Professional Documents

Culture Documents

로보스타 - CONTROLLER

로보스타 - CONTROLLER

Uploaded by

choihero3329Copyright:

Available Formats

You might also like

- Sconi 2250 ADocument2 pagesSconi 2250 A반기서No ratings yet

- 01 Varistor KorDocument29 pages01 Varistor Kor이태규No ratings yet

- 용성Document22 pages용성박건호 (잼디아)No ratings yet

- MS Servo PDFDocument29 pagesMS Servo PDFdae hee hanNo ratings yet

- MD모터사양서V14GDocument77 pagesMD모터사양서V14Gsangwoo jungNo ratings yet

- Neopis Epic-M2500 Kor Cat V2.5Document8 pagesNeopis Epic-M2500 Kor Cat V2.5jundong choNo ratings yet

- Curve จานหมุน Over voltage Type GVO-CD1Document5 pagesCurve จานหมุน Over voltage Type GVO-CD1หนุ่ม วัยทองNo ratings yet

- LS2107PF-LW1152PF - 매뉴얼 - 240513 v2Document8 pagesLS2107PF-LW1152PF - 매뉴얼 - 240513 v2kimgangmin1003No ratings yet

- K-PAM DG3300 사양서 (V2.01)Document72 pagesK-PAM DG3300 사양서 (V2.01)marron66666No ratings yet

- Curve จานหมุน Under Voltage Type GVU-CD1Document4 pagesCurve จานหมุน Under Voltage Type GVU-CD1หนุ่ม วัยทองNo ratings yet

- VS (Ver 4.3) (041-060)Document20 pagesVS (Ver 4.3) (041-060)NikoNo ratings yet

- Tokimec Eha Catalog - 20210209Document10 pagesTokimec Eha Catalog - 20210209박채영No ratings yet

- EM 계전 VIPAM3300-F K-2017Document23 pagesEM 계전 VIPAM3300-F K-2017marron66666No ratings yet

- E50S Cat Kor 160408Document3 pagesE50S Cat Kor 160408머신비전No ratings yet

- 스텝모터원리Document58 pages스텝모터원리jinriNo ratings yet

- (※별첨1.) Dc Acb Catalog Ko 202102Document92 pages(※별첨1.) Dc Acb Catalog Ko 202102LS ELECTRIC INDIANo ratings yet

- CDHD2 KR 2019 V1.0Document2 pagesCDHD2 KR 2019 V1.0viptrungkienNo ratings yet

- Technical Description Cat Kor 160704Document6 pagesTechnical Description Cat Kor 160704머신비전No ratings yet

- Battery Charger (Tdc-9030a) ManualDocument15 pagesBattery Charger (Tdc-9030a) Manualauto etrustNo ratings yet

- 부품목록Document3 pages부품목록originalappleNo ratings yet

- 인버터 원리Document14 pages인버터 원리kim minNo ratings yet

- 서지보호기 spd k 1107Document40 pages서지보호기 spd k 1107조성철No ratings yet

- RDS3□30시리즈 (5포트파일럿타입솔레노이드밸브) 직접배관형 190909 (품번원위치)Document8 pagesRDS3□30시리즈 (5포트파일럿타입솔레노이드밸브) 직접배관형 190909 (품번원위치)정재엽No ratings yet

- AT8PSN AT8PMN W Cat 150310Document3 pagesAT8PSN AT8PMN W Cat 150310liser0604shsonNo ratings yet

- 설계04. AD - DA 컨버터 응용 전기회로 설계Document12 pages설계04. AD - DA 컨버터 응용 전기회로 설계댕댕이No ratings yet

- Shinhanelec 22990 ZzltryDocument7 pagesShinhanelec 22990 ZzltryMohammad AbdullahNo ratings yet

- 사용설명서 배전반용디지털집합계기 (KDX-300) 광성계측기 (상세)Document28 pages사용설명서 배전반용디지털집합계기 (KDX-300) 광성계측기 (상세)blackhandNo ratings yet

- EM 계전 VIPAM3500 K 2017Document41 pagesEM 계전 VIPAM3500 K 2017marron66666No ratings yet

- Tob Lance RHDocument9 pagesTob Lance RHazza aghniyaNo ratings yet

- EORC CatalogDocument4 pagesEORC Catalogducnam502No ratings yet

- Rectifier of Ballast Water - 150107 (다원시스)Document6 pagesRectifier of Ballast Water - 150107 (다원시스)Justice KNo ratings yet

- Alt 6400Document14 pagesAlt 6400Jeonghyeon KimNo ratings yet

- InsulationDocument1 pageInsulationRodel PelimianoNo ratings yet

- Eocr Total KR 2014-Press2Document150 pagesEocr Total KR 2014-Press2정정호No ratings yet

- VFD-M 한글메뉴얼 PDFDocument131 pagesVFD-M 한글메뉴얼 PDF조현의No ratings yet

- Sungho SHF 60Document2 pagesSungho SHF 60Nguyễn Quốc KhaNo ratings yet

- Sungho SHF-60Document2 pagesSungho SHF-60Nguyễn Quốc KhaNo ratings yet

- 02.Soft Starter 자료Document13 pages02.Soft Starter 자료rony andrewNo ratings yet

- Cam Switch 02Document70 pagesCam Switch 02Nguyễn Anh TuấnNo ratings yet

- 12. 수소연료전지 특성 측정 2Document23 pages12. 수소연료전지 특성 측정 2김찬우No ratings yet

- 사업계획서 에이스Document15 pages사업계획서 에이스Zephyr ArchangelNo ratings yet

- motrex, 폭스바겐Document47 pagesmotrex, 폭스바겐gilljung730No ratings yet

- 계통전압제어Document66 pages계통전압제어KI OHNo ratings yet

- OZBV Ver 2.0 시리즈 BLDC 드라이버 사용 설명서: Ozsystems OZNO 2011.09.01Document30 pagesOZBV Ver 2.0 시리즈 BLDC 드라이버 사용 설명서: Ozsystems OZNO 2011.09.01TEKNISI FREELANCENo ratings yet

- 실생활 전기전자회로-3주차-자동스위치Document40 pages실생활 전기전자회로-3주차-자동스위치skej sNo ratings yet

- Spac-S9: Sequence Power SupplyDocument4 pagesSpac-S9: Sequence Power Supplytrung nguyenNo ratings yet

- MDA7000 Catalogue (국문)Document5 pagesMDA7000 Catalogue (국문)Esau HernandezNo ratings yet

- DataSheet L12-XXPT-3 Rev1.2Document8 pagesDataSheet L12-XXPT-3 Rev1.2M Ilman NuryakusumahNo ratings yet

- Eocr Eocr-PdmDocument3 pagesEocr Eocr-PdmtalibanindonesiaNo ratings yet

- Sconi SL DSCDocument3 pagesSconi SL DSCfarscapefeatNo ratings yet

- Kasys Relay Socket - KoreaDocument44 pagesKasys Relay Socket - Koreatuanvutt0% (1)

- XGT 특수 - V21 -Document146 pagesXGT 특수 - V21 -sklee0730No ratings yet

- 세기전자정비메뉴얼 (구형) 노랑색Document28 pages세기전자정비메뉴얼 (구형) 노랑색최영진No ratings yet

- VFD-F 한글메뉴얼 PDFDocument142 pagesVFD-F 한글메뉴얼 PDF조현의No ratings yet

- Vse002 05 - Ko KRDocument3 pagesVse002 05 - Ko KRkoths202010807No ratings yet

- 정류기 운영 Manual - - REV01Document24 pages정류기 운영 Manual - - REV01Justice KNo ratings yet

- Mep Villla Da NangDocument37 pagesMep Villla Da NangVõ Thế QuyềnNo ratings yet

- Eocr ArDocument2 pagesEocr ArM25 PatrickNo ratings yet

로보스타 - CONTROLLER

로보스타 - CONTROLLER

Uploaded by

choihero3329Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

로보스타 - CONTROLLER

로보스타 - CONTROLLER

Uploaded by

choihero3329Copyright:

Available Formats

Single-Axis Controller

1-Axis Linear Controller Servo Driver

RCS7000D Series 주요 특징

32Bit 고속 DSP를 채용한 고성능 고기능의 AC Servo Drive

최대 0.05um 고분해능의 리니어 엔코더 사용으로 고정밀 제어가 가능

자극 센서가 없는 모터의 Sensorless 제어가 가능

초소형, 초경량 전원 일체형 디자인으로 최상의 시스템 구성이 가능합니다

Model Designation

RCS - 70 01 D - L S N N S

Motor Capa Motor

01 : 100W L : Linear Motor

02 : 200W R : Rotary Motor S : Standard

Single Axis 7000 04 : 400W S : Serial Rotary S : Standard

Drive C : Position N : N Common N : Standard

Robot Controller Series 05 : 500W Motor E : CE

control only

08 : 750W X : Sensorless

10 : 1KW Linear Motor

H

F F

Small Capacity Middle Capacity Small Capacity Middle Capacity

(RCS-7001D~7004D) (RCS-7005D~7010D) (RCS-7001D~7004D) (RCS-7005D~7010D)

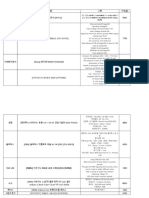

Model A B C D E F G H I

RCS-7001D-7004D 199.5 178 73 134 R2.75 R2.75 R2.75 15 30

RCS-7005D-7010D 231.5 210 81 195 R2.75 R2.75 R2.75 15 40

Specifications (기본 사항)

Model RCS-7000D Series

Item 7001D / 7002D 7004D 7005D 7008D 7010D

Input Power 단상 AC220-230V, 50~60Hz 단상/3상 AC220-230V, 50~60Hz

power Power Capa.(KVA) 0.8 1.3 1.5 1.8 2.1

Weight(kg) 1.2 1.4 2.0 2.2 2.4

Regenerative resistor(W/Ω) - 50W / 50Ω 140W / 50Ω 140W / 50Ω 140W / 50Ω

Cooling System Natural Convection Cooling

Control System Sine wave pwm system

Position Feedback Differential line receive (Position, Magnetic pole)

Output Signal Differential line drive

Monitor Accurancy 5μm, 1μm, 0.5μm, 0.1μm, 0.05μm

Monitor output DC 5[V], under 0.3[A]

7-Segment Servo State Display, Alarm, Parameter Editing, Variables Monitoring

Protection Function Over current, Over load, Over voltage, Under voltage, Over speed, Follow error, Encoder error

Protection Available(operation condition settable)

Dymatic Bake

Function

Regenerative Resistor Possible to attach Eternal regenerative resistor for 400W motor

DA Output(option) position / Speed / Torque command and feedback error, etc. (max, ±5V)

1. Linear scale (A, A, B, B) / Incremental Converter with Hall sensor

286 Robostar Product Information

Single-Axis Controller

Series

RM

1-Axis Linear Controller Servo Driver

( Clean )

Series

RM

RCS7000D Series 주요 특징

(Tap 취부)

Series

32Bit 고속 DSP를 채용한 고성능 고기능의 AC Servo Drive

RS

최대 0.05um 고분해능의 리니어 엔코더 사용으로 고정밀 제어가 가능

자극 센서가 없는 모터의 Sensorless 제어가 가능

초소형, 초경량 전원 일체형 디자인으로 최상의 시스템 구성이 가능합니다

( Clean )

Series

RC

Model Designation

(판너트 취부)

RCS - 70 01 D - L S N N S

Series

RJ

Motor Capa Motor

01 : 100W L : Linear Motor

02 : 200W R : Rotary Motor S : Standard

Single Axis 7000 04 : 400W S : Serial Rotary S : Standard

RK Series

Drive C : Position N : N Common N : Standard

Robot Controller Series E : CE

Belt-

05 : 500W Motor control only

08 : 750W X : Sensorless

10 : 1KW Linear Motor

RS Series

Belt-

H

RJ Series

Belt-

ZW Unit

Combina-

F F

Bracket

tion

Small Capacity Middle Capacity Small Capacity Middle Capacity

(RCS-7001D~7004D) (RCS-7005D~7010D) (RCS-7001D~7004D) (RCS-7005D~7010D)

Model A B C D E F G H I

Robot

Linear

RCS-7001D-7004D 199.5 178 73 134 R2.75 R2.75 R2.75 15 30

RCS-7005D-7010D 231.5 210 81 195 R2.75 R2.75 R2.75 15 40

Gantry

Robot

Specifications (기본 사항)

Model RCS-7000D Series

Item 7001D / 7002D 7004D 7005D 7008D 7010D

Stage

Input Power 단상 AC220-230V, 50~60Hz 단상/3상 AC220-230V, 50~60Hz

power Power Capa.(KVA) 0.8 1.3 1.5 1.8 2.1

Weight(kg) 1.2 1.4 2.0 2.2 2.4

SCARA

Robot

Regenerative resistor(W/Ω) - 50W / 50Ω 140W / 50Ω 140W / 50Ω 140W / 50Ω

Cooling System Natural Convection Cooling

Desktop

Control System Sine wave pwm system

Robot

Position Feedback Differential line receive (Position, Magnetic pole)

Output Signal Differential line drive

Monitor Accurancy 5μm, 1μm, 0.5μm, 0.1μm, 0.05μm

Servo

Press

Monitor output DC 5[V], under 0.3[A]

7-Segment Servo State Display, Alarm, Parameter Editing, Variables Monitoring

Parallel

Over current, Over load, Over voltage, Under voltage, Over speed, Follow error, Encoder error

Robot

Protection Function

Protection Available(operation condition settable)

Dymatic Bake

Function

Regenerative Resistor Possible to attach Eternal regenerative resistor for 400W motor

Controller

DA Output(option) position / Speed / Torque command and feedback error, etc. (max, ±5V)

1. Linear scale (A, A, B, B) / Incremental Converter with Hall sensor

Accessory

Global Leader in Robotics & Automation 287

Single-Axis Controller

1 Axis Linear Servo Driver

RCS-7000D Series Wiring Diagram

RCS-7000D

MCCB MCL High voltage stage

AC220~230V L1 U

50/60Hz NF L2 V

EMC SM

*1) L3 W

UNIT

FG

*3)

P *2) r

B t

Regenerative E

discharge

CN2

N B

resistor 18 ENCA C R

15 / ENCA O A

D K

16 ENCB E E

CN1 INPUT 13 / ENCB R

+24VIN 48 14 ENCZ

- + 11 / ENCZ

SVONEN 36

5 ENCU

SPD1/GEAR1 13 6 / ENCU

3 ENCV

SPD2/GEAR2 37 4 / ENCV

1 ENCW

SPD3/MODE 14

2 / ENCW

DIR 38 19 5V

9 0V

LMT+ 16 case

Input signal

LMT - 39

CN1 INPUT

AFLMT 40

7 PAO

ARST/PCLR 18 32 / PAO

6 PBO

ESTP 17 31 / PBO Pulse output

5 PZO

PI/P 15

30 / PZO

STOP/START 41

46

RDY

SREF 27 45

Speed command INPOS / INSPD

(0 to ±10[V]) *4) GND

20

ZSPD

Force command FREF 28 19

BRK

(0 to ±10[V]) *4) GND

47

ALARM

PFIN 9 Output signal

22

/ PFIN 10 ALM1

Command pulse

(Use 250kpps or smaller) PRIN 11 24

ALM2

/ PRIN 12

23

FG 50 ALM3

21

FLMT

Twist pair 43

GND24

Note

*1) Under RCS-7004D is prohibited to use L3 terminal.

*2) For under RCS-7004D, there is no r, t terminal.

*3) It is used only for CE type.

*4) Use one of 1, 3, 8, 26, 34 to use GND terminal.

1. When using the 200V single-phase, use under 400W connected to the L1, L2 terminal.

2. Connect ZNR(DIODE) to each sides of the brake, for brakes other than 24V use external relays.

288 Robostar Product Information

Single-Axis Controller

Series

RM

1-Axis Servo Controller

( Clean )

Series

RM

RCS7000C Series 주요 특징

(Tap 취부)

Series

Full Digital 제어

RS

로봇 프로그램 실행 중 프로그램 및 파라미터 확인 가능

이동 중 위치, 속도, 토크 제어 가능

RS-485 Multipoint 통신운전, CC-link

( Clean )

Series

RC

미쯔비시 PLC에 직접연결하여 PLC I/O공유, PLC Ladder 프로그램에 의한 운전

Model Designation

(판너트 취부)

Series

RCS - 70 01 C - R S N N S

RJ

N : 표준_선택품목 없음

Motor Capa C : CC-Link (V2.0)

01 : 100W I : Incremental F : CC-Link (V3.0)

RK Series

Single Axis 7000 02 : 200W Controller Motor S : Standard N : N Common S : Standard

Belt-

B : Profibus

Robot Controller Series 04 : 400W A : Absolute L : Line Drive P : P Common E : CE

05 : 500W Motor D : DeviceNet

08 : 750W E : EX I/O B/D

P : Pulse Counter

RS Series

Belt-

RJ Series

H

Belt-

ZW Unit

Combina-

Bracket

F F

tion

Small Capacity Middle Capacity CC-LINK CARD installed RTS-9100(A)

(RCS-7001C~7004C) (RCS-7005C~7008C)

Robot

Model A B C D E F G H I

Linear

RCS-7001-7004 199.5 178 73(97) 134 R2.75 R2.75 R2.75 15 30

RCS-7005-7010 231.5 210 81(108) 195 R2.75 R2.75 R2.75 15 40

※( ) CC-Link B/D 부착 시

Gantry

Robot

Specifications (기본 사항)

Model RCS-7000 Series

Item 7001C / 7002C 7004C 7005C 7008C

Stage

Motor(W) 100W / 200W 400W 500W 750W

power 단상 AC220-230V, 50~60Hz 단상/3상 AC 220-230V, 50~60Hz

Power Capacity(KVA) 0.8 0.9 1.1 1.8

SCARA

Robot

Regenerative resistor(W/Ω) - 50W / 50Ω - 140W / 50Ω

Weight(kg) 1.44 1.48 2.34 2.38

Desktop

Encoder Optical Incremental Encoder(15Line, 9Line)

Robot

Programming Teach pendent, PC communication program

I/O Input 16 / Output 16

Program Storage Robot Program 8EA, PLC program 4EA : 1000 Step for each Program

Servo

Press

Protection Function Over Current, Overheat Voltage, Over Load, Following error, IPM error

EMG stop, Line error, Program error, Memory error etc.

Cooling System

Parallel

Natural Convention Cooling

Robot

Running Temp / Humidity 0~45℃, 85%RH (Non-condensing)

Storage Temp / Humidity -15~65℃, 90%RH (Non-condensing)

Controller

Teach Pendant RTS-9100 (AB)

1. Encoder 15Line use Panasonic MINAS AC servo motor Standards, also compatable for Panasonic 10 line type

Accessory

Global Leader in Robotics & Automation 289

Single-Axis Controller

1 Axis Servo Controller

RCS-7000C Wiring Diagram

Single Phase

AC220V RCS-7000C Series

50/60Hz

CN3 SERIAL CN2 ENC

+12V 1 1 W

RxD 2 2 /W

TxD 3 3 V SM

-12V 4 4 /V

ENCODER

GND 5 5 U

EMG 6 6 /U

FG 11 7 -

RDA 12 8 - Brake

RDB 13 9 GND(5V)

BDA 14 10 -

SDB 15 11 /Z

12 SHIELD

13 /B

14 Z

15 /A

16 B

17 -

18 A

19 +5v

20 -

BRAKE / OUTPUT

SYS INPUT INSTALLING <*4> 50 BRAKE+

ROB-RUN 25 BRAKE-

CN1 INPUT 2 / APHASE_OUT

PCL-RUN EMG+ 23

STOP 3 APHASE_OUT

EMG- 48 4 / BPHASE_OUT Encoder

RESET PCOM(ICOM0) 18 27 BPHASE_OUT output

SVON B000 14 28 / CPHASE_OUT

SVOFF B001 39 29 CPHASE_OUT

ORIGIN B002 15 24 PCOM(INCOM0)

STEP B003 40 26 AIN_COM

PGM_SEL B004 16 49 FG

PGM_SEL 0~2 B005 41 1 GND

JOG +/- B006 17 9 NCOM(OUTCOM0)

JOG_SET 0,1 B007 42 5 B030

JOG_MODE PCOM(ICOM1) 43 30 B031

IOPOS 0~7 B010 19 6 B032

B011 44 31 B033

IOSPD 0,1

B012 20 7 B034

CW S/W

B013 45 32 B035

CCW S/W B014 21

ORIGIN S/W 8 B036

B015 46 33 B037

B016 22 34 NCOM(OUTCOM1)

MOVT_ST B017 47 10 B040

SYS OUTPUT INSTALLING 35 B041

ALARM CC-Link CC-LINK(OPTION) 11 B042

READY DA 1 36 B043

Master

ORIGIN_OK DB 2 12 B044

IN_POS DG 3 37 B045

SLD 4 13 B046

ALARM ø~3

FG 5 38 B047

BRAKE

1. When using the 200V single-phase, use under 400W connected to the R, S terminal.

2. Using the RS 232/422 Converter, driving multiple Controllers using RS422 can be driven with a single PC or Controller.

3. Connect ZNR(DIODE) to each sides of the brake, for brakes other than 24V use external relays.

4. SYSTEM I/O must use the user I/O contact points.

5. For PNP type, refer to the diagram in red letters.

290 Robostar Product Information

N1 Controller

Series

RM

N1 Controller Series

( Clean )

Series

RM

(Tap 취부)

Series

RS

System Configuration

CC-link

( Clean )

Cne Profibus

Series

RC

DeviceNet

I/O

(판너트 취부)

Series

RJ

RK Series

Belt-

Teaching Pendant

RS Series

Accessory Feature

Belt-

Standard Part별 모듈화 설계로 착탈이 가능하여 Slot 단위 A/S 가능

1. T/P 더미 19" Rack 타입 설계로 Panel 부착 용이 (일반 4축 기준)

RJ Series

2. 표준 I/O 커넥터 RTOS를 통한 실시간 Multi Tasking 제어

Belt-

(System 1ea, User Input 1ea, User Output 1ea) Full Digital 방식의 Servo 제어 Driver 적용

3. 전원 케이블 Servo 제어용 Process를 별도 적용하여 제어 성능 향상

Option 17Bit Encorder 채용에 따른 위치 정밀도 향상

ZW Unit

1. Teach Pendant 다채널 분리 (로봇2채널+제어용1채널)로 멀티 로봇 구동 가능

2. I/O 단자대, I/O 단자대 케이블 Job, Point 저장 공간 확장 및 안정성 상향

다양한 Fieldbus 채용 (CC-Link, Profibus, Device-Net, Cnet)

Combina-

Bracket

Controller Specification

tion

Item N1 CE N1 KCs

CPU spec 300MHz, 1,800MIPS, 64Bit

Task Processing Method Max 3channel (Robot 2ch + I/O 1ch)

Robot

Linear

Controllable Axis Up to 6 Axis

Control System PTP, CP, ARC, Sealing, Palletizing, Linear, Circular, Semi-PLC

Drive System Digital AC servo / 1 Board : 2 Axis

Max motor capacity per axis 750W (1Kw - under development)

Gantry

Robot

Panasonic A4 Series (Abs) 17Bit, (Inc) 2500PPR, A5 Series (Abs) 17Bit

Controllable Motor

Sewoo Linear Motor, Yaskawa Linear Motor (Under development)

Panasonic, Tamagawa Protocol

Encoder Protocol

LinearDigital Encoder (Under development)

Stage

Program (JOB / Step) 200program / 2000step

Point (Local / Global) 2000point / 1024point

Data Backup Uni-Host

Teaching Method Remote, Direct, MDI

SCARA

Robot

Error Display 7-Segment / Teaching pendant

Protection Function O.C, O.L, O.V, U.V, Position Error, Encoder Error, IPM Error

System + User Input : 24, Output : 12 / Input : 16, Output : 16

Standard I/O

Desktop

Limit±, Origin (Per axis)

Robot

Robot

Position Latch 2ea (Per 2axis)

Communication

RS-232C C-NET, Uni-Host (115200bps)

Interface

Option Slots Digital I/O (Input 64, Output 64),

Servo

Press

(Max 2slots) CC-LINK, DeviceNet, Profibus-dp

Temperature Storage / Running -15~60℃ / 0~45℃

Humidity Storage / Running 10~90% / 20~65% RH less (No condensation)

Safety Category Safety category 1 Safety category 4

Parallel

Robot

Main Single-phase AC 220V(±10%, 50/60Hz)

Power Source Single-phase AC 220V(±10%, 50/60Hz)

Control Single-phase AC 220V(±10%, 50/60Hz)

Degree of Protection IP20 (CE)

Controller

2 axis : 344 X 245 X 183 / 10Kg

Dimension (W X H X D) / Weight 4 axis : 440 X 245 X 183 / 12Kg 4 axis : 583 X 255 X 208 / 12Kg

6 axis : 536 X 245 X 183 / 15Kg 6 axis : 676 X 255 X 208 / 14Kg

Available Robots Cartesian, Scara Robot

Accessory

Global Leader in Robotics & Automation 291

N1 Controller

Controller

2축 CE형

4/6축 CE형

4/6축 KCs형

ROBOT Ordering method

1. Series 2. Motor 3. I/O 4. Option1 5. Option2 6. Case 7. MAIN 8. Power 9. Safety 10. Version

N1 8442XX N C X Q X G C1 S11

1 N1 Series Model 명

S : 50W 1 : 100W 2 : 200W 4 : 400W 8 : 750W

2 8442XX Motor cap acity

A : 1kW B : 2kW C : 2kW D : 3kW E : 5kW

3 N I/O N : NCOM P : PCOM

I : 확장 I/O NCOM C : CCLINK D : DEVICENET

4 C Option1

P : PROFIBUS R : RTEX A : AIO X : 없음

I : 확장 I/O NCOM C : CCLINK D : DEVICENET

5 7X Option2

P : PROFIBUS R : RTEX A : AIO X : 없음

6 Q Case Q : 4축 CASE H : 6축 CASE R : RTEX

7 X Main BD E : ETHERNET U : USB F : ETHERNET+USB X : 없음

8 G Power G : 단일전원 U : 전원분리

9 C1 Safety C1 : 안전등급1 C3 : 안전등급4

10 C1 Version S11 : CE S12 : KCs

Teach Pendant

RTM-9100 Teaching Method

적용 제어기 : N1 Remote Teaching JOG KEY로 목적 위치까지 이동시켜 티칭

지원 언어 : 영어 Direct Teaching : 서보 오프 상태에서 로봇을 손으로 움직여 티칭

오른손 잡이 전용으로 제작 팬던트입니다 MDI(man data input) Teaching : 좌표값을 수치 입력하여 티칭

Teaching 기능

Teaching Point, Integer, Float 편집 및 저장

Job Program, Parameter 편집 및 저장

I/O, Task Monitoring, I/O Output On/Off

292 Robostar Product Information

Accessory

Series

RM

System Diagram & Accessory

( Clean )

Series

RM

(Tap 취부)

Series

RS

System Diagram

( Clean )

GP RTM-9100

Series

PC

RC

(판너트 취부)

Series

RJ

2 Axis Robot

RS 232/422 Converter

RK Series

Belt-

Servo Controller

N1 Seires (2 Axis Controller)

RS Series

Belt-

IO Terminal

RJ Series

Belt-

ZW Unit

Accessory

① ② ③ ④ ⑤

Combina-

Bracket

tion

Robot

Linear

⑥ ⑦ ⑧ ⑨ ⑩

Gantry

Robot

Stage

⑪ ⑫ ⑬

SCARA

Robot

Desktop

Robot

Specifications

NO Product Description NO Product Description

1 RCS, N1 공용 System I/O Connector 10 BODY HARNESS : 일반 표준 MSMR용

Servo

Press

2 RCS용 I/O Terminal 11 RCS 1축 USER INPUT 19점, OUTPUT 16점(혼합) Connector

3 N1용 System+User I/O Terminal 12 N1용 USER INPUT 16점 Connector

4

Parallel

13

Robot

1축 비가동 케이블 (5M~10M) : RCS-7000C Series용 N1용 USER OUTPUT 16점 Connector

5 1~6축 가동 케이블 (5M~10M) : N1용

6 RS-232 통신 케이블

Controller

7 RCS 1축 TEACH PENDANT : RTS-9100

8 N1_CE형 2/4축 TEACH PENDANT : RTM-9100

9 N1_KCs형 4/6축 TEACH PENDANT : RT6-9000

Accessory

Global Leader in Robotics & Automation 293

You might also like

- Sconi 2250 ADocument2 pagesSconi 2250 A반기서No ratings yet

- 01 Varistor KorDocument29 pages01 Varistor Kor이태규No ratings yet

- 용성Document22 pages용성박건호 (잼디아)No ratings yet

- MS Servo PDFDocument29 pagesMS Servo PDFdae hee hanNo ratings yet

- MD모터사양서V14GDocument77 pagesMD모터사양서V14Gsangwoo jungNo ratings yet

- Neopis Epic-M2500 Kor Cat V2.5Document8 pagesNeopis Epic-M2500 Kor Cat V2.5jundong choNo ratings yet

- Curve จานหมุน Over voltage Type GVO-CD1Document5 pagesCurve จานหมุน Over voltage Type GVO-CD1หนุ่ม วัยทองNo ratings yet

- LS2107PF-LW1152PF - 매뉴얼 - 240513 v2Document8 pagesLS2107PF-LW1152PF - 매뉴얼 - 240513 v2kimgangmin1003No ratings yet

- K-PAM DG3300 사양서 (V2.01)Document72 pagesK-PAM DG3300 사양서 (V2.01)marron66666No ratings yet

- Curve จานหมุน Under Voltage Type GVU-CD1Document4 pagesCurve จานหมุน Under Voltage Type GVU-CD1หนุ่ม วัยทองNo ratings yet

- VS (Ver 4.3) (041-060)Document20 pagesVS (Ver 4.3) (041-060)NikoNo ratings yet

- Tokimec Eha Catalog - 20210209Document10 pagesTokimec Eha Catalog - 20210209박채영No ratings yet

- EM 계전 VIPAM3300-F K-2017Document23 pagesEM 계전 VIPAM3300-F K-2017marron66666No ratings yet

- E50S Cat Kor 160408Document3 pagesE50S Cat Kor 160408머신비전No ratings yet

- 스텝모터원리Document58 pages스텝모터원리jinriNo ratings yet

- (※별첨1.) Dc Acb Catalog Ko 202102Document92 pages(※별첨1.) Dc Acb Catalog Ko 202102LS ELECTRIC INDIANo ratings yet

- CDHD2 KR 2019 V1.0Document2 pagesCDHD2 KR 2019 V1.0viptrungkienNo ratings yet

- Technical Description Cat Kor 160704Document6 pagesTechnical Description Cat Kor 160704머신비전No ratings yet

- Battery Charger (Tdc-9030a) ManualDocument15 pagesBattery Charger (Tdc-9030a) Manualauto etrustNo ratings yet

- 부품목록Document3 pages부품목록originalappleNo ratings yet

- 인버터 원리Document14 pages인버터 원리kim minNo ratings yet

- 서지보호기 spd k 1107Document40 pages서지보호기 spd k 1107조성철No ratings yet

- RDS3□30시리즈 (5포트파일럿타입솔레노이드밸브) 직접배관형 190909 (품번원위치)Document8 pagesRDS3□30시리즈 (5포트파일럿타입솔레노이드밸브) 직접배관형 190909 (품번원위치)정재엽No ratings yet

- AT8PSN AT8PMN W Cat 150310Document3 pagesAT8PSN AT8PMN W Cat 150310liser0604shsonNo ratings yet

- 설계04. AD - DA 컨버터 응용 전기회로 설계Document12 pages설계04. AD - DA 컨버터 응용 전기회로 설계댕댕이No ratings yet

- Shinhanelec 22990 ZzltryDocument7 pagesShinhanelec 22990 ZzltryMohammad AbdullahNo ratings yet

- 사용설명서 배전반용디지털집합계기 (KDX-300) 광성계측기 (상세)Document28 pages사용설명서 배전반용디지털집합계기 (KDX-300) 광성계측기 (상세)blackhandNo ratings yet

- EM 계전 VIPAM3500 K 2017Document41 pagesEM 계전 VIPAM3500 K 2017marron66666No ratings yet

- Tob Lance RHDocument9 pagesTob Lance RHazza aghniyaNo ratings yet

- EORC CatalogDocument4 pagesEORC Catalogducnam502No ratings yet

- Rectifier of Ballast Water - 150107 (다원시스)Document6 pagesRectifier of Ballast Water - 150107 (다원시스)Justice KNo ratings yet

- Alt 6400Document14 pagesAlt 6400Jeonghyeon KimNo ratings yet

- InsulationDocument1 pageInsulationRodel PelimianoNo ratings yet

- Eocr Total KR 2014-Press2Document150 pagesEocr Total KR 2014-Press2정정호No ratings yet

- VFD-M 한글메뉴얼 PDFDocument131 pagesVFD-M 한글메뉴얼 PDF조현의No ratings yet

- Sungho SHF 60Document2 pagesSungho SHF 60Nguyễn Quốc KhaNo ratings yet

- Sungho SHF-60Document2 pagesSungho SHF-60Nguyễn Quốc KhaNo ratings yet

- 02.Soft Starter 자료Document13 pages02.Soft Starter 자료rony andrewNo ratings yet

- Cam Switch 02Document70 pagesCam Switch 02Nguyễn Anh TuấnNo ratings yet

- 12. 수소연료전지 특성 측정 2Document23 pages12. 수소연료전지 특성 측정 2김찬우No ratings yet

- 사업계획서 에이스Document15 pages사업계획서 에이스Zephyr ArchangelNo ratings yet

- motrex, 폭스바겐Document47 pagesmotrex, 폭스바겐gilljung730No ratings yet

- 계통전압제어Document66 pages계통전압제어KI OHNo ratings yet

- OZBV Ver 2.0 시리즈 BLDC 드라이버 사용 설명서: Ozsystems OZNO 2011.09.01Document30 pagesOZBV Ver 2.0 시리즈 BLDC 드라이버 사용 설명서: Ozsystems OZNO 2011.09.01TEKNISI FREELANCENo ratings yet

- 실생활 전기전자회로-3주차-자동스위치Document40 pages실생활 전기전자회로-3주차-자동스위치skej sNo ratings yet

- Spac-S9: Sequence Power SupplyDocument4 pagesSpac-S9: Sequence Power Supplytrung nguyenNo ratings yet

- MDA7000 Catalogue (국문)Document5 pagesMDA7000 Catalogue (국문)Esau HernandezNo ratings yet

- DataSheet L12-XXPT-3 Rev1.2Document8 pagesDataSheet L12-XXPT-3 Rev1.2M Ilman NuryakusumahNo ratings yet

- Eocr Eocr-PdmDocument3 pagesEocr Eocr-PdmtalibanindonesiaNo ratings yet

- Sconi SL DSCDocument3 pagesSconi SL DSCfarscapefeatNo ratings yet

- Kasys Relay Socket - KoreaDocument44 pagesKasys Relay Socket - Koreatuanvutt0% (1)

- XGT 특수 - V21 -Document146 pagesXGT 특수 - V21 -sklee0730No ratings yet

- 세기전자정비메뉴얼 (구형) 노랑색Document28 pages세기전자정비메뉴얼 (구형) 노랑색최영진No ratings yet

- VFD-F 한글메뉴얼 PDFDocument142 pagesVFD-F 한글메뉴얼 PDF조현의No ratings yet

- Vse002 05 - Ko KRDocument3 pagesVse002 05 - Ko KRkoths202010807No ratings yet

- 정류기 운영 Manual - - REV01Document24 pages정류기 운영 Manual - - REV01Justice KNo ratings yet

- Mep Villla Da NangDocument37 pagesMep Villla Da NangVõ Thế QuyềnNo ratings yet

- Eocr ArDocument2 pagesEocr ArM25 PatrickNo ratings yet