Professional Documents

Culture Documents

G Go Bget

G Go Bget

Uploaded by

Mohamed SelimOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

G Go Bget

G Go Bget

Uploaded by

Mohamed SelimCopyright:

Available Formats

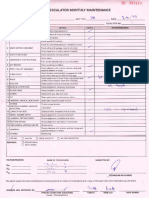

fEC:

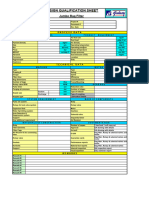

INSTALLATION QUALIFICATION SHEET

A

EQUIPMENT

Project P4’b

TIQ# ISP!hD fE

Name HCL SStr 9unt

Documen& i’th- SC jg -ag- vol

MECHANICAL

ERECTiON

Status

J Date Reiiett’?.

WflIN0!NA

Orientation correct )‘ts ‘No! NA

Levelling of equipment Pfs ‘No! NA

Vertical alignment of equipment No! NA

Equipment properly rested and supported 4e ! No! NA

All nuts and bolts checked tar tightness frtes ! No! NA

MOC of nub and bolt, Yes! No! NA

MOC of the gasket correct Yes! No! NA

Size of nuts and bolts l proper ! Hal NA

Gaskets In place at required place, I No! NA

Type!MOC or valve used Is correct ! No! NA

Valves placed in all desired position I4! No! NA

Proper MDC & type of NRV provided Yes! No! NA

Pressure tapings at required locations Yes! No! NA

Temperature tapings at required locations Yes! No I NA

Pressure switch tapings given Yes! No! NA

Temperature switch tapings given Yes! No! NA

LT!Ieval switch tapings given Yes! No / NA

Suppiy!Return connections to limpet/jacket Yes! No! NA

Seal pot fitted with cooling arrangement n! No! NA

Air/Nitrogen supply line to seal pat df! No! NA

Seal cooling!flushing arrangement )%s! No! NA

Sight glass provided ,Ws ! No! NA

Motor Alignment wIth equIpment proper p6s ! No! NA

Coupling guard provided ! No! NA

Motor Guard provided 7s ! No! NA

insulstionffracing complotad Yes/No! NA

Proper insulation material & thickness used Yes / Na! NA

Cladding MDC correct & done properly Yes! No! NA

Flanges S valves insulated property Yes! No! NA

Flange Guards given Yes! No! NA

Any Other

CIVIL

Foundeilon ioc:Uon as desired I i I NA n

Size or the foundatIon correct ( Yea) No! NA &J

Foundation holes no of holes PCD proper (ti) No! NA fT

Foundation bolts of correct size S tightened /V) No! NA —

Grouting proper N) No I NA %t

Anti.corrosivo coating!tillng completed (vS_es) Nol NA

-

-‘

Foundation finishing completed No! NA

Any Other

ELECTRICAL

Electrical cable routed properly pY! No! NA

Cablo trays are fixed property CxC7 No! NA

Eartiting to motor provided No! NA

Earthing to equIpment provIded Yes! N3LNC

Ozi/Off push button location proper xeTN0! NA

Push button Guard providad Yes! Noapinr—

Sight Glass Lamp provide -. Yos!Notfl%

Any Other —— — — — ——

NPT/SOP/PER/012/FOi Roy No.00 EfI2ciivo dub (WI 1/20(7 Page I 0(2

S

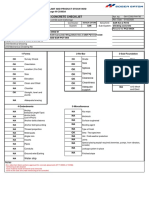

I N 55 R U M E N T AT 10 N

Correct type & range PG installed Ypdl&! NA I ltDtSt4t_ 1 W.

Correct type & range TO Installed Ye,) No)p4”j

Pressure switch Installed Yes! No I

Temperature switch Installed Yes! Not NA— -

Level transmitter/switch installed Yes! No / Nt..—’

Safety valves/Rupture discs lnstaiied Yes! No! NA_ —

Fire arrester Installed at required location Yes! No! NA . —-

Any other

CLEANING & LUBRICATION

Equipment cleaned internally & externally ‘) No! NA

inlet line cieanod is5fNo)

Outiet lIne cleaned #No! NA j

Other associated pipeline, cleaned No / NA

Surrounding areas cieaned e?No! NA

Required Grade & quantity of oil in Gearbox Ye,) Not NA

Rare Grade & qnty of oil In Timing gearbox Yost No / NA

Oil level visibie in sight glass Yea! No / NA

Required grade greasing applied to bearin9 Yes / No) NA

Seal pot filied with desired liquid Yes / No! NA

Any Other

NOT ES & RECOMMENDATIONS

#1

#2

#3

#4

#5

#6

#7

#5

#9

#10

PEN_DING_JOGS

# Desc,!pt/on offob Tarat Remarks

#1

#2

#3

#4

#5

#6

#7

#5

#9

#10

The eqIsipmLnt Is instailed to satisfaction and I cltarod for running trIal Yes! No

Name Data i3IG I Zcn signa1ur

A A45j0P

IeckrF’ (jtfC/aat3

KAL/ttJ Gb%

NPT/SOPA-ER/012/FO1 Rev Ni 00 ElfcctiO dale iS/i i’2017 Pace 2 of 2

You might also like

- AWTF80SC ManualDocument2 pagesAWTF80SC ManualАанатолий СлободянNo ratings yet

- Maestro EDGE (Feb, 2017)Document144 pagesMaestro EDGE (Feb, 2017)Kishonkumar Kishon100% (1)

- Ambition 135 PDFDocument127 pagesAmbition 135 PDFSANTOSH KUMAR71% (7)

- Service Facts: Variable Speed Outdoor Compatible Convertible Air HandlersDocument44 pagesService Facts: Variable Speed Outdoor Compatible Convertible Air HandlersfjeroNo ratings yet

- STI SP001 SPCC Plan Inspection Form WISCONSINDocument2 pagesSTI SP001 SPCC Plan Inspection Form WISCONSINCarlos Molina100% (1)

- Versacount ManualDocument33 pagesVersacount Manualluis_iq18006100% (1)

- Passion Pro Parts CatalogueDocument84 pagesPassion Pro Parts CatalogueBiplab Kumar SamalNo ratings yet

- Astm F477Document4 pagesAstm F477ruletherockNo ratings yet

- Valve TrainingDocument25 pagesValve TrainingSameOldHat100% (1)

- 6ey18al Part Book List 2017Document221 pages6ey18al Part Book List 2017Ravinder Singh83% (6)

- SheetgchDocument2 pagesSheetgchMohamed SelimNo ratings yet

- SheethgcDocument2 pagesSheethgcMohamed SelimNo ratings yet

- T.Hayi: PT-TBDocument2 pagesT.Hayi: PT-TBMohamed SelimNo ratings yet

- E Iq SbbvffhkheetDocument2 pagesE Iq SbbvffhkheetMohamed SelimNo ratings yet

- SheetggjozhggDocument2 pagesSheetggjozhggMohamed SelimNo ratings yet

- Q SheetbvbkkDocument2 pagesQ SheetbvbkkMohamed SelimNo ratings yet

- P02???.e Iq SheetDocument2 pagesP02???.e Iq SheetMohamed SelimNo ratings yet

- Electrical Panels Analysis Checklist: RemarksDocument1 pageElectrical Panels Analysis Checklist: RemarksAsad PatelNo ratings yet

- Precommissioning Activities Reinstatement ChecklistDocument1 pagePrecommissioning Activities Reinstatement ChecklistYusufNo ratings yet

- Wired As Per PCB Silk Screen. Check Ulsuiation of Wires. 4.4 Soldered Joints. Check For Solder ShortsDocument4 pagesWired As Per PCB Silk Screen. Check Ulsuiation of Wires. 4.4 Soldered Joints. Check For Solder Shortslucas praisNo ratings yet

- Isolat orDocument1 pageIsolat orNOTOFIRE PVT. LTD.No ratings yet

- Panasonic Rq-S Series SiDocument1 pagePanasonic Rq-S Series Si裴兆奇No ratings yet

- Control Module TCDocument1 pageControl Module TCNOTOFIRE PVT. LTD.No ratings yet

- Property of Ididi T, Inc Property of Ididi T, Inc Property of Ididi T, IncDocument1 pageProperty of Ididi T, Inc Property of Ididi T, Inc Property of Ididi T, IncAlex Medrano RamirezNo ratings yet

- SounderDocument1 pageSounderNOTOFIRE PVT. LTD.No ratings yet

- Chanasma Gearwise Progress 09.12.2023Document10 pagesChanasma Gearwise Progress 09.12.2023Ankit TamrakarNo ratings yet

- Monthly Maintenance: EscalatorDocument1 pageMonthly Maintenance: Escalatorroland.bunsay.gsbmNo ratings yet

- ST-6293-02 Mobile Crane 50.5 TonDocument14 pagesST-6293-02 Mobile Crane 50.5 TonMohammed HamzaNo ratings yet

- Blank 8Document3 pagesBlank 8Andika ArifiansyahNo ratings yet

- NR Test Items Acceptance Remark/Results: MEP-G-005 Unit: 03015-0Document1 pageNR Test Items Acceptance Remark/Results: MEP-G-005 Unit: 03015-0pepenapao1217No ratings yet

- Safety Work Permit ProofDocument2 pagesSafety Work Permit Proofchaitra rNo ratings yet

- MCP TCDocument1 pageMCP TCNOTOFIRE PVT. LTD.No ratings yet

- Strucutral Steel QA Checklist: N.: Comments, Report# Etc. Inspection Items Inspected As OKDocument1 pageStrucutral Steel QA Checklist: N.: Comments, Report# Etc. Inspection Items Inspected As OKSteelcraft engineeringNo ratings yet

- Escalator: Monthly MaintenanceDocument1 pageEscalator: Monthly Maintenanceroland.bunsay.gsbmNo ratings yet

- Major Minor: Scoring SummaryDocument30 pagesMajor Minor: Scoring SummaryChaerul AnamNo ratings yet

- Supplying&Commissioning of Cantonment Dhaka.: CCTV at RajanecDocument2 pagesSupplying&Commissioning of Cantonment Dhaka.: CCTV at RajanecMohammed MohiuddinNo ratings yet

- Control Panel TCDocument1 pageControl Panel TCNOTOFIRE PVT. LTD.No ratings yet

- Preventive Maintenance Schedule For Bowl Mill & Coal Feeder of "U# 8, D.P.P.S."Document7 pagesPreventive Maintenance Schedule For Bowl Mill & Coal Feeder of "U# 8, D.P.P.S."mrinal mandalNo ratings yet

- Isolator TCDocument1 pageIsolator TCNOTOFIRE PVT. LTD.No ratings yet

- LTB145D1 Test ReportDocument10 pagesLTB145D1 Test ReportSiddharth BhawsarNo ratings yet

- Special Process Procedure Details From Schedule QDocument1 pageSpecial Process Procedure Details From Schedule QAnonymous VohpMtUSNNo ratings yet

- Cpontrol ModuleDocument3 pagesCpontrol ModuleNOTOFIRE PVT. LTD.No ratings yet

- Minas A6 Error CodeDocument15 pagesMinas A6 Error CodeWahyu SaputraNo ratings yet

- Valve Service Final Report - SampleDocument4 pagesValve Service Final Report - SampleNazmi100% (1)

- OptimDocument8 pagesOptimVIP VIDEONo ratings yet

- Radio Design V1 N1 1927 FallDocument8 pagesRadio Design V1 N1 1927 FallVictor AsterdamNo ratings yet

- TroubleshootingDocument6 pagesTroubleshootingLeonardo FleiNo ratings yet

- ATS Takada 2000ATDocument3 pagesATS Takada 2000ATaaronchestercruzNo ratings yet

- Form - Pre-Concrete Checklist: Fiche de Contrôle Avant Le BétonnageDocument2 pagesForm - Pre-Concrete Checklist: Fiche de Contrôle Avant Le BétonnageMvomoNo ratings yet

- CCTV Survey FormDocument1 pageCCTV Survey FormJoeven VillanuevaNo ratings yet

- Goldstar cp14b80hDocument2 pagesGoldstar cp14b80hRaulNo ratings yet

- Pipelineman No.2882Document3 pagesPipelineman No.2882Hussein HishamNo ratings yet

- Welding Record: N O Nozzle Conection JOI N NO - Pipe Welde R Stamp Visual Result KeteranganDocument3 pagesWelding Record: N O Nozzle Conection JOI N NO - Pipe Welde R Stamp Visual Result KeteranganAndri RivaldiNo ratings yet

- Function Test 132kv Avc PanelDocument9 pagesFunction Test 132kv Avc PanelratheeshkumardNo ratings yet

- Rele Sobrecorriente 7SK8854 SiemensDocument25 pagesRele Sobrecorriente 7SK8854 SiemensJoseNo ratings yet

- Maintenance Schedule PSR Cycloconverter Ver3Document1 pageMaintenance Schedule PSR Cycloconverter Ver3IdhamtanahbaruNo ratings yet

- WTG58.Punch ListDocument8 pagesWTG58.Punch ListIbraHim RaGabNo ratings yet

- Insptcti0N (LLTS) A I-Eading I/Dt: IrainingDocument1 pageInsptcti0N (LLTS) A I-Eading I/Dt: Irainingআশার আলোNo ratings yet

- Machine Setup Check List CNC003Document2 pagesMachine Setup Check List CNC003zulfahmyNo ratings yet

- Figure 1 Fuse Blown: Q822, Q825etDocument9 pagesFigure 1 Fuse Blown: Q822, Q825etCarlos Torres AriasNo ratings yet

- 6lpsohàrzfkduwripdoixqfwlrq : 4. TroubleshootingDocument57 pages6lpsohàrzfkduwripdoixqfwlrq : 4. TroubleshootingBrandon MendozaNo ratings yet

- WTG64.Punch List 2Document9 pagesWTG64.Punch List 2IbraHim RaGabNo ratings yet

- Daewoo TV CN155 ChassisDocument4 pagesDaewoo TV CN155 ChassisAngelos AnagnostouNo ratings yet

- 33 KVDocument2 pages33 KVChennai RathiNo ratings yet

- JnyeusbtrfeasvdDocument6 pagesJnyeusbtrfeasvdMohamed SelimNo ratings yet

- UtyftdrfdDocument1 pageUtyftdrfdMohamed SelimNo ratings yet

- 5 Kme 6 U 5 JwsnyabteDocument1 page5 Kme 6 U 5 JwsnyabteMohamed SelimNo ratings yet

- JegtbrhdxfDocument3 pagesJegtbrhdxfMohamed SelimNo ratings yet

- YrthdfDocument1 pageYrthdfMohamed SelimNo ratings yet

- RjyhetrsgdfzDocument1 pageRjyhetrsgdfzMohamed SelimNo ratings yet

- FHHFG ControlDocument13 pagesFHHFG ControlMohamed SelimNo ratings yet

- GwesvdgtrDocument3 pagesGwesvdgtrMohamed SelimNo ratings yet

- HwrasgvdzsgDocument2 pagesHwrasgvdzsgMohamed SelimNo ratings yet

- J 67 e 5 STRHGDDocument3 pagesJ 67 e 5 STRHGDMohamed SelimNo ratings yet

- BfgjuestDocument2 pagesBfgjuestMohamed SelimNo ratings yet

- Gvaersd CDocument2 pagesGvaersd CMohamed SelimNo ratings yet

- AFCشربDocument2 pagesAFCشربMohamed SelimNo ratings yet

- D ResponsibilvjkgDocument3 pagesD ResponsibilvjkgMohamed SelimNo ratings yet

- لابئري)Document2 pagesلابئري)Mohamed SelimNo ratings yet

- لقرشس) ) ~ءقشرسيDocument1 pageلقرشس) ) ~ءقشرسيMohamed SelimNo ratings yet

- NPT SOP PDE 004 F11 BOM Diaphragm ValveDocument4 pagesNPT SOP PDE 004 F11 BOM Diaphragm ValveMohamed SelimNo ratings yet

- 1.3 GlossaryfbjfdhnDocument3 pages1.3 GlossaryfbjfdhnMohamed SelimNo ratings yet

- HHKK Policy and Objectives Including Quality Management SystemDocument3 pagesHHKK Policy and Objectives Including Quality Management SystemMohamed SelimNo ratings yet

- NPT Sop Pde 006 f02 DQ AgitatorDocument2 pagesNPT Sop Pde 006 f02 DQ AgitatorMohamed SelimNo ratings yet

- V CJ K Ngs and ImprovementDocument2 pagesV CJ K Ngs and ImprovementMohamed SelimNo ratings yet

- 1.2 Distribution ListDocument1 page1.2 Distribution ListMohamed SelimNo ratings yet

- GnhucticesDocument4 pagesGnhucticesMohamed SelimNo ratings yet

- GbnjonsDocument2 pagesGbnjonsMohamed SelimNo ratings yet

- GvnjentDocument2 pagesGvnjentMohamed SelimNo ratings yet

- FhhingDocument4 pagesFhhingMohamed SelimNo ratings yet

- GvnnuesDocument1 pageGvnnuesMohamed SelimNo ratings yet

- GgnhcedureDocument7 pagesGgnhcedureMohamed SelimNo ratings yet

- Hhfsessment For QualityDocument8 pagesHhfsessment For QualityMohamed SelimNo ratings yet

- VNNGCDocument2 pagesVNNGCMohamed SelimNo ratings yet

- SA35AC E01 MergedDocument87 pagesSA35AC E01 MergedClassyNo ratings yet

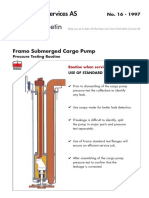

- 16 - FRAMO Submerged Cargo Pump - Pressure Testing RoutineDocument6 pages16 - FRAMO Submerged Cargo Pump - Pressure Testing RoutineMomchil DimitrovNo ratings yet

- SI-WX-1213 Parts N Oil Charge ImprovementsDocument4 pagesSI-WX-1213 Parts N Oil Charge ImprovementsRabea EzzatNo ratings yet

- Daihatsu DK 20Document4 pagesDaihatsu DK 20Suzette AbejuelaNo ratings yet

- Krautzberger Dok 208 enDocument19 pagesKrautzberger Dok 208 enMurilo Peres De MoraesNo ratings yet

- KLINGER Ballostar KHA 3 Pieces Ball Valve DN 10 - 150: Edition 2011Document36 pagesKLINGER Ballostar KHA 3 Pieces Ball Valve DN 10 - 150: Edition 2011Andy LuthorNo ratings yet

- Masoneilan 21000 Series: Top Guided Globe Valve With Lo-dB /anti-Cavitation CapabilitiesDocument24 pagesMasoneilan 21000 Series: Top Guided Globe Valve With Lo-dB /anti-Cavitation CapabilitiesManoj KumarNo ratings yet

- AI Air Duct Systems 1020Document88 pagesAI Air Duct Systems 1020jonh366100% (1)

- Finite Element Simulation of Bolt-Up Process of Pipe Flange Connections With Spiral Wound GasketDocument9 pagesFinite Element Simulation of Bolt-Up Process of Pipe Flange Connections With Spiral Wound GasketVarghese MathewNo ratings yet

- Steam BoilerDocument3 pagesSteam BoilerMohammad AzlanNo ratings yet

- Oisd 144Document135 pagesOisd 144Mwkthangkwr Brahma67% (6)

- Chetak Spare Parts Catalog Rev Dec 2004Document75 pagesChetak Spare Parts Catalog Rev Dec 2004mnc19No ratings yet

- Atlas Copco: Stationary Air CompressorsDocument72 pagesAtlas Copco: Stationary Air Compressorsnugrohowijaya37No ratings yet

- HJ125-7 Fa2133d83h-Xxe10Document74 pagesHJ125-7 Fa2133d83h-Xxe10Cristian CernaNo ratings yet

- D.I. Catalogue) 9th Edition) PDFDocument70 pagesD.I. Catalogue) 9th Edition) PDFArunprasad MurugesanNo ratings yet

- 13 Lubrication SystemDocument5 pages13 Lubrication Systemsalvador3410% (1)

- Dipaco Cat CatalogueDocument32 pagesDipaco Cat CatalogueKevin TtitoNo ratings yet

- VO Model O & M ManualDocument17 pagesVO Model O & M ManualJigyesh SharmaNo ratings yet

- Manual Valvula Fisher Modelo 95L-95H PDFDocument16 pagesManual Valvula Fisher Modelo 95L-95H PDFArturo VillenaNo ratings yet

- RERFEFRDocument1 pageRERFEFRMechanicalNo ratings yet

- Tri Clamp CatalogueDocument25 pagesTri Clamp CatalogueNenad PetrovicNo ratings yet

- Selector ValvesDocument23 pagesSelector Valveswalk111No ratings yet

- Tolvas PronesaDocument26 pagesTolvas PronesaVicente Salazar TorresNo ratings yet

- Exalco Albio 235 Sliding SystemDocument61 pagesExalco Albio 235 Sliding SystemAdmir MatoshiNo ratings yet