Professional Documents

Culture Documents

Sheetgch

Sheetgch

Uploaded by

Mohamed SelimOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sheetgch

Sheetgch

Uploaded by

Mohamed SelimCopyright:

Available Formats

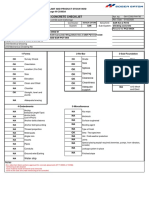

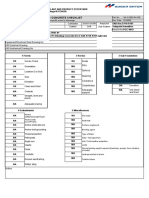

INSTALLATION QUALIFICATION SHEET

L1’nL7

(!‘ EQUIPMENT

Project

Tag# j8p13.E

Name HCL 5crobr 2 eeor

Documen — 5C 1.S - oq- od

MECHANICAL

u Status Date jRemarks

ERECTION 1A’ss!No!NA

Orientation correct .YTs (No! NA

Levelling of equipment fl, INo! NA

Vertical alignment or equipment Ys ! No! NA

Equipment property rested and supported xgsi No! NA

All nuts and bolts checked for tIghtness frCs ! No! NA

MDC or nuts and bolts Yes! No I NA

MDC of the gasket correct Yes! No! NA

Size of nuts and bolts is proper ! No I NA

Gaskets In place at required places zYts (No! NA

Type!MOC or valve used is correct ,XI No! NA

Valves placed in all desired posilion 4! No! NA

Proper MDC type of NRV provided Yes! No! NA

Pressure tapings at required locations Yes! No! NA

Temperature tapings at required locations Yes ! No! NA

Pressure switch tapings given Yes I No! NA

Temperature switch tapings given Yes! No NA

LT!level switch tapings given Yes ! No! NA

Suppiy!Retum connections to lImpet/jacket Yes! No! NA

Seal pot titled with coolIng arrangement

Air!Nitrogen supply line to seal pot

[ ?‘is ! No! NA

! No! NA

Seai cooling/Rushing arrangement ! No! NA

Sight glass provided ale! No! NA

Motor Alignment with equipment proper tea No I NA

Coupling guard provided No! NA

Motor Guard provided ‘No! NA

insuiatlonlTracing completed Yes! No! NA

Proper insulation materIal e. thickness used Yes! No! NA

Cladding MDC correct & done property Yes’ No! NA

Flanges & valves Insulated property Yes’ No! NA

Fiange Guards given Yes! No! NA

Any Other

CIVIL

Foundatfon location as desired jS’ei) No! NA

H

“A

Size of the foundation correct

Foundation holes, no or holes PCD proper

(TAil No ! NA -i:J

&oej No! NA V

Foundation bolts of correct size & tightened (s) No! NA 4N

Grouting proper -

(±t’ No! NA ‘n

Anti.corrosive coatingitillng completed (ye/No! NA -

Foundation fitilahing completed ft es) No! NA .1

Any Other

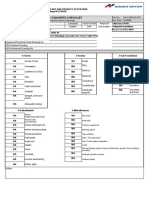

ELECTRICAL

Electrical cable routed proporly

Cable trays are rixed properly

Earthing to motor provided

Earthing to equipment pmvfried

On/Off pusi, button location proper

Push button Guard provided

Sight Glass Lamp providu

Any Othor

NPT/SOP/PER/U 12/Fol Rev No. GO ElfecI .u data 1511 l/2C:7 Paya 1 of 2

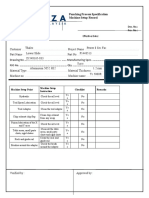

INSTRUMENTATION - -

Correct type & range PG installed

Correct type & range TO installed

YMJMI NA ow /

Yes I No I

Pressure switch installed Yes INoINfl

Temperature switch Instailed Yea I No I

Level transmiuer)swltch lnstaiied Yes I No)

Sarety vaiveslRupture discs insteiled Yes I No I NA —

-

Fire arrester installed at required location Yes $ No $

Any other

CL EA N I NG & Lu B RIC AT DN

Equipment cleaned Internally & externally (VeJI No I NA

inlet line cleaned &xa, No) NA

Outlet line cleaned Ys? No) NA

Other associated pipelines cleaned ,t6-FNoI NA

Surrounding area, cleaned ,4t5No/ NA

Required Grade & quantity of oil in Gearbox Yes) Not NA

Rare Grads &qnty of oil In Timing gearbox Yea) N0tNA

Dii level visible In sight glass Yes! Not NA

Required grade greasing applied to bearing Yes I No! NA

Seal pot filled with desired liquid Yea) No! NA

Any Other

N OT ES & RECOMMEN DATIONS

#1

#2

#3

#4

#5

#6

#7

#6

#,

#10

PEN_DING_JOBS

# DescrIption ofJob Ta,gef Remarks

#1

#2

ea

#4

#5

#5

#7

#8

#g

#10

The equipment is installed to satisfaction and is cleared for running trial Yost No

Namo P4VnPA 1) Ink) Data 3IAIZO) Sign atu

jV

\Lk) 2.S11

JLIt4ttec1 CadL

Kk41

NPTISOPIPERIOI2!F01 Rev No.00 EffCtive djlo;15I1112017 Page 2 of 2

You might also like

- 120G Motor Grader PDFDocument766 pages120G Motor Grader PDFpapyrus100% (15)

- Audiolab 8000A Owner's Manual PDFDocument10 pagesAudiolab 8000A Owner's Manual PDFRastko ManojlovicNo ratings yet

- 05.0 Electricity IIIDocument18 pages05.0 Electricity IIIAmish0% (1)

- JSA Piling WorksDocument13 pagesJSA Piling WorksMon Trang Nguyễn100% (1)

- G Go BgetDocument2 pagesG Go BgetMohamed SelimNo ratings yet

- T.Hayi: PT-TBDocument2 pagesT.Hayi: PT-TBMohamed SelimNo ratings yet

- E Iq SbbvffhkheetDocument2 pagesE Iq SbbvffhkheetMohamed SelimNo ratings yet

- SheethgcDocument2 pagesSheethgcMohamed SelimNo ratings yet

- Q SheetbvbkkDocument2 pagesQ SheetbvbkkMohamed SelimNo ratings yet

- SheetggjozhggDocument2 pagesSheetggjozhggMohamed SelimNo ratings yet

- P02???.e Iq SheetDocument2 pagesP02???.e Iq SheetMohamed SelimNo ratings yet

- Electrical Panels Analysis Checklist: RemarksDocument1 pageElectrical Panels Analysis Checklist: RemarksAsad PatelNo ratings yet

- Blank 8Document3 pagesBlank 8Andika ArifiansyahNo ratings yet

- SounderDocument1 pageSounderNOTOFIRE PVT. LTD.No ratings yet

- Special Process Procedure Details From Schedule QDocument1 pageSpecial Process Procedure Details From Schedule QAnonymous VohpMtUSNNo ratings yet

- Pre Commissioning Checklist For Screw ChillersDocument2 pagesPre Commissioning Checklist For Screw Chillersnihar039255No ratings yet

- Isolat orDocument1 pageIsolat orNOTOFIRE PVT. LTD.No ratings yet

- During Weld PDFDocument1 pageDuring Weld PDFAnilkumarGopinathanNairNo ratings yet

- During Weld PDFDocument1 pageDuring Weld PDFAnilkumarGopinathanNairNo ratings yet

- Novec 1230 All CalculationsDocument5 pagesNovec 1230 All CalculationsKhyle Laurenz DuroNo ratings yet

- LTB145D1 Test ReportDocument10 pagesLTB145D1 Test ReportSiddharth BhawsarNo ratings yet

- Report About Inspected Turbines 2Document8 pagesReport About Inspected Turbines 2IbraHim RaGabNo ratings yet

- WTG58.Punch ListDocument8 pagesWTG58.Punch ListIbraHim RaGabNo ratings yet

- Form - Pre-Concrete Checklist: Fiche de Contrôle Avant Le BétonnageDocument2 pagesForm - Pre-Concrete Checklist: Fiche de Contrôle Avant Le BétonnageMvomoNo ratings yet

- Wired As Per PCB Silk Screen. Check Ulsuiation of Wires. 4.4 Soldered Joints. Check For Solder ShortsDocument4 pagesWired As Per PCB Silk Screen. Check Ulsuiation of Wires. 4.4 Soldered Joints. Check For Solder Shortslucas praisNo ratings yet

- Daewoo TV CN155 ChassisDocument4 pagesDaewoo TV CN155 ChassisAngelos AnagnostouNo ratings yet

- Safety Work Permit ProofDocument2 pagesSafety Work Permit Proofchaitra rNo ratings yet

- BearingsDocument10 pagesBearingsafif atmaja100% (1)

- Precommissioning Activities Reinstatement ChecklistDocument1 pagePrecommissioning Activities Reinstatement ChecklistYusufNo ratings yet

- Control Module TCDocument1 pageControl Module TCNOTOFIRE PVT. LTD.No ratings yet

- WTG64.Punch List 2Document9 pagesWTG64.Punch List 2IbraHim RaGabNo ratings yet

- Form - Pre-Concrete Checklist: Fiche de Contrôle Avant Le BétonnageDocument2 pagesForm - Pre-Concrete Checklist: Fiche de Contrôle Avant Le BétonnageMvomoNo ratings yet

- Maintenance Schedule PSR Cycloconverter Ver3Document1 pageMaintenance Schedule PSR Cycloconverter Ver3IdhamtanahbaruNo ratings yet

- Form - Pre-Concrete Checklist: Fiche de Contrôle Avant Le BétonnageDocument2 pagesForm - Pre-Concrete Checklist: Fiche de Contrôle Avant Le BétonnageMvomoNo ratings yet

- Pre-Concreting Checklist Ditch Concrete KM 2 SAR P205-P203 Leftt Side OKDocument2 pagesPre-Concreting Checklist Ditch Concrete KM 2 SAR P205-P203 Leftt Side OKMvomoNo ratings yet

- 10 A1 Johar Town NM ChecklistDocument1 page10 A1 Johar Town NM ChecklistarsajidNo ratings yet

- Form - Pre-Concrete Checklist: Fiche de Contrôle Avant Le BétonnageDocument2 pagesForm - Pre-Concrete Checklist: Fiche de Contrôle Avant Le BétonnageMvomoNo ratings yet

- INV Trouble Shootguide (Engver.)Document108 pagesINV Trouble Shootguide (Engver.)Yohanes Triatmojo100% (1)

- Valve Service Final Report - SampleDocument4 pagesValve Service Final Report - SampleNazmi100% (1)

- NR Test Items Acceptance Remark/Results: MEP-G-005 Unit: 03015-0Document1 pageNR Test Items Acceptance Remark/Results: MEP-G-005 Unit: 03015-0pepenapao1217No ratings yet

- Function Test 132kv Avc PanelDocument9 pagesFunction Test 132kv Avc PanelratheeshkumardNo ratings yet

- Form - Pre-Concrete Checklist: Fiche de Contrôle Avant Le BétonnageDocument2 pagesForm - Pre-Concrete Checklist: Fiche de Contrôle Avant Le BétonnageMvomoNo ratings yet

- Major Minor: Scoring SummaryDocument30 pagesMajor Minor: Scoring SummaryChaerul AnamNo ratings yet

- Form - Pre-Concrete Checklist: Fiche de Contrôle Avant Le BétonnageDocument2 pagesForm - Pre-Concrete Checklist: Fiche de Contrôle Avant Le BétonnageMvomoNo ratings yet

- MCP TCDocument1 pageMCP TCNOTOFIRE PVT. LTD.No ratings yet

- PCC - 0043 Blinding Concrete KM 2 SAR P210-P207 Right SiteDocument2 pagesPCC - 0043 Blinding Concrete KM 2 SAR P210-P207 Right SiteMvomoNo ratings yet

- Sel-487v Relay Test For CapacitorDocument21 pagesSel-487v Relay Test For CapacitorSentaNo ratings yet

- Monthly Maintenance: EscalatorDocument1 pageMonthly Maintenance: Escalatorroland.bunsay.gsbmNo ratings yet

- RMU Test ReportDocument2 pagesRMU Test ReportfilescloudstoreNo ratings yet

- ST-6293-02 Mobile Crane 50.5 TonDocument14 pagesST-6293-02 Mobile Crane 50.5 TonMohammed HamzaNo ratings yet

- Shanny Flashes Compare Canon and NikonDocument1 pageShanny Flashes Compare Canon and NikonBaliNo ratings yet

- Form - Pre-Concrete Checklist: Fiche de Contrôle Avant Le BétonnageDocument2 pagesForm - Pre-Concrete Checklist: Fiche de Contrôle Avant Le BétonnageMvomoNo ratings yet

- Spanish LookoutDocument48 pagesSpanish Lookoutkenric SimpsonNo ratings yet

- Strucutral Steel QA Checklist: N.: Comments, Report# Etc. Inspection Items Inspected As OKDocument1 pageStrucutral Steel QA Checklist: N.: Comments, Report# Etc. Inspection Items Inspected As OKSteelcraft engineeringNo ratings yet

- Hardware TestDocument1 pageHardware TestLanreSKNo ratings yet

- Pre-Concreting Checklist Ditch Concrete KM 2 SAR P205-P203 Leftt SideDocument2 pagesPre-Concreting Checklist Ditch Concrete KM 2 SAR P205-P203 Leftt SideMvomoNo ratings yet

- Chanasma Gearwise Progress 09.12.2023Document10 pagesChanasma Gearwise Progress 09.12.2023Ankit TamrakarNo ratings yet

- Rollei FlashDocument10 pagesRollei FlashIulian ComanescuNo ratings yet

- All Links TSS - LOS - Summary ReportDocument14 pagesAll Links TSS - LOS - Summary ReportChika AlbertNo ratings yet

- CCTV Survey FormDocument1 pageCCTV Survey FormJoeven VillanuevaNo ratings yet

- Machine Setup Check List CNC003Document2 pagesMachine Setup Check List CNC003zulfahmyNo ratings yet

- Goldstar cp14b80hDocument2 pagesGoldstar cp14b80hRaulNo ratings yet

- Preventive Maintenance Schedule For Bowl Mill & Coal Feeder of "U# 8, D.P.P.S."Document7 pagesPreventive Maintenance Schedule For Bowl Mill & Coal Feeder of "U# 8, D.P.P.S."mrinal mandalNo ratings yet

- JnyeusbtrfeasvdDocument6 pagesJnyeusbtrfeasvdMohamed SelimNo ratings yet

- UtyftdrfdDocument1 pageUtyftdrfdMohamed SelimNo ratings yet

- 5 Kme 6 U 5 JwsnyabteDocument1 page5 Kme 6 U 5 JwsnyabteMohamed SelimNo ratings yet

- JegtbrhdxfDocument3 pagesJegtbrhdxfMohamed SelimNo ratings yet

- YrthdfDocument1 pageYrthdfMohamed SelimNo ratings yet

- RjyhetrsgdfzDocument1 pageRjyhetrsgdfzMohamed SelimNo ratings yet

- FHHFG ControlDocument13 pagesFHHFG ControlMohamed SelimNo ratings yet

- GwesvdgtrDocument3 pagesGwesvdgtrMohamed SelimNo ratings yet

- HwrasgvdzsgDocument2 pagesHwrasgvdzsgMohamed SelimNo ratings yet

- J 67 e 5 STRHGDDocument3 pagesJ 67 e 5 STRHGDMohamed SelimNo ratings yet

- BfgjuestDocument2 pagesBfgjuestMohamed SelimNo ratings yet

- Gvaersd CDocument2 pagesGvaersd CMohamed SelimNo ratings yet

- AFCشربDocument2 pagesAFCشربMohamed SelimNo ratings yet

- D ResponsibilvjkgDocument3 pagesD ResponsibilvjkgMohamed SelimNo ratings yet

- لابئري)Document2 pagesلابئري)Mohamed SelimNo ratings yet

- لقرشس) ) ~ءقشرسيDocument1 pageلقرشس) ) ~ءقشرسيMohamed SelimNo ratings yet

- NPT SOP PDE 004 F11 BOM Diaphragm ValveDocument4 pagesNPT SOP PDE 004 F11 BOM Diaphragm ValveMohamed SelimNo ratings yet

- 1.3 GlossaryfbjfdhnDocument3 pages1.3 GlossaryfbjfdhnMohamed SelimNo ratings yet

- HHKK Policy and Objectives Including Quality Management SystemDocument3 pagesHHKK Policy and Objectives Including Quality Management SystemMohamed SelimNo ratings yet

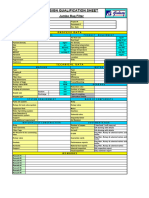

- NPT Sop Pde 006 f02 DQ AgitatorDocument2 pagesNPT Sop Pde 006 f02 DQ AgitatorMohamed SelimNo ratings yet

- V CJ K Ngs and ImprovementDocument2 pagesV CJ K Ngs and ImprovementMohamed SelimNo ratings yet

- 1.2 Distribution ListDocument1 page1.2 Distribution ListMohamed SelimNo ratings yet

- GnhucticesDocument4 pagesGnhucticesMohamed SelimNo ratings yet

- GbnjonsDocument2 pagesGbnjonsMohamed SelimNo ratings yet

- GvnjentDocument2 pagesGvnjentMohamed SelimNo ratings yet

- FhhingDocument4 pagesFhhingMohamed SelimNo ratings yet

- GvnnuesDocument1 pageGvnnuesMohamed SelimNo ratings yet

- GgnhcedureDocument7 pagesGgnhcedureMohamed SelimNo ratings yet

- Hhfsessment For QualityDocument8 pagesHhfsessment For QualityMohamed SelimNo ratings yet

- VNNGCDocument2 pagesVNNGCMohamed SelimNo ratings yet

- Ikey Plus Portable USB Recorder User's GuideDocument109 pagesIkey Plus Portable USB Recorder User's Guidecantius100% (1)

- Aspire 9300/7000 Service GuideDocument143 pagesAspire 9300/7000 Service GuideRodel BarnayjaNo ratings yet

- Sony DSC-V3 Level 2 Service Manual (P. N. - 987676232)Document59 pagesSony DSC-V3 Level 2 Service Manual (P. N. - 987676232)tm5u2r0% (1)

- AN - CLC CLW Oil Over Water - E - 11160 ADocument3 pagesAN - CLC CLW Oil Over Water - E - 11160 Acalvarez_5No ratings yet

- q615 Electrical Electronics and Control EngineeringDocument36 pagesq615 Electrical Electronics and Control Engineeringjustooln2No ratings yet

- Pau Fas FPS FSSDocument4 pagesPau Fas FPS FSSAntonio SerranoNo ratings yet

- Flynn's ClassificationDocument46 pagesFlynn's ClassificationmasumiNo ratings yet

- Voltage Drop in Transmission LinesDocument1 pageVoltage Drop in Transmission LinesPradeep SinghNo ratings yet

- Manual Completo Sinovo SD600Document221 pagesManual Completo Sinovo SD600Felipe de PaulaNo ratings yet

- Precision 3431 Small Form FactorDocument2 pagesPrecision 3431 Small Form FactorAlexia HoNo ratings yet

- Catalogus Rivet Expert enDocument145 pagesCatalogus Rivet Expert enClaudio AndréNo ratings yet

- GPS Dec SiemensDocument17 pagesGPS Dec Siemensjulio mouraNo ratings yet

- Juki LK 1850Document68 pagesJuki LK 1850Alan AlexandreNo ratings yet

- Manual Instalare FS5200P ENDocument2 pagesManual Instalare FS5200P ENOctavian Flavian BabaNo ratings yet

- LG 22mn43D 24MN43 LD02M PDFDocument37 pagesLG 22mn43D 24MN43 LD02M PDFboroda2410No ratings yet

- Wiring The 9X-9591 Electrical Converter GP (PULSE WIDTH MODULATED) (1421, 1901, 7490)Document6 pagesWiring The 9X-9591 Electrical Converter GP (PULSE WIDTH MODULATED) (1421, 1901, 7490)Jose FavaNo ratings yet

- Cpu 1Document8 pagesCpu 1seema raniNo ratings yet

- Kertas Penerangan SirDocument21 pagesKertas Penerangan SirPAUL KENNY TSHONGNo ratings yet

- PIR Motion Sensor TutorialDocument10 pagesPIR Motion Sensor Tutorialsuman kumarNo ratings yet

- Dimensions: V15-W-5M-PURDocument1 pageDimensions: V15-W-5M-PUREric MontesNo ratings yet

- HEV V-Elph 2Document9 pagesHEV V-Elph 2api-3709675No ratings yet

- Viper 3105v Installation GuideDocument10 pagesViper 3105v Installation GuideadiNo ratings yet

- Technical Data LT460Document4 pagesTechnical Data LT460Prince Al RossiNo ratings yet

- Etna - Fire Pump Systems in Accordance With EN 12845 Standard Technical LeafletDocument28 pagesEtna - Fire Pump Systems in Accordance With EN 12845 Standard Technical LeafletRedha Sabr100% (1)

- Ericsson RBS CommissioningDocument16 pagesEricsson RBS Commissioningsidney TeahNo ratings yet

- Instruction Manual: 4W Mobile CB TransceiverDocument122 pagesInstruction Manual: 4W Mobile CB TransceiverkisjoskaNo ratings yet