Professional Documents

Culture Documents

Design and Development of A Coconut Shell Shaver Machine

Design and Development of A Coconut Shell Shaver Machine

Uploaded by

nandarulsOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design and Development of A Coconut Shell Shaver Machine

Design and Development of A Coconut Shell Shaver Machine

Uploaded by

nandarulsCopyright:

Available Formats

Engineering and Technology Journal e-ISSN: 2456-3358

Volume 08 Issue 08 August -2023, Page No.- 2531-2535

DOI: 10.47191/etj/v8i8.06, I.F. – 7.136

© 2023, ETJ

Design and Development of a Coconut Shell Shaver Machine

Renee C. Tan1, Edgardo C. Morales2, Reynaldo M. Subang3

ABSTRACT: This research focuses on the conceptualization and creation of an innovative coconut shell shaver machine, aimed at

significantly enhancing the efficiency of shell cleaning for handicrafts while prioritizing safety. The proposed design aims to achieve

an elevated level of cleaning proficiency across the coconut shell's surface. This advancement intends to alleviate the labor burden

of handicraft artisans, streamline the processing time for coconut shell crafts, and ultimately elevate the overall production rate of

coconut shell crafts.

The machine's structure encompasses a motor housed within a protective casing, interconnected through belts and pulleys

to a centrally-positioned shaft. This shaft is equipped with circular brushes at both ends. The circular brushes are thoughtfully

encased by a steel plate, meticulously engineered to safeguard against dust during operation and ensure operator safety.

The intended outcome of this innovation is to amplify the capabilities of local farmers in the Province of Surigao del Norte,

particularly at the village level. The fabrication of the device adheres to standardized measurements, with subsequent phases

involving thorough testing and precise adjustments to optimize its operational performance. A comprehensive demonstration of the

coconut shell shaver machine is also slated for presentation during the evaluation process.

KEYWORDS: Coconut shaver, shaving, testing, coconut shell and fabrication

BACKGROUND AND RATIONALE ash (Arena et al., 2016). Research has demonstrated the

Coconut holds a prominent position within the agricultural versatile utility of coconut shells in diverse applications,

landscape of the Philippines, standing as a pivotal crop. With including the creation of semi-crystalline magnetite

an annual yield of approximately 347 million metric tons, the nanoparticles (Sebastian et al., 2018), biosorbents for Ag ion

Philippines ranks as a significant global coconut producer. sorption (Staron et al., 2017), thermal insulation (Arajo et al.,

This agricultural phenomenon spans across 69 out of the 2015), agglomerates (Fiorelli et al., 2012), panels (Ayrilmis

country's 82 provinces, with the Davao Region leading the et al., 2011), and substrates for cultivating vegetables and

charge by contributing over 50% of the nation's total output. fruits such as tomatoes (Ramos et al., 2008) and other

In acknowledgment of its economic impact and versatility, innovative uses.

coconut has been included in The Premium 7, a distinguished Inggi Priyanata et al. (2022) have highlighted the

collection of Philippine commodities endorsed by the impact of the ongoing COVID-19 pandemic, coupled with a

Department of Trade and Industry. Notably, the global lack of inventive approaches to utilize coconut waste for

demand for Philippine coconut products has propelled its valuable products, resulting in challenges for individuals to

exports to contribute up to 3.6% of the nation's gross value meet their basic needs. Leveraging coconut waste as an

added (GVA). untapped resource for crafting unique and creative souvenirs

Around 70% of the nation's annual coconut harvest and decorations—such as trophies, key chains, study lamps,

is already dedicated to the production and export of diverse flower pots, and more—has emerged as an alternative

coconut-based commodities, encompassing coconut oil, solution to bolster local economies.

desiccated coconut, and copra meal. These compelling In light of these considerations, this study embarks

statistics underscore the widespread allure of Philippine on the design and development of a coconut shell shaver

coconut products. Not only do these products bolster the machine. This innovative endeavor aims to optimize the

nation's economy and enhance the livelihoods of countless process of shell cleaning for handicrafts, ensuring utmost

"tree of life" farmers, but they also solidify the Philippines' safety. By enhancing the cleaning efficiency on the coconut

presence on the international culinary map. shell's surface, the designed machine seeks to alleviate the

As reported by Ayrilmis et al. (2011), the coconut labor burden for artisans, expedite the production of coconut

shell comprises approximately 85% of the fruit's total weight, shell crafts, and elevate the overall production rate.

with its composition encompassing 33.30% lignin, 30.58% The coconut shell shaver machine comprises a

cellulose, 26.70% hemicellulose, 8.86% water, and 0.56% motor encased within a protective housing, intricately

2531 Renee C. Tan,ETJ Volume 08 Issue 08 August 2023

“Design and Development of a Coconut Shell Shaver Machine”

connected to shafts via pulleys and belts. Each shaft is fitted address the unique attributes of coconuts, notably their

with a circular brush on either end, thoughtfully enveloped by rugged shells.

a steel plate to safeguard against dust and ensure operational Following the machining phase, the diverse

safety. This ingenious device holds the potential to empower components were methodically assembled. During assembly,

village-level farmers in the Province of Surigao del Norte and the shaft underwent precision threading at both ends to

contribute to the expansion of their capabilities. accommodate the wire brush. The shaft, crucially supported

Objectives by dual pillow blocks, facilitated seamless brush rotation

The aims of this research encompass the subsequent goals: (a) during operation, while linkage to a 1.5 Hp motor was

to conceptualize and fabricate a coconut shell shaver machine achieved through two b-belts. Positioned centrally for

tailored for the craft production within village-level coconut convenient access, a switch facilitated device activation and

shell enterprises; and (b) to meticulously assess the deactivation. Notably, protective measures were instituted to

operational efficacy of the pressing apparatus. safeguard against potential hazards posed by the round brush.

Moreover, each round brush was thoughtfully equipped with

MATERIALS AND METHODS a tool rest, strategically positioned to enhance the ease of

Designing coconut shaver device coconut shell shaving.

Illustrated in Figure 1 are the technical

Evaluation Testing and Fine-Tuning of the Device

specifications and perspectives of the coconut shaver device,

Upon the successful fabrication and meticulous

inclusive of its diverse components. Constructed from 50mm

assembly of the Coconut Shell Shaver Machine, a thorough

x 50mm angle bars for the legs and framework, supplemented

and systematic testing and fine-tuning stage will ensue, aimed

by a (1&1/2X1/4) flat bar for structural reinforcement, the

at optimizing and enhancing the device's operational

machine also incorporates a 2mm-thick steel plate for its

performance. The central goal of this phase is to ensure the

cover and housing. The composition further encompasses 1"

machine's adeptness in efficiently shaving mature coconut

shafts for the wheel steel, a set of 12-inch wheel steel brushes

shells while minimizing time expenditure. It is foreseen that

employed as the shaving mechanism, a pair of 1" pillow

minor modifications and enhancements will be iteratively

blocks, and a dual-pulley configuration with a 2-inch

introduced as part of the continuous improvement trajectory

diameter, as depicted in the figure provided below.

prior to the conclusive evaluation.

Performance of the Device

Multiple iterations or trials will be conducted,

involving the shaving of mature coconut shells of varying

sizes, encompassing both whole shells and half shells. The

outcomes of these experiments will be subjected to analysis

and scrutiny, engaging in discussions regarding their efficacy.

Results and Discussion

The Coconut Shaving Device

The photograph depicted in Figure 2 provides a

visual representation of the coconut shaving device's actual

setup. The wire brush is firmly secured at both ends through

threaded connections, ensuring its stability. A protective

cover is in place to shield the operator from dust and

Figure 1: Technical specification and details (includes extraneous particles while the device is engaged. Positioned

the views and dimensions) at the central point of the configuration, a dual pulley

arrangement is attached to the shaft, which is linked to a 1.5

Fabrication of the Coconut Shell Shaver Machine Hp single-phase motor. The motor is equipped with an

The fabrication of the device adhered to established integrated pulley situated on the spindle, with a belt used to

standard measurements. Materials were precisely cut and transfer power and propel the wire brush. For maintenance

shaped, then meticulously machined to the specified purposes, the shaft cover can be easily opened when required.

dimensions, utilizing locally available resources to ensure The machine incorporates start and stop buttons, facilitating

cost-effectiveness. the initiation and cessation of its operation. To mitigate

The design considerations for the coconut shaving vibrations during use, the base is thoughtfully designed in a

device encompassed a range of factors, encompassing the rectangular form. Furthermore, the tool rest of the machine is

anticipated coconut shell volume for processing, desired ergonomically shaped in a semi-circular manner to

shaving efficiency, user-friendliness, and maintenance effectively accommodate the contours of the coconut shell.

requisites. The device's design was tailored to effectively

2532 Renee C. Tan,ETJ Volume 08 Issue 08 August 2023

“Design and Development of a Coconut Shell Shaver Machine”

Figure 2. The Coconut Shaving Device

Figure 3. Actual Photos during testing

2533 Renee C. Tan,ETJ Volume 08 Issue 08 August 2023

“Design and Development of a Coconut Shell Shaver Machine”

Figure 4. Results during testing (Whole and half coconut shell)

Evaluation of the Performance of the Machine 1700 RPM. As evidenced in Figure 4, the shaved coconut

Figure 3 illustrates the live process of coconut shell shaving shell effectively eliminates one hundred percent (100%) of

utilizing the machine's pair of circular wire brushes. The the fiber from both the whole and half coconut shells. This

complete and half coconut shells undergo shaving within a serves as a clear demonstration of the rapid shaving capability

coconut shell shaving machine that operates at a speed of achieved through the use of superior shell shaving techniques.

The Comparative Performance of Manual and Motorized Coconut Shell Shaver

Half Coconut Shell Whole Coconut Shell

Manual Shaver 15 minutes per shell 30 minutes per shell

Motorized Coconut Shell Shaver 3 minutes per shell 7 minutes per shell

The composite performance of the Motorized Coconut Shell Shaver

Category Manual Coconut Shell Shaver Machine

Manual Shaver 15 minutes per shell 30 minutes per shell

Motorized Coconut Shell Shaver 3 minutes per shell 7 minutes per shell

CONCLUSION elevates production capacity, ultimately resulting in the

The research centered on creating and crafting a Coconut creation of vastly improved, high-quality coconut shells.

Shell Shaver tailored for application within the farm-level

industry, with the aim of addressing the challenges and REFERENCES

requirements of handicraft producers and exporters in the 1. Ali, M., Liu, A., Sou, H., & Chouw, N. (2012).

CARAGA Region. The device has been meticulously Mechanical and dynamic properties of coconut fibre

designed to efficiently eliminate coconut fiber from the shell, reinforced concrete. Construction and Building

employing a straightforward approach that ensures a Materials, 30, 814-825.

heightened production rate of top-notch end products, while 2. Araujo, P., Felix Filho, L. F., & Barbosa, J. J. (2015).

also emphasizing user-friendliness and ease of maintenance. Estudo das propriedades termofísicas da fibra de

By revolutionizing the conventional cleaning process and coco minimamente processada visando aplicação

expediting the shaving process, the equipment significantly como isolante térmico. Revista Interdisciplinar de

Pesquisa e Inovação, 1(1), 134-142.

2534 Renee C. Tan,ETJ Volume 08 Issue 08 August 2023

“Design and Development of a Coconut Shell Shaver Machine”

3. Asasutjarit, C., Hirunlabh, J., Khedari, J., conventional coarse aggregate in concrete.

Charoenvai, S., Zeghmati, B., & Shin, U. C. (2007). International Journal of Innovative Research in

Development of coconut coir-based lightweight Science, Engineering and Technology, 3(3), 10316-

cement board. Construction and Building 10323.

Materials, 21(2), 277-288. 15. Raghavan, V., & Ramachandran, T. (2017). Study

4. Ayrilmis, N., Jarusombuti, S., Fueangvivat, V., of coconut shell as a partial replacement of coarse

Bauchongkol, P., & White, R. H. (2011). Coir fiber aggregate in concrete. International Journal of Civil

reinforced polypropylene composite panel for Engineering and Technology, 8(7), 755-762.

automotive interior applications. Fibers and 16. Singh, S., & Singh, R. (2017). Experimental study

polymers, 12(7), 919-926. on coconut shell as coarse aggregate in concrete.

5. Das, G., & Biswas, S. (2016, February). Physical, International Research Journal of Engineering and

mechanical and water absorption behaviour of coir Technology, 4(1), 331-336.

fiber reinforced epoxy composites filled with Al2O3 17. Staron, P., Cojocaru, C., Parvulescu, V. I., & Su, B.

particulates. In IOP conference series: materials L. (2017). Coconut shell activated carbons for heavy

science and engineering (Vol. 115, No. 1, p. metals removal from waters: adsorption equilibrium

012012). IOP Publishing. and kinetics. Journal of Environmental

6. Fiorelli, J., Curtolo, D. D., Barrero, N. G., Savastano Management, 203, 867-877.

Jr, H., Pallone, E. M. D. J. A., & Johnson, R. (2012). 18. Ganesan, K., & Rajkumar, R. (2017). Study on

Particulate composite based on coconut fiber and Mechanical Properties of Concrete Using Coconut

castor oil polyurethane adhesive: An eco-efficient Shell as Coarse Aggregate. Materials Today:

product. Industrial Crops and Products, 40, 69-75. Proceedings, 4(2), 1951-1956.

7. Ramos, S. (2008). Cancer chemoprevention and 19. Prajitno, D. H., Suharyanto, H. R., & Suhendra, A.

chemotherapy: dietary polyphenols and signalling S. (2018). Properties of coconut shell particle

pathways. Molecular nutrition & food reinforced epoxy composites. IOP Conference

research, 52(5), 507- Series: Materials Science and Engineering, 349(1),

526.https://scholar.google.com/scholar?hl=en&as_s 012019.

dt=0%2C5&q=Ramos+et+al.%2C+2008&btnG=

8. Sivakumar Babu, G. L., & Vasudevan, A. K. (2008).

Strength and stiffness response of coir fiber-

reinforced tropical soil. Journal of materials in civil

engineering, 20(9), 571-577.

9. Staroń, P., Chwastowski, J., & Banach, M. (2017).

Sorption and desorption studies on silver ions from

aqueous solution by coconut fiber. Journal of

Cleaner Production, 149, 290-301.

10. Sudirman, R., Baharuddin, A. S., & Ghani, M. A. A.

(2020). Development of Coconut Shell Shaver

Machine for Coconut Husk Processing. Journal of

Physics: Conference Series, 1529(5), 052040.

11. Petchkongkaew, N., & Loryuenyong, V. (2017).

Design and Fabrication of a Coconut Shell Shredder

Machine. In AIP Conference Proceedings (Vol.

1791, No. 1, p. 020064).

12. Siripattanakul-Ratpukdi, S. (2008). Effects of

coconut shell as aggregate on properties of

lightweight concrete. Construction and Building

Materials, 22(4), 555-560.

13. Baskar, C., Jayabalan, M., & Sivakumar, P. (2012).

Utilization of coconut shell as coarse aggregate in

concrete. International Journal of Innovative

Research in Science, Engineering and Technology,

1(1), 130-135.

14. Pawar, S. B., & Padhye, A. B. (2014). Utilization of

coconut shell powder as replacement of

2535 Renee C. Tan,ETJ Volume 08 Issue 08 August 2023

You might also like

- Year11 IGCSE Physics Scheme of WorkDocument20 pagesYear11 IGCSE Physics Scheme of WorkTiras Ngugi100% (1)

- PILI NUT CRACKING MACHINE - An Innovative StudyDocument86 pagesPILI NUT CRACKING MACHINE - An Innovative StudyEmmanuel Cristo83% (6)

- Case 2290 PDFDocument90 pagesCase 2290 PDFDarioNo ratings yet

- Airtester HP-3-GB D3188001 03Document7 pagesAirtester HP-3-GB D3188001 03federalulNo ratings yet

- Science Reviewer (NDEA EXAM)Document5 pagesScience Reviewer (NDEA EXAM)Joenard Celis100% (1)

- Development of A Cost-Effective Coconut Dehusking MachineDocument9 pagesDevelopment of A Cost-Effective Coconut Dehusking MachineInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- New Microsoft Office Word DocumentDocument52 pagesNew Microsoft Office Word Documentshiva basappaNo ratings yet

- Methods of GratingDocument11 pagesMethods of GratingGrayg MalvarNo ratings yet

- Dehusking Machine Research PaperDocument22 pagesDehusking Machine Research PaperEltone MoralesNo ratings yet

- Conceptual Design of Coconut Dehusking MachineDocument10 pagesConceptual Design of Coconut Dehusking Machineசிங்கக்குட்டி சின்னக் கவுண்டர்No ratings yet

- Chapter-1: Fabrication of Coconut Coir Making Machine 2023-24Document40 pagesChapter-1: Fabrication of Coconut Coir Making Machine 2023-24shiva basappaNo ratings yet

- Development Coconut Dehusking Machine PDFDocument7 pagesDevelopment Coconut Dehusking Machine PDFRamiro JancoNo ratings yet

- CassavaDocument7 pagesCassavaagrey athanasiNo ratings yet

- Design Fabrication and Testing of Coconut Milking MachineDocument9 pagesDesign Fabrication and Testing of Coconut Milking MachineAnonymous O1916O100% (1)

- Reference2 - Development of An Automated Coconut Scraping MachineDocument14 pagesReference2 - Development of An Automated Coconut Scraping MachineRenz Callejo100% (1)

- Engr. Jorge B. YasayDocument2 pagesEngr. Jorge B. YasayHenry DatangelNo ratings yet

- Irjaes V4n2p688y19Document3 pagesIrjaes V4n2p688y19Maria Eliza Rizon DolleteNo ratings yet

- Modification of Locally Developed Groundnut Sheller: August 2019Document15 pagesModification of Locally Developed Groundnut Sheller: August 2019GAMUCHIRAI MUGADZANo ratings yet

- Design and Fabrication of Groundnut Pods and Shell StripperDocument5 pagesDesign and Fabrication of Groundnut Pods and Shell StripperSanket WaradeNo ratings yet

- Performance Evaluation of Two Palm Kernel Nut Cracker MachinesDocument13 pagesPerformance Evaluation of Two Palm Kernel Nut Cracker MachinesAgus RasidNo ratings yet

- 12-Alhassan JPE 21 No1Document7 pages12-Alhassan JPE 21 No1lance galorportNo ratings yet

- Design, Manufacture and Perfomance Evaluation of An Effective Dual Operated Groundnut Decorticator With BlowerDocument5 pagesDesign, Manufacture and Perfomance Evaluation of An Effective Dual Operated Groundnut Decorticator With BlowerAsuako EnochNo ratings yet

- Coconut Dehusking MachineDocument11 pagesCoconut Dehusking Machineryeue100% (1)

- Fabrication and Testing of Abaca Fiber Decorticator: Josef Vill S. VillanuevaDocument7 pagesFabrication and Testing of Abaca Fiber Decorticator: Josef Vill S. Villanuevabojik2No ratings yet

- Cassava PeelerDocument22 pagesCassava PeelerRodel Ongcoy100% (1)

- Production of Chips of Porang (Amorphophallus Oncophyllus) by Slicing Machine With Rotating Double CuttersDocument7 pagesProduction of Chips of Porang (Amorphophallus Oncophyllus) by Slicing Machine With Rotating Double CuttersIJIRAE- International Journal of Innovative Research in Advanced EngineeringNo ratings yet

- 109am - 5.EPRA JOURNALS-5089Document7 pages109am - 5.EPRA JOURNALS-5089ashraf.imraishNo ratings yet

- Design and Fabrication of Low Cost Coconut Dehusking MachineDocument6 pagesDesign and Fabrication of Low Cost Coconut Dehusking MachineibrahimNo ratings yet

- My Project New EditDocument38 pagesMy Project New Editmuhammad m butuNo ratings yet

- Coconut DehuskingDocument50 pagesCoconut DehuskingRaghavendra NaikNo ratings yet

- Design and Construction of A Batch Cassava Peeling Machine: Oluwole O. O., Adio M. ADocument6 pagesDesign and Construction of A Batch Cassava Peeling Machine: Oluwole O. O., Adio M. AJustine DaquioagNo ratings yet

- Multi CropchipperforhouseholduseDocument8 pagesMulti CropchipperforhouseholduseJuanGonzalesNo ratings yet

- Design of A Coconut Dehusking MachineDocument15 pagesDesign of A Coconut Dehusking Machinelheo ducog0% (1)

- Intro UnfinishedRevised VDocument12 pagesIntro UnfinishedRevised Vlance galorportNo ratings yet

- Development of A Palm Fruit Bunch Chopper and Spikelet StripperDocument7 pagesDevelopment of A Palm Fruit Bunch Chopper and Spikelet Stripperinventionjournals100% (1)

- Co Code Shelling Mach NeDocument6 pagesCo Code Shelling Mach NeiamkimsteinNo ratings yet

- Rancang Bangun Mesin Pembelah PinangDocument16 pagesRancang Bangun Mesin Pembelah Pinangabdul gafurNo ratings yet

- Development of Small Scale Equipment For DepulppinDocument15 pagesDevelopment of Small Scale Equipment For DepulppinFlorian HonfinNo ratings yet

- IJSRDV7I20236Document3 pagesIJSRDV7I20236gokeNo ratings yet

- Global Journal of Engineering and Technology AdvancesDocument7 pagesGlobal Journal of Engineering and Technology Advancesghassanalhadad2No ratings yet

- FinalPaperAutomatic Coconut Dehusking Machine191390Document2 pagesFinalPaperAutomatic Coconut Dehusking Machine191390PRAJWALNo ratings yet

- Design and Fabrication of A ShredderDocument9 pagesDesign and Fabrication of A ShredderEphraim MekonnenNo ratings yet

- Design and Fabrication of Corn De-Seeding MachineDocument8 pagesDesign and Fabrication of Corn De-Seeding MachineAnonymous 1mMOyt9zNo ratings yet

- Cocunut Dehusking, Cutting and Scrapper MachineDocument13 pagesCocunut Dehusking, Cutting and Scrapper Machinesauravsajeev007No ratings yet

- Development and Performance Evaluation of A Coconut Milk Extracting MachineDocument8 pagesDevelopment and Performance Evaluation of A Coconut Milk Extracting MachineFelizardo GuiananNo ratings yet

- Groundnut ThrasherDocument27 pagesGroundnut ThrasherBoopathi KalaiNo ratings yet

- 4-P Ijsrdv3i40185Document5 pages4-P Ijsrdv3i40185zyzerlyngNo ratings yet

- Irjet V2i8145Document3 pagesIrjet V2i8145Abhilash HmNo ratings yet

- 9 PDFDocument9 pages9 PDFMaret Enggar PrasetyaNo ratings yet

- Design of A Modernized Cassava Peeling MachineDocument9 pagesDesign of A Modernized Cassava Peeling MachineAnonymous lAfk9gNP100% (2)

- Description of Technologies RuTAG 2.0Document15 pagesDescription of Technologies RuTAG 2.0rohillagunjanNo ratings yet

- Optimization and Development of Existing Corn Sheller MachineDocument5 pagesOptimization and Development of Existing Corn Sheller MachineIJRASETPublicationsNo ratings yet

- Source of DesignDocument9 pagesSource of DesigngemeeNo ratings yet

- Minna CoconutDocument8 pagesMinna CoconutJenny AtienzaNo ratings yet

- Design and Fabrication of Groundnut Pods and Shell Stripper: April 2018Document6 pagesDesign and Fabrication of Groundnut Pods and Shell Stripper: April 2018Sanket WaradeNo ratings yet

- Cassava PeelerDocument6 pagesCassava PeelerKim Oliver TorinoNo ratings yet

- A Design and Fabrication of Fish Feed Pelleting MachineDocument7 pagesA Design and Fabrication of Fish Feed Pelleting MachineXuan Phuong HuynhNo ratings yet

- Pallet Poster RAMMMLDocument1 pagePallet Poster RAMMMLaa86421358No ratings yet

- Design & Fabrication of A Motorized Maize Shelling MachineDocument10 pagesDesign & Fabrication of A Motorized Maize Shelling MachineSahi SahiNo ratings yet

- Article 1509432663Document21 pagesArticle 1509432663brondon bateNo ratings yet

- Design and Fabrication of A Cassava Peeling Machine: December 2016Document6 pagesDesign and Fabrication of A Cassava Peeling Machine: December 2016Ella MarianiNo ratings yet

- Speech PresentationDocument15 pagesSpeech PresentationJeremiah KarrisNo ratings yet

- Aedt 04 02 2023Document15 pagesAedt 04 02 2023nandarulsNo ratings yet

- Mulching Definitions For Different CropsDocument7 pagesMulching Definitions For Different CropsnandarulsNo ratings yet

- Pocket Book Agri Statistics 2021 Final Web FileDocument457 pagesPocket Book Agri Statistics 2021 Final Web FilenandarulsNo ratings yet

- Irrigation Hand BookDocument8 pagesIrrigation Hand BooknandarulsNo ratings yet

- Maize January 2022Document4 pagesMaize January 2022nandarulsNo ratings yet

- Unit Operation Lab ReportDocument4 pagesUnit Operation Lab ReportJosephine Wong Sian CheeNo ratings yet

- Eclectica FSH ADV-091-0108-ENDocument1 pageEclectica FSH ADV-091-0108-ENsebastianNo ratings yet

- Walker Filtration Alpha Medical Vacuum Filter DatasheetDocument2 pagesWalker Filtration Alpha Medical Vacuum Filter DatasheetDHINAKARAN KumarNo ratings yet

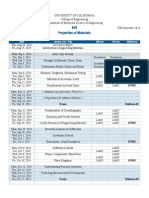

- E45 Properties of MaterialsDocument5 pagesE45 Properties of Materials2ezliNo ratings yet

- Astm A217-A217m 2010Document4 pagesAstm A217-A217m 2010rcfrcf279No ratings yet

- Grasa Ceplattyn RNDocument6 pagesGrasa Ceplattyn RNDAvid Alvarez CastilloNo ratings yet

- EATONDocument24 pagesEATONAli Tavakoli NiaNo ratings yet

- Data Storage On Fingure NailDocument17 pagesData Storage On Fingure NailpallavinooluNo ratings yet

- Wireless Electro OsmosisDocument6 pagesWireless Electro Osmosishyu2123No ratings yet

- Sloshing Tank Sbs Tutorial CosmosDocument10 pagesSloshing Tank Sbs Tutorial Cosmosdarklord338No ratings yet

- Test Method T160 PDFDocument6 pagesTest Method T160 PDFPalacios CervantesNo ratings yet

- SPD12 WRE - 8207 - 06 - 05 - 85 - Rev02Document221 pagesSPD12 WRE - 8207 - 06 - 05 - 85 - Rev02Mohammad Reza AnghaeiNo ratings yet

- ქუთაისი საწყობიDocument2 pagesქუთაისი საწყობისალომე ქადარიაNo ratings yet

- Chapter 1 FinishedDocument10 pagesChapter 1 FinishedAlexNo ratings yet

- 43 TDS - TEA99 Eng.Document2 pages43 TDS - TEA99 Eng.Andrea OrtizNo ratings yet

- Apha 1020QCDocument10 pagesApha 1020QCErick Leonardo Valle MendozaNo ratings yet

- C Sol Ch-20 Organic+ChemistryDocument4 pagesC Sol Ch-20 Organic+Chemistrymysoftinfo.incNo ratings yet

- Cambridge International Examinations: Chemistry 9701/41 May/June 2017Document12 pagesCambridge International Examinations: Chemistry 9701/41 May/June 2017Robby ReyNo ratings yet

- Pilkington Product Guide Technical DataDocument8 pagesPilkington Product Guide Technical DatangoctramnntNo ratings yet

- 1 Advanced Mould Manufacturing TechniquesDocument14 pages1 Advanced Mould Manufacturing Techniquescipet imphal100% (1)

- SCES3083 Topic 5 FluidDocument44 pagesSCES3083 Topic 5 Fluid胡佳玲No ratings yet

- SI Base UnitsDocument11 pagesSI Base UnitsHasan BashoriNo ratings yet

- Group 5 Lab 2 - Q&ADocument2 pagesGroup 5 Lab 2 - Q&AChocolocoSampayanNo ratings yet

- Paper 6 Final Revision: Food TestsDocument6 pagesPaper 6 Final Revision: Food TestsSara AnmerNo ratings yet

- Applied Source Rock GeochemistryDocument28 pagesApplied Source Rock GeochemistryHuber Alberto Rivera Rosado100% (1)