Professional Documents

Culture Documents

Aggregate Production Site Visit Report

Aggregate Production Site Visit Report

Uploaded by

Yoze MeraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aggregate Production Site Visit Report

Aggregate Production Site Visit Report

Uploaded by

Yoze MeraCopyright:

Available Formats

Addis Ababa University

Addis Ababa Institute of Technology

School of Civil and Environmental Engineering

Construction Materials (CENG-6105)

AGGREGATE PRODUCTION SITE VISIT

REPORT

SUBMITTED BY: Zenamarkos Zinabie (ID: GSR/6426/16)

Frehiwot Kassa (ID: GSR/3603/16)

Biruk Bogale (ID: GSR/5683/16)

SUBMITTED TO: Biruktawit Taye, Dr.

NOVEMBER 16, 2023

CONSTRUCTION MATERIALS ASSIGNMENT NO. 1

ACKNOWLEDGEMENT

First and foremost, praise and thanks to the God, the Almighty, for His blessings during the

whole of our site visit and report work.

We also would like to express our deepest gratitude to all those who gave us the opportunity to

complete this report. Special thanks go to our instructor, Dr. Biruktawit Taye, for giving us the

opportunity to gain practical knowledge and external industry exposure.

We would also like to acknowledge with much appreciation the crucial role played by the staff of

AACRA Aggregate Production Unit and Israel Aggregate Production Company who allowed us

to see all the basic equipment, production processes and materials necessary to complete the task.

AGGREGATE PRODUCTION SITE VISIT REPORT Page 1

CONSTRUCTION MATERIALS ASSIGNMENT NO. 1

EXECUTIVE SUMMARY

Since aggregates account for approximately 60% to 75% of the total volume of concrete, their

selection is important. Aggregates should consist of particles with adequate strength and

resistance to exposure conditions and should not contain materials that will cause deterioration of

the concrete. A continuous gradation of aggregate particle size is desirable for efficient use of the

paste. The main focus of this report is to visit different aggregate production sites and try to

have a knowhow on a extraction process of raw material from quarry site, visualize step by step

production process of different aggregates including base coarse, subbase, 00, 01, 02 aggregates,

understanding about the handling of aggregates, selling price, efficiency of aggregate crushing

machine and the consistency of their product in terms of supply, quality and sustainability,

furthermore the profitability of the companies are discussed.

AGGREGATE PRODUCTION SITE VISIT REPORT Page 2

CONSTRUCTION MATERIALS ASSIGNMENT NO. 1

Contents

ACKNOWLEDGEMENT ................................................................................................................................... 1

EXECUTIVE SUMMARY .................................................................................................................................. 2

1. Introduction .......................................................................................................................................... 4

2. OBJECTIVE OF SITE VISIT ....................................................................................................................... 5

3. METHODOLOGY AND DISCUSSION ....................................................................................................... 6

3.1 METHODOLOGIES ......................................................................................................................... 6

3.2 DISCUSSIONS ................................................................................................................................. 6

3.2.1 GENERAL DESCRIPTION OF THE SITES................................................................................... 6

3.2.2 WORK PROCEDURES IN THE PRODUCTION PROCESS ........................................................... 8

3.2.3 General condition of the production site and quarry site condition .................................... 10

4. CONCLUSION ....................................................................................................................................... 14

5. RECOMMENDATIONS.......................................................................................................................... 14

6. REFERENCES ........................................................................................................................................ 14

List of Tables

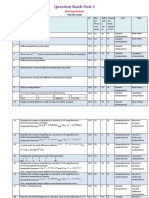

Table 1: production cost for different aggregates ....................................................................................... 11

Table 2: Selling price for different aggregates............................................................................................ 11

List of figures

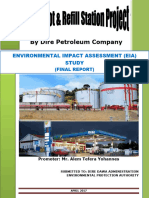

Figure 1: stone crushing plant layout ........................................................................................................... 9

Figure 2: Pictures in AACRA production site ............................................................................................... 12

Figure 3: pictures at Israel Production Company........................................................................................ 13

AGGREGATE PRODUCTION SITE VISIT REPORT Page 3

CONSTRUCTION MATERIALS ASSIGNMENT NO. 1

1. Introduction

It is well known that aggregates are the most important constituents of concrete. Aggregates

generally account for 65-75% of the volume of concrete. Therefore, due attention should be paid

to their selection, grading and proportioning. Traditionally, aggregates have been regarded as

chemically inert materials, but it is now recognized that their physical and chemical properties

can affect the concrete paste over time, such as sulfate attack.

Aggregates can be sourced both naturally and artificially. Natural sources can be sourced from

riverbeds as fine aggregate and from quarries (crushed rock) as coarse and fine aggregates, or it

can be sourced artificially as industrial by-products in the form of ground granulated blast

furnace slag (GGBS) and pulverized fuel ash (PFA), or it can be sourced from recycled sources

such as demolished concrete structures.

Listed below are the main properties that need to be considered when selecting good quality

aggregates for concrete mix design.

Physical property: This includes size, shape, grading and surface texture, and may also

affect the workability of the concrete.

Chemical property: such as alkali-aggregate reaction (AAR), alkali-silica reaction

(ASR) and alkali- carbonate reaction (ACR).

Mechanical property: including strength, toughness, hardness, durability and bond

strength.

In our country, Ethiopia, most of the time coarse aggregates are obtained from an open pit mine

(quarry) which is naturally found on the open earth surface. The most common purpose of

quarries is to extract material for the construction of buildings, roads and other public and private

infrastructure. Selecting the best quarry site is therefore critical and involves testing the physical,

mechanical and chemical properties to ensure that the material source is suitable for aggregate

and a geotechnical survey is carried out to determine if the area has a potential source. In

addition, a number of criteria are considered in the selection of a quarry site such as; slope of the

quarry rock face, distance to the quarry site, land use/land cover, accessibility, rock type and

degree of weathering.

This particular site visit report discusses aggregate production sites from quarry to final

production point. It is noted that aggregate suppliers go through different processes and steps to

finalize the product for the intended use.

AGGREGATE PRODUCTION SITE VISIT REPORT Page 4

CONSTRUCTION MATERIALS ASSIGNMENT NO. 1

2. OBJECTIVE OF SITE VISIT

The main aim of the site visit is to gain an understanding of the aggregates production process,

from quarrying to the finished product, and to link the theoretical view with the actual work on

site. Finally, it is essential to complement the course in the classroom. In addition, it plays a vital

role in exploring and understanding the different activities and techniques carried out in the

aggregate production process, getting to know different machinery and equipment and

discovering the workforce involved in the production process.

AGGREGATE PRODUCTION SITE VISIT REPORT Page 5

CONSTRUCTION MATERIALS ASSIGNMENT NO. 1

3. METHODOLOGY AND DISCUSSION

3.1 METHODOLOGIES

The method we used to produce this particular report was to physically visit the site and

interview those involved in the production process, such as the materials engineer and production

foreman.

3.2 DISCUSSIONS

3.2.1 GENERAL DESCRIPTION OF THE SITES

In this report we have selected and visited two aggregate production sites in Addis Ababa, which

are located in refenti behind Bole International Airport, fortunately one belongs to the Addis

Ababa City Road Authority (AACRA) and the other belongs to private.

Site-1 Refenti (behind bole international airport)

The Addis Ababa City Road Authority (AACRA) materials production site, which is located in

the Bole sub-city behind Addis Ababa International Airport, was established as a crushing site in

2019 GC, but prior to that the site was used for the production of sub base, base coarse, capping

and masonry materials. Since 2019 GC, after carrying out proper geological survey, this site was

determined to have potential for aggregate production in addition to base coarse and sub base

material production and then AACRA installed the aggregate crushing machine and started

production. Since then it has been supplying material to the public projects consistently, so it is a

government organization, they will not supply the material to the private sector. The total area of

the quarry is 472,878 m2 and it has a potential capacity to supply material for more than 50

years.

Type of material produced

Base coarse

Sub base

02 aggregate (passing through 25mm sieve)

02 aggregate (passing through 19mm sieve)

01 aggregate (passing through 9.5mm sieve)

00 aggregate (passing through 4.75mm sieve)

Production capacity:

65m³/hr. for base coarse

60 m³/hr. for base coarse since it requires harder material

60 m³/hr. for 00 to 02 gravel collectively

Method of quarrying

AGGREGATE PRODUCTION SITE VISIT REPORT Page 6

CONSTRUCTION MATERIALS ASSIGNMENT NO. 1

Blasting and jack hammer excavation

Machineries and Equipment's used for production:

Crusher plant

Excavator with bucket

Excavator with jack hammer

Loaders

Trucks with capacity of 23m³

Wagon Driller (that works with air pressure)

Generator

Facilities on site: Generator powerhouse, explosive house, water tanker, offices, resting rooms,

and tea break areas.

Work force on-site: maintenance crew, production crew, accountants, police assigned for

Explosive issues and guards at main gate (total man power about 80 people).

Site-2 Refenti (Behind Bole International Airport)

Israel Aggregate Production Company is a private company established to provide different

types of aggregates and the same area as AACRA and it is believed to have the same potential

for material and resources as AACRA and the site has covered more than 30,000 m² areas for

their quarry site.

Type of material produced

Base coarse

Sub base

02 aggregate (passing through 25mm sieve)

02 aggregate (passing through 19mm sieve)

01 aggregate (passing through 9.5mm sieve)

00 aggregate (passing through 4.75mm sieve)

Production capacity:

20 m³/hr. of size 02 gravel, 20m³/hr. and 20m³/hr. so it has a capacity of 60m³/hr. to

produce at a time.

65m³/hr. for base coarse

60 m³/hr. for base coarse

Method of quarrying

AGGREGATE PRODUCTION SITE VISIT REPORT Page 7

CONSTRUCTION MATERIALS ASSIGNMENT NO. 1

Blasting and jack hammer excavation

Machinery and Equipment's used for production:

Crasher plant

Explosives

Excavator with bucket

Excavator with jackhammer

Loaders

Trucks with capacity of 16m³

Facilities on site: Generator powerhouse, explosive house, water tanker, offices, resting rooms,

and tea break areas.

Work force on-site: maintenance crew, production crew, accountants, police assigned for

Explosive issues and guards at main gate (total man power about 25 people).

3.2.2 WORK PROCEDURES IN THE PRODUCTION PROCESS

Material extraction and production

This process can be done in two ways, the first is by blasting using explosives and it requires

technical staff so the process is a controlled process. The activity involved is that they drill the

surface up to 3m but the machine has the capacity to drill up to 20m and then the explosives are

used to extract and crush the material.

The second way is to extract the material using a jackhammer excavator.

If we compare the two in terms of production, the blasting technique is more efficient than

jackhammering, but in terms of cost, bureaucracy and noise pollution, jackhammering is more

effective.

Transportation of material (boulders) to the crusher machine

The extracted and produced material has transported and stocked on the area which is

appropriate for feeding to the crusher machine.in our case the quarry site is 1km away to the

crushing plant.

Feeding the material to primary crusher

The stockpiled material is fed to the coarse crushing equipment (jaw crusher) by means of a

loader.

Primary Crusher

In this process, the boulders are partially crushed into smaller pieces and will be ready for the

secondary crusher (impact crusher).

AGGREGATE PRODUCTION SITE VISIT REPORT Page 8

CONSTRUCTION MATERIALS ASSIGNMENT NO. 1

Secondary Crusher (Impact crusher)

Material crushed in the primary crusher is transported to the impact crusher via a conveyor

system. This system continuously feeds the impact crushers at appropriate times.

Screening

Stone from the impact crusher is transferred to the screen panel by a conveyor belt and vibration.

To produce aggregate types of 00, 01, 02 the screen panel are arranged and assembled in

declining order of 25mm, 19mm, 9.5mm, 4.75mm and the material retained on 25mm sieve has

to go back to secondary crushing process and then come back to screening whereas the other

passing through 25mm sieve is going to 4 out lets and gives us 4 types of aggregates this process

is repeated till the material retained on 25mm sieve has come to the desired size and pass through

it.

Where as to produce base coarse and sub base there is only one screen assembled on the top and

its size is 6m length and 2m width and in this the screen is arranged as 4m² 37.5mm sieve, 4m²

9.5mm sieve and 4m² 4.75mm sieve and the material passing through these sieves has mixed and

come through in one out let, hence the material needed for base coarse and sub base has to

contain all types of grading.

Figure 1: stone crushing plant layout

AGGREGATE PRODUCTION SITE VISIT REPORT Page 9

CONSTRUCTION MATERIALS ASSIGNMENT NO. 1

3.2.3 General condition of the production site and quarry site condition

1. Availability of material/continuity

In terms of material availability, both sites have great potential for aggregate production, which

is estimated to provide material for more than 30 years.

2. Material storage and handling

On both sites they have stored the material close to the production unit or the out let. So in some

cases when there is a lot of stockpile there is lack of area for workability and movement,

additionally the stockpile is exposed to contamination with the dusts coming from the production

unit, it is also exposed to the weather, so it is stockpiled on open air surface. We asked them how

to deal with these aggregates that have been stored for more than a month and they explained

that we have supplied these materials by mixing them with the newly produced ones and in this

way they will improve the quality.

3. Consistency in terms of quality and supply

Both sites have very good aggregate quality in terms of strength, hardness and durability. This is

why their quarries are located in the same area. They are also consistent in terms of aggregate

size distribution. However, we have information that it is difficult to maintain this consistency

during the rainy season due to the muddy nature of the site.

When we come to the supply, Site 1 (AACRA) belongs to the public or the government, so it can

only supply the production for the projects of the Addis Ababa city administration, therefore the

supply of Site 1 depends on the demand of the government projects in Addis Ababa, which

means when there is a higher demand they will produce material for 24 hours and when the

demand is less they will work normal hour for 8 hours.

Site 2 (Israel Aggregate Production) belongs to the private sector and they have been supplying

their material for different customers, so there is always a higher aggregate demand, they always

work for 24 hours in two shifts and they use more than two crushing plants to meet the demand.

They are always working unless the machine is down for some other reason.

4. Quality control

The quality of the aggregates is tested in every 1000m3 of production on site, they have their

own laboratory on site and in every 10,000m3 of production the sample is taken to central testing

to make sure that the produced aggregates meet all requirements.

AGGREGATE PRODUCTION SITE VISIT REPORT Page 10

CONSTRUCTION MATERIALS ASSIGNMENT NO. 1

5. Production cost, selling price and efficiency of the plants

Production Cost

production cost/m3

Sn Aggregate type (ETB)

1 00 (passing through 4.75mm sieve) 561.14

2 01 (passing through 9.5mm sieve) 488.82

3 02 (passing through 19mm sieve) 436.13

4 02 (passing through 25 mm sieve) 436.13

Table 1: production cost for different aggregates

Selling Price

Sn Aggregate type Selling Price/m3 (ETB)

1 00 (passing through 4.75mm sieve) $ 1,600.00

2 01 (passing through 9.5mm sieve) $ 1,000.00

3 02 (passing through 19mm sieve) $ 1,500.00

4 Base coarse $ 1,600.00

5 Sub base $ 900.00

Table 2: Selling price for different aggregates

Efficiency of Plants

Rather than additional factors such as particle shape, size distribution and strength of the raw

materials the plants are efficient, which can be expressed in the below formula.

In our case this is between 85 to 90 percent.

AGGREGATE PRODUCTION SITE VISIT REPORT Page 11

CONSTRUCTION MATERIALS ASSIGNMENT NO. 1

Figure 2: Pictures in AACRA production site

AGGREGATE PRODUCTION SITE VISIT REPORT Page 12

CONSTRUCTION MATERIALS ASSIGNMENT NO. 1

Figure 3: pictures at Israel Production Company

AGGREGATE PRODUCTION SITE VISIT REPORT Page 13

CONSTRUCTION MATERIALS ASSIGNMENT NO. 1

4. CONCLUSION

From the visit, we concluded that aggregate production is in its infancy stage and we need to

perform better to meet the demand and we noticed that aggregate production business is a

profitable business if it is managed properly and if it is done with sufficient study starting from

source selection, machine selection and management techniques used. We were also able to see

and understand the whole process of gravel production. The problem that the companies faced,

the market, the demand, etc. Some of the problems faced by the companies are

There is a power cut so they are forced to use generators most of the time. They also face some

bans on the use of explosives due to security reasons, noise pollution and bureaucracy to do it.

We were also able to understand the company's initiative to do some rehabilitation work on the

quarry finished areas like backfilling and planting and also they have used water to reduce the

dust particles going to the neighborhood.

5. RECOMMENDATIONS

Hence there is a huge demand in the market, government aggregate production companies like

ACCRA has to supply their production to the private need, in this case we can reduce the

shortage of material and when we are going to establish this kind of plants it is better to consider

the environment and the people living there and environmental impact assessments have to be

done.

The concerned legal body will have to supervise the production area and should pay due

attention to solve the problems faced by the supplier like provision of constant electricity,

provision of explosive materials.

6. REFERENCES

Design and Control of Concrete Mixtures

Steven H. Kosmatka, Beatrix Kerkhoff, and William C. Panarese

AGGREGATE PRODUCTION SITE VISIT REPORT Page 14

You might also like

- Apola Ose-Otura (PopoolaDocument33 pagesApola Ose-Otura (PopoolaLucas Rachid100% (17)

- Hydrological Investigation in Determining Subsurface ResourcesDocument47 pagesHydrological Investigation in Determining Subsurface ResourcesJohn Carlo AbalaNo ratings yet

- Ern Baxter - Thy Kingdom ComeDocument20 pagesErn Baxter - Thy Kingdom ComeAussiedler77100% (1)

- Uhone Broker GuideDocument28 pagesUhone Broker Guidestech137No ratings yet

- Matthews Ridge Pre Feasibility Study W App FinalDocument975 pagesMatthews Ridge Pre Feasibility Study W App FinalIsaac VisualNo ratings yet

- CENG-6105 Construction Materials Assignment 1 - (Agg Production Site Visit Report)Document12 pagesCENG-6105 Construction Materials Assignment 1 - (Agg Production Site Visit Report)Andu TadesseNo ratings yet

- Grouting in Difficult DamDocument68 pagesGrouting in Difficult DamTam Eng Sun67% (3)

- Chapter Three Agg. Prod. Eth.Document16 pagesChapter Three Agg. Prod. Eth.N8hom100% (1)

- Tamiru TolchaDocument85 pagesTamiru TolchaRidwan Sultan100% (2)

- Company Profile 2017 New PDFDocument14 pagesCompany Profile 2017 New PDFJasinthaja AsankaNo ratings yet

- Teff Beater With Blower MachineDocument117 pagesTeff Beater With Blower MachineAsnakeNo ratings yet

- Engineering Characteristics of Red SoilDocument100 pagesEngineering Characteristics of Red SoilbereketNo ratings yet

- Attachment To LRPS-2017-9135981 Hydro-Geophysical Study - ANNEX B - TORDocument11 pagesAttachment To LRPS-2017-9135981 Hydro-Geophysical Study - ANNEX B - TORBonaventure NzeyimanaNo ratings yet

- CES 25 - 2013, Concrete Sewer PipesDocument9 pagesCES 25 - 2013, Concrete Sewer PipesephremNo ratings yet

- Text BookDocument535 pagesText Bookbassnala100% (1)

- EzanaDocument36 pagesEzanaTesfaye DegefaNo ratings yet

- Attachment 3 - Cost ScheduleDocument5 pagesAttachment 3 - Cost ScheduleJoel Koma EmesangeNo ratings yet

- Agro ProDocument18 pagesAgro ProSami Wondimu67% (3)

- Adis AbebaDocument74 pagesAdis AbebaYemataw FilatieNo ratings yet

- Fdocuments - Us pdf3232kbDocument102 pagesFdocuments - Us pdf3232kbAbiued EjigueNo ratings yet

- Fiker AlebachewDocument118 pagesFiker AlebachewTeka TesfayeNo ratings yet

- Canal AlignmentDocument12 pagesCanal AlignmentsudarsancivilNo ratings yet

- Foundations On Black Cotton Soil PDFDocument4 pagesFoundations On Black Cotton Soil PDFprasadnn2001No ratings yet

- Fentahun Ayalneh MekonnenDocument117 pagesFentahun Ayalneh MekonnenBiyyaa DagafuuNo ratings yet

- Ebrahim Jemal Id 428.10Document71 pagesEbrahim Jemal Id 428.10Ebrahim JemalNo ratings yet

- Enchalew Aderaw 2Document66 pagesEnchalew Aderaw 2Muket AgmasNo ratings yet

- VETERINARY MEDICINE Producing Plant REvised FinalDocument28 pagesVETERINARY MEDICINE Producing Plant REvised FinalFirezegiNo ratings yet

- Utilization of Guinea Corn (Sughurm Vulgare) Husk For Preparation of Bio-Based Silica and It's Characterization StudiesDocument6 pagesUtilization of Guinea Corn (Sughurm Vulgare) Husk For Preparation of Bio-Based Silica and It's Characterization StudiesIJEAB JournalNo ratings yet

- My ProjectDocument21 pagesMy Projecthabtu tesemaNo ratings yet

- Research Proposal. 2023Document10 pagesResearch Proposal. 2023Biniam BelaynehNo ratings yet

- University of GondarDocument39 pagesUniversity of GondarMuket AgmasNo ratings yet

- Probation Period Accomplishment Report: Metahara Sugar FactoryDocument38 pagesProbation Period Accomplishment Report: Metahara Sugar FactoryAbera Mamo100% (4)

- 1 Shor Small Scale Irrigation Project Finished End LastDocument119 pages1 Shor Small Scale Irrigation Project Finished End LastOtoma OrkaidoNo ratings yet

- The Future of Lean Construction in EthiopianDocument8 pagesThe Future of Lean Construction in EthiopianEDEN2203No ratings yet

- Addis College: Department of Civil EngineeringDocument12 pagesAddis College: Department of Civil EngineeringAlemayehu DargeNo ratings yet

- Dam Construction: Aggregate Production - The Acceptability of Natural Aggregates Is Judged Upon The PhysicalDocument4 pagesDam Construction: Aggregate Production - The Acceptability of Natural Aggregates Is Judged Upon The PhysicalAbdi KaamilNo ratings yet

- 11 Aa Last Finished Alemayehu Water ThesisDocument67 pages11 Aa Last Finished Alemayehu Water ThesisAlas StudioNo ratings yet

- DBE Presentation in English FinalisedDocument65 pagesDBE Presentation in English Finalisedbekele abrahamNo ratings yet

- Ministry Agriculture Ethiopia Community Based Watershed Management Guideline 2005 Part 1 A 2Document74 pagesMinistry Agriculture Ethiopia Community Based Watershed Management Guideline 2005 Part 1 A 2hana fentaNo ratings yet

- 01 Technical Report Adama WWTPDocument97 pages01 Technical Report Adama WWTPaberraNo ratings yet

- A118 PDFDocument93 pagesA118 PDFsamNo ratings yet

- 122340hcb ProductionDocument8 pages122340hcb ProductionYared100% (1)

- Assignment 3 Rs & GisDocument6 pagesAssignment 3 Rs & GisShreyas PatelNo ratings yet

- Farm MachineDocument74 pagesFarm MachineMULUKEN TILAHUNNo ratings yet

- Level 1. EngineerDocument5 pagesLevel 1. EngineerDaniel mekete100% (1)

- Project Information Document Ethiopia Digital Foundations Project P171034Document20 pagesProject Information Document Ethiopia Digital Foundations Project P171034Asfaw Wossen100% (1)

- Derkesi River BridgeDocument15 pagesDerkesi River BridgeYared SolomonNo ratings yet

- HrU - 29th - Research and Extension Review - Proceedings PDFDocument214 pagesHrU - 29th - Research and Extension Review - Proceedings PDFHelen Teshome100% (2)

- Computer Aided Analysis and Design of Multi Storeyed Buildings PDFDocument9 pagesComputer Aided Analysis and Design of Multi Storeyed Buildings PDFakash pandeyNo ratings yet

- Asfaw Dessie PDFDocument95 pagesAsfaw Dessie PDFIztok ArshadNo ratings yet

- Tewodros DugasaDocument90 pagesTewodros DugasaHabtu AregawiNo ratings yet

- Project Prefab SeminarDocument48 pagesProject Prefab SeminarAlemu RegasaNo ratings yet

- Final Internship Report by TemeDocument40 pagesFinal Internship Report by Temebiramoabinet59100% (1)

- Addis Ababa Science and Technology UniversityDocument7 pagesAddis Ababa Science and Technology UniversityYabsra kasahun100% (1)

- Bussiness Plan of DUDBCDocument161 pagesBussiness Plan of DUDBCPramod Raj UpdNo ratings yet

- Print 2Document50 pagesPrint 2Daniel Pasy SelekaNo ratings yet

- Water Pollution and Treatment: LL.M, 2nd Year, Dr. RML National Law University, Lucknow - 226012Document8 pagesWater Pollution and Treatment: LL.M, 2nd Year, Dr. RML National Law University, Lucknow - 226012Metages ZerihunNo ratings yet

- Final Project Design of Diversion Structure: Faculity of Civil and Water Resource EngineeringDocument76 pagesFinal Project Design of Diversion Structure: Faculity of Civil and Water Resource EngineeringReffisa JiruNo ratings yet

- Ecsu 15513 538 Brief Article Review GuidelineDocument7 pagesEcsu 15513 538 Brief Article Review GuidelineAmanuel BefekaduNo ratings yet

- HCB Manual GTZ 2008Document14 pagesHCB Manual GTZ 2008suvajjit RoyNo ratings yet

- Petroleum Deport EIA - FinalDocument104 pagesPetroleum Deport EIA - FinalJoey MW100% (1)

- Ecohydrology: Vegetation Function, Water and Resource ManagementFrom EverandEcohydrology: Vegetation Function, Water and Resource ManagementNo ratings yet

- Cven 9809-Reinforced Concrete Design Assignment-2: Strut & Tie ModelDocument18 pagesCven 9809-Reinforced Concrete Design Assignment-2: Strut & Tie ModelSibani MishraNo ratings yet

- Wachamo UniverstyDocument16 pagesWachamo Universtygizew geremewNo ratings yet

- Reinforcement of Concrete Shoring SystemDocument10 pagesReinforcement of Concrete Shoring SystemYoze MeraNo ratings yet

- Zenamarkos Zinabie, System Analysis and Management Techniqes I, Assignment 1Document14 pagesZenamarkos Zinabie, System Analysis and Management Techniqes I, Assignment 1Yoze MeraNo ratings yet

- Professional EthicsDocument17 pagesProfessional EthicsYoze MeraNo ratings yet

- Building Industrialization and Prefabrication in EthiopiaDocument16 pagesBuilding Industrialization and Prefabrication in EthiopiaYoze MeraNo ratings yet

- The Cotton Industry in The Philippines: ' Country StatementDocument8 pagesThe Cotton Industry in The Philippines: ' Country StatementJocelle AlcantaraNo ratings yet

- Life of GalileoDocument4 pagesLife of GalileoBilly AslamNo ratings yet

- Computer Graphics I UNIT NotesDocument24 pagesComputer Graphics I UNIT Notesgouse1210100% (1)

- Makalah Conditional SentencesDocument14 pagesMakalah Conditional SentencesNanda Dwi FitriyaniNo ratings yet

- Reliable and Cost-Effective Sump Pumping With Sulzer's EjectorDocument2 pagesReliable and Cost-Effective Sump Pumping With Sulzer's EjectorDavid Bottassi PariserNo ratings yet

- Salvation Series-Lesson5-EternallifeyourchoiceDocument3 pagesSalvation Series-Lesson5-EternallifeyourchoiceKim M. BaraquelNo ratings yet

- Design of Screw FasteningDocument37 pagesDesign of Screw FasteningDhayane RedoquerioNo ratings yet

- 29 Modeling FRP-confined RC Columns Using SAP2000 PDFDocument20 pages29 Modeling FRP-confined RC Columns Using SAP2000 PDFAbdul LatifNo ratings yet

- Excel Master Data On Is 456-2000 & Is 3370-1965Document24 pagesExcel Master Data On Is 456-2000 & Is 3370-1965Thirumalaichettiar Rangarajan100% (1)

- Butterfly Ayurveda Private Limited 198, Sec-8, IMT Manesar, Gurgaon (Haryana)Document2 pagesButterfly Ayurveda Private Limited 198, Sec-8, IMT Manesar, Gurgaon (Haryana)Mulayam Singh YadavNo ratings yet

- Role of Physiotherapy in ICUDocument68 pagesRole of Physiotherapy in ICUprasanna3k100% (2)

- Aebersold FREE Rapidreference PDFDocument10 pagesAebersold FREE Rapidreference PDFTiago Ramos100% (1)

- Reflex Control of The Spine and Posture - A Review of The Literature From A Chiropractic PerspectiveDocument18 pagesReflex Control of The Spine and Posture - A Review of The Literature From A Chiropractic PerspectiveWeeHoe LimNo ratings yet

- Past The Last Mountain 01 Paul AllorDocument23 pagesPast The Last Mountain 01 Paul AllorRalf Singh (Graphics)No ratings yet

- (Leafospirosis Deadly Disease From Rat: Fiqh Al-Hadith-Based Analysis) Leptospirosis Wabak Maut Dari Tikus: Analisis Berasaskan Fiqh Al-HadithDocument16 pages(Leafospirosis Deadly Disease From Rat: Fiqh Al-Hadith-Based Analysis) Leptospirosis Wabak Maut Dari Tikus: Analisis Berasaskan Fiqh Al-Hadith0050 MUHAMMAD HAIKAL BIN SAHARINo ratings yet

- Ubd Template 2 0 Shortened VersionDocument6 pagesUbd Template 2 0 Shortened Versionapi-261286206No ratings yet

- Sarnafil S 327-20lchceDocument5 pagesSarnafil S 327-20lchceAhmed MontashNo ratings yet

- Oh! To Be Like Thee: WORDS: Thomas O. Chisholm, Pub.1897. MUSIC: William J. Kirkpatrick, 1897. Public DomainDocument1 pageOh! To Be Like Thee: WORDS: Thomas O. Chisholm, Pub.1897. MUSIC: William J. Kirkpatrick, 1897. Public DomainAlonge EmmanuelNo ratings yet

- My Dream Hotel: By. YeongseoDocument7 pagesMy Dream Hotel: By. YeongseoYoutube whiteNo ratings yet

- Question Bank-Unit 2: MATH 2300Document8 pagesQuestion Bank-Unit 2: MATH 2300ROHAN TRIVEDI 20SCSE1180013No ratings yet

- The Real Green Revolution Organic and Agroecological FarmingDocument151 pagesThe Real Green Revolution Organic and Agroecological FarmingKlausEllegaard11No ratings yet

- Roboshot Brochure enDocument19 pagesRoboshot Brochure envantuan17792No ratings yet

- Lecture 3Document28 pagesLecture 3Lovely ZahraNo ratings yet

- AP300Document2 pagesAP300Wislan LopesNo ratings yet

- CMP002Document98 pagesCMP002Black kosmosNo ratings yet

- Winchester Model 70 Bolt Action Rifle Owner's Manual: LicenseeDocument0 pagesWinchester Model 70 Bolt Action Rifle Owner's Manual: Licenseecarlosfanjul1No ratings yet