Professional Documents

Culture Documents

1 F 01

1 F 01

Uploaded by

Eddy Dwi Cahyono0 ratings0% found this document useful (0 votes)

9 views3 pagesOriginal Title

1-F-01

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

9 views3 pages1 F 01

1 F 01

Uploaded by

Eddy Dwi CahyonoCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 3

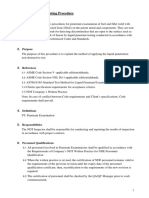

Lampiran Persetujuan Penggunaan No

Tanggal

Lay RI N

42148-T/BT/PPIDIM 7/2018

MATAN, TEKAN

‘Nomor : 003/48-7/5T/DMT/2018

Pengguna / Perk

Loki / Unit Instalasi

DATA BEJANA TEKAN

Jers

Nomar item (Tag No.)

Nomor Ser (Serial Number)

Patrik Peruat

Tahun Dibuat/ Daunakan

Tipe

Devensi

a. Tebal (Sheth

© Tebal (Tube)

¢ Diameter dan Panjang

6. Diameter dan Panjang

8 Data Desan

2 Tekanan Desain

D Temperatur Desai

¢ Tekanan Kerja Maksimum (MAWP)

{. Toba Minimum Desan

©. Um Layan Desan

9. Data Operasi

2 Tekanan Operas

b. Temperatur Operasi

© Kepastas

40, Dagunakan untuk

ut

MAWP Perhitungan

Lau Korosi

SSisa Umur Layan Perhtungan

Jens Uj Tidak Merusak (NOT)

Up Tokan (bia ada)

‘a. Media Untuk Pengujan (Test Media)

> Tokanan Uj

6 Tanggal Pemeriksaan Keselamatan

‘Masa berlaku sampai cengan

ya K

‘nip 19820219 200502 2004

PT Pertamina (Persero) RU VI! - Kasim

Sorong ~ Papua Barat

Heat Exchanger

1-F-01

'888-06231

PT Surya Besindo Sakti

1998 / 1996

Horizontal! Vertical

481mm,

7.4 mm (Convention Coil 7.1 mm (Radiant Coil)

168.3 mm (OD) x 4886 mm (i) {Convention Col!)

168.3 mm (OD) x 9875 mm (L) (Radiant Coil)

149.35 Psig / 10,50 Kg/em?g

850°F / 445°C.

149,35 Psig / 10.50 Kgiom'g

7.4 mm (Convention Coil) / 7,1 mm (Radiant Col)

6.8 Kglom'g

3srC

Crude Charge Heater

19592 Psig 167.42 Kglem*g

0,254 mmtahun

48 tahun

UT Thicknes

3 November 2017

3 November 2021

Dew Asti Murdaningsin

NIP 19820628 200601 2001

a

s* PERTAMINA

MAWP CALCULATION

Tag No 1-F-01 Report No. : 062-02-

Serial No. : SBS-06231 SMC/062/E.038/P8/2019

Service: CDU Reactor Heater Date 224 APRIL 2019

Location —_: Refinery Unit VII Kasim - Sorong Year Built 1996

[Remaining MAWP Calculation

. SES thse where, fused = thet ~ (2"UK"Interval Insp)

oe Ro - 0.4 tused 6,37 mm

0,251 inch

13938 x10 x__0,251

3,313 - 04 x 0,251

= 1087,80 psi or 76,48 —kg/om*

Result Praie > __MAWP _ (Satisfactory)

‘SHELL EVALUATION (API 530)

Outside Diameter, OD : 1683 = mm or 66 — inch

Material Grade A335 PS

[Allowable Stress,S : 13938 = psi“ SCH40 : 0.2370 = AW

Prev. IICKNESS, trey 0,00 mm C.AFactor,f :” 0,76

|Actual | NICKNESS, tac: 6,56 mm

INOM. I NICKNESS, thom 27,41 mm

Required Inickness, trea

7 PDo

as 28+2P

- 149,35 6,626

2 13938 2 x «1493

= 0,035 inch or 0,892 = mm

Result tee > eg (Satisfactory)

tr = ts +(FCA)

= 0,035 +( 0760 x 0,118 )

= 0,125 inch or = 3,17 mm

AW = Min. Wall/0,875

= 0,143 inch 0,892 mm

Result tee < leq _ (Satisfactory)

CONCLUSION

1. MAWP Used 10,5 kglom*

2 Remaining Life Used 236,8 years

a

fs” PERTAMINA

MAWP CALCULATION

TagNo : 1-F-01 Report No. : 062-02-

Serial No. : SBS-06231 SMC/062/E.038/P8/2019

Service: CDU Reactor Heater Date 24 APRIL 2019

Location: Refinery Unit VII Kasim - Sorong Year Built 1996

GENERAL DATA

Design Pressure, P 10,5 kgom* Shell Joint Eff., Es 10

149,35 psi

Design Temperature 445 cc Year Last Inspection 2018

Corr. Allowance, CA 2,997 mm Year of Inspection 2019

0,118 Inch

MAWP. 10,5 kg/om*

‘SHELL EVALUATION

Outside Diameter, OD 168,3 == mm or 6,626 _inch

Material Grade A335 PS

Allowable Stress, S 13938 psi

Prev. INICKNESS, tyrey 0,00 mm

[Actual | NICkNess, tect 6,56 mm

Nom. 1 nIckNeSS, thom 711 mm

Required 1 nickness, reg

t. 4 P Ro

“= SEs+04P

3,313

13938 x 1 04 149,35

= 0,035 inch or 0,898 mm

Result tect > tes (Satisfactory)

Corrosion Rate, CR

Long Term A

oii ie ct

CR = ——te BEWESR Tana nT aa

= 0,024 mmiyear

Shor Term a

vious : ct

OR = ame BeWeST Trecon OTT Tea

= -6,560 mmiyear

ICR Used 0,024 mmiyear

Remaining Life, RL

Ro 2 tee

Corrosion Rate

= 2368 years

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 3 F 01Document4 pages3 F 01Eddy Dwi CahyonoNo ratings yet

- Hand Out API 510 - IBT Reg Class - Rev 7 - Aug 2019Document41 pagesHand Out API 510 - IBT Reg Class - Rev 7 - Aug 2019Eddy Dwi CahyonoNo ratings yet

- 16 External Pressure IntroDocument6 pages16 External Pressure IntroEddy Dwi CahyonoNo ratings yet

- 27 ImpactDocument8 pages27 ImpactEddy Dwi CahyonoNo ratings yet

- Sop UtDocument6 pagesSop UtEddy Dwi CahyonoNo ratings yet

- Sop RTDocument9 pagesSop RTEddy Dwi CahyonoNo ratings yet

- Sop MTDocument6 pagesSop MTEddy Dwi CahyonoNo ratings yet

- Sop PTDocument5 pagesSop PTEddy Dwi CahyonoNo ratings yet

- Inspection Plan 101-E-501-A, B RevDocument1 pageInspection Plan 101-E-501-A, B RevEddy Dwi CahyonoNo ratings yet