Professional Documents

Culture Documents

Third Angle Projection Do Not Scale: Operating Parameters

Third Angle Projection Do Not Scale: Operating Parameters

Uploaded by

陆军Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Third Angle Projection Do Not Scale: Operating Parameters

Third Angle Projection Do Not Scale: Operating Parameters

Uploaded by

陆军Copyright:

Available Formats

1 2 3 4 5 6 7 8 9 10

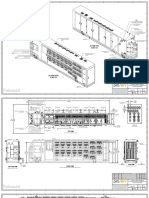

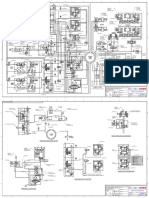

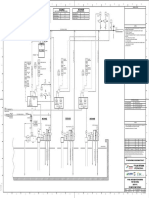

DO NOT SCALE THIRD ANGLE PROJECTION DIMENSIONS IN MILLIMETRES

OPERATING PARAMETERS

HYDRAULIC TEST AND WORKING PRESSURES A

A

HYDROSTATIC TEST PRESSURE MAINSTAGE: 1035 bar (15000 psi)

HYDROSTATIC TEST PRESSURE PILOTSTAGE: 1035 bar (15000 psi)

Serial No : BFSMMYY-1234

Max WP P - 690bar

HYDROSTATIC TEST PRESSURE RETURN: 100 bar (1450 psi)

DESIGN PRESSURE MAINSTAGE: 690 bar (10000 psi)

DESIGN PRESSURE PILOTSTAGE: 690 bar (10000 psi)

DESIGN PRESSURE RETURN: 60 bar (870 psi)

WORKING PRESSURE MAINSTAGE: 690 bar (10000 psi)

WORKING PRESSURE PILOTSTAGE: 690 bar (10000 psi)

WORKING PRESSURE RETURN: 60 bar (870 psi)

Unique no. issued by Bifold Fluidpower Subsea MIN PILOT LATCH PRESSURE: 320 bar (4640 psi) @ 690 bar MAINSTAGE

B (to include Year and Month of Manufacture identifier) B

MIN WORKING PRESSURE: 100 bar (1450 psi) (EQUAL MAINSTAGE AND PILOT PRESSURE)

DELATCH PRESSURE: 30 to 60 bar (435 to 870 psi)

WORKING AND STORAGE TEMP

4 x M8 BOLTS OPERATING TEMP -5 TO +40°C

DESIGN TEMP: -5 TO +40°C

STORAGE TEMP: -18 TO +50°C

FLOW RATE AND LEAKAGE

C LEAK RATE: 0.1cc/min (6 ml/hr max) C

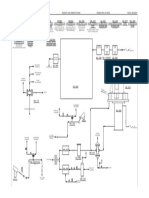

WIRING DIAGRAM CROSS FLOW LEAKAGE (OPEN STROKE): None after open function

COIL 1 COIL 2 CROSS FLOW LEAKAGE (CLOSE STROKE): None after close function

FLOW P TO A @ 10 bar Dp (145 psi): 9 l/min (2.35 USgal/min)

FLOW A TO R @ 10 bar Dp (145 psi): 9 l/min (2.35 USgal/min)

133,4

131,9

+ - + - B

Cv - P TO A: 0.2 min

PIN No 1

PIN No 3

PIN No 2

PIN No 4

Cv - A TO R: 0.2 min

90,8

89,9

DC VOLTAGE Serial No : BFSMMYY-1234

Bifold Part no. FPS10/S3/M2/32/N/3- SOLENOID

24D/90S/G35A/SL_X

Refer to Detail B for Pin No. position

D NOMINAL VOLTAGE: 24 VDC D

MAXIMUM VOLTAGE: 27.6 VDC

12,1 MINIMUM VOLTAGE: 20.4 VDC

9,9

PULSE DURATION ( TO LATCH): 500 milli sec MIN

r 0.05 MAXIMUM POWER CONSUMPTION: 14.4 Watts @ 24 VDC (-18°C) per coil

58 NOMINAL POWER CONSUMPTION: 12 Watts @ 24 VDC (20°C) per coil

KEYWAY

INSULATION RESISTANCE : > 100 Mohm @ 500 VDC (Dry 1 Atmoshere)

> 10 Mohm @ 500 VDC (Wetted 343 bar Hyperbaric)

5

4 6

38,1

PHYSICAL PROPERTIES

3 1 37,9

9 ,5

2 19,1 97,4 WEIGHT: 4.95kg dry (calcutated)

O5

18,9 E

E 4 HOLES O8.8 EXTERNAL VALVE MATERIALS: 316 STAINLESS STEEL

DETAIL B FOR M8 MOUNTING BOLTS A EXTERNAL SOLENOID MATERIALS: 430F STAINLESS STEEL COATED WITH ELECTROLESS

NICKEL PLATING AND EPOXY COATING

EXTERNAL ELECTRICAL CONNECTOR MATERIAL: MARINE BRONZE

15,1 19,1

14,9 18,9

A

MOUNTING BOLT TORQUE: 22 Nm

R P R P A

MOUNTING BOLT MATERIAL: A4-80 (AISI316) (SUPPLIED)

38,1

37,9

25,5

25,3

SPP SPP

SCHEMATIC DIAGRAM

DETAIL A A

F 15,1 15,1 F

14,9 14,9 62,3

4 HOLES (SPP, R, A & P) 28 160,3

O3.5 PORT 159,5 83,6

O-RING O7.1 x 1.6 63,5

R P SPP

NOTES : VALVE TYPES/USED ON Bifold Fluidpower Limited

Greenside way,Middleton, Manchester, M24 ISW

1.) O-RING MATERIAL CODE N = NBR FPS10/S3/M2/32/N/3-24D/90S/G35A/SL Telephone (44) 0161 345 4777 Fax (44) 0161 345 4780

H = HNBR PROJECT TITLE PROJECT NO.

FPS10 SERIES SUBSEA VALVE

G 2.) ALL DIMENSIONS NOMINAL UNLESS OTHERWISE STATED. DRAWING TITLE DRAWING NO. REV.

G

FPS10/S3/M2/32/N/3-24D/90S/G35A/SL-INST I0741 0

0 01/10/13 DK PRODUCTON ISSUE DRAWN DATE CHECKED DATE APPROVED DATE

DK 03.10.13

REV DATE DRAWN CHECKED REVISION Copyright C 2012 BIFOLD FLUIDPOWER LTD. All Rights Reserved C.A.D. Produced Drawing DO NOT Change By Hand

1 2 3 4 5 6 7 8 9 10

You might also like

- Jue-87 (E) 7zpsc0461a (Ed06) - Service ManualDocument248 pagesJue-87 (E) 7zpsc0461a (Ed06) - Service ManualLeonardo Velasquez100% (1)

- BT Reachtruck Error ListDocument25 pagesBT Reachtruck Error ListПетр100% (5)

- Esquematico C9, CATDocument2 pagesEsquematico C9, CATramahua126075% (4)

- Operating ParametersDocument1 pageOperating Parameters陆军No ratings yet

- Third Angle Projection Do Not Scale: Dimensions in MillimetresDocument1 pageThird Angle Projection Do Not Scale: Dimensions in Millimetres陆军No ratings yet

- Released: Iso View Back SCALE 1:30Document6 pagesReleased: Iso View Back SCALE 1:30Mohammed Saleem Syed KhaderNo ratings yet

- Quick Calculation ColdroomDocument1 pageQuick Calculation Coldroom15690100% (2)

- Curva Patterson 4x3x11aDocument4 pagesCurva Patterson 4x3x11ajose valladares floresNo ratings yet

- Third Angle Projection Do Not Scale: Operating ParametersDocument1 pageThird Angle Projection Do Not Scale: Operating Parameters陆军No ratings yet

- RUB No-08 JMC-GAD 2Document1 pageRUB No-08 JMC-GAD 2jayeshs750No ratings yet

- Minor Bridge No 25 GDocument1 pageMinor Bridge No 25 GRajender Reddy ParneNo ratings yet

- Pecifications: HD785 O - H TDocument8 pagesPecifications: HD785 O - H TMsnandaNo ratings yet

- Pecifications: HD785 O - H TDocument5 pagesPecifications: HD785 O - H TTomy Arif WidodoNo ratings yet

- Third Angle Projection Do Not Scale: Operating ParametersDocument1 pageThird Angle Projection Do Not Scale: Operating Parameters陆军No ratings yet

- The HD 6000 Psi: Drilling ModuleDocument2 pagesThe HD 6000 Psi: Drilling ModuleMaria Julieta Calderon OrtizNo ratings yet

- GP Process Pump Brochure en 3Document12 pagesGP Process Pump Brochure en 3Yadir BojacaNo ratings yet

- Raft Foudation - Sana SawhneyDocument1 pageRaft Foudation - Sana SawhneySana SawhneyNo ratings yet

- Cummins Inc.: Unless Otherwise Specified The Information Within This Title Block Shall ApplyDocument1 pageCummins Inc.: Unless Otherwise Specified The Information Within This Title Block Shall ApplyGui SaidNo ratings yet

- Ipal PDFDocument1 pageIpal PDFAjiNo ratings yet

- At Intersection: Wall Base ReinforcingDocument9 pagesAt Intersection: Wall Base ReinforcingJet ArcaNo ratings yet

- Minor Bridge No 6Document1 pageMinor Bridge No 6Rajender Reddy ParneNo ratings yet

- Ficha Técnica - ElectricaDocument8 pagesFicha Técnica - ElectricainspeccionestecnicasnfpaNo ratings yet

- Software: GeosystemDocument1 pageSoftware: GeosystemdjokoherususantoNo ratings yet

- VERSA 2016 Engine Control System (Powertrain Management) - ALLDATA RepairDocument3 pagesVERSA 2016 Engine Control System (Powertrain Management) - ALLDATA RepairMarcos Ortega LeonNo ratings yet

- Ziegler Fire Pump FPN 1000 - 10-1000 - 15-1000 - EnglDocument2 pagesZiegler Fire Pump FPN 1000 - 10-1000 - 15-1000 - EnglSatria 'igin' Girindra NugrahaNo ratings yet

- 07.200 Ed8 2 EN OPTDocument4 pages07.200 Ed8 2 EN OPTpablo gerardo gil cocaNo ratings yet

- Plano-General Skid Medidor de Flujo Venturi 3 in Con Valvulas Rev.2Document2 pagesPlano-General Skid Medidor de Flujo Venturi 3 in Con Valvulas Rev.2Andres BenitezNo ratings yet

- Bermad Bermad Bermad: Waterworks Waterworks WaterworksDocument6 pagesBermad Bermad Bermad: Waterworks Waterworks WaterworksDjapaNo ratings yet

- TAREA PLANO-ModeloDocument1 pageTAREA PLANO-ModeloJadner Gerardo Meléndez AristaNo ratings yet

- General Drawing Exchanger N°5Document1 pageGeneral Drawing Exchanger N°5calinvasco190670No ratings yet

- Re Wall Panel Re Wall Panel: Hill Side Hill SideDocument1 pageRe Wall Panel Re Wall Panel: Hill Side Hill SidekanagarajodishaNo ratings yet

- is样本 (硕博)Document6 pagesis样本 (硕博)VINIT KUMAR SINGHNo ratings yet

- DWG Hyd Schematic: None 3/5/2013Document2 pagesDWG Hyd Schematic: None 3/5/2013Danilo MarinNo ratings yet

- e C7330 - 1FDocument4 pagese C7330 - 1Fmina fawzyNo ratings yet

- A-03.2 Site Plan-A-03.2 Site PlanDocument1 pageA-03.2 Site Plan-A-03.2 Site Planitsme.dennysNo ratings yet

- Wear Ring Pada PompaDocument12 pagesWear Ring Pada PompaIrma 2019No ratings yet

- Konics SS 3070Document2 pagesKonics SS 3070hoamnNo ratings yet

- Ii 2Gd Ciib TX: Series P820Document4 pagesIi 2Gd Ciib TX: Series P820asandoval8168No ratings yet

- E SH35 MJB DD 001 Sheet 1Document1 pageE SH35 MJB DD 001 Sheet 1MATHANNo ratings yet

- GA37 SchematicsDocument18 pagesGA37 Schematicstechbiomed100% (1)

- Pump Curve 1500Document1 pagePump Curve 1500AHMED TAHERNo ratings yet

- General Drawing Exchanger N°3Document1 pageGeneral Drawing Exchanger N°3calinvasco190670No ratings yet

- Dayao-Reyes - Sanchez (Safety Electrical Plan) Not FinalDocument1 pageDayao-Reyes - Sanchez (Safety Electrical Plan) Not FinalJerichoNo ratings yet

- S30 Non-Metallic Containment Duty Pump: Technical Data SheetDocument2 pagesS30 Non-Metallic Containment Duty Pump: Technical Data SheetMuhamad nurul aminNo ratings yet

- Ckd-Filter w1000 SeriesDocument5 pagesCkd-Filter w1000 SeriessunhuynhNo ratings yet

- Sales & Engineering Data: Px01X-Xxx-Xxx-Axxx 10 - 125 1:1Document4 pagesSales & Engineering Data: Px01X-Xxx-Xxx-Axxx 10 - 125 1:1jarosNo ratings yet

- Electrical Planl - PDF 1st FloorDocument1 pageElectrical Planl - PDF 1st Floorkristine fugabanNo ratings yet

- A Proposed One-Storey Residential Building S1Document1 pageA Proposed One-Storey Residential Building S1Jezreel FlotildeNo ratings yet

- Interactive Hydraulic Schematic 740AJ, 800A, 800AJ: 1. Select Function Arrow On Sheet A To Activate Hydraulic CircuitDocument4 pagesInteractive Hydraulic Schematic 740AJ, 800A, 800AJ: 1. Select Function Arrow On Sheet A To Activate Hydraulic CircuitRafael MeloNo ratings yet

- D 1867 3E10 7603 - UpdateDocument1 pageD 1867 3E10 7603 - UpdateHadi SuagungNo ratings yet

- Curva CertificadaDocument1 pageCurva CertificadaJorge RiveraNo ratings yet

- STD WR 012Document1 pageSTD WR 012Tyburg R DhliwayoNo ratings yet

- Symbol On P ID 1714418978Document48 pagesSymbol On P ID 1714418978trrjz7k2hgNo ratings yet

- Tank 100KL 12M A3 - 5 Layout1Document1 pageTank 100KL 12M A3 - 5 Layout1Tarun SinghalNo ratings yet

- Model 950XLT2: Top Access Double Check Valve AssemblyDocument2 pagesModel 950XLT2: Top Access Double Check Valve AssemblykuraimundNo ratings yet

- 0403bon N WM Qp02 Ci DRD 0001 b01 Battery LimitsDocument6 pages0403bon N WM Qp02 Ci DRD 0001 b01 Battery LimitsNaji RaheemNo ratings yet

- FS1 Y FLOW 9010561.usDocument1 pageFS1 Y FLOW 9010561.usmr. doveNo ratings yet

- Komatsu Excavators Spec 470e45Document6 pagesKomatsu Excavators Spec 470e45subandi pippoNo ratings yet

- Double and Single Barrel Box CulvertDocument10 pagesDouble and Single Barrel Box Culvertronulfo fabulaNo ratings yet

- Semhl 22 1226 - DR001Document1 pageSemhl 22 1226 - DR001BHIYA JINo ratings yet

- CASE IH AXIAL-FLOW 7120 - 8120 - 9120 Combines Hydraulic Schematic - 47462779Document6 pagesCASE IH AXIAL-FLOW 7120 - 8120 - 9120 Combines Hydraulic Schematic - 47462779MilanNo ratings yet

- RND 04Document1 pageRND 04Man ManNo ratings yet

- Subsea DCV ListingDocument1 pageSubsea DCV Listing陆军No ratings yet

- Third Angle Projection Do Not Scale: Dimensions in MillimetresDocument1 pageThird Angle Projection Do Not Scale: Dimensions in Millimetres陆军No ratings yet

- Third Angle Projection Do Not Scale: Operating ParametersDocument1 pageThird Angle Projection Do Not Scale: Operating Parameters陆军No ratings yet

- Passive Compensator Load Variation For Deep-Water DrillingDocument10 pagesPassive Compensator Load Variation For Deep-Water Drilling陆军No ratings yet

- Reducing The Static Friction in Hydraulic Cylinders by Maintaining Relative Velocity Between Piston and CylinderDocument6 pagesReducing The Static Friction in Hydraulic Cylinders by Maintaining Relative Velocity Between Piston and Cylinder陆军No ratings yet

- 05 - (直动电磁阀)SVP8 x 08 Series (February 2007)Document4 pages05 - (直动电磁阀)SVP8 x 08 Series (February 2007)陆军No ratings yet

- KelTec Contract and Catalog 3pgDocument3 pagesKelTec Contract and Catalog 3pgAllegheny JOB WatchNo ratings yet

- Kheraj Price List 2021 FinalDocument10 pagesKheraj Price List 2021 FinalManoj DoshiNo ratings yet

- Power Transmission Accessories: (Prices Exclusive of Goods and Services Tax)Document24 pagesPower Transmission Accessories: (Prices Exclusive of Goods and Services Tax)irshad aliNo ratings yet

- Tle CSS Mod5Document2 pagesTle CSS Mod5john kingNo ratings yet

- AF-E-06-16 - 0 - 132kV Bus Section E09 - Schematic DiagramDocument42 pagesAF-E-06-16 - 0 - 132kV Bus Section E09 - Schematic DiagramAdetunji Babatunde TaiwoNo ratings yet

- 2014 NEC Changes (Homestudy) - FLDocument74 pages2014 NEC Changes (Homestudy) - FLgrand_ammarNo ratings yet

- Mechanical Measurement and Control - Question BankDocument3 pagesMechanical Measurement and Control - Question BankPrithvi ManwaniNo ratings yet

- Electro-Pneumatic SystemDocument10 pagesElectro-Pneumatic Systemfarhan jalaludinNo ratings yet

- Setra 268 Ex Intrinsically Safe Differential Pressure TransmitterDocument2 pagesSetra 268 Ex Intrinsically Safe Differential Pressure TransmitterFerryNo ratings yet

- Laser Range Finder Module LDB6-X7N2 in Pakistan - Electronics ProDocument6 pagesLaser Range Finder Module LDB6-X7N2 in Pakistan - Electronics ProSyed Hassan TariqNo ratings yet

- Turning and Drilling PPT MFG Chapter23 FinalDocument78 pagesTurning and Drilling PPT MFG Chapter23 FinalRavichandran GNo ratings yet

- Modelo Matematico AtiDocument5 pagesModelo Matematico AtiJuan BarrientosNo ratings yet

- MB SchedeProdotto2022 BF90.3 Rev20221103Document1 pageMB SchedeProdotto2022 BF90.3 Rev20221103Claudio MattaroloNo ratings yet

- Zelio Logic SR2B121FUDocument5 pagesZelio Logic SR2B121FUSedep NenadNo ratings yet

- Vendor Wira Makmur PratamaDocument1 pageVendor Wira Makmur PratamaferyNo ratings yet

- 1-X-210 SERIES Diaphragm Pneumatic ActuatorsDocument12 pages1-X-210 SERIES Diaphragm Pneumatic ActuatorsGiovanni PetrizzoNo ratings yet

- Boq Rev 01 - Proposed Restaurant at Jumeirah 1Document7 pagesBoq Rev 01 - Proposed Restaurant at Jumeirah 1md tanveerNo ratings yet

- HandoutsDocument5 pagesHandoutsJomar MontallanaNo ratings yet

- Sony TCM-400DV ManualDocument18 pagesSony TCM-400DV ManualStefan LaurentiuNo ratings yet

- 【Installation】Ground Mounting System from Fasten Solar PDFDocument16 pages【Installation】Ground Mounting System from Fasten Solar PDFSukhbat DashnyamNo ratings yet

- Nikken NC Tooling System PDFDocument284 pagesNikken NC Tooling System PDFzulfikar zulfikarNo ratings yet

- From 4 Different Sources:Auto Power Supply Control Solar, Mains, Generator & Inverter To Ensure No Break PowerDocument7 pagesFrom 4 Different Sources:Auto Power Supply Control Solar, Mains, Generator & Inverter To Ensure No Break PowerHumeraNo ratings yet

- Esp LVDocument104 pagesEsp LVAbdullaKakkadKarumbilNo ratings yet

- 1980 - XFP Addressable Panel Engineer ManualDocument36 pages1980 - XFP Addressable Panel Engineer ManualLeonardusNo ratings yet

- Single 20231230 123813Document7 pagesSingle 20231230 123813roboo99457255No ratings yet

- Diving Gear Setup InstructionsDocument7 pagesDiving Gear Setup InstructionsmaustanichNo ratings yet

- Bms-Io-Summary-For HVACDocument3 pagesBms-Io-Summary-For HVACRoyal AirconNo ratings yet