Professional Documents

Culture Documents

Super STR

Super STR

Uploaded by

vamsiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Super STR

Super STR

Uploaded by

vamsiCopyright:

Available Formats

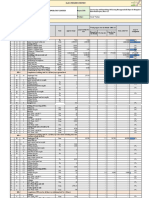

CHAPTER-14

SUPER-STRUCTURE

Ref. to

Remarks/

Sr No MoRTH Description Unit Quantity Rate Rs Cost Rs

Input ref.

Spec.

14.1F F PSC Grade M-45

Unit = 1 cum

Taking output = 120 cum

a) Material

Cement tonne 55.80 5600.00 312480.00 M-081

Coarse sand cum 54.00 1139.78 61548.03 M-004

20 mm Aggregate cum 64.80 1403.51 90947.20 M-053

10 mm Aggregate cum 43.20 1137.26 49129.47 M-051

Admixture @ 0.4 per cent of cement kg 223.20 61.00 13615.20 M-180

b) Labour

Mate day 0.94 515.00 484.10 L-12

Mason day 3.50 524.00 1834.00 L-11

Mazdoor day 20.00 490.00 9800.00 L-13

c) Machinery

Batching Plant @ 20 cum/hour hour 6.00 1380.00 8280.00 P&M-002

Generator 100 KVA hour 6.00 1261.00 7566.00 P&M-080

Loader hour 6.00 1844.00 11064.00 P&M-017

Transit Mixer ( capacity 4.0 cu.m )

Transit Mixer 4 cum capacity lead upto1 Km hour 15.00 2532.40 37986.00 P&M-049

Lead beyond 1 Km, L - lead in Kilometer tonne.km 300L 0.00 0.00 Lead =0 km

& P&M-050

Concrete Pump hour 6.00 899.00 5394.00 P&M-007

Basic Cost of Labour, Material & Machinery (a+b+c) 610129.00

for 120 cum

For formwork and staging add the following:

14.1F (i) For solid slab/voided slab super-structure, 16-26 per

cent of cost of concrete (a+b+c)

(p) Height upto 5m

Basic Cost of Labour, Material & Machinery (a+b+c) for 610129.00

120 cum

d) Formwork and staging 16 per cent of (a+b+c) 16.00 97620.64

e) Overhead charges @ 20 % on (a+b+c+d) 141549.93

f) Contractor's profit @ 10 % on (a+b+c+d+e) 84929.96

Cost for 120 cum = a+b+c+d+e+f 934229.52

Rate per cum = (a+b+c+d+e+f)/120 7785.25

say 7785.00

g) seiniorage charges per cum

Coarse Sand cum 0.45 40.00 18.00

Aggregate cum 0.90 75.00 67.50

Add District Mineral Fund (DMF) @ 30% and SMET @ 2% 0.320 85.50 27.36

on Seinorage charges

Rate per cum say 112.86

14.1F (q) Height 5m to 10m

(i)

Basic Cost of Labour, Material & Machinery (a+b+c) for 610129.00

120 cum

d) Formwork and staging 43 per cent of (a+b+c) 43.00 262355.47

e) Overhead charges @ 20 % on (a+b+c+d) 174496.89

f) Contractor's profit @ 10 % on (a+b+c+d+e) 104698.14

Cost for 120 cum = a+b+c+d+e+f 1151679.50

Rate per cum = (a+b+c+d+e+f)/120 9597.33

say 9597.00

g) seiniorage charges per cum 112.86

Rate per cum say 112.86 9709.86

SOR 2021-22 (15% OH) Page: 138 SUPER STRUCTURE

Ref. to

Remarks/

Sr No MoRTH Description Unit Quantity Rate Rs Cost Rs

Input ref.

Spec.

14.2 1600 Supplying, fitting and placing HYSD bar reinforcement

in super-structure complete as per drawing and

technical specifications

Unit = 1 MT

Taking output = 1 MT

a) Material

HYSD bars including 5 per cent for laps and wastage tonne 1.05 57000.00 59850.00 M-082

Binding wire Kg 8.00 66.00 528.00 M-072

b) Labour for cutting, bending, tying and placing in

position

Mate day 0.44 515.00 226.60 L-12

Blacksmith day 3.00 522.50 1567.50 L-02

Mazdoor day 8.00 490.00 3920.00 L-13

Basic Cost of Labour & Material (a+b) 66093.00

c) Overhead charges @ 20 % on (a+b) 13218.42

d) Contractor's profit @ 10 % on (a+b+c) 7931.05

Rate per MT = a+b+c+d 87241.57

say 87242.00

14.3 1800 High tensile steel wires/strands including all

accessories for stressing, stressing operations and

grouting complete as per drawing and Technical

Specifications

Unit = 1 MT

Taking output = 0.377 MT

Details of cost for 12T13 strand 40 m long cable (weight =

0.377 MT)

a) Material

H.T. Strand @ 9.42 kg/m including 2 per cent for tonne 0.39 70000.00 26950.00 M-119

wastage and extra length for jacking

Sheathing duct ID 66 mm along with 5 per cent extra metre 42.00 54.00 2268.00 M-165

length 40 x 1.05 = 42 m.

Tube anchorage set complete with bearing plate, each 2.00 200.00 400.00 M-187

permanent wedges etc

Cement for grouting including 3 per cent wastage @ tonne 0.125 5600.00 700.00 M-081

3.00 kg/m = 3 x 1.03 x 40 = 123.60 kg (say, = 125 kg)

Add 0.50 per cent cost of material for Spacers, 1515.90

Insulation tape and miscellaneous items

b) Labour

i) For making and fixing cables, anchorages

Mate day 0.16 515.00 82.40 L-12

Blacksmith day 1.00 522.50 522.50 L-02

Mazdoor day 3.00 490.00 1470.00 L-13

ii) For prestressing

Mate/Supervisor day 0.05 515.00 25.75 L-12

Prestressing operator / Fitter day 0.25 620.00 155.00 L-08

Mazdoor day 1.00 490.00 490.00 L-13

iii) For grouting

Mate/Supervisor day 0.05 515.00 25.75 L-12

Mason day 0.25 524.00 131.00 L-11

Mazdoor day 1.00 490.00 490.00 L-13

c) Machinery

Stressing jack with pump hour 2.50 158.00 395.00 P&M-040

Grouting pump with agitator hour 1.00 418.60 418.60 M-111

Generator 33 KVA. hour 3.50 1237.40 4330.90 P&M-079

d) Overhead charges @ 20 % on (a+b+c) 8074.16

e) Contractor's profit @ 10 % on (a+b+c+d) 4844.50

Cost for 0.377 MT (a+b+c+d+e) 53289.46

Rate per MT = (a+b+c+d+e)/0.377 141351.34

SOR 2021-22 (15% OH) Page: 139 SUPER STRUCTURE

Ref. to

Remarks/

Sr No MoRTH Description Unit Quantity Rate Rs Cost Rs

Input ref.

Spec.

say 141351.00

Note Cost of HT steel has been taken for delivery at site. Hence

carriage has not been considered.

14.7 2703, Construction of RCC railing of M30 Grade in-situ with 20

1500, mm nominal size aggregate, true to line and grade,

1600 & tolerance of vertical RCC post not to exceed 1 in 500,

1700 centre to centre spacing between vertical post not to

exceed 2000 mm, leaving adequate space between

vertical post for expansion, complete as per approved

drawings and technical specifications.

Unit = 1 RM

Taking output = 2 x 24 m span = 48 m.

a) Material

Cement concreteM30 Grade Refer relevant item of cum 4.092 4637.00 18974.60 Item

concrete in Item 14.1(C) by using batching plant, 14.1(C)

excluding formwork i.e. per cum basic cost (a+b+c)

No. of vertical posts = (12 + 2)2 = 28 Nos., External

area of vertical post 0.25x0.275 = 0.069sqm,

Concrete in vehicle posts = 0.069 x 28 = 1.932 cum,

Hand rail in 3 tiers = 3 x 24 = 72 m, External area =

0.170 x 0.175 = 0.03 sqm, Concrete in hand rails =

0.03 x 72 = 2.16 cum, Total Concrete = 1.932 + 2.16 =

4.092 cum. (Refer MoRTH SD / 202).

Add 12 per cent of above cost for form work. 2276.95

HYSD bar reinforcement Rate as per item No tonne 0.87 66093.00 57170.45 Item 14.2 A

14.2(Excluding OH & CP)

refer MoRTH SD / 202.

b) Overhead charges @ 20 % on (a) 15684.40

c) Contractor's profit @ 10 % on (a+b) 9410.64

Rate for 48 m (a+b+c) 103517.04

Rate per metre (a+b+c)/48 2156.61

say 2157.00

g) seiniorage charges per cum

sand cum 0.04 40.00 1.53

Metal 0.08 75.00 5.75

Add District Mineral Fund (DMF) @ 30% and SMET @ 2% 0.320 7.29 2.33

on Seinorage charges

Rate per cum say 9.62 2166.62

14.9 2705 Drainage Spouts complete as per drawing and Technical

specification

Unit = 1 No.

Taking output = 1 No.

a) Material

Corrosion resistant Structural steel including 5 per Kg 4.00 57.00 228.00 M-

cent wastage 087/1000

GI pipe 100mm dia metre 2.00 288.00 576.00 M-056

GI bolt 10 mm Dia each 6.00 7.00 42.00 M-110

Galvanised MS flat clamp each 2.00 12.38 24.76 M-101

b) Labour

For fabrication

Mate day 0.02 515.00 10.30 L-12

Skilled (Blacksmith, welder etc.) day 0.02 522.50 10.45 L-02

Mazdoor day 0.02 490.00 9.80 L-13

For fixing in position

Mate day 0.01 515.00 5.15 L-12

Mason day 0.01 524.00 5.24 L-11

Mazdoor day 0.20 490.00 98.00 L-13

Add @ 5 per cent of cost of material and labour for 50.49

electrodes, cutting gas, sealant, anti-corrosive

bituminous paint, mild steel grating etc.

c) Overhead charges @ 20 % on (a+b) 212.04

SOR 2021-22 (15% OH) Page: 140 SUPER STRUCTURE

Ref. to

Remarks/

Sr No MoRTH Description Unit Quantity Rate Rs Cost Rs

Input ref.

Spec.

d) Contractor's profit @ 10 % on (a+b+c) 127.22

Rate per metre (a+b+c+d) 1399.44

say 1399.00

Note 1. In case of viaducts in urban areas, the drainage spouts

should be connected with suitably located pipelines to

discharge the surface run-off to drains provided at ground

level.

2. In case of bridges, sufficient length of G.I Pipe shall be

provided to ensure that there is no splashing of water from

the drainage spout on the structure.

14.18 (ii) Providing & fixing 20 mm thick compressible fibre board

in expansion joint complete as per drawing & Technical

Specification.

Unit = Running meter

Taking output = 12 m

a) Labour

For carrying, placing & fixing.

Mate day 0.008 515.00 4.12 L-12

Mazdoor day 0.10 490.00 49.00 L-13

Mazdoor (Skilled) day 0.10 524.00 52.40 L-15

b) Material

20 mm thick compressible fibre board 12 m long x 25 sqm 3.00 580.00 1740.00 M-084

cm deep.

Area = 12 x 0.25 = 3 sqm

c) Overhead charges @ 20 % on (a+b) 369.10

d) Contractor's profit @ 10 % on (a+b+c) 221.46

Cost for 12 m = (a+b+c+d) 2436.09

Rate per m = (a+b+c+d)/12 203.01

say 203.00

SOR 2021-22 (15% OH) Page: 141 SUPER STRUCTURE

Ref. to

Remarks/

Sr No MoRTH Description Unit Quantity Rate Rs Cost Rs

Input ref.

Spec.

14.22 2607 Strip Seal Expansion Joint

Providing and laying of a strip seal expansion joint

catering to maximum horizontal movement upto 70 mm,

complete as per approved drawings and standard

specifications to be installed by the

manufacturer/supplier or their authorised representative

ensuring compliance to the manufacturer's instructions

for installation.

Unit = Running meter

Taking output = 12 m

a) Labour

Mate day 0.05 515.00 25.75 L-12

Mazdoor day 1.00 490.00 490.00 L-13

Mazdoor (Skilled) day 0.25 524.00 131.00 L-15

b) Material

Supply of complete assembly of strip seal expansion metre 12.00 7800.00 93600.00 M-178

joint comprising of edge beams, anchorage, strip seal

element and complete accessories as per approved

specifications and drawings.

Add 5 per cent of cost of material for anchorage 4712.34

reinforcement, welding and other incidentals.

c) Overhead charges @ 20 % on (a+b) 19791.82

d) Contractor's profit @ 10 % on (a+b+c) 11875.09

Cost for 12 m = (a+b+c+d) 130626.00

Rate per m = (a+b+c+d)/12 10885.50

say 10885.00

Note 1. The installation shall be done by the manufacturer or his

authorised representative to the satisfaction of the Engineer.

2. The concreting for joining the expansion joint assembly

with the deck has not been included in this analysis as the

same is catered in the quantities of RCC deck.

SOR 2021-22 (15% OH) Page: 142 SUPER STRUCTURE

You might also like

- System Engineering Management Plan (SEMP)Document18 pagesSystem Engineering Management Plan (SEMP)Joseph KamenyaNo ratings yet

- BSR - NH - Circle - Jaipur - 2019 Final PDFDocument109 pagesBSR - NH - Circle - Jaipur - 2019 Final PDFRohit Bali100% (1)

- Reference PDCA-FTA New 2021Document6 pagesReference PDCA-FTA New 2021ubllcNo ratings yet

- 498186: Vamsi Krishna Nadella: BSCPL Infrastructure LTDDocument1 page498186: Vamsi Krishna Nadella: BSCPL Infrastructure LTDvamsiNo ratings yet

- Rate Analysis - Mastic Asphalt & BitumenDocument7 pagesRate Analysis - Mastic Asphalt & BitumenA M0% (1)

- Rate Analysis For M20 by KhajaDocument14 pagesRate Analysis For M20 by KhajaRavi RajaNo ratings yet

- Construction of A Breakwater and A Quay Wall Made of Box CaissonsDocument2 pagesConstruction of A Breakwater and A Quay Wall Made of Box CaissonsAhmad Balah100% (1)

- M11406 RootBeerGameV2 PDFDocument4 pagesM11406 RootBeerGameV2 PDFaeromeropNo ratings yet

- PM Master Data Template v1Document250 pagesPM Master Data Template v1Ram Kumar50% (2)

- Unit CumDocument1 pageUnit Cumanon_789699787No ratings yet

- Sub STRDocument1 pageSub STRvamsiNo ratings yet

- TMT BarsDocument3 pagesTMT BarsExecutive EngineerNo ratings yet

- Unit Cum: Taking Output 195 Cum (450 Tonnes)Document1 pageUnit Cum: Taking Output 195 Cum (450 Tonnes)Rajkumar SagarNo ratings yet

- Sec3 15-09 PDFDocument3 pagesSec3 15-09 PDFS S Reddy SomuNo ratings yet

- Analysis of Rate: Recycling Miled Asphalt (With 2% Lime & 3.5% Emulsion) With 28% Additional MaterialDocument1 pageAnalysis of Rate: Recycling Miled Asphalt (With 2% Lime & 3.5% Emulsion) With 28% Additional MaterialRajkumar SagarNo ratings yet

- Gravel Rate-DSR2016 - Kuttanadu TalukDocument2 pagesGravel Rate-DSR2016 - Kuttanadu Talukaneeshp_4No ratings yet

- Tile & SheetDocument12 pagesTile & Sheetaneeshp_4No ratings yet

- Aeration Tank 3 & 4 EstimateDocument5 pagesAeration Tank 3 & 4 EstimateRao G100% (1)

- PCC M-15Document1 pagePCC M-15Faisal RizwanNo ratings yet

- Rate Analysis - Highways-MDR - Part - IDocument389 pagesRate Analysis - Highways-MDR - Part - IAmitabha DebNo ratings yet

- Rate AnalysisDocument34 pagesRate AnalysisDEEPAK SHARMANo ratings yet

- Shedule of Rates For Type XI SignboardsDocument3 pagesShedule of Rates For Type XI SignboardsRAJ KUMAR SAGARNo ratings yet

- Analysis of M15 ConcreteDocument2 pagesAnalysis of M15 ConcreteChau Suktana EnlingNo ratings yet

- Rate AnalysisDocument2 pagesRate AnalysisDevendrasingh DeoraNo ratings yet

- Sub Grade With CementDocument1 pageSub Grade With CementK KarthikNo ratings yet

- Rate Analysis For Concrete PavementDocument1 pageRate Analysis For Concrete PavementSuraj Shenoy Nagar100% (1)

- Estimate Chandpur KhadDocument418 pagesEstimate Chandpur KhadSunita ShoniNo ratings yet

- By HMP (Analysis)Document7 pagesBy HMP (Analysis)Prashant VermaNo ratings yet

- Asphalting Detailed EstimateDocument19 pagesAsphalting Detailed EstimateAsrar Hussain KhanNo ratings yet

- Print PCCC 100x10 New Rates EdgeDocument1 pagePrint PCCC 100x10 New Rates EdgechhunuryadavNo ratings yet

- 1x3 MTR by HMPDocument35 pages1x3 MTR by HMPPrashant VermaNo ratings yet

- Laying of CC Road From Srinivas Naik (H) To Malyanaik (H) of Utakunta Thanda (V) of Narayanpet (M)Document3 pagesLaying of CC Road From Srinivas Naik (H) To Malyanaik (H) of Utakunta Thanda (V) of Narayanpet (M)K KARTHIKNo ratings yet

- Trashed-4Document3 pagesTrashed-4justlodiNo ratings yet

- Piling & Concrete Rate AnlysisDocument79 pagesPiling & Concrete Rate AnlysisfinesomalinNo ratings yet

- Rate Analysis For PTBC LayerDocument1 pageRate Analysis For PTBC LayerVijaypal NegiNo ratings yet

- Laying of Roads by Gravel Around PPV Aand GIC in Pedashapur Thanda Village, Shamshabad MandalDocument15 pagesLaying of Roads by Gravel Around PPV Aand GIC in Pedashapur Thanda Village, Shamshabad Mandalyadagirireddy bolluNo ratings yet

- Cement Concrete Pavement AnalysisDocument8 pagesCement Concrete Pavement AnalysisSarin100% (1)

- Weep HolesDocument1 pageWeep HolesExecutive EngineerNo ratings yet

- Formation of Road by Gravel From Pathlavath Shiva (H) To Sabavath Shankar (H) at Pedashapur Thanda (V), Shamshabad MandalDocument15 pagesFormation of Road by Gravel From Pathlavath Shiva (H) To Sabavath Shankar (H) at Pedashapur Thanda (V), Shamshabad Mandalyadagirireddy bolluNo ratings yet

- Gravel 2Document15 pagesGravel 2yadagirireddy bolluNo ratings yet

- Final Bill Luckey Traders Sept 2008Document6 pagesFinal Bill Luckey Traders Sept 2008api-3823524No ratings yet

- Taking Output 1 MTDocument1 pageTaking Output 1 MTanon_789699787No ratings yet

- Rate AnalysisDocument213 pagesRate Analysiskhokhar infrastructureNo ratings yet

- Pile Boring Analysis PDFDocument1 pagePile Boring Analysis PDFRanjan Kumar SahooNo ratings yet

- BC With PlasticDocument3 pagesBC With PlasticKiran AEE BvrmNo ratings yet

- 13.4 (RRM) Morth Data BookDocument1 page13.4 (RRM) Morth Data Bookabhishek negiNo ratings yet

- Rate Analysis HUme PipesDocument14 pagesRate Analysis HUme PipesSarin67% (3)

- Ar BCDocument15 pagesAr BCa k pantNo ratings yet

- Sno Description Unit Rate Rs. Amount RS.: Data 2020-21 QuantityDocument24 pagesSno Description Unit Rate Rs. Amount RS.: Data 2020-21 QuantitysagarNo ratings yet

- MORTH Data Book-Rate Analysis 23 JULY2008Document378 pagesMORTH Data Book-Rate Analysis 23 JULY2008surendraNo ratings yet

- Standard Data BookDocument327 pagesStandard Data Bookvikas sainiNo ratings yet

- Desulfer Rate AnalysisDocument2 pagesDesulfer Rate AnalysisSyed Adnan AqibNo ratings yet

- DPR Dated 05-12-2023Document103 pagesDPR Dated 05-12-2023Rakshith MarichennaiahNo ratings yet

- Code Description Unit Quantity Rate Amount: Sub Head: 16-Road WorkDocument2 pagesCode Description Unit Quantity Rate Amount: Sub Head: 16-Road WorkSanjan Sameer100% (1)

- Annexure - III - Mizoram SOR 2016 (Relevant Pages) PDFDocument20 pagesAnnexure - III - Mizoram SOR 2016 (Relevant Pages) PDFPrafulla Borgohain100% (2)

- 7-6 Culvert YL RoadDocument57 pages7-6 Culvert YL Roadeerbkovvur r&bNo ratings yet

- Rate AnalysisDocument3 pagesRate AnalysisExecutive EngineerNo ratings yet

- Applicant Has Copies of Tax Paid Receipt, Katha, Building Plan & Power of Attorney. The Building Attracts Prorata For All Floors On Commercial RatesDocument1 pageApplicant Has Copies of Tax Paid Receipt, Katha, Building Plan & Power of Attorney. The Building Attracts Prorata For All Floors On Commercial Ratesdeepashree_krNo ratings yet

- (Eastern Colony) of NSRS Srisailam Project, Kurnool Dist., APDocument8 pages(Eastern Colony) of NSRS Srisailam Project, Kurnool Dist., APrvkumar361No ratings yet

- BSR NH Circle Jaipur 2016Document103 pagesBSR NH Circle Jaipur 2016vikash kumar50% (4)

- B T Rates y S R Tadigadapadata 2021-22Document288 pagesB T Rates y S R Tadigadapadata 2021-22Ashwin Kumar GoudNo ratings yet

- Pangibitan, Geojanni R. - Activity 3 - A5Document4 pagesPangibitan, Geojanni R. - Activity 3 - A5Geojanni PangibitanNo ratings yet

- JSW Scope: Jsw-Bellary Project Labour, Aluminum Wire & Paint Cost Estimation For Railway BridgeDocument2 pagesJSW Scope: Jsw-Bellary Project Labour, Aluminum Wire & Paint Cost Estimation For Railway BridgeCorrosion FactoryNo ratings yet

- 20mm Thick Open-Graded Premix Carpet Using Bituminous (Penetration Grade/modified Bitumen) BinderDocument149 pages20mm Thick Open-Graded Premix Carpet Using Bituminous (Penetration Grade/modified Bitumen) BinderPragadeeswaran Ramanathan100% (1)

- Maholes 1Document12 pagesMaholes 1k v rajeshNo ratings yet

- Rates of Material Including Lead and Conveynace Charges For The Year 2021-22Document2 pagesRates of Material Including Lead and Conveynace Charges For The Year 2021-22vamsiNo ratings yet

- 2Document9 pages2vamsiNo ratings yet

- Wwwtatainterview 015Document2 pagesWwwtatainterview 015vamsiNo ratings yet

- Bridge Geometry ManualDocument91 pagesBridge Geometry ManualvamsiNo ratings yet

- Methodology For Initial Verticl Pile Load Test: Anindya Infratech PVT LTD 1Document15 pagesMethodology For Initial Verticl Pile Load Test: Anindya Infratech PVT LTD 1vamsiNo ratings yet

- Civil Engineering Basics: Concrete GradeDocument9 pagesCivil Engineering Basics: Concrete GradevamsiNo ratings yet

- P5Document22 pagesP5vamsiNo ratings yet

- Physical Requirements:: Cement Test ResultsDocument3 pagesPhysical Requirements:: Cement Test ResultsvamsiNo ratings yet

- Irc - Gov.in.014.2004 01Document28 pagesIrc - Gov.in.014.2004 01ManojNo ratings yet

- 2 Lean Six Sigma Guide CH PDFDocument81 pages2 Lean Six Sigma Guide CH PDFjose2392100% (1)

- Performing Preventive MaintenanceDocument20 pagesPerforming Preventive MaintenanceJohn Paul Espiña CandoNo ratings yet

- Standard Test Procedures PDFDocument391 pagesStandard Test Procedures PDFferdinanad100% (1)

- 《Advanced Manufacturing Technology》Experimental ReportDocument11 pages《Advanced Manufacturing Technology》Experimental ReportFarhan mahmud RashikNo ratings yet

- Aatcc TM 124 1996 PDFDocument5 pagesAatcc TM 124 1996 PDFTimmi Timmi ChoiceNo ratings yet

- BHEL Was Founded in 1950s. BHEL orDocument27 pagesBHEL Was Founded in 1950s. BHEL orashish_coolboyNo ratings yet

- Spring and HibernateDocument4 pagesSpring and HibernateShah RukhNo ratings yet

- Ashish Yadav Electronics & Instrumentation Engineer: Career ObjectiveDocument4 pagesAshish Yadav Electronics & Instrumentation Engineer: Career Objectivepankaj semwalNo ratings yet

- BDC Part4 For AbapDocument8 pagesBDC Part4 For AbapLatha JujariNo ratings yet

- Why Projects FailDocument18 pagesWhy Projects FailGursimran SinghNo ratings yet

- Stars Chema BDocument10 pagesStars Chema Bxavo_27No ratings yet

- PeopleSoft Campus Solutions CS 9.2 Release NotesDocument8 pagesPeopleSoft Campus Solutions CS 9.2 Release NotesAkash Kumar Shandilya100% (1)

- Chromo LithographyDocument6 pagesChromo LithographyPaula ZorziNo ratings yet

- 2017 Winter Model Answer Paper PDFDocument12 pages2017 Winter Model Answer Paper PDFabdul rehman syed parvezNo ratings yet

- Curriculum Vitae: Md. Rabiul IslamDocument4 pagesCurriculum Vitae: Md. Rabiul IslamSkhan KhanNo ratings yet

- Of Chinaptpl: Power Industry Standard of P.R. ChinaDocument501 pagesOf Chinaptpl: Power Industry Standard of P.R. ChinaMuhammad Junaid KhanNo ratings yet

- ClassicSpecs PDFDocument184 pagesClassicSpecs PDFRana Tahir SultanNo ratings yet

- Letter On Safety OfficerDocument2 pagesLetter On Safety OfficerRaja RamNo ratings yet

- Conveyor Pulleys PDFDocument8 pagesConveyor Pulleys PDFDhirendraRaviNo ratings yet

- Brochure Styrolution PS Product Selection Guide enDocument2 pagesBrochure Styrolution PS Product Selection Guide enSiddharth PalNo ratings yet

- 3d Printing Research PaperDocument7 pages3d Printing Research Paperafnkeuooulejtl100% (1)

- Project FailureDocument12 pagesProject Failurebronco7211100% (1)

- EAI Architecture Vodafone IndiaDocument11 pagesEAI Architecture Vodafone IndiaacetaleleNo ratings yet

- Example Fax PDFDocument2 pagesExample Fax PDFJamesNo ratings yet

- Balanced Scorecard Basics (BSC)Document5 pagesBalanced Scorecard Basics (BSC)ni gede agung septiNo ratings yet