Professional Documents

Culture Documents

Aeroshell Fluid 31

Aeroshell Fluid 31

Uploaded by

mertaktayOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aeroshell Fluid 31

Aeroshell Fluid 31

Uploaded by

mertaktayCopyright:

Available Formats

Technical Data Sheet

AeroShell Fluid 31

AeroShell Fluid 31 is a synthetic hydrocarbon based aircraft hydraulic fluid with greatly improved fire resistance

characteristics when compared with conventional petroleum products.

AeroShell Fluid 31 has a specially designed base stock which imparts a relatively high flash point, excellent low

temperature properties and good oxidation and thermal stability. In addition, AeroShell Fluid 31 is formulated with

high technology additives to provide oxidation and corrosion resistance, antiwear, and anti-foaming protection.

· AeroShell Fluid 31 is a synthetic hydrocarbon based aircraft hydraulic fluid with greatly improved fire resistance

characteristics when compared with conventional petroleum products.

· AeroShell Fluid 31 has a specially designed base stock which imparts a relatively high flash point, excellent low

temperature properties and good oxidation and thermal stability. In addition, AeroShell Fluid 31 is formulated

with high technology additives to provide oxidation and corrosion resistance, antiwear, and anti-foaming

protection.

· AeroShell Fluid 31 is superclean filtered to ensure optimum performance in particulate monitored systems.

· AeroShell Fluid 31 is dyed red. The useful operating temperature range is –40 to +2050C.

Main Applications · AeroShell Fluid 31 is compatible with AeroShell Fluids 41,

· AeroShell Fluid 31 is recommended for use in aircraft,

ordnance, and missile systems operating from –40 C to0

and 61 and can be used in systems designed to operate with

MIL-PRF-5606, MIL-PRF-6083, MIL-PRF-87257 and MIL-

0

+205 C . This fluid should be considered for use in auto PRF-46170 fluids.

pilots, shock absorbers, brakes, flight control systems,

hydraulic servo-controlled systems and other systems

· Chlorinated solvents should not be used for cleaning

hydraulic components which use AeroShell Fluid 31. The

using synthetic elastomer seals. An increasing number of residual solvent contaminates the hydraulic fluid and may

aircraft manufacturers now recommend use of this type of lead to corrosion.

fluid in aircraft hydraulic systems in preference to mineral

Specifications, Approvals & Recommendations

·

hydraulic oils. This move has been prompted by need to

MIL-PRF-83282D

use fluids with better fire resistant properties.

· AeroShell Fluid 31 is also approved for use in the · French: DCSEA 437/A

Honeywell (formerly Garrett) cooling turbine (cabin air · NATO Code H-537

compressors). Increasingly this type of hydraulic fluid is

being adopted for use in hydraulic systems of military

· Joint Service Designation OX-19

For a full listing of equipment approvals and

aircraft in place of mineral hydraulic fluids. recommendations, please consult your local Shell Technical

· AeroShell Fluid 31 is a synthetic hydrocarbon oil and

should not be used in contact with incompatible seal

Helpdesk.

materials.

Typical Physical Characteristics

Properties Method MIL-PRF-83282D Typical

Oil type Synthetic Hydrocarbon Synthetic Hydrocarbon

Colour Red

Page 1 of 2 AeroShell Fluid 31, v 1.3 21.07.2021.12.41

Properties Method MIL-PRF-83282D Typical

Specific Gravity @15.6/15 ASTM D1298 Report 0.851

.60C

Kinematic Viscosity @2050C mm2/s ASTM D445 1.0 min 1.06

Kinematic Viscosity @1000C mm2/s ASTM D445 3.45 min 3.53

Kinematic Viscosity @400C mm2/s ASTM D445 14.0 min 14.3

Kinematic Viscosity @–400C mm2/s ASTM D445 2 200 max 2 059

Pour Point 0

C ASTM D97 -55 max -69

Flash Point 0

C ASTM D92 205 min 218

Fire Point (COC) 0

C ASTM D92 245 min 251

Total Acid Number mgKOH/g ASTM D664 0.10 max 0.02

Evaporation Loss @2050C %m FED-STD-791 20 max 10

M.350

Low temperature stability 72 @-400C FED-STD-791- Must pass Passes

hrs 3458

Barium content mg/kg ASTM D5185 10 max 0

Gravimetric analysis mg/100ml ASTM D4898 0.3 max 0.2

Solid Particle Contamination FED-STD-791 Must pass Passes

M.3009

Water Content mg/kg ASTM D1744 100 max 60

Foaming Characteristics - Seq ml/ml ASTM D892 65/0 Passes

I Tendency Stability

Flame Propagation cm/s ASTM D5306 Must pass Passes

4-Ball Wear, 750C - scar dia 1 kg mm ASTM D4172 0.21 max 0.16

load/1200

rpm

4-Ball Wear, 750C - scar dia 10 kg mm ASTM D4172 0.30 max 0.22

load/1200

rpm

4-Ball Wear, 750C - scar dia 40 kg mm ASTM D4172 0.65 max 0.51

load/1200

rpm

Corrosion & oxidation stability @1210C mg/cm2 ASTM D4636 Must pass Passes

168 hrs - metal weight change

Corrosion & oxidation stability % ASTM D4636 10 max <10

(168 hrs @ 1210C) - viscosity

change

Corrosion & oxidation stability @1210C mgKOH/g ASTM D4636 0.2 max <0.02

168 hrs - acid number change

These characteristics are typical of current production. Whilst future production will conform to Shell's specification,

variations in these characteristics may occur.

Health, Safety & Environment

· Health and Safety

This product is unlikely to present any significant health or safety hazard when properly used in the recommended

application and good standards of personal hygiene are maintained.

Avoid contact with skin. Use impervious gloves with used oil. After skin contact, wash immediately with soap and water.

Guidance on Health and Safety is available on the appropriate Safety Data Sheet, which can be obtained from

https://www.epc.shell.com

· Protect the Environment

Take used oil to an authorised collection point. Do not discharge into drains, soil or water.

Additional Information

· Advice

Advice on applications not covered here may be obtained from your Shell representative.

Page 2 of 2 AeroShell Fluid 31, v 1.3 21.07.2021.12.41

You might also like

- OB MBA Final Summer 22 OB MBA Final Summer 22: Test ContentDocument10 pagesOB MBA Final Summer 22 OB MBA Final Summer 22: Test ContentDUAA ALJEFFRINo ratings yet

- FT Grease 22Document2 pagesFT Grease 22Edgar Leonel CortésNo ratings yet

- Aeroshell Grease 22: Main Applications Specifications, Approvals & RecommendationsDocument2 pagesAeroshell Grease 22: Main Applications Specifications, Approvals & RecommendationsyierbNo ratings yet

- Aeroshell Fluid 3Document2 pagesAeroshell Fluid 3mertaktayNo ratings yet

- PassportDocument2 pagesPassportAzat ZaripovNo ratings yet

- AeroShell Fluid 41Document2 pagesAeroShell Fluid 41Pawang SingaNo ratings yet

- Aeroshell 41Document2 pagesAeroshell 41Farid SaadNo ratings yet

- Shell GT32 1451468381Document2 pagesShell GT32 1451468381Pramod SokhariyaNo ratings yet

- Aircol SR 68Document2 pagesAircol SR 68nauta007No ratings yet

- MDS SHELL Turbo Oil T68Document2 pagesMDS SHELL Turbo Oil T68Antonio CardosoNo ratings yet

- Shell Turbo Oil T 68Document2 pagesShell Turbo Oil T 68Muhammad SaputraNo ratings yet

- Fluidmatic Syn T668: Key DataDocument2 pagesFluidmatic Syn T668: Key Datazac.mechanicalNo ratings yet

- Shell Turbo T 68Document2 pagesShell Turbo T 68Eid EeidNo ratings yet

- Shell Turbo: Premium Based Industrial Steam, Gas and Combined Cycle Turbine LubricantDocument2 pagesShell Turbo: Premium Based Industrial Steam, Gas and Combined Cycle Turbine Lubricantfaisalnadim100% (1)

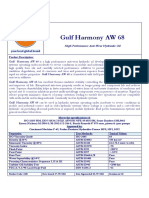

- 3508 Gulf Harmony AW 68 DataDocument1 page3508 Gulf Harmony AW 68 Datakatty_89No ratings yet

- 3508 Gulf Harmony AW 68 DataDocument1 page3508 Gulf Harmony AW 68 DataHitesh MahajanNo ratings yet

- Shell Fire-Resistant Hydraulic Fluid S3 DU 100Document2 pagesShell Fire-Resistant Hydraulic Fluid S3 DU 100Jorge Arrieta TorresNo ratings yet

- Evolution Full-Tech Fe 5w-30 EngDocument1 pageEvolution Full-Tech Fe 5w-30 EngDaniel MartínNo ratings yet

- Enersyn RC-S RangeDocument2 pagesEnersyn RC-S RangecarmaNo ratings yet

- Aeroshell Grease 58: Main ApplicationsDocument2 pagesAeroshell Grease 58: Main ApplicationsSophia RoseNo ratings yet

- Gpcdoc Local Tds Iraq Shell Turbo T 68 (Ar-Iq) TdsDocument2 pagesGpcdoc Local Tds Iraq Shell Turbo T 68 (Ar-Iq) TdsBar AvaitNo ratings yet

- Shell Turbo Oil J 32Document2 pagesShell Turbo Oil J 32Agus F RahmanNo ratings yet

- Gulf Harmony AW 46 Data SheetDocument1 pageGulf Harmony AW 46 Data SheetRezaNo ratings yet

- Techinical Data-Proton X70 DCT FluidDocument2 pagesTechinical Data-Proton X70 DCT Fluidjasonccw.pqholdingsNo ratings yet

- Gengear Series SPL-A Up To 320Document3 pagesGengear Series SPL-A Up To 320Hakim AmmorNo ratings yet

- Aeroshell Ascender: Performance, Features & Benefits Main ApplicationsDocument3 pagesAeroshell Ascender: Performance, Features & Benefits Main ApplicationsRicardo LacskoNo ratings yet

- Aircol HC 7, HC 10Document2 pagesAircol HC 7, HC 10Vladislav TrempoletsNo ratings yet

- Shell Spirax S5 DCT 11: Performance, Features & Benefits Main ApplicationsDocument2 pagesShell Spirax S5 DCT 11: Performance, Features & Benefits Main ApplicationsFernando Yupa SalazarNo ratings yet

- EfekDocument2 pagesEfekGasa RafliNo ratings yet

- Hyspin ZZ Range: DescriptionDocument2 pagesHyspin ZZ Range: DescriptionDaniel VuletaNo ratings yet

- 4454 Turbine Oil 46Document1 page4454 Turbine Oil 46AANo ratings yet

- Repsol Maker Hydraulico SC 46Document1 pageRepsol Maker Hydraulico SC 46ibrahim maulanaNo ratings yet

- Perfecto T Range: DescriptionDocument2 pagesPerfecto T Range: Descriptiondforsythe639No ratings yet

- J 32 - Premium Industrial Turbine OilDocument2 pagesJ 32 - Premium Industrial Turbine OilRaden ArdyNo ratings yet

- Rimula r2 0w 50Document2 pagesRimula r2 0w 50Aji WibowoNo ratings yet

- Shell Turbo Oil T32: Performance, Features & BenefitsDocument2 pagesShell Turbo Oil T32: Performance, Features & BenefitsCertified Rabbits LoverNo ratings yet

- P000258 Motorbike 4T 10W 40 Scooter 42 en GBDocument1 pageP000258 Motorbike 4T 10W 40 Scooter 42 en GBimranrezaNo ratings yet

- Shell Corena S4 P 68 TDSDocument3 pagesShell Corena S4 P 68 TDSmuralisunNo ratings yet

- 08-TDS - Canroyal Full Synthetic Diesel Engine Oil Sae 15W-40 Api Ci-4.Document1 page08-TDS - Canroyal Full Synthetic Diesel Engine Oil Sae 15W-40 Api Ci-4.catpilar274No ratings yet

- 77 Molej GMX - 5W 30Document1 page77 Molej GMX - 5W 30Ondřej KlímaNo ratings yet

- TDS Transpro 40 - Sae 15W-40Document1 pageTDS Transpro 40 - Sae 15W-40Andaru GunawanNo ratings yet

- Eastman Turbo Oil 25 TDSDocument2 pagesEastman Turbo Oil 25 TDSbarcaza_13No ratings yet

- Shell Rimula R2 Extra 20W-50 (CF-4/228.1) : Performance, Features & BenefitsDocument2 pagesShell Rimula R2 Extra 20W-50 (CF-4/228.1) : Performance, Features & BenefitsWajahat RasoolNo ratings yet

- PDS Castrol RLX Super 40Document2 pagesPDS Castrol RLX Super 40epesanoNo ratings yet

- Gpcdoc Local Tds Iraq Shell Turbo T 32 (Ar-Iq) TdsDocument3 pagesGpcdoc Local Tds Iraq Shell Turbo T 32 (Ar-Iq) Tds100impianNo ratings yet

- Airtop HTDocument1 pageAirtop HTtribolasNo ratings yet

- Shell Turbo Oil T 100Document2 pagesShell Turbo Oil T 100Muhammad SaputraNo ratings yet

- Shell Turbo Oil T32: Performance, Features & BenefitsDocument2 pagesShell Turbo Oil T32: Performance, Features & BenefitsHANIF AKBARNo ratings yet

- Repsol Telex HVLP 32Document2 pagesRepsol Telex HVLP 32ibrahim maulanaNo ratings yet

- GPCDOC Local TDS Oman Shell Rimula R3+ 40 CF 228.0 en TDS v1Document2 pagesGPCDOC Local TDS Oman Shell Rimula R3+ 40 CF 228.0 en TDS v1Nokiabhre WijayaNo ratings yet

- HTS and HPC Specification DifferencesDocument11 pagesHTS and HPC Specification Differencesmohammed kareemNo ratings yet

- Shell Rimula R4 L 15W-40: Performance, Features & Benefits Specifications, Approvals & RecommendationsDocument2 pagesShell Rimula R4 L 15W-40: Performance, Features & Benefits Specifications, Approvals & RecommendationsAMITNo ratings yet

- Shell Turbo Oil J 32Document2 pagesShell Turbo Oil J 32Muhammad SaputraNo ratings yet

- S-Oil+hydro+fluid TDS PDFDocument1 pageS-Oil+hydro+fluid TDS PDFphucdc095041No ratings yet

- TDS TotalEnergies Rubia-TIR-7400-15W-40 13T 202206 ENDocument2 pagesTDS TotalEnergies Rubia-TIR-7400-15W-40 13T 202206 ENRe ZanoNo ratings yet

- Shell Rimula R3 X 20W-50 (CH-4/228.3) : Performance, Features & BenefitsDocument2 pagesShell Rimula R3 X 20W-50 (CH-4/228.3) : Performance, Features & Benefitssamsoon80No ratings yet

- Total Caprano TD 30 - 40Document1 pageTotal Caprano TD 30 - 40Emiliano BoggianoNo ratings yet

- Rubia SX 30Document2 pagesRubia SX 30Renato FerreiraNo ratings yet

- Aeroshel 500 DatasheetDocument2 pagesAeroshel 500 DatasheetRolando Antonio Cuenca PironaNo ratings yet

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceFrom EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceNo ratings yet

- Internet of Things: Jordi Salazar, Santiago SilvestreDocument31 pagesInternet of Things: Jordi Salazar, Santiago SilvestreMaicol CoaguilaNo ratings yet

- KV DH1L 5 - DatasheetDocument1 pageKV DH1L 5 - DatasheetWSR indiaNo ratings yet

- Employer'S Virtual Pag-Ibig Enrollment Form: Address and Contact DetailsDocument2 pagesEmployer'S Virtual Pag-Ibig Enrollment Form: Address and Contact DetailstheffNo ratings yet

- PLC Instruction ListDocument4 pagesPLC Instruction ListPrestoneKNo ratings yet

- Philips Projection Catalogue 2021-22Document15 pagesPhilips Projection Catalogue 2021-22James StanleyNo ratings yet

- Shinigami EyesDocument1 pageShinigami EyesMartina SandrićNo ratings yet

- Terjemahan MBT 726 - 728Document2 pagesTerjemahan MBT 726 - 728Muchammad FauziNo ratings yet

- (IJCST-V10I3P35) :aisha Farhana, Aswani K.S, Aswathy A.C, Divya Jolly M, Elia NibiaDocument7 pages(IJCST-V10I3P35) :aisha Farhana, Aswani K.S, Aswathy A.C, Divya Jolly M, Elia NibiaEighthSenseGroupNo ratings yet

- A New Fretting Fatigue Testing Machine Design, Utilizing Rotating-Bending Principle ApproachDocument12 pagesA New Fretting Fatigue Testing Machine Design, Utilizing Rotating-Bending Principle Approachkamal reddyNo ratings yet

- 5KE Series - Supressor DiodesDocument4 pages5KE Series - Supressor DiodesMarcelo VilachanNo ratings yet

- Full Auto Vacuum BCT Production Line - TenghuDocument11 pagesFull Auto Vacuum BCT Production Line - TenghuImad HassenNo ratings yet

- Managing Projects and Program BUS 5611 Written Assignment - 7Document6 pagesManaging Projects and Program BUS 5611 Written Assignment - 7Fahruddin ArrazyNo ratings yet

- Tutorial 1: A Review of AC Circuit Analysis and Frequency Response AnalysisDocument5 pagesTutorial 1: A Review of AC Circuit Analysis and Frequency Response AnalysisSahil WalkeNo ratings yet

- 2 Combination StrategyDocument4 pages2 Combination Strategyxomavi8122No ratings yet

- Methodology 4.1 Algorithm: Chapter 4 Web Application of Secure and Trusted Matrimonial SystemDocument3 pagesMethodology 4.1 Algorithm: Chapter 4 Web Application of Secure and Trusted Matrimonial SystemShekhar JadhavNo ratings yet

- API 614 Comments Mac-Su-3563-EDocument17 pagesAPI 614 Comments Mac-Su-3563-EJESUSNo ratings yet

- Corporate H ScriDocument4 pagesCorporate H ScriHGL ConsultingNo ratings yet

- Spreadsheet Modeling and Decision Analysis A Practical Introduction To Business Analytics 7th Edition Cliff Ragsdale Test Bank Full DownloadDocument41 pagesSpreadsheet Modeling and Decision Analysis A Practical Introduction To Business Analytics 7th Edition Cliff Ragsdale Test Bank Full Downloadmichaeljonesjecimdobxs100% (26)

- Pengaruh Harga Dan Fasilitas Terhadap Keputusan Berkunjung Wisatawan Di Objek Wisata Bukit Gibeon Kecamatan Ajibata Kabupaten Toba SamosirDocument17 pagesPengaruh Harga Dan Fasilitas Terhadap Keputusan Berkunjung Wisatawan Di Objek Wisata Bukit Gibeon Kecamatan Ajibata Kabupaten Toba Samosirjalan hajetNo ratings yet

- Automatic Power Factor Corrector Using ArduinoDocument77 pagesAutomatic Power Factor Corrector Using ArduinoVinay kumarNo ratings yet

- Shashank Eumind ProjectDocument3 pagesShashank Eumind Projectapi-536196914No ratings yet

- Anamorphic Art: Science, Math, and Art Make Magic?Document8 pagesAnamorphic Art: Science, Math, and Art Make Magic?a hNo ratings yet

- Crouzet Millenium - Mascable Programming CableDocument2 pagesCrouzet Millenium - Mascable Programming CableFeras AdvertisementsNo ratings yet

- Groupes - S5 Ling 2016 12 28Document47 pagesGroupes - S5 Ling 2016 12 28Kabe LabelloNo ratings yet

- Toaz - Info Acing Css 40 Books 240 Takeaways by Bilal Zahoorpdf PRDocument282 pagesToaz - Info Acing Css 40 Books 240 Takeaways by Bilal Zahoorpdf PRFurqan AliNo ratings yet

- 7 Tools For The Quality Journey: Dr. Maricel Correa GalangDocument23 pages7 Tools For The Quality Journey: Dr. Maricel Correa Galangfull sunNo ratings yet

- CVDocument2 pagesCVAdindaHumairaNo ratings yet

- licM08V Eng PDFDocument2 pageslicM08V Eng PDFFeeze WdsNo ratings yet

- Concepts (PPT) - Data PreprocessingDocument19 pagesConcepts (PPT) - Data Preprocessingmtemp7489No ratings yet