Professional Documents

Culture Documents

Sheethgc

Sheethgc

Uploaded by

Mohamed SelimOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sheethgc

Sheethgc

Uploaded by

Mohamed SelimCopyright:

Available Formats

6 f4a/aayj

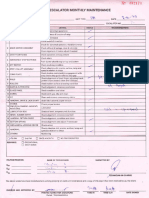

INSTALLATION QUALIFICATION SHEET

C

1 .•

EQUIPMENT

Project j014 6

Tag#

Name

Document!!

502

Pq6- .sc(cI

-cc%A’cter -CU-taoS

2 CtC4a, 9u.n(J

MECHANICAL

Status Date Remarks

ERECTION ?6!N0INA

Orientation correct )d I No! NA

Levelling of equipment .Y I No! NA

Vertical alignment of equipment No! NA

Equipment properly rested and supported )t I No! NA

All nuts and bolts checked for tightness No! NA

MDC of nuts and bolts rI No! NA

MOC of the gasket correct aC! No! NA

Size of nuts and boils is proper I No! NA

Gaskets In place at required places Cs I No! NA

Type/MOC or valve used is correct I No’ NA

Valves placed in all desired position d’! No! NA

Proper MOC 8. type of NRV provided Yes! No! NA

Pressure tapings at required locations Yes! No! NA

Temperature tapings at required locations Yes I No! NA

Pressure switch tapings given Yes / No / NA

Temperature switch tapings given Yes! No! NA

LT!level switch tapings given Yes! No! NA

Supply!Return connections to limpeujacket Yes! No! NA

Seal pot fitted with cooling arrangement ?6c! No! NA

AirlNitrogen supply line to seal pot e! No! NA

Seal cooitng!flushlng arrangement ts ! No! NA

Sight glass provided I No! NA

MotorAllgnment with equipment proper XI No! NA

Coupling guard provided j6s1 No! NA

Motor Guard provided s I No! NA

insuiallonflracing completed Yes! No! NA

Proper Insulation materialS thickness used Yes! No! NA

Cladding MOC correct S done property Yes! No! NA

Flanges & valves Insulated properly Yes! No! NA

Flange Guards given Yes! No! NA

Any Other

CIVIL

FoundatIon locatton as desired • (jDINOINA n

(QE5I

Size of the foundation correct No I NA ;:

Foundation holes no of holes PCD proper (Yj9 No I NA nI

FoundatIon bolts of correct size 8. tightened (YI No I NA -%-

Grouting proper jcesj No! NA %n

Anti-corrosIve coating/tiling completed (ca) No! NA --

Foundation finishing completed ( Yes)! No! NA ri

-

Any Other

ELECTRICAL

Etectricat cable routad property J4s I No! NA

Cable trays are fixed properly La3en10! NA

Earthing to motor provkied j No! NA

Earthing_to equipment provided — — Yes! No! N

OnfOffpusti button locatIon proper Y —1 No NA /

Push button Guard provided — Yes I No —

Sight Giazs Lamp provide Yes I No It

Any Oilier

NPTISORPL-n’o 12/FOl Rev No 00 Effeclivo djta 15/1112017 Puje I of 2

INSTRUMENTATION

Corroct typo & range PG installed

Correct typo & range rn installed

Ye4TI& / NA

Yes? No! NA.

tYtat,-L4._—-3—? 4.

Pressure switch installed Yes? No? N /

Temperature switch Installed Yes? No? NA C”

Level transmitter/switch installed Yes? No? NA ‘—‘

Safety valves/Rupture discs installed Yes? No? NA .

Fire arrester installed at required location Yes? No? NA C/

Any other

CLEANING & LUDRICATI )N

Equipment cleaned Internally & externally {te) No? NA

Inlet line cleaned r No ? NA

Outlet line cleaned (?flj? No / NA

Other associated pipelines cleaned Yii])4o/ NA

Surrounding areas cleaned ,—tei1o / NA

Required Grade & quantity of oil in Gearbox Yes? Not NA

Rare Grade & qnty of oil In Timing gearbox Yes? Not NA

Oillevel visible in sight glass Yes? Not NA

Roquired grade greasing applied to bearing Yes? Not NA

Seal pot tilled wIth desired liquId Yes? Not NA

Any Other

NOTES&RECOMMENDATIONS N

#1 N

#2

#3

#4

#5

#6

#7

#8

#9

#10

N PENDING_JOBS

# Descflpt?on 0/job Target Remarks

#1

#2

#3

#4

#5

#6

#7

#8

#9

#10

The equipment is installed to satisfaction and Is cleared for running trial Yes? No

Name ed 9N) tab

Pl’kiYn Data 3 IG I 7oZS Slgnalure

t-1a&kc1 Sc\ev’\z kLZ lb I Lø 2-

4tcA429 j4J 4

çk0tJ

NPT?S0PIPER/012/F01 Rev No.00 Effective dsh, 15/11/2017 P ije 2 of 2

You might also like

- 120G Motor Grader PDFDocument766 pages120G Motor Grader PDFpapyrus100% (15)

- G Go BgetDocument2 pagesG Go BgetMohamed SelimNo ratings yet

- SheetggjozhggDocument2 pagesSheetggjozhggMohamed SelimNo ratings yet

- SheetgchDocument2 pagesSheetgchMohamed SelimNo ratings yet

- T.Hayi: PT-TBDocument2 pagesT.Hayi: PT-TBMohamed SelimNo ratings yet

- E Iq SbbvffhkheetDocument2 pagesE Iq SbbvffhkheetMohamed SelimNo ratings yet

- P02???.e Iq SheetDocument2 pagesP02???.e Iq SheetMohamed SelimNo ratings yet

- Q SheetbvbkkDocument2 pagesQ SheetbvbkkMohamed SelimNo ratings yet

- Isolat orDocument1 pageIsolat orNOTOFIRE PVT. LTD.No ratings yet

- Electrical Panels Analysis Checklist: RemarksDocument1 pageElectrical Panels Analysis Checklist: RemarksAsad PatelNo ratings yet

- Precommissioning Activities Reinstatement ChecklistDocument1 pagePrecommissioning Activities Reinstatement ChecklistYusufNo ratings yet

- Control Module TCDocument1 pageControl Module TCNOTOFIRE PVT. LTD.No ratings yet

- Wired As Per PCB Silk Screen. Check Ulsuiation of Wires. 4.4 Soldered Joints. Check For Solder ShortsDocument4 pagesWired As Per PCB Silk Screen. Check Ulsuiation of Wires. 4.4 Soldered Joints. Check For Solder Shortslucas praisNo ratings yet

- Control Panel TCDocument1 pageControl Panel TCNOTOFIRE PVT. LTD.No ratings yet

- MCP TCDocument1 pageMCP TCNOTOFIRE PVT. LTD.No ratings yet

- Major Minor: Scoring SummaryDocument30 pagesMajor Minor: Scoring SummaryChaerul AnamNo ratings yet

- Isolator TCDocument1 pageIsolator TCNOTOFIRE PVT. LTD.No ratings yet

- Preventive Maintenance Schedule For Bowl Mill & Coal Feeder of "U# 8, D.P.P.S."Document7 pagesPreventive Maintenance Schedule For Bowl Mill & Coal Feeder of "U# 8, D.P.P.S."mrinal mandalNo ratings yet

- Escalator: Monthly MaintenanceDocument1 pageEscalator: Monthly Maintenanceroland.bunsay.gsbmNo ratings yet

- Panasonic Rq-S Series SiDocument1 pagePanasonic Rq-S Series Si裴兆奇No ratings yet

- Report About Inspected Turbines 2Document8 pagesReport About Inspected Turbines 2IbraHim RaGabNo ratings yet

- WTG58.Punch ListDocument8 pagesWTG58.Punch ListIbraHim RaGabNo ratings yet

- Form - Pre-Concrete Checklist: Fiche de Contrôle Avant Le BétonnageDocument2 pagesForm - Pre-Concrete Checklist: Fiche de Contrôle Avant Le BétonnageMvomoNo ratings yet

- Cpontrol ModuleDocument3 pagesCpontrol ModuleNOTOFIRE PVT. LTD.No ratings yet

- SounderDocument1 pageSounderNOTOFIRE PVT. LTD.No ratings yet

- ST-6293-02 Mobile Crane 50.5 TonDocument14 pagesST-6293-02 Mobile Crane 50.5 TonMohammed HamzaNo ratings yet

- Valve Service Final Report - SampleDocument4 pagesValve Service Final Report - SampleNazmi100% (1)

- Check List For Survey InstrumentsDocument2 pagesCheck List For Survey InstrumentsVasim ShaikhNo ratings yet

- LTB145D1 Test ReportDocument10 pagesLTB145D1 Test ReportSiddharth BhawsarNo ratings yet

- Maintenance Schedule PSR Cycloconverter Ver3Document1 pageMaintenance Schedule PSR Cycloconverter Ver3IdhamtanahbaruNo ratings yet

- WTG64.Punch List 2Document9 pagesWTG64.Punch List 2IbraHim RaGabNo ratings yet

- Monthly Maintenance: EscalatorDocument1 pageMonthly Maintenance: Escalatorroland.bunsay.gsbmNo ratings yet

- MOTO E5 Plus Row Trouble Shooting GuideDocument23 pagesMOTO E5 Plus Row Trouble Shooting GuideAlejandro JuarezNo ratings yet

- Rele Sobrecorriente 7SK8854 SiemensDocument25 pagesRele Sobrecorriente 7SK8854 SiemensJoseNo ratings yet

- Pre-Concreting Checklist Ditch Concrete KM 2 SAR P205-P203 Leftt Side OKDocument2 pagesPre-Concreting Checklist Ditch Concrete KM 2 SAR P205-P203 Leftt Side OKMvomoNo ratings yet

- OptimDocument8 pagesOptimVIP VIDEONo ratings yet

- Special Process Procedure Details From Schedule QDocument1 pageSpecial Process Procedure Details From Schedule QAnonymous VohpMtUSNNo ratings yet

- Asset FormDocument1 pageAsset FormGajendran SriramNo ratings yet

- RM 1601 Service ReportDocument1 pageRM 1601 Service ReportshaktiNo ratings yet

- Goldstar cp14b80hDocument2 pagesGoldstar cp14b80hRaulNo ratings yet

- Pasolink Radio Training Course: NESIC CairoDocument63 pagesPasolink Radio Training Course: NESIC CairoAmerullah NiaziNo ratings yet

- Strucutral Steel QA Checklist: N.: Comments, Report# Etc. Inspection Items Inspected As OKDocument1 pageStrucutral Steel QA Checklist: N.: Comments, Report# Etc. Inspection Items Inspected As OKSteelcraft engineeringNo ratings yet

- ATS Takada 2000ATDocument3 pagesATS Takada 2000ATaaronchestercruzNo ratings yet

- CCTV Survey FormDocument1 pageCCTV Survey FormJoeven VillanuevaNo ratings yet

- C. Division ICIS TemplateDocument2 pagesC. Division ICIS TemplateKurt KellmanNo ratings yet

- Form - Pre-Concrete Checklist: Fiche de Contrôle Avant Le BétonnageDocument2 pagesForm - Pre-Concrete Checklist: Fiche de Contrôle Avant Le BétonnageMvomoNo ratings yet

- Electronics Practical (1) 3rd SemDocument17 pagesElectronics Practical (1) 3rd SemSuprabha479No ratings yet

- Interruptor de Porta e de Ajuste FinoDocument14 pagesInterruptor de Porta e de Ajuste FinoLeonardo Marteleto BerniniNo ratings yet

- Fakoor Sanat Tehran: Circuit Breaker & Earth Switch Commissioning Test Formats Description: CIRCUIT BREAKERDocument1 pageFakoor Sanat Tehran: Circuit Breaker & Earth Switch Commissioning Test Formats Description: CIRCUIT BREAKERkarimiNo ratings yet

- Form - Pre-Concrete Checklist: Fiche de Contrôle Avant Le BétonnageDocument2 pagesForm - Pre-Concrete Checklist: Fiche de Contrôle Avant Le BétonnageMvomoNo ratings yet

- Fakoor Sanat Tehran: Circuit Breaker & Earth Switch Commissioning Test Formats Description: CIRCUIT BREAKERDocument1 pageFakoor Sanat Tehran: Circuit Breaker & Earth Switch Commissioning Test Formats Description: CIRCUIT BREAKERkarimiNo ratings yet

- Panasonic Ne-1054f, Ne1064f, Ne1024f Service ManualDocument8 pagesPanasonic Ne-1054f, Ne1064f, Ne1024f Service ManualAngel MartinezNo ratings yet

- Operation and Maintenance Protocol For Electrical Panels - UpdatedDocument2 pagesOperation and Maintenance Protocol For Electrical Panels - UpdatedScribdTranslationsNo ratings yet

- Quduwave UjiDocument1 pageQuduwave UjiZiya Zizan Zamy FamilyNo ratings yet

- Pre-Concreting Checklist Ditch Concrete KM 2 SAR P205-P203 Leftt SideDocument2 pagesPre-Concreting Checklist Ditch Concrete KM 2 SAR P205-P203 Leftt SideMvomoNo ratings yet

- 10 A1 Johar Town NM ChecklistDocument1 page10 A1 Johar Town NM ChecklistarsajidNo ratings yet

- Form - Pre-Concrete Checklist: Fiche de Contrôle Avant Le BétonnageDocument2 pagesForm - Pre-Concrete Checklist: Fiche de Contrôle Avant Le BétonnageMvomoNo ratings yet

- Engine Scania Dc16: Short Block & Ass'y SheetDocument4 pagesEngine Scania Dc16: Short Block & Ass'y SheetJaya PranataNo ratings yet

- 13 Check List For Survey InstrumentsDocument1 page13 Check List For Survey InstrumentssoorajNo ratings yet

- JnyeusbtrfeasvdDocument6 pagesJnyeusbtrfeasvdMohamed SelimNo ratings yet

- UtyftdrfdDocument1 pageUtyftdrfdMohamed SelimNo ratings yet

- 5 Kme 6 U 5 JwsnyabteDocument1 page5 Kme 6 U 5 JwsnyabteMohamed SelimNo ratings yet

- JegtbrhdxfDocument3 pagesJegtbrhdxfMohamed SelimNo ratings yet

- YrthdfDocument1 pageYrthdfMohamed SelimNo ratings yet

- RjyhetrsgdfzDocument1 pageRjyhetrsgdfzMohamed SelimNo ratings yet

- FHHFG ControlDocument13 pagesFHHFG ControlMohamed SelimNo ratings yet

- GwesvdgtrDocument3 pagesGwesvdgtrMohamed SelimNo ratings yet

- HwrasgvdzsgDocument2 pagesHwrasgvdzsgMohamed SelimNo ratings yet

- J 67 e 5 STRHGDDocument3 pagesJ 67 e 5 STRHGDMohamed SelimNo ratings yet

- BfgjuestDocument2 pagesBfgjuestMohamed SelimNo ratings yet

- Gvaersd CDocument2 pagesGvaersd CMohamed SelimNo ratings yet

- AFCشربDocument2 pagesAFCشربMohamed SelimNo ratings yet

- D ResponsibilvjkgDocument3 pagesD ResponsibilvjkgMohamed SelimNo ratings yet

- لابئري)Document2 pagesلابئري)Mohamed SelimNo ratings yet

- لقرشس) ) ~ءقشرسيDocument1 pageلقرشس) ) ~ءقشرسيMohamed SelimNo ratings yet

- NPT SOP PDE 004 F11 BOM Diaphragm ValveDocument4 pagesNPT SOP PDE 004 F11 BOM Diaphragm ValveMohamed SelimNo ratings yet

- 1.3 GlossaryfbjfdhnDocument3 pages1.3 GlossaryfbjfdhnMohamed SelimNo ratings yet

- HHKK Policy and Objectives Including Quality Management SystemDocument3 pagesHHKK Policy and Objectives Including Quality Management SystemMohamed SelimNo ratings yet

- NPT Sop Pde 006 f02 DQ AgitatorDocument2 pagesNPT Sop Pde 006 f02 DQ AgitatorMohamed SelimNo ratings yet

- V CJ K Ngs and ImprovementDocument2 pagesV CJ K Ngs and ImprovementMohamed SelimNo ratings yet

- 1.2 Distribution ListDocument1 page1.2 Distribution ListMohamed SelimNo ratings yet

- GnhucticesDocument4 pagesGnhucticesMohamed SelimNo ratings yet

- GbnjonsDocument2 pagesGbnjonsMohamed SelimNo ratings yet

- GvnjentDocument2 pagesGvnjentMohamed SelimNo ratings yet

- FhhingDocument4 pagesFhhingMohamed SelimNo ratings yet

- GvnnuesDocument1 pageGvnnuesMohamed SelimNo ratings yet

- GgnhcedureDocument7 pagesGgnhcedureMohamed SelimNo ratings yet

- Hhfsessment For QualityDocument8 pagesHhfsessment For QualityMohamed SelimNo ratings yet

- VNNGCDocument2 pagesVNNGCMohamed SelimNo ratings yet

- Rod Handler RH 714: Ranger, ScoutDocument20 pagesRod Handler RH 714: Ranger, ScoutcristianNo ratings yet

- 1 - Fuses & Circuit Breakers PDFDocument13 pages1 - Fuses & Circuit Breakers PDFSallak Idris100% (1)

- Perkins Series 400 Injection AnglesDocument40 pagesPerkins Series 400 Injection Anglesbudimir231083% (6)

- SOFAR 60K 80KTLX-G3 - DatasheetDocument2 pagesSOFAR 60K 80KTLX-G3 - DatasheetRusnacNo ratings yet

- Empty BOQ For Pricing MEPDocument26 pagesEmpty BOQ For Pricing MEPabdullah sahibNo ratings yet

- Toro Grounds Keeper GK212 User GuideDocument36 pagesToro Grounds Keeper GK212 User GuidesudoTdayNo ratings yet

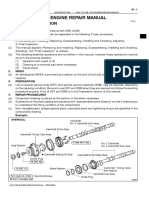

- How To Use This Engine Repair Manual: General InformationDocument3 pagesHow To Use This Engine Repair Manual: General InformationHenry SilvaNo ratings yet

- Tool Safety & Inspection: Company Name HereDocument6 pagesTool Safety & Inspection: Company Name HereEl KhanNo ratings yet

- Tig Cerbera PDFDocument43 pagesTig Cerbera PDFDonatas VaNo ratings yet

- Mijia Double Induction Cooker With Griddle Product ManualDocument11 pagesMijia Double Induction Cooker With Griddle Product ManualHexeneNo ratings yet

- Electromotor - TITAN PDFDocument8 pagesElectromotor - TITAN PDFajeng mayang20100% (1)

- Application of Hydraulic Actuator On MarineDocument4 pagesApplication of Hydraulic Actuator On MarineAyumi PNo ratings yet

- Sku Sua5000rmi5uDocument3 pagesSku Sua5000rmi5uBawuk SukesiNo ratings yet

- Grundfos Machine SelectionDocument8 pagesGrundfos Machine SelectionMussie BekeleNo ratings yet

- PID Controllers: Final Control ElementDocument3 pagesPID Controllers: Final Control ElementJêmš NavikNo ratings yet

- Digital Satellite Tuner: Single Chip Tuner For DVB-S/ABS-S ReceiverDocument17 pagesDigital Satellite Tuner: Single Chip Tuner For DVB-S/ABS-S Receivertecniloco80No ratings yet

- Electrical Engineering Multiple Choice Questions: SF6 Free SwitchgearDocument32 pagesElectrical Engineering Multiple Choice Questions: SF6 Free SwitchgearVikash SinghNo ratings yet

- Interfacing Bluetooth With 8051Document9 pagesInterfacing Bluetooth With 8051adeivaseelanNo ratings yet

- C091 (J) Aisg C091 (K) 1MDocument2 pagesC091 (J) Aisg C091 (K) 1MВадим ЧеховскийNo ratings yet

- Canon Irc3580pcDocument188 pagesCanon Irc3580pcCornel SusanuNo ratings yet

- NTV 121-EDocument24 pagesNTV 121-EJoseph TingNo ratings yet

- NA Parts.120132712Document1 pageNA Parts.120132712Dandy MartinNo ratings yet

- Dedicated Circuit For 3-Channel LED Constant Current Drive TM1914Document11 pagesDedicated Circuit For 3-Channel LED Constant Current Drive TM1914dsfgdsfgNo ratings yet

- Experiment No-1: Aim:-Low Resistance Using Kelvin Double BridgeDocument21 pagesExperiment No-1: Aim:-Low Resistance Using Kelvin Double BridgegnathblNo ratings yet

- Hov Pod SPX LM Frequently Asked QuestionsDocument3 pagesHov Pod SPX LM Frequently Asked Questionshovpod6214No ratings yet

- L Series: Bi-Rotational, Four Port DesignDocument4 pagesL Series: Bi-Rotational, Four Port DesignAdemilson Rangel VieiraNo ratings yet

- PDS10002480Document19 pagesPDS10002480NguyễnBìnhPhươngNo ratings yet

- Transistors Diodes Led & ETCDocument98 pagesTransistors Diodes Led & ETCSelvanNo ratings yet

- CCT Minuette Range DatasheetDocument4 pagesCCT Minuette Range DatasheetvishakNo ratings yet