Professional Documents

Culture Documents

Transfer Function Response

Transfer Function Response

Uploaded by

Abdullah KutbiCopyright:

Available Formats

You might also like

- ch08 1 40Document55 pagesch08 1 40Hadi Sobian100% (2)

- Transshipment LP Model For Minimizing The Utility Cost in A Heat Exchanger NetworkDocument7 pagesTransshipment LP Model For Minimizing The Utility Cost in A Heat Exchanger NetworkRicardo ACNo ratings yet

- 4 ChapterDocument46 pages4 ChapterRama ChilpuriNo ratings yet

- w5.4 - Modelling Thermal Systems (Ogata)Document3 pagesw5.4 - Modelling Thermal Systems (Ogata)mazlumNo ratings yet

- Mathematical Modeling of Chemical ProcessesDocument12 pagesMathematical Modeling of Chemical ProcessesSeanne CruzNo ratings yet

- Refrigeration and Air ConditioningDocument263 pagesRefrigeration and Air ConditioningAjeet Verma92% (12)

- Modeling A Process - Filling A Tank: in - Out AccumulationDocument3 pagesModeling A Process - Filling A Tank: in - Out Accumulationmnb100% (1)

- Cycle EfficiencyDocument17 pagesCycle Efficiencyrashm006ranjanNo ratings yet

- Principal of Entropy IncreaseDocument18 pagesPrincipal of Entropy IncreaseakashkumardevNo ratings yet

- Simulation and Identification of Drum - Boiler Dynamics: Msc. Thesis by Giambattista PistoreDocument11 pagesSimulation and Identification of Drum - Boiler Dynamics: Msc. Thesis by Giambattista PistoreAlfredo ToyosNo ratings yet

- Other Physical Examples of First-Order System - LEC 5Document12 pagesOther Physical Examples of First-Order System - LEC 5jaja59No ratings yet

- EntropyDocument39 pagesEntropyRohit Singh LatherNo ratings yet

- Thermodynamics 4Document13 pagesThermodynamics 4steyvohmannaNo ratings yet

- BTD Avail Irr 1-AKBDocument17 pagesBTD Avail Irr 1-AKBJyoti SharmaNo ratings yet

- Thermodynamics EquationsDocument11 pagesThermodynamics EquationsDilene DuarcadasNo ratings yet

- Homework 4: X =μ∗X−D∗X S= μ∗X Y D∗ (S S)Document7 pagesHomework 4: X =μ∗X−D∗X S= μ∗X Y D∗ (S S)katelynNo ratings yet

- 11 Anewdynamicmodelforashell and TubeheatexchangerDocument9 pages11 Anewdynamicmodelforashell and TubeheatexchangerHejoolju GrubsNo ratings yet

- Chapter Five PDFDocument24 pagesChapter Five PDFعبدالله رعد حران 32No ratings yet

- Dynamic SystemDocument28 pagesDynamic SystemA - STARNo ratings yet

- Rankine and Carnot NumericalsDocument59 pagesRankine and Carnot NumericalsBhargav PrajwalNo ratings yet

- Control PDFDocument18 pagesControl PDFTaban ShahabNo ratings yet

- Support 1Document175 pagesSupport 1Knv ChaitanyaNo ratings yet

- First Law Open SystemsDocument6 pagesFirst Law Open SystemsxplodeitupNo ratings yet

- 03 Part1a To CMSDocument32 pages03 Part1a To CMSthahirhussainNo ratings yet

- 7th and 8 TH Week Revised-DonusturulduDocument68 pages7th and 8 TH Week Revised-DonusturuldunaverfallNo ratings yet

- Ecuaciones Basicas de Transferecia de CalorDocument6 pagesEcuaciones Basicas de Transferecia de Calorruben'sNo ratings yet

- Chapter FiveDocument24 pagesChapter Fiveeng213810140No ratings yet

- Chapter 10Document46 pagesChapter 10Jason IskandarNo ratings yet

- Reversible ProcessesDocument38 pagesReversible Processeschemsac2No ratings yet

- ADP CalculationDocument12 pagesADP Calculationnim_gourav1997No ratings yet

- Basic Heat Exchanger Equations and Calculations: Perry'sDocument1 pageBasic Heat Exchanger Equations and Calculations: Perry'sPrathap VuyyuruNo ratings yet

- Reversible ProcessDocument37 pagesReversible ProcessTushar Kant SwainNo ratings yet

- Unit Iii Shell Energy Balance and Boundary ConditionsDocument8 pagesUnit Iii Shell Energy Balance and Boundary Conditions3004 Divya Dharshini. MNo ratings yet

- A-Cold Liquid Feed B - Saturated Liquid Feed C - Partially Vaporized Feed D - Saturated Vapor Feed e - Superheated Vapor FeedDocument16 pagesA-Cold Liquid Feed B - Saturated Liquid Feed C - Partially Vaporized Feed D - Saturated Vapor Feed e - Superheated Vapor FeedAmr HassanNo ratings yet

- Physics 127a: Class Notes: Lecture 5: Energy, Heat and The Carnot CycleDocument4 pagesPhysics 127a: Class Notes: Lecture 5: Energy, Heat and The Carnot CyclezhwNo ratings yet

- Energy and Energy TransferDocument31 pagesEnergy and Energy TransferShubham SharmaNo ratings yet

- Vapour Power Cycle Module 1Document59 pagesVapour Power Cycle Module 1ajaitkmNo ratings yet

- TP U3Document14 pagesTP U3Vignesh KNo ratings yet

- Thermodynamics PoeDocument8 pagesThermodynamics Poeg0227518cNo ratings yet

- Psychrometric ProcessesDocument14 pagesPsychrometric ProcessesKabin BoraNo ratings yet

- Entropy Generation Lost Work 03Document15 pagesEntropy Generation Lost Work 03Ferdous ShamaunNo ratings yet

- The Property Diagram in Heat Transfer and Its Applications: Chen Qun, Xu Yunchao & Guo ZengyuanDocument7 pagesThe Property Diagram in Heat Transfer and Its Applications: Chen Qun, Xu Yunchao & Guo ZengyuanAnonymous N3LpAXNo ratings yet

- Energy Performance Assessment of Heat ExchangersDocument22 pagesEnergy Performance Assessment of Heat ExchangersShailesh PatelNo ratings yet

- 4.4 Heat Ex ChangersDocument7 pages4.4 Heat Ex Changersmukesh kaushikNo ratings yet

- Control Engineering WorkDocument20 pagesControl Engineering WorkWilsonNo ratings yet

- Control Element For Installation in Operation The ReactorDocument7 pagesControl Element For Installation in Operation The ReactorHisyamuddin AliahNo ratings yet

- Unit - 4 Vapour Power Cycles: H T L PDocument14 pagesUnit - 4 Vapour Power Cycles: H T L PMukesh MystNo ratings yet

- CHE160 2022-2023 Module4Document39 pagesCHE160 2022-2023 Module4anthonyNo ratings yet

- Modeling Szymczyk Transactions 130 2015Document10 pagesModeling Szymczyk Transactions 130 2015Jack CavaluzziNo ratings yet

- 공조냉동 Stoecker 2022Document123 pages공조냉동 Stoecker 2022안호준No ratings yet

- Cool Lab ManualDocument12 pagesCool Lab Manualgiri_shwetaNo ratings yet

- Energies: Analysis and Experiment of Hot-Spot Temperature Rise of 110 KV Three-Phase Three-Limb TransformerDocument12 pagesEnergies: Analysis and Experiment of Hot-Spot Temperature Rise of 110 KV Three-Phase Three-Limb Transformeraisya mutia syafiiNo ratings yet

- Thermodynamics 2 Rankine CycleDocument207 pagesThermodynamics 2 Rankine CycleRyan TegioNo ratings yet

- A Modern Course in Statistical PhysicsFrom EverandA Modern Course in Statistical PhysicsRating: 3.5 out of 5 stars3.5/5 (2)

- CHE401 Midterm SummaryDocument15 pagesCHE401 Midterm SummaryAbdullah KutbiNo ratings yet

- Concept MCQ AIDocument30 pagesConcept MCQ AIAbdullah KutbiNo ratings yet

- Chapter 2Document46 pagesChapter 2Abdullah KutbiNo ratings yet

- Class Activity 2 Applications of Learning in Life 201834800Document8 pagesClass Activity 2 Applications of Learning in Life 201834800Abdullah KutbiNo ratings yet

- مستندات ممسوحة ضوئيًاDocument2 pagesمستندات ممسوحة ضوئيًاAbdullah KutbiNo ratings yet

- The Preschooler and The SchoolerDocument16 pagesThe Preschooler and The Schoolerquidditch07No ratings yet

- Thermicam: The World'S First Integrated Thermal Traffic SensorDocument2 pagesThermicam: The World'S First Integrated Thermal Traffic SensorSudipta BhadraNo ratings yet

- Is Codes ListDocument37 pagesIs Codes Listmoondonoo7No ratings yet

- Moral Stories - Situated Reasoning About Norms, Intents, Actions, and Their Consequences 2012.15738Document21 pagesMoral Stories - Situated Reasoning About Norms, Intents, Actions, and Their Consequences 2012.15738Zhu XUNo ratings yet

- Soal Quizziz Buat Sendiri Kelas Xii TTG News ItemDocument6 pagesSoal Quizziz Buat Sendiri Kelas Xii TTG News ItemJorus RukuNo ratings yet

- Astm A194Document11 pagesAstm A194Jarek CieslakNo ratings yet

- 3 Generations of Human RightsDocument1 page3 Generations of Human RightsDzenan HakalovicNo ratings yet

- Reasons For Diminishing Returns To A FactorDocument2 pagesReasons For Diminishing Returns To A FactorRobert AyalaNo ratings yet

- ECE 5325/6325 Fall 2009: Exam 1 SolutionsDocument2 pagesECE 5325/6325 Fall 2009: Exam 1 Solutionswilfred godfreyNo ratings yet

- Job Posting Groups ListDocument3 pagesJob Posting Groups ListShrutika singhNo ratings yet

- Be RealDocument3 pagesBe RealТатьяна СоколоваNo ratings yet

- Aras Innovator Programmers GuideDocument105 pagesAras Innovator Programmers Guidem0de570No ratings yet

- Bank Management System Source CodeDocument5 pagesBank Management System Source CodetheblueartboxNo ratings yet

- Higher Eng Maths 9th Ed 2021 Solutions ChapterDocument17 pagesHigher Eng Maths 9th Ed 2021 Solutions ChapterAubrey JosephNo ratings yet

- RRLsDocument6 pagesRRLsRobot RobotNo ratings yet

- 13-GB 50018-2002-EnDocument109 pages13-GB 50018-2002-Enyyyy071220100% (1)

- Brac Bank LimitedDocument1 pageBrac Bank LimitedMd Mojibar RahmanNo ratings yet

- Ujian General Mobile CraneDocument5 pagesUjian General Mobile CraneAgil Wahyu PamungkasNo ratings yet

- William James - PsychologistDocument5 pagesWilliam James - PsychologistCecilia SusaiNo ratings yet

- Tacha's ReusmeDocument2 pagesTacha's ReusmeJames HamptonNo ratings yet

- HR304Document3 pagesHR304Tanmoy MondalNo ratings yet

- Noun (Subject) + Verb + The + Superlative Adjective + Noun (Object)Document6 pagesNoun (Subject) + Verb + The + Superlative Adjective + Noun (Object)anaNo ratings yet

- Chechk List Fokker 50Document1 pageChechk List Fokker 50Felipe PinillaNo ratings yet

- GattaniDocument18 pagesGattaniKhushbu NovhalNo ratings yet

- Heater: Hydrate PreventionDocument12 pagesHeater: Hydrate PreventionMahmoud Ahmed Ali AbdelrazikNo ratings yet

- Lean StartupDocument10 pagesLean StartupAlfredo Romero GNo ratings yet

- Modeling and Simulation of Fluid Catalytic Cracking Unit: Reviews in Chemical Engineering January 2005Document38 pagesModeling and Simulation of Fluid Catalytic Cracking Unit: Reviews in Chemical Engineering January 2005Diyar AliNo ratings yet

- Creating A Sample BI Report in Oracle Cloud With Excel Template - TrinamixDocument1 pageCreating A Sample BI Report in Oracle Cloud With Excel Template - TrinamixIshaq Ali KhanNo ratings yet

- F101-1 Client Information Form and ApprovalDocument4 pagesF101-1 Client Information Form and ApprovalgoyalpramodNo ratings yet

Transfer Function Response

Transfer Function Response

Uploaded by

Abdullah KutbiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Transfer Function Response

Transfer Function Response

Uploaded by

Abdullah KutbiCopyright:

Available Formats

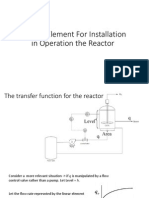

To model the transfer functions for the heat exchanger (E-100) and the reboiled

distillation column (T-100) with respect to time starting from mass and energy

balances, we need to derive equations based on the dynamics of each process. Here

is a simplified approach:

Heat Exchanger (E-100) Transfer Function:

For the heat exchanger, the transfer function can be derived from an energy balance

around the exchanger. Assuming a simple first-order process without phase change,

the energy balance is given by:

Q = mCp dT/dt

Where:

- Q is the heat input (which can be a function of time if it's being manipulated by

a PID controller),

- m is the mass flow rate,

- Cp is the specific heat capacity of the fluid,

- T is the temperature of the fluid,

- dT/dt is the rate of temperature change with respect to time.

The transfer function G(s) for the heat exchanger can be defined as the Laplace

transform of the output (temperature change) over the input (heat input), which can

be written as:

G(s) = Output(s)/Input(s) = T(s)/Q(s)

Assuming a linear system and applying the Laplace transform to the energy balance

equation, we get:

Q(s) = mCp sT(s)

Hence, the transfer function G(s) is:

G(s) = T(s)/Q(s) = 1/(mCps)

Reboiled Distillation Column (T-100) Transfer Function:

For the reboiled distillation column, the transfer function can be derived from

both mass and energy balances, taking into account the reboiler's duty which

affects the vapor flow rate and therefore the mass flow rate at the bottom of the

column.

The mass balance for a component i in the reboiler can be expressed as:

Fi + Ri = Di + Bi + Vi

Where:

- Fi is the feed rate of the component,

- Ri is the rate of return of the component from the column,

- Di is the distillate rate of the component,

- Bi is the bottom rate of the component,

- Vi is the vaporization rate of the component.

The energy balance around the reboiler can be given by:

Qr = Bi hb + Vi hv - Fi hf - Ri hr

Where h represents the specific enthalpy of the respective streams.

Taking the Laplace transform and assuming steady-state initial conditions, we can

derive the transfer function for the mass flow rate concerning time as a function

of the reboiler heat input Qr. The specific form of the transfer function will

depend on the relationship between Qr and Vi (since Vi affects Bi by the mass

balance).

The transfer function H(s) could be expressed in terms of the bottom product

concentration, xB, and the reboiler duty, Qr, assuming a first-order dynamics, as:

H(s) = xB(s)/Qr(s) = K/(τs + 1)

Where:

- K is the process gain,

- τ is the process time constant.

These are generic forms of the transfer functions, and actual models would require

specific process data to determine the parameters such as process gain and time

constants. Moreover, in a real distillation column, multiple stages and non-

idealities may require a more complex model than the first-order transfer function

provided here. If you have specific process data or parameters, we can refine these

models further.

You might also like

- ch08 1 40Document55 pagesch08 1 40Hadi Sobian100% (2)

- Transshipment LP Model For Minimizing The Utility Cost in A Heat Exchanger NetworkDocument7 pagesTransshipment LP Model For Minimizing The Utility Cost in A Heat Exchanger NetworkRicardo ACNo ratings yet

- 4 ChapterDocument46 pages4 ChapterRama ChilpuriNo ratings yet

- w5.4 - Modelling Thermal Systems (Ogata)Document3 pagesw5.4 - Modelling Thermal Systems (Ogata)mazlumNo ratings yet

- Mathematical Modeling of Chemical ProcessesDocument12 pagesMathematical Modeling of Chemical ProcessesSeanne CruzNo ratings yet

- Refrigeration and Air ConditioningDocument263 pagesRefrigeration and Air ConditioningAjeet Verma92% (12)

- Modeling A Process - Filling A Tank: in - Out AccumulationDocument3 pagesModeling A Process - Filling A Tank: in - Out Accumulationmnb100% (1)

- Cycle EfficiencyDocument17 pagesCycle Efficiencyrashm006ranjanNo ratings yet

- Principal of Entropy IncreaseDocument18 pagesPrincipal of Entropy IncreaseakashkumardevNo ratings yet

- Simulation and Identification of Drum - Boiler Dynamics: Msc. Thesis by Giambattista PistoreDocument11 pagesSimulation and Identification of Drum - Boiler Dynamics: Msc. Thesis by Giambattista PistoreAlfredo ToyosNo ratings yet

- Other Physical Examples of First-Order System - LEC 5Document12 pagesOther Physical Examples of First-Order System - LEC 5jaja59No ratings yet

- EntropyDocument39 pagesEntropyRohit Singh LatherNo ratings yet

- Thermodynamics 4Document13 pagesThermodynamics 4steyvohmannaNo ratings yet

- BTD Avail Irr 1-AKBDocument17 pagesBTD Avail Irr 1-AKBJyoti SharmaNo ratings yet

- Thermodynamics EquationsDocument11 pagesThermodynamics EquationsDilene DuarcadasNo ratings yet

- Homework 4: X =μ∗X−D∗X S= μ∗X Y D∗ (S S)Document7 pagesHomework 4: X =μ∗X−D∗X S= μ∗X Y D∗ (S S)katelynNo ratings yet

- 11 Anewdynamicmodelforashell and TubeheatexchangerDocument9 pages11 Anewdynamicmodelforashell and TubeheatexchangerHejoolju GrubsNo ratings yet

- Chapter Five PDFDocument24 pagesChapter Five PDFعبدالله رعد حران 32No ratings yet

- Dynamic SystemDocument28 pagesDynamic SystemA - STARNo ratings yet

- Rankine and Carnot NumericalsDocument59 pagesRankine and Carnot NumericalsBhargav PrajwalNo ratings yet

- Control PDFDocument18 pagesControl PDFTaban ShahabNo ratings yet

- Support 1Document175 pagesSupport 1Knv ChaitanyaNo ratings yet

- First Law Open SystemsDocument6 pagesFirst Law Open SystemsxplodeitupNo ratings yet

- 03 Part1a To CMSDocument32 pages03 Part1a To CMSthahirhussainNo ratings yet

- 7th and 8 TH Week Revised-DonusturulduDocument68 pages7th and 8 TH Week Revised-DonusturuldunaverfallNo ratings yet

- Ecuaciones Basicas de Transferecia de CalorDocument6 pagesEcuaciones Basicas de Transferecia de Calorruben'sNo ratings yet

- Chapter FiveDocument24 pagesChapter Fiveeng213810140No ratings yet

- Chapter 10Document46 pagesChapter 10Jason IskandarNo ratings yet

- Reversible ProcessesDocument38 pagesReversible Processeschemsac2No ratings yet

- ADP CalculationDocument12 pagesADP Calculationnim_gourav1997No ratings yet

- Basic Heat Exchanger Equations and Calculations: Perry'sDocument1 pageBasic Heat Exchanger Equations and Calculations: Perry'sPrathap VuyyuruNo ratings yet

- Reversible ProcessDocument37 pagesReversible ProcessTushar Kant SwainNo ratings yet

- Unit Iii Shell Energy Balance and Boundary ConditionsDocument8 pagesUnit Iii Shell Energy Balance and Boundary Conditions3004 Divya Dharshini. MNo ratings yet

- A-Cold Liquid Feed B - Saturated Liquid Feed C - Partially Vaporized Feed D - Saturated Vapor Feed e - Superheated Vapor FeedDocument16 pagesA-Cold Liquid Feed B - Saturated Liquid Feed C - Partially Vaporized Feed D - Saturated Vapor Feed e - Superheated Vapor FeedAmr HassanNo ratings yet

- Physics 127a: Class Notes: Lecture 5: Energy, Heat and The Carnot CycleDocument4 pagesPhysics 127a: Class Notes: Lecture 5: Energy, Heat and The Carnot CyclezhwNo ratings yet

- Energy and Energy TransferDocument31 pagesEnergy and Energy TransferShubham SharmaNo ratings yet

- Vapour Power Cycle Module 1Document59 pagesVapour Power Cycle Module 1ajaitkmNo ratings yet

- TP U3Document14 pagesTP U3Vignesh KNo ratings yet

- Thermodynamics PoeDocument8 pagesThermodynamics Poeg0227518cNo ratings yet

- Psychrometric ProcessesDocument14 pagesPsychrometric ProcessesKabin BoraNo ratings yet

- Entropy Generation Lost Work 03Document15 pagesEntropy Generation Lost Work 03Ferdous ShamaunNo ratings yet

- The Property Diagram in Heat Transfer and Its Applications: Chen Qun, Xu Yunchao & Guo ZengyuanDocument7 pagesThe Property Diagram in Heat Transfer and Its Applications: Chen Qun, Xu Yunchao & Guo ZengyuanAnonymous N3LpAXNo ratings yet

- Energy Performance Assessment of Heat ExchangersDocument22 pagesEnergy Performance Assessment of Heat ExchangersShailesh PatelNo ratings yet

- 4.4 Heat Ex ChangersDocument7 pages4.4 Heat Ex Changersmukesh kaushikNo ratings yet

- Control Engineering WorkDocument20 pagesControl Engineering WorkWilsonNo ratings yet

- Control Element For Installation in Operation The ReactorDocument7 pagesControl Element For Installation in Operation The ReactorHisyamuddin AliahNo ratings yet

- Unit - 4 Vapour Power Cycles: H T L PDocument14 pagesUnit - 4 Vapour Power Cycles: H T L PMukesh MystNo ratings yet

- CHE160 2022-2023 Module4Document39 pagesCHE160 2022-2023 Module4anthonyNo ratings yet

- Modeling Szymczyk Transactions 130 2015Document10 pagesModeling Szymczyk Transactions 130 2015Jack CavaluzziNo ratings yet

- 공조냉동 Stoecker 2022Document123 pages공조냉동 Stoecker 2022안호준No ratings yet

- Cool Lab ManualDocument12 pagesCool Lab Manualgiri_shwetaNo ratings yet

- Energies: Analysis and Experiment of Hot-Spot Temperature Rise of 110 KV Three-Phase Three-Limb TransformerDocument12 pagesEnergies: Analysis and Experiment of Hot-Spot Temperature Rise of 110 KV Three-Phase Three-Limb Transformeraisya mutia syafiiNo ratings yet

- Thermodynamics 2 Rankine CycleDocument207 pagesThermodynamics 2 Rankine CycleRyan TegioNo ratings yet

- A Modern Course in Statistical PhysicsFrom EverandA Modern Course in Statistical PhysicsRating: 3.5 out of 5 stars3.5/5 (2)

- CHE401 Midterm SummaryDocument15 pagesCHE401 Midterm SummaryAbdullah KutbiNo ratings yet

- Concept MCQ AIDocument30 pagesConcept MCQ AIAbdullah KutbiNo ratings yet

- Chapter 2Document46 pagesChapter 2Abdullah KutbiNo ratings yet

- Class Activity 2 Applications of Learning in Life 201834800Document8 pagesClass Activity 2 Applications of Learning in Life 201834800Abdullah KutbiNo ratings yet

- مستندات ممسوحة ضوئيًاDocument2 pagesمستندات ممسوحة ضوئيًاAbdullah KutbiNo ratings yet

- The Preschooler and The SchoolerDocument16 pagesThe Preschooler and The Schoolerquidditch07No ratings yet

- Thermicam: The World'S First Integrated Thermal Traffic SensorDocument2 pagesThermicam: The World'S First Integrated Thermal Traffic SensorSudipta BhadraNo ratings yet

- Is Codes ListDocument37 pagesIs Codes Listmoondonoo7No ratings yet

- Moral Stories - Situated Reasoning About Norms, Intents, Actions, and Their Consequences 2012.15738Document21 pagesMoral Stories - Situated Reasoning About Norms, Intents, Actions, and Their Consequences 2012.15738Zhu XUNo ratings yet

- Soal Quizziz Buat Sendiri Kelas Xii TTG News ItemDocument6 pagesSoal Quizziz Buat Sendiri Kelas Xii TTG News ItemJorus RukuNo ratings yet

- Astm A194Document11 pagesAstm A194Jarek CieslakNo ratings yet

- 3 Generations of Human RightsDocument1 page3 Generations of Human RightsDzenan HakalovicNo ratings yet

- Reasons For Diminishing Returns To A FactorDocument2 pagesReasons For Diminishing Returns To A FactorRobert AyalaNo ratings yet

- ECE 5325/6325 Fall 2009: Exam 1 SolutionsDocument2 pagesECE 5325/6325 Fall 2009: Exam 1 Solutionswilfred godfreyNo ratings yet

- Job Posting Groups ListDocument3 pagesJob Posting Groups ListShrutika singhNo ratings yet

- Be RealDocument3 pagesBe RealТатьяна СоколоваNo ratings yet

- Aras Innovator Programmers GuideDocument105 pagesAras Innovator Programmers Guidem0de570No ratings yet

- Bank Management System Source CodeDocument5 pagesBank Management System Source CodetheblueartboxNo ratings yet

- Higher Eng Maths 9th Ed 2021 Solutions ChapterDocument17 pagesHigher Eng Maths 9th Ed 2021 Solutions ChapterAubrey JosephNo ratings yet

- RRLsDocument6 pagesRRLsRobot RobotNo ratings yet

- 13-GB 50018-2002-EnDocument109 pages13-GB 50018-2002-Enyyyy071220100% (1)

- Brac Bank LimitedDocument1 pageBrac Bank LimitedMd Mojibar RahmanNo ratings yet

- Ujian General Mobile CraneDocument5 pagesUjian General Mobile CraneAgil Wahyu PamungkasNo ratings yet

- William James - PsychologistDocument5 pagesWilliam James - PsychologistCecilia SusaiNo ratings yet

- Tacha's ReusmeDocument2 pagesTacha's ReusmeJames HamptonNo ratings yet

- HR304Document3 pagesHR304Tanmoy MondalNo ratings yet

- Noun (Subject) + Verb + The + Superlative Adjective + Noun (Object)Document6 pagesNoun (Subject) + Verb + The + Superlative Adjective + Noun (Object)anaNo ratings yet

- Chechk List Fokker 50Document1 pageChechk List Fokker 50Felipe PinillaNo ratings yet

- GattaniDocument18 pagesGattaniKhushbu NovhalNo ratings yet

- Heater: Hydrate PreventionDocument12 pagesHeater: Hydrate PreventionMahmoud Ahmed Ali AbdelrazikNo ratings yet

- Lean StartupDocument10 pagesLean StartupAlfredo Romero GNo ratings yet

- Modeling and Simulation of Fluid Catalytic Cracking Unit: Reviews in Chemical Engineering January 2005Document38 pagesModeling and Simulation of Fluid Catalytic Cracking Unit: Reviews in Chemical Engineering January 2005Diyar AliNo ratings yet

- Creating A Sample BI Report in Oracle Cloud With Excel Template - TrinamixDocument1 pageCreating A Sample BI Report in Oracle Cloud With Excel Template - TrinamixIshaq Ali KhanNo ratings yet

- F101-1 Client Information Form and ApprovalDocument4 pagesF101-1 Client Information Form and ApprovalgoyalpramodNo ratings yet