

- User Manual: PrefaceDocument92 pagesUser Manual: PrefaceJosé Gregorio González TorresNo ratings yet

- Tai Lieu Man Hinh HMI AutonicsDocument80 pagesTai Lieu Man Hinh HMI AutonicsViệnVuiVẻNo ratings yet

- THERMOVAC Transmitter: TTR 101N, TTR 101N S Operating Manual 300544655 - 002 - A0Document41 pagesTHERMOVAC Transmitter: TTR 101N, TTR 101N S Operating Manual 300544655 - 002 - A0Cuauhtémoc Arroyo GonzalezNo ratings yet

- User Manual: Auto Crib-It Ac SeriesDocument21 pagesUser Manual: Auto Crib-It Ac SeriesForum PompieriiNo ratings yet

- Ab 6590 PDFDocument20 pagesAb 6590 PDFMeffendi PenpenNo ratings yet

- SCA 102UB v2.0Document89 pagesSCA 102UB v2.0Henry CharriereNo ratings yet

- Im11g02q02 51en PDFDocument45 pagesIm11g02q02 51en PDFsagar_ovhalNo ratings yet

- Single Loop Controller SDC15 User's Manual: "Installation & Configurations"Document208 pagesSingle Loop Controller SDC15 User's Manual: "Installation & Configurations"Phan Van SinhNo ratings yet

- Beam 201Document24 pagesBeam 201emilioNo ratings yet

- Manuale UtenteDocument124 pagesManuale UtentepercorsielmarNo ratings yet

- User's Manual: Model ISC450G Inductive Conductivity Converter (Style: S2)Document81 pagesUser's Manual: Model ISC450G Inductive Conductivity Converter (Style: S2)Roger Molina GomezNo ratings yet

- Luxpower Sna 6000 Wide PV ManualDocument21 pagesLuxpower Sna 6000 Wide PV Manual2ddpNo ratings yet

- Wilo F 020000140002383f00010092Document17 pagesWilo F 020000140002383f00010092Ion TestaNo ratings yet

- Light Source SLS-2100PDocument18 pagesLight Source SLS-2100PVictor BlancoNo ratings yet

- Sharp PN-655U Manuel D'utilisationDocument128 pagesSharp PN-655U Manuel D'utilisationYann BajardNo ratings yet

- KRN1000 EN Comm DRW190833AA 20191013 WDocument115 pagesKRN1000 EN Comm DRW190833AA 20191013 WAbraham galvánNo ratings yet

- Becken BAC4255 Air ConditionerDocument182 pagesBecken BAC4255 Air ConditionerMarcelo Peixoto Del PelosoNo ratings yet

- FL-560 - 2025 Operation Manual PDFDocument129 pagesFL-560 - 2025 Operation Manual PDFMartin Fuemayor MavarezNo ratings yet

- One Series Rotational Viscometer: Instruction ManualDocument53 pagesOne Series Rotational Viscometer: Instruction Manualcristhian manzanoNo ratings yet

- Bizhub c450Document780 pagesBizhub c450mapsonNo ratings yet

- Im12b07c05 01eDocument88 pagesIm12b07c05 01eYasir JamilNo ratings yet

- S1 Huayuan ManualDocument95 pagesS1 Huayuan ManualTrần Đinh MinhNo ratings yet

- Instruction Manual: E84111-K00060-00 Published Feb.2008 Ver.3-1.01Document36 pagesInstruction Manual: E84111-K00060-00 Published Feb.2008 Ver.3-1.01Kluzu Formaggio100% (1)

- User Manual: Panel PCDocument38 pagesUser Manual: Panel PCMarcos De AlmeidaNo ratings yet

- HKN 93 Series Manual de ServiciopdfDocument86 pagesHKN 93 Series Manual de ServiciopdfантонNo ratings yet

- Electrostatic Precipitation (ESP) Filter UnitDocument46 pagesElectrostatic Precipitation (ESP) Filter UnitDjordjeNo ratings yet

- Ir 400 ImDocument119 pagesIr 400 ImzaffarNo ratings yet

- Bizhub - 162 - 210Document660 pagesBizhub - 162 - 210houdaa salaNo ratings yet

- Liebert Ita2 30kva Ups User Manual v1.2Document108 pagesLiebert Ita2 30kva Ups User Manual v1.2nelson yenner ramirez minayaNo ratings yet

- Bizhub Pro 920Document640 pagesBizhub Pro 920Abdul WahabNo ratings yet

- Technical DataDocument246 pagesTechnical DataABDUL GHAFOORNo ratings yet

- Chainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesFrom EverandChainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesRating: 5 out of 5 stars5/5 (1)

- Automotive Actuators and EVAP System TestingFrom EverandAutomotive Actuators and EVAP System TestingRating: 4.5 out of 5 stars4.5/5 (4)

- Ethiopian Health Systems and PolicyDocument81 pagesEthiopian Health Systems and PolicyFami Mohammed100% (2)

- To-Do List FormulaDocument1 pageTo-Do List FormulaPre MANo ratings yet

- Final Management Project On Geo TVDocument35 pagesFinal Management Project On Geo TVAli Malik100% (1)

- 1 A-2 Mann - Concept of Infrastructural PowerDocument11 pages1 A-2 Mann - Concept of Infrastructural Powerrichiflowers11gmail.comNo ratings yet

- Size & Estimation of DWDocument12 pagesSize & Estimation of DWGiuseppe GiuseppeNo ratings yet

- The 5 Founding Fathers and A History of Positive PsychologyDocument11 pagesThe 5 Founding Fathers and A History of Positive PsychologyItno WatiNo ratings yet

- University of WorcesterDocument8 pagesUniversity of WorcesterchhaiiNo ratings yet

- Various Artists - The Joy of ClassicsDocument82 pagesVarious Artists - The Joy of ClassicsCarlos Toledo88% (16)

- Working Capital Management Maruti SuzukiDocument76 pagesWorking Capital Management Maruti SuzukiAmit singhNo ratings yet

- Aire - 1 ReinigenDocument25 pagesAire - 1 Reinigengino aldo palomino ludeñaNo ratings yet

- CFP Registration Process (Final) - 3Document39 pagesCFP Registration Process (Final) - 3nishiNo ratings yet

- Thesis APDocument31 pagesThesis APIvy SorianoNo ratings yet

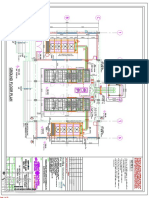

- Dg-1 (Remote Radiator) Above Control Room Slab: 05-MAR-2018 Atluri Mohan Krishna (B845)Document32 pagesDg-1 (Remote Radiator) Above Control Room Slab: 05-MAR-2018 Atluri Mohan Krishna (B845)Shaik AbdullaNo ratings yet

- OO ALV Status Led LightDocument6 pagesOO ALV Status Led LightRam PraneethNo ratings yet

- CH 3 Online Advertising vs. Offline AdvertisingDocument4 pagesCH 3 Online Advertising vs. Offline AdvertisingKRANTINo ratings yet

- Abhinavagupta (C. 950 - 1016 CEDocument8 pagesAbhinavagupta (C. 950 - 1016 CEthewitness3No ratings yet

- English - Fine - Tune Your English 2019Document3 pagesEnglish - Fine - Tune Your English 2019NishaNo ratings yet

- MUSIC10 Q2 (Latin American Music, Jazz and Pop Music) Week 2 - CardelDocument5 pagesMUSIC10 Q2 (Latin American Music, Jazz and Pop Music) Week 2 - CardelJeff Nieva CardelNo ratings yet

- How Will 'Chipageddon' Affect You ?Document50 pagesHow Will 'Chipageddon' Affect You ?Satyaki DuttaNo ratings yet

- Mortality RateDocument5 pagesMortality Rateamit kumar dewanganNo ratings yet

manual-ELB (TEDL) Operation Manual-Eng

manual-ELB (TEDL) Operation Manual-Eng

Uploaded by

Nuno PintoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

manual-ELB (TEDL) Operation Manual-Eng

manual-ELB (TEDL) Operation Manual-Eng

Uploaded by

Nuno PintoCopyright:

Available Formats

OPERATING & MAINTENANCE MANUAL MODEL : ELB series

OPERATION & MAINTENANCE

MANUAL

ELB-TEDL : ELEVATED OMNIDIRECTIONAL LOW INTENSITY LIGHT

YOUYANG AIRPORT LIGHTING EQUIPMENT INC.

YOUYANG AIRPORT LIGHTING EQUIPMENT INC. PAGE 1/34

OPERATING & MAINTENANCE MANUAL MODEL : ELB series

REVISION RECORD

This Revision Record of Manual is written in below Table and we supply new

updated Manual with product.

This Manual can be revised anytime for better improvement of products and its

Revision contents are made by company production process regulation and will

give to customers as newly updated Hard copy and Soft copy by CD.

This Manual not including content for discontinued parts and products.

REVISION RECORD

REVISION NO CONTENTS DATE SIGN

Rev 0 FIRST MADE 2015-02-24

YOUYANG AIRPORT LIGHTING EQUIPMENT INC. PAGE 2/34

OPERATING & MAINTENANCE MANUAL MODEL : ELB series

CONTENTS

1. General

1.1 Knowledge before Operation(use)

1.2 Cautions for Safety

1.3 Quality guaranty

2. Product specification

3. Installation

4. Maintenance & Repair procedure

5. Transportation & Storage

6. Drawings & Parts List

6.1 Ordering Code Information

YOUYANG AIRPORT LIGHTING EQUIPMENT INC. PAGE 3/34

OPERATING & MAINTENANCE MANUAL MODEL : ELB series

1. General

1.1 Knowledge before use

Please read carefully this Manual with below Caution before use and use correctly.

If you do not understand and have any questions, please contact with below

department and make best Installation, Operation and Maintenance after sufficient

knowledge from us.

Please transfer this Manual to person in charge of end user and maintenance person

and Duty maintenance manager.

Please store this Manual where can see easy by person in charge always and use

anytime when required.

Company: YOUYANG AIRPORT LIGHTING EQUIPMENT INC. KOREA

Department: Quality Assurance Team

Tel: +82-31-422-0021

Fax: +82-31-424-6044

E - Mail youyang@youyang.co.kr

YOUYANG AIRPORT LIGHTING EQUIPMENT INC. PAGE 4/34

OPERATING & MAINTENANCE MANUAL MODEL : ELB series

1.2 Cautions for Safety

Keep this Caution to use products at safely and correctly to prevent before any

troubles and dangerous cases are occurred.

Use this product function as sufficiently and safely after carefully reading of this

Manual.

The Caution means as below 2 kinds:

When user do violate this Introduction of Manual, it

WARNING cause serious injury and death to user.

When user do violate this Manual introduction, it

NOTICE cause light injury to user and made products

troubles.

YOUYANG AIRPORT LIGHTING EQUIPMENT INC. PAGE 5/34

OPERATING & MAINTENANCE MANUAL MODEL : ELB series

WARNING

1. Do not Repair work when Power is ON and electrical circuit operated. This will make

Electric Shock to user.

2. Do not cabling work and disassembly work of products even Power is not connected.

Do period check only by eye. Otherwise this will make Electrical shock.

3. Do not work and touch when any small Water is covered on the product. This will

make Electrical shock to user.

4. Do not use when a Cable is peeled off and damaged. This will make Electrical shock to

user.

5. Do Make sure Fastening and fix after installation of product.

NOTICE

1. Please use input power as allowed range. Otherwise, this will make product damage

and fire reason.

2. Please do not make water input and dust entering to product. This will make product

damages and fire reason.

3. Please use all parts must be correct parts to product. Otherwise, this will make

product damages and fire reason.

4. Please do not make product inside cabling by arbitrary changing. This will make

product damages and fire reason.

5. Please do maintenance by trained technician only. Otherwise, non-qualified persons

make product damages and trouble.

YOUYANG AIRPORT LIGHTING EQUIPMENT INC. PAGE 6/34

OPERATING & MAINTENANCE MANUAL MODEL : ELB series

1.3 QUALITY GUARANTY

The product guaranty under this manual applied is 1 year after supply to site. The

consumable parts are excluded from guaranty period.

The troubles caused by products defects will be free of charge during guaranty period,

but, user mistakes and mis-use will be charged.

PRODUCT GUARANTY RANGE

Div. A/S charge Guaranty & support period

Product free A/S 1 year after supply to site

defect charge A/S 10-15 years after guaranty finished.

Free A/S None

User defect

Charge A/S 10-15 years from guaranty finished.

YOUYANG AIRPORT LIGHTING EQUIPMENT INC. PAGE 7/34

OPERATING & MAINTENANCE MANUAL MODEL : ELB series

2. Product Specification

2.1 TEDL: ELEVATED OMNIDIRECTIONAL LOW INTENSITY LIGHT

No Item Specification

Operating temperature -55 ~ +55℃

Storage temperature -40 ~ +60℃

Environme Precipitation IP54

1 ntal

Property Salt fog Exposure to a corrosive salt atmosphere

Temperature shock Exposure of the hot light fixture to cold water spray

Wind Velocity Exposure to wind velocities of 90m/Sec.

In put power 6.6A series circuit

Power consumption 28.7VA

Lamp LED lamp

Electrical

2

Property

Lamp type XP-E(CREE)

Lamp specification Blue : 1W

Lamp life >50,000 hour

Light color Blue

Photometr Main beam angle Vertical : 0°~ 6°, Horizontal : 360°

3 ic

Property

Min intensity Blue : 2 cd

Chromaticity Blue (x : 0.1322, y : 0.0603)

Installation height 300mm. Maximum

Mechanic size Ø 112*300 Maximum

4 al

Property Weight 1.6Kg

Breakable under 230Kg pressure on 30cm

Frangibility of coupling

from breakable points

YOUYANG AIRPORT LIGHTING EQUIPMENT INC. PAGE 8/34

OPERATING & MAINTENANCE MANUAL MODEL : ELB series

No Item Specification

Wind velocity 300 knots

Treatment Powder electrostatic painting

Surface

5

Treatment

color Aviation yellow

Body Aluminum die-casting (ADC 6)

Body support Aluminum die-casting (ADC 6)

Compositi

6

on

Globe Polycarbonate (Clear)

2 Pole plug L- 823 , STYLE 6.

YOUYANG AIRPORT LIGHTING EQUIPMENT INC. PAGE 9/34

OPERATING & MAINTENANCE MANUAL MODEL : ELB series

2.2 ELB-TEDL: ELEVATED OMNIDIRECTIONAL LOW INTENSITY LIGHT Outer Drawing

YOUYANG AIRPORT LIGHTING EQUIPMENT INC. PAGE 10/34

OPERATING & MAINTENANCE MANUAL MODEL : ELB series

3. INSTALLATION

3.1 INTRODUCTION

The light fixture shall be substantially assembled and supplied, based on the user’s

demand.

The light fixtures shall be in accordance with KS, ICAO and FAA specifications and

lamp wattages and color of beam shall be agreed with the user for the different

conditions of the site.

The following comments for the installation of the light fixture and it shall be in

compliant with ICAO, FAA, and any other countries’installation specifications.

3.2 INSTALLATION OF THE LIGHT FIXTURE

3.2.1 INSTALLATION OF TAXIWAY LIGHTS

BAPID

EXIT TAXIWAY

3m Min

STRAIGHT TAXIWAY 60m max

Figure 1.1 Lighting configuration

1. Taxiway edge lights on a straight section of a taxiway and a runway forming

part of a standard taxi-route should be spaced at uniform longitudinal intervals

of not more than 60M.

2. The lights on a curve should be spaced at intervals less than 60M so that a

clear indication of the curve is provided.

3. Taxiway edge lights on a holding bay, de-icing/anti-dicing facility, apron, etc.

should be spaced at uniform longitudinal intervals of not more than 60M.

4. The lights should be located as near as practicable to the edge of the taxiway

at a distance of not more than 3M.

YOUYANG AIRPORT LIGHTING EQUIPMENT INC. PAGE 11/34

OPERATING & MAINTENANCE MANUAL MODEL : ELB series

Taxiway edge lights on a runway turn pad should be spaced at uniform longitudinal

intervals of not more than 30M.

3.3 LIGHT BASE MOUNTING

The installation methods and procedures are listed as below and must be installed

either in the Deep base or Shallow base. The base(box) installation method

is in accordance with FAA AC 150/5340-26. However, users shall be follow

the special installation methods under their country’s regulations, and this

process shall be discussed together, between manufacturer and end user,

to decide a proper installation method.

3.3.1 MOUNTING DEEP BASE

FLANGE RING

MUD DAM

(OPTIONAL) 3mm

STEEL REINFORCING 6mm APPROX

CAGE #4 BARS CONCRETE

VARIES

76mm

BASE AND

305mm MIN OR SUBBASE

VARIES

FLEXIBLE CONDUIT

152 mm Min SUBGRADE

RIGID CONDUIT 102 mm VARIES

Notes:

1. Flexible conduit may be connected to the base either

through a hub or grommet.

Figure 3.2 DEEP BASE (L-867 TYPE)

Deep base for runway edge lights shall be mounted and installed as per below

procedure.

YOUYANG AIRPORT LIGHTING EQUIPMENT INC. PAGE 12/34

OPERATING & MAINTENANCE MANUAL MODEL : ELB series

1) Prepare the installation drawing for deep base which shall be installed on the

paved runway & taxiway.

2) Mark the installation point of deep base.

3) Cut the area where the deep base shall be installed. (Refer to Figure 3.2)

4) Cut the surface of the asphalt pavement to make the cable conduit through the

cable way.

5) The lower part of cutting comes to the size of min. 152mm extra spacing as the

bottom and of min. 305mm extra spacing as the side.

6) Place the deep base in position.

7) Fix the deep base in line with both directions of runway as shown in the below

figure.

BEAM DIRECTION OF DEEP BASE

8) Connect earth wire and earth rods.

9) Burry the deep base and fill epoxy resin or concrete in a space of the mounted

deep base.

10) Clean and dry thoroughly the deep base.

YOUYANG AIRPORT LIGHTING EQUIPMENT INC. PAGE 13/34

OPERATING & MAINTENANCE MANUAL MODEL : ELB series

3.3.2 CONNECTION FOR TRANSFORMER AND PRIMARY CONNECTOR KIT

Figure 4.1 CONNECTION FOR TRANSFORMER AND PRIMARY CONNECTOR KIT

Figure 4.2 4.1 CONNECTION FOR TRANSFORMER AND SECONDARY CONNECTOR KIT

1) Clean the inside of the cable conduit and remove moisture or liquid remaining in

the cable conduit. Damage on joint bolts and connection parts of the cable

conduit should not be present.

2) Lay down the light fixture on the soft surface of the ground.

3) Remove coupling from the light fixture and connect it to male screw of the

conduit.

And then, fix it tightly with spanner.

YOUYANG AIRPORT LIGHTING EQUIPMENT INC. PAGE 14/34

OPERATING & MAINTENANCE MANUAL MODEL : ELB series

4) Make secondary connector kit connected with isolating transformer toward

outside.

5) Lay down the light fixture on soft fabric and connect secondary lead wire plug of

the light

fixture with receptacle of the secondary cable of the isolating transformer.

(Refer to Figure 4.2)

6) Clean the surface of the plug of lead wire of light fixture and receptacle of

isolating transformer

And do tightly taping with EPR tape and PVC isolation tape.

7) Fill the surplus lead wire into the buried elbow conduit and fix the light fixture

with coupling by

fastening with three bolts. Make sure that power connection cable should be

well arranged without knot or twist.

8) Finally check if the light fixture is completely installed and clean the

surroundings in work area.

9) Make alignment for the installed light fixture with jig and leveling tools.

(Refer to section 3.5 : procedure of alignment of the light fixture)

YOUYANG AIRPORT LIGHTING EQUIPMENT INC. PAGE 15/34

OPERATING & MAINTENANCE MANUAL MODEL : ELB series

3.4 INSTALLATION OF LIGHT FIXTURE

WARNING

Replace the light fixture when disconnected from line voltage

CAUTION

1. Do not allow scar or impurities such as residue of glue to remain in frangible

joint parts where the light fixture and the deep base are in contact.

2. Remove water from the deep base or cable conduit when installing the light

fixture. Especially water remaining in the deep base will be bloated when frozen

and it may cause damage to the light fixture.

3. Fix tightly secondary cable of the light fixture and isolating transformer.

4. Do not carry or move the light fixture when connected with isolating

transformer and secondary lead wire.

5. In case of replacement for the light fixture, check if the replaced light fixture is

equal type in the same color of light.

6. Do not allow any tools or device to remain in work place after installation and

clean the light fixture with plastic bar or brush to avoid mechanical damage to

the light fixture.

YOUYANG AIRPORT LIGHTING EQUIPMENT INC. PAGE 16/34

OPERATING & MAINTENANCE MANUAL MODEL : ELB series

3.4.1 EQUIPMENT AND TOOLS

Equipment and tools should be available prior to installation as follows.

Arranging Jig equipped with optical device

Torque wrench

Ring spanner set

“L” shape wrench set

Silicon grease

Driver set

Miscellaneous tools required if any

3.4.2 CHECK POINTS BEFORE INSTALLING THE LIGHT FIXTURE

The deep base or shallow base should be mounted properly before installing the light

fixture in accordance with the following requirements. Check if ;

The light base is located correctly in compliance with requirement in KS, ICAO

and FAA

The light base is aligned in compliance with the required regulations

Isolating transformer is connected to direct load circuit.

3.4.3 PROCEDURE OF INSTALLING LIGHT FIXTURE

1) Prior to installation of the light fixture, check and confirm if the light base is

correctly installed in accordance with beam direction and in line with ground level.

2) Closely check if any damage on the light base exists.

3) Clean the light base and remove water or moisture in it.

4) Lay the light fixture down on the soft surface of the ground with the bottom of the

light forwarded to the upper part.

5) Connect secondary lead wire plug (FAA L-823 2 polarity plug or P3A) of the light

fixture to receptacle of isolating transformer and secondary connector kit. Clean

the conducting parts such as pin & socket and rubber surface by diluent.

6) Do taping the connecting parts with EPR tape or PVC insulation tape.

7) Connect the light fixture on the light base. Make sure that power cable should be

well aligned not to be twisted or tied .

8) Check and make alignment for the light fixture in accordance with correct beam

direction, color of light and mentioned arrow.

9) Fix the light fixture on the light base torqued with 30N.m with torque wrench and

apply anti-pulling substance such as lock-tight on the bolts.

10) Finally check if the light fixture is correctly installed and clean the surroundings in

work area.

YOUYANG AIRPORT LIGHTING EQUIPMENT INC. PAGE 17/34

OPERATING & MAINTENANCE MANUAL MODEL : ELB series

3.5 ALIGNMENT OF THE LIGHT FIXTURE

This section contains how to do alignment for the light fixture with JIG and tool

after installation.

3.5.1 HOW TO USE ALIGNMENT TOOLS

3.5.1.1 LEVELING TOOL

Leveling tool is to make horizontal alignment of the light fixture after installation.

Remove the external lens (globe) from the light fixture and place the leveling tool

on it.

Check hydro-level in the vial of the leveling tool and align it to be horizontal with

reference to the below figures showing the hydro level.

Leveling tool has ±1° of tolerance and direction toward the bubble means it is

placed in higher position

Shape of leveling tool and status of level

Normal level Level higher in the left

YOUYANG AIRPORT LIGHTING EQUIPMENT INC. PAGE 18/34

OPERATING & MAINTENANCE MANUAL MODEL : ELB series

3.5.2 THE METHOD TO SET HORIZONTAL ANGLE

NO. PHOTO DESCRIPTION

Take the jig out of storage box

Loosen a little enough to adjust horizontal angle of the

1.

bracket holding upper assembly of the fixture with

wrench.

Fit the jig on the fixture.

2

Adjust the angle with hydro-level vial.

3

Fix the locking bracket with wrench after setting the

4

angle.

5 Detach the jig from the fixture.

6 Store the equipment in storage box after work.

YOUYANG AIRPORT LIGHTING EQUIPMENT INC. PAGE 19/34

OPERATING & MAINTENANCE MANUAL MODEL : ELB series

4. MAINTENANCE & TROUBLESHOOTING

4.1 MAINTENANCE TASK & SCHEDULE

Preventive maintenance for airfield lighting fixtures is crucial for safe air operation.

Check and follow preventive maintenance schedule with reference to the below

table to keep elevated runway edge light operating efficiently.

PREVENTIVE MAINTENANCE CHECK LIST

HALF-

ARTICLE OF MAINTENANCE DAILY WEEKLY MONTHLY ANUALLY EMERGENCY

YARLY

LIGHTING ILLUMINATION STATUS ●

GRASS HINDERING ILLUMINATION ●

CLEANING & DAMAGE TO LENS ●

ALIGNMENT & DIRECTION OF BEAM ●

CLEANING OF LAMPS & SOCKETS ●

HEIGHT OF THE LIGHTING ●

MOISTURE INSIDE THE LIGHTING ●

RUST, PAINT PEELED OFF ●

BREAK OF THE LIGHTING ●

CABLE RESISTANCE ●

PACKINGS ●

DEICEING & REMOVING SNOW ●

YOUYANG AIRPORT LIGHTING EQUIPMENT INC. PAGE 20/34

OPERATING & MAINTENANCE MANUAL MODEL : ELB series

4.2 TROUBLESHOOTING

This section covers the most common problems that may be encountered.

Check and follow the below procedures when trouble occurs.

However, in order to reduce shutdown time of airport operation, it is recommended

that full set of the light fixture shall be replaced by new one first of all and then

the damaged light fixture shall be repaired at workshop.

TROUBLESHOOTING

This table provides the cause and corrective actions against most commonly

occurred problems

Problem Cause Corrective Action

- Lamp faults Replace Power section

- Each connector not well connected Repair faulty circuits

Lamp not working - Wiring(Polarity) of the lamp is fault Replace Power section

Replace isolated

- Faulty isolated transformer

transformer

Color of the lighting

looking different than - Lamp fault Replace Power section

other lightings

- Lamp fault Replace the lamp

- Reflector fault Replace the reflector

Lamp looking dimmer Replace isolated

than other lamps. - Faulty isolated transformer

transformer

- Polluted lens Clean the lens

- Power section fault Replace Power section

Intensity not changed - Check the specification of Power Fit in properly

YOUYANG AIRPORT LIGHTING EQUIPMENT INC. PAGE 21/34

OPERATING & MAINTENANCE MANUAL MODEL : ELB series

Problem Cause Corrective Action

to selected step

section

(applicable to the

lightings whose step

- Power section fault Replace the section

can be changed.)

Replace the

- Isolated Transformer fault

transformer

[Caution]

To reduce power shut-down period, the way as for the damaged lighting to be replaced

the whole fixture itself taking in workshop and repair any damaged part of the fixture is

used.

YOUYANG AIRPORT LIGHTING EQUIPMENT INC. PAGE 22/34

OPERATING & MAINTENANCE MANUAL MODEL : ELB series

4.3 REPLACEMENT PROCEDURE

4.3.1 REPLACEMENT OF LAMP AND GLOBE

1) TOOLS AND MATERIAL

TOOLS MATERIAL

1. Globe

(+)shape Driver 2. Lens

3. Packing

1) METHOD OF WORK

NO DEPICTION DESCRIPTION

1 Shape of lighting before maintenance

After loosening 4 bolts(M4) fixing upper cover, remove

the faulty glove and replace with new one.

2 1)Globe,

2) Bolts(For fixing globe),

3) Upper Cover,

Remove bolts(for fixing lens)

1) Glove and bolts,

2) Bolts(For fixing upper cover)

3 3) O-ring

4) Upper cover

5) Lens

6) Bolts(For fixing lens)

YOUYANG AIRPORT LIGHTING EQUIPMENT INC. PAGE 23/34

OPERATING & MAINTENANCE MANUAL MODEL : ELB series

NO DEPICTION DESCRIPTION

4 No Depiction Replace with new lens after removing faulty one.

[CAUTION]

1. O-ring and Packing shall not be reused (Should these have to be used, confirm any

damage inflicted in them.)

2. Wear soft gloves on replacing lamp. (Do not touch the surface of lamp by naked hand)

4.3.2 LED LAMP REPLACEMENT

1) TOOLS AND MATERIAL

TOOLS MATERIAL

(+)shape Driver 1. LED LAMP

Electric soldering iron

2) METHOD OF WORK

NO DEPICTION DESCRIPTION

1 Shape of lighting before maintenance.

Separate the globe by loosening 4 bolts fixing the globe.

1) Globe,

2

2) Bolts(For fixing bolts),

3) Upper cover,

Remove the lens by loosening 4 bolts fixing the lens.

1) Globe and bolts,

3

2) Bolts(For fixing upper cover)

3) O-ring

YOUYANG AIRPORT LIGHTING EQUIPMENT INC. PAGE 24/34

OPERATING & MAINTENANCE MANUAL MODEL : ELB series

NO DEPICTION DESCRIPTION

4) Upper cover

5) Lens

6) Bolts(For fixing lens)

Loosening PC bolts fixing LED

1) LED

4

2)Bolts

-. Using a solder to remove the faulty LED and install new LED

lamp

-. Assembly shall be done in reverse order of disassembly

5

[CAUTION]

1. O-ring and Packing shall not be reused (Should these have to be used, confirm any

damage inflicted in them.)

2. Wear soft gloves on replacing lamp. (Do not touch the surface of lamp by naked hand)

YOUYANG AIRPORT LIGHTING EQUIPMENT INC. PAGE 25/34

OPERATING & MAINTENANCE MANUAL MODEL : ELB series

4.3.3 COUPLING REPLACEMENT

1) TOOLS AND MATERIAL

TOOLS MATERIAL

(+) shape Driver 1. Coupling

2) METHOD OF WORK

NO PHOTO CONTENTS

Shape of lighting before maintenance

1) The fixture

1

2) Coupling

3) Base plate

Separate Coupling and Support of the fixture by

loosening bolts fixing Coupling and Support together

2 1. 1) Support of the fixture

2. 2) Coupling

3. 3) Bolts

Assemble with new Coupling

Assembly shall be done in reverse order of disassembly

3

1) Bolts

2) Coupling

YOUYANG AIRPORT LIGHTING EQUIPMENT INC. PAGE 26/34

OPERATING & MAINTENANCE MANUAL MODEL : ELB series

4.3.4 POWER SECTION REPLACEMENT

1) TOOLS AND MATERIAL

TOOLS MATERIAL

(+)shape Driver 1. Power section assembly

2. O-ring

2) METHOD OF WORK

NO DEPICTION DESCRIPTION

Shape of lighting before maintenance.

Removing 4 bolts fixing Upper cover.

1) Globe,

2

2) Bolts(For fixing globe)

3) Upper cover

Separate terminals connected to lead wire from Power

section assembly.

1) Upper part of the lighting,

3

2) O- Ring

3) Terminal

4) Power Assembly

Detach terminals to which lead wire is connected from

Power section assembly.

4

1) Power Assembly

2) Connector

YOUYANG AIRPORT LIGHTING EQUIPMENT INC. PAGE 27/34

OPERATING & MAINTENANCE MANUAL MODEL : ELB series

NO DEPICTION DESCRIPTION

3) Luminary Section Assembly

Detach Connectors to which LED is connected.

1) Luminary Section Assembly Power section assembly

5

2) Power section assembly

3) Bolt

Substitute with new Power section assembly after

6 No photograph

removing faulty Power section assembly

[CAUTION]

O-ring and Packing shall not be reused (Should these have to be used, confirm any

damage inflicted in them)

YOUYANG AIRPORT LIGHTING EQUIPMENT INC. PAGE 28/34

OPERATING & MAINTENANCE MANUAL MODEL : ELB series

4.3.5 REPLACEMENT OF LEAD WIRE

1) TOOLS AND MATERIAL

TOOLS MATERIAL

1. (+)shape Driver 1. LEAD WIRE

2. (-)shape Driver

3. L-wrench(5mm)

2.) REPLACEMENT OF LEAD WIRE

NO PHOTO DESCRIPTION

1 Shape of lighting before maintenance

Remove 4 bolts fixing upper cover.

1) Bolts

2

2) Upper cover

Separate terminals connected to lead wire from

Power section assembly.

1) Upper lighting fixture

3

2) O-Ring

3) Terminals

4) Power section assembly

Pull out lead wire from the fixture after removing Code

4 Push fixing the wire of Upper fixture.

1) The fixture

YOUYANG AIRPORT LIGHTING EQUIPMENT INC. PAGE 29/34

OPERATING & MAINTENANCE MANUAL MODEL : ELB series

NO PHOTO DESCRIPTION

2) Silicon glass tube

3) Lead wire

4) Flier

1) Take in upper fixture new lead wire in reverse order

of disassembly.

2) Hold the wire to upper fixture with Code Push. The

5 No depiction

wire connected to the socket has to be more than

0.5m.

3) Assemble in reverse order of disassembly.

YOUYANG AIRPORT LIGHTING EQUIPMENT INC. PAGE 30/34

OPERATING & MAINTENANCE MANUAL MODEL : ELB series

5. STORAGE & SHIPPING

5.1 STORAGE

1) All light fixtures are packed in a separate box with label indicating its contents.

2) Lighting fixtures shall be stored indoor under dry condition kept away from dust.

5.2 STORAGE CONDITION

1) Place : Dry place without dust

2) Temperature : : From -55˚C to 70˚C

3) Humidity : Below 90%

5.3 SHIPPING

1) The heavier package of the light fixtures shall be placed at the bottom and lighter

box of package shall be placed on the upper position.

2) Bigger outer box covering smaller boxes of package shall indicate contents of the

boxes in a label.

3) Racks, boxes and closed containers may be used for shipping.

4) Precautions shall be taken before opening the shipping container to protect the

contents of the package from dust or impurities. .

5) Shipment shall be made in compliance with General Terms and Conditions for air

and ocean freight.

YOUYANG AIRPORT LIGHTING EQUIPMENT INC. PAGE 31/34

OPERATING & MAINTENANCE MANUAL MODEL : ELB series

6. DRWAING & PARTS LIST

ELB-TEDL : ELEVATED OMNIDIRECTIONAL LOW INTENSITY LIGHT

YOUYANG AIRPORT LIGHTING EQUIPMENT INC. PAGE 32/34

OPERATING & MAINTENANCE MANUAL MODEL : ELB series

Parts List

No Parts Name Specification Qt’y Ordering No.

1 Globe Polycarbonate 1 142-019A

2 Bolt M3*10Stainless steel) 4 324-190C

3 LED lens Acrylic 1 152-215C

4 Bolt M3*8(Stainless steel) 4 324-190A

5 O ring Ø59.4* Ø3.1(G90) 1 151-124B

6 Bolt M3*6(Polycarbonate) 3 326-160A

7 LED(Blue) XP-E(CREE) 1 122-208A

Ø112*21(Aluminum

8 Upper cover 1 215-101A

die-casting)

9 Bolt M4*14(Stainless steel) 4 324-781A

TEDL/LED 1W/5STEP

10 Control assembly 1 411-026R

(LINEAR)/BLUE(160mA)

11 Bolt M3*8(Stainless steel) 2 324-084B

12 O ring Ø89.4* Ø3.1(G90) 1 151-123B

13 Tube Silicon 2 126-109A

Ø112*91(Aluminum

14 Upper body 1 215-102A

die-casting)

15 Bolt M6*20(Stainless steel) 1 324-217A

R35*34(Aluminum die-

16 Body clamp 2 215-103A

casting)

17 Cord push 6NR16 1 126-304A

Ø65*98(Aluminum die-

18 Body support 1 215-104A

casting)

19 Bolt M6*12(Stainless steel) 3 324-108A

Ø65*78*54C(Aluminum

20 Breakable coupling 1 215-105A

die-casting)

FAA L-823

21 2-Pole plug 1 124-011A

600V 1.25SQ*2C*0.5M

YOUYANG AIRPORT LIGHTING EQUIPMENT INC. PAGE 33/34

OPERATING & MAINTENANCE MANUAL MODEL : ELB series

6.1 Ordering Code Information

YOUYANG AIRPORT LIGHTING EQUIPMENT INC. PAGE 34/34

You might also like

- HKN-93 Series Manual de Servicio PDFDocument84 pagesHKN-93 Series Manual de Servicio PDFDiana Vega86% (7)

- NEC NP-V332X V332W V302H Service Manual (2nd Ed)Document343 pagesNEC NP-V332X V332W V302H Service Manual (2nd Ed)RandyCairo100% (2)

- Very Advanced Maternal Age, TOG-2021Document10 pagesVery Advanced Maternal Age, TOG-2021saeed hasan saeedNo ratings yet

- Jesus The Liberator - Jon SorbinoDocument321 pagesJesus The Liberator - Jon SorbinoavaMotivatorije94% (16)

- Gateway-and-Apple 1111Document5 pagesGateway-and-Apple 1111Khulan Tsetsegmaa100% (3)

- Mercruiser Service Manual #14 Alpha I Gen II Outdrives 1991-NewerDocument715 pagesMercruiser Service Manual #14 Alpha I Gen II Outdrives 1991-NewerM5Melo100% (10)

- vxBjICCrQ7eQYyAgq0O3cg - Debit Credit Rules ActivityDocument1 pagevxBjICCrQ7eQYyAgq0O3cg - Debit Credit Rules ActivityAlok PatilNo ratings yet

- Gymnastic Bodies Fundamentals GuideDocument17 pagesGymnastic Bodies Fundamentals GuideGianniNo ratings yet

- Lince: User'S and Installer'S ManualDocument15 pagesLince: User'S and Installer'S ManualDragos VidmichiNo ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Religion and Belief Systems in Australia Post 1945Document6 pagesReligion and Belief Systems in Australia Post 1945Jananee SundarakumarNo ratings yet

- Offshore Engineer-February 2015Document84 pagesOffshore Engineer-February 2015ilkerkozturk100% (2)

- Spotify Strategig Possining and Product Life Cycle Four Basic Stages.Document5 pagesSpotify Strategig Possining and Product Life Cycle Four Basic Stages.Jorge YeshayahuNo ratings yet

- Kasatha 5eDocument1 pageKasatha 5eBryce St. LouisNo ratings yet

- Tgs-Led: Taxiway Guidance Sign: Technical Specification & Operation ManualDocument26 pagesTgs-Led: Taxiway Guidance Sign: Technical Specification & Operation ManualJavier Eduardo Alzate BogotaNo ratings yet

- User'S Manual Operating & Maintenance: RGL-L: Runway Guard Light (Led)Document21 pagesUser'S Manual Operating & Maintenance: RGL-L: Runway Guard Light (Led)Javier Eduardo Alzate BogotaNo ratings yet

- NVC DCP551B Um CP SP 1032e 18Document220 pagesNVC DCP551B Um CP SP 1032e 18johnductamNo ratings yet

- Model DT450G Dust Monitor: User's ManualDocument41 pagesModel DT450G Dust Monitor: User's ManualzaffarNo ratings yet

- User's Manual: AQ2200 Series Modules Checking The Contents of The Package and Handling Precautions of The ModulesDocument10 pagesUser's Manual: AQ2200 Series Modules Checking The Contents of The Package and Handling Precautions of The Modulessagar_ovhalNo ratings yet

- Autonics CX Series - User ManualDocument87 pagesAutonics CX Series - User ManualEldglay da Silva DomingosNo ratings yet

- Manual de Uso Coagulador Bipolar BP-200Document20 pagesManual de Uso Coagulador Bipolar BP-200Clinica de Estudios Oftalmologicos PracticanteNo ratings yet

- Dell 2209WA Service Manual Rev 1.0Document85 pagesDell 2209WA Service Manual Rev 1.01133523568585No ratings yet

- Burner Controller User's Manual: Model AUR890Document66 pagesBurner Controller User's Manual: Model AUR890Edwin Salazar OrtizNo ratings yet

- AgilePID - User Manual - Ver10 - 20210113Document24 pagesAgilePID - User Manual - Ver10 - 20210113Raj GaneshNo ratings yet

- TK - EN - User ManualDocument125 pagesTK - EN - User ManualHector CamachoNo ratings yet

- Projector Manual 2550Document73 pagesProjector Manual 2550narozNo ratings yet

- Adb Uel-1-120Document41 pagesAdb Uel-1-120FranciscoVicenteNo ratings yet

- Manual de Utilizare Motor Automatizare Rulouri Motorline TUB25Document6 pagesManual de Utilizare Motor Automatizare Rulouri Motorline TUB25Daniel PanciuNo ratings yet

- Incubadora de Transporte DAVID TI-2000 Service ManualDocument99 pagesIncubadora de Transporte DAVID TI-2000 Service ManualDaniela GonzalezNo ratings yet

- VG User en 190129 WDocument126 pagesVG User en 190129 WaluiziojoseNo ratings yet

- Ir 202 ImDocument103 pagesIr 202 ImzaffarNo ratings yet

- TMU220 PrintersDocument18 pagesTMU220 PrintersAlmir PedrottiNo ratings yet

- XWEB300D/500D/500 EVO: Installation ManualDocument24 pagesXWEB300D/500D/500 EVO: Installation ManualHalilNo ratings yet

- Manual - Autonics Vision Sensor VGDocument124 pagesManual - Autonics Vision Sensor VGMuhammad Imam MuthahharNo ratings yet

- Autonics TK ManualDocument124 pagesAutonics TK ManualFathurrahman Yudhi NugrahaNo ratings yet

- User Manual: PrefaceDocument92 pagesUser Manual: PrefaceJosé Gregorio González TorresNo ratings yet

- Tai Lieu Man Hinh HMI AutonicsDocument80 pagesTai Lieu Man Hinh HMI AutonicsViệnVuiVẻNo ratings yet

- THERMOVAC Transmitter: TTR 101N, TTR 101N S Operating Manual 300544655 - 002 - A0Document41 pagesTHERMOVAC Transmitter: TTR 101N, TTR 101N S Operating Manual 300544655 - 002 - A0Cuauhtémoc Arroyo GonzalezNo ratings yet

- User Manual: Auto Crib-It Ac SeriesDocument21 pagesUser Manual: Auto Crib-It Ac SeriesForum PompieriiNo ratings yet

- Ab 6590 PDFDocument20 pagesAb 6590 PDFMeffendi PenpenNo ratings yet

- SCA 102UB v2.0Document89 pagesSCA 102UB v2.0Henry CharriereNo ratings yet

- Im11g02q02 51en PDFDocument45 pagesIm11g02q02 51en PDFsagar_ovhalNo ratings yet

- Single Loop Controller SDC15 User's Manual: "Installation & Configurations"Document208 pagesSingle Loop Controller SDC15 User's Manual: "Installation & Configurations"Phan Van SinhNo ratings yet

- Beam 201Document24 pagesBeam 201emilioNo ratings yet

- Manuale UtenteDocument124 pagesManuale UtentepercorsielmarNo ratings yet

- User's Manual: Model ISC450G Inductive Conductivity Converter (Style: S2)Document81 pagesUser's Manual: Model ISC450G Inductive Conductivity Converter (Style: S2)Roger Molina GomezNo ratings yet

- Luxpower Sna 6000 Wide PV ManualDocument21 pagesLuxpower Sna 6000 Wide PV Manual2ddpNo ratings yet

- Wilo F 020000140002383f00010092Document17 pagesWilo F 020000140002383f00010092Ion TestaNo ratings yet

- Light Source SLS-2100PDocument18 pagesLight Source SLS-2100PVictor BlancoNo ratings yet

- Sharp PN-655U Manuel D'utilisationDocument128 pagesSharp PN-655U Manuel D'utilisationYann BajardNo ratings yet

- KRN1000 EN Comm DRW190833AA 20191013 WDocument115 pagesKRN1000 EN Comm DRW190833AA 20191013 WAbraham galvánNo ratings yet

- Becken BAC4255 Air ConditionerDocument182 pagesBecken BAC4255 Air ConditionerMarcelo Peixoto Del PelosoNo ratings yet

- FL-560 - 2025 Operation Manual PDFDocument129 pagesFL-560 - 2025 Operation Manual PDFMartin Fuemayor MavarezNo ratings yet

- One Series Rotational Viscometer: Instruction ManualDocument53 pagesOne Series Rotational Viscometer: Instruction Manualcristhian manzanoNo ratings yet

- Bizhub c450Document780 pagesBizhub c450mapsonNo ratings yet

- Im12b07c05 01eDocument88 pagesIm12b07c05 01eYasir JamilNo ratings yet

- S1 Huayuan ManualDocument95 pagesS1 Huayuan ManualTrần Đinh MinhNo ratings yet

- Instruction Manual: E84111-K00060-00 Published Feb.2008 Ver.3-1.01Document36 pagesInstruction Manual: E84111-K00060-00 Published Feb.2008 Ver.3-1.01Kluzu Formaggio100% (1)

- User Manual: Panel PCDocument38 pagesUser Manual: Panel PCMarcos De AlmeidaNo ratings yet

- HKN 93 Series Manual de ServiciopdfDocument86 pagesHKN 93 Series Manual de ServiciopdfантонNo ratings yet

- Electrostatic Precipitation (ESP) Filter UnitDocument46 pagesElectrostatic Precipitation (ESP) Filter UnitDjordjeNo ratings yet

- Ir 400 ImDocument119 pagesIr 400 ImzaffarNo ratings yet

- Bizhub - 162 - 210Document660 pagesBizhub - 162 - 210houdaa salaNo ratings yet

- Liebert Ita2 30kva Ups User Manual v1.2Document108 pagesLiebert Ita2 30kva Ups User Manual v1.2nelson yenner ramirez minayaNo ratings yet

- Bizhub Pro 920Document640 pagesBizhub Pro 920Abdul WahabNo ratings yet

- Technical DataDocument246 pagesTechnical DataABDUL GHAFOORNo ratings yet

- Chainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesFrom EverandChainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesRating: 5 out of 5 stars5/5 (1)

- Automotive Actuators and EVAP System TestingFrom EverandAutomotive Actuators and EVAP System TestingRating: 4.5 out of 5 stars4.5/5 (4)

- Ethiopian Health Systems and PolicyDocument81 pagesEthiopian Health Systems and PolicyFami Mohammed100% (2)

- To-Do List FormulaDocument1 pageTo-Do List FormulaPre MANo ratings yet

- Final Management Project On Geo TVDocument35 pagesFinal Management Project On Geo TVAli Malik100% (1)

- 1 A-2 Mann - Concept of Infrastructural PowerDocument11 pages1 A-2 Mann - Concept of Infrastructural Powerrichiflowers11gmail.comNo ratings yet

- Size & Estimation of DWDocument12 pagesSize & Estimation of DWGiuseppe GiuseppeNo ratings yet

- The 5 Founding Fathers and A History of Positive PsychologyDocument11 pagesThe 5 Founding Fathers and A History of Positive PsychologyItno WatiNo ratings yet

- University of WorcesterDocument8 pagesUniversity of WorcesterchhaiiNo ratings yet

- Various Artists - The Joy of ClassicsDocument82 pagesVarious Artists - The Joy of ClassicsCarlos Toledo88% (16)

- Working Capital Management Maruti SuzukiDocument76 pagesWorking Capital Management Maruti SuzukiAmit singhNo ratings yet

- Aire - 1 ReinigenDocument25 pagesAire - 1 Reinigengino aldo palomino ludeñaNo ratings yet

- CFP Registration Process (Final) - 3Document39 pagesCFP Registration Process (Final) - 3nishiNo ratings yet

- Thesis APDocument31 pagesThesis APIvy SorianoNo ratings yet

- Dg-1 (Remote Radiator) Above Control Room Slab: 05-MAR-2018 Atluri Mohan Krishna (B845)Document32 pagesDg-1 (Remote Radiator) Above Control Room Slab: 05-MAR-2018 Atluri Mohan Krishna (B845)Shaik AbdullaNo ratings yet

- OO ALV Status Led LightDocument6 pagesOO ALV Status Led LightRam PraneethNo ratings yet

- CH 3 Online Advertising vs. Offline AdvertisingDocument4 pagesCH 3 Online Advertising vs. Offline AdvertisingKRANTINo ratings yet

- Abhinavagupta (C. 950 - 1016 CEDocument8 pagesAbhinavagupta (C. 950 - 1016 CEthewitness3No ratings yet

- English - Fine - Tune Your English 2019Document3 pagesEnglish - Fine - Tune Your English 2019NishaNo ratings yet

- MUSIC10 Q2 (Latin American Music, Jazz and Pop Music) Week 2 - CardelDocument5 pagesMUSIC10 Q2 (Latin American Music, Jazz and Pop Music) Week 2 - CardelJeff Nieva CardelNo ratings yet

- How Will 'Chipageddon' Affect You ?Document50 pagesHow Will 'Chipageddon' Affect You ?Satyaki DuttaNo ratings yet

- Mortality RateDocument5 pagesMortality Rateamit kumar dewanganNo ratings yet