Professional Documents

Culture Documents

Quote 5960A

Quote 5960A

Uploaded by

Gyan Ka Data PackCopyright:

Available Formats

You might also like

- NJP 1200 Series Automatic Capsule Filling Machine PDFDocument53 pagesNJP 1200 Series Automatic Capsule Filling Machine PDFtrungvu80% (5)

- Weider CrossbowDocument24 pagesWeider CrossbowAmish PatelNo ratings yet

- ROTALIGN PRO Manual Part 2 PDFDocument86 pagesROTALIGN PRO Manual Part 2 PDFTheerayoot Poomchai67% (3)

- Group 3 - Gearbox Daf-CfDocument504 pagesGroup 3 - Gearbox Daf-Cfюрий ерёменко100% (1)

- Visual Inspection ReportDocument5 pagesVisual Inspection ReportOmar WardehNo ratings yet

- SC100V ManualDocument22 pagesSC100V ManualPeter OberauerNo ratings yet

- MRO Stop Industrial Fastener CatalogDocument53 pagesMRO Stop Industrial Fastener CatalogMROstop.comNo ratings yet

- Inspection Report: Page 1 of 2 Vendor P.O. NODocument4 pagesInspection Report: Page 1 of 2 Vendor P.O. NOsudipta dasNo ratings yet

- TATA PIGMENT Vendor Registration & Assessment Form For Manufacturer - TPLDocument15 pagesTATA PIGMENT Vendor Registration & Assessment Form For Manufacturer - TPLVikrant SinghNo ratings yet

- Irn 20.09.2019 Fl-Smidth VoltampDocument2 pagesIrn 20.09.2019 Fl-Smidth VoltampHARI PRASATHNo ratings yet

- Inspection Report: Page 1 of 2 Vendor P.O. NODocument3 pagesInspection Report: Page 1 of 2 Vendor P.O. NOsudipta dasNo ratings yet

- nITP For Suspenion Hanger Pin Alt 2Document4 pagesnITP For Suspenion Hanger Pin Alt 2ABHISHEK KUMARNo ratings yet

- Casing Stabbing BoardDocument1 pageCasing Stabbing BoardRanjithNo ratings yet

- LAB 115 Services IndDocument2 pagesLAB 115 Services IndUsama JavedNo ratings yet

- Sub Supplier Declaration For Raw Material Source: Dated: 14.05.2016Document5 pagesSub Supplier Declaration For Raw Material Source: Dated: 14.05.2016AjayNo ratings yet

- Chemical Analysis Report (Pmi / Spectro - Oes) : Naser M. AL-Baddah & Partner General Trading & Contracting Co. W.L.LDocument1 pageChemical Analysis Report (Pmi / Spectro - Oes) : Naser M. AL-Baddah & Partner General Trading & Contracting Co. W.L.Lm.aliNo ratings yet

- Inspection Report: Page 1 of 3 Vendor P.O. NODocument3 pagesInspection Report: Page 1 of 3 Vendor P.O. NOsudipta dasNo ratings yet

- D7057 - NOI - 033 Rev.7 - MechDocument1 pageD7057 - NOI - 033 Rev.7 - Mechnisha_khanNo ratings yet

- Ir 0703Document3 pagesIr 0703sheikmoinNo ratings yet

- MATL PFAB DR Preparation 0060Document18 pagesMATL PFAB DR Preparation 0060Sakshi SinghNo ratings yet

- Packaging Details: Vendor Name & AddressDocument4 pagesPackaging Details: Vendor Name & AddressPk NimiwalNo ratings yet

- Technical Services Division: Mechanical Testing LaboratoryDocument1 pageTechnical Services Division: Mechanical Testing Laboratorym.aliNo ratings yet

- 1046A Sraf No.Document1 page1046A Sraf No.Imran KhanNo ratings yet

- 3x5 BP Part1Document12 pages3x5 BP Part1siva dhamotharanNo ratings yet

- Visit Report: TUV Control No.: TUV SAP No: 8115236437 (Branch: Report NoDocument4 pagesVisit Report: TUV Control No.: TUV SAP No: 8115236437 (Branch: Report NoVinay YadavNo ratings yet

- 12-12-19 IR#10193372207 (W203.2, W979 - Walmart) - Pass - Self PDFDocument13 pages12-12-19 IR#10193372207 (W203.2, W979 - Walmart) - Pass - Self PDFrubel sabiNo ratings yet

- WPQ Process As Per ISO-9606-1 2013Document4 pagesWPQ Process As Per ISO-9606-1 2013Md Anamul Hoque0% (1)

- Technip - IVR - 8116970849 - Sr. No.01 - R00 - 077015C002-PO-1310-0012-02-O9833 PDFDocument18 pagesTechnip - IVR - 8116970849 - Sr. No.01 - R00 - 077015C002-PO-1310-0012-02-O9833 PDFAbhay KarandeNo ratings yet

- Datasheet, Drawings & QAP For Pressure Relief Valve DN400 PN16-LBC - 180920 PDFDocument4 pagesDatasheet, Drawings & QAP For Pressure Relief Valve DN400 PN16-LBC - 180920 PDFYogesh GawadeNo ratings yet

- Datasheet, Drawings & QAP For Pressure Relief Valve DN400 PN16-LBC - 180920 PDFDocument4 pagesDatasheet, Drawings & QAP For Pressure Relief Valve DN400 PN16-LBC - 180920 PDFYogesh GawadeNo ratings yet

- Ho SơDocument47 pagesHo SơHuy BầuNo ratings yet

- Part Submission Warrant (PSW)Document8 pagesPart Submission Warrant (PSW)api-980604No ratings yet

- FA ReportDocument4 pagesFA ReportBudi ArtantoNo ratings yet

- Pgca MR D06 005 - C1 - 2Document90 pagesPgca MR D06 005 - C1 - 2Ami PutraNo ratings yet

- Welder Qualification Test Certificate BS EN ISO 9606-1: 2013Document2 pagesWelder Qualification Test Certificate BS EN ISO 9606-1: 2013LeonNo ratings yet

- Failure Analysis Report: Information - 01Document4 pagesFailure Analysis Report: Information - 01Budi ArtantoNo ratings yet

- Welding Procedure qualificationsQW483 PDFDocument2 pagesWelding Procedure qualificationsQW483 PDFTC Chick WilliamNo ratings yet

- Wire PDFDocument3 pagesWire PDFm.aliNo ratings yet

- Cp5-Itp CWC RomanuDocument22 pagesCp5-Itp CWC RomanuherdiansyahNo ratings yet

- Inspection Report: 150 MW Dhamangaon Solar Project, MaharashtraDocument6 pagesInspection Report: 150 MW Dhamangaon Solar Project, Maharashtrakaushik21185No ratings yet

- Release Note N°: RN210607060EDocument3 pagesRelease Note N°: RN210607060ESantosh Iim LucknowNo ratings yet

- Vinfast PIDDocument16 pagesVinfast PIDGalva decoNo ratings yet

- IVR 050112009522 - 95 2 Rev.0Document6 pagesIVR 050112009522 - 95 2 Rev.0Vinay YadavNo ratings yet

- Inspection Report: IR No.: QETO/IR/SUD/110Document2 pagesInspection Report: IR No.: QETO/IR/SUD/110sudipta dasNo ratings yet

- 4845 PDFDocument1 page4845 PDFRavi patelNo ratings yet

- Bis-Dk-Rt-1049 - Ip2022-CeDocument2 pagesBis-Dk-Rt-1049 - Ip2022-CeTomasPavlovicNo ratings yet

- Marking Guidelines - PM-PU-6.022Document14 pagesMarking Guidelines - PM-PU-6.022PINNACLE ENGINEERINGNo ratings yet

- Bis-Dk-Rt-1047 - Ip2022-CeDocument2 pagesBis-Dk-Rt-1047 - Ip2022-CeTomasPavlovicNo ratings yet

- 1SV10110-110C08-BEC-MAT-AR-0068-C0 - Material Submittal For Porcelain Tile RT02 (900x400x20mm) at ROOF (Maintenance Walkway) From ALFANARDocument176 pages1SV10110-110C08-BEC-MAT-AR-0068-C0 - Material Submittal For Porcelain Tile RT02 (900x400x20mm) at ROOF (Maintenance Walkway) From ALFANAROmar TarekNo ratings yet

- IVR-8117994011-01 - Rev.00Document6 pagesIVR-8117994011-01 - Rev.00Abhay KarandeNo ratings yet

- Cpri Section II - Technical Specification Tender Enquery No: PUR/UHVRL-04/14-15Document3 pagesCpri Section II - Technical Specification Tender Enquery No: PUR/UHVRL-04/14-15Gaurav KumarNo ratings yet

- Orifice Cal. Rev.2Document75 pagesOrifice Cal. Rev.2waheed2286No ratings yet

- Muhammad WaqasDocument1 pageMuhammad WaqasthehitechmultanNo ratings yet

- Ibo Pm9s Exe I19 99 Qac RPT 0006 - Rev. B (Amended)Document6 pagesIbo Pm9s Exe I19 99 Qac RPT 0006 - Rev. B (Amended)Gokhula KannanNo ratings yet

- Purchase Request (PR) : AttachmentsDocument6 pagesPurchase Request (PR) : AttachmentsDILNo ratings yet

- FeasibilityDocument8 pagesFeasibilityTarun MarskoleNo ratings yet

- WPS P1 Group Any To P1 Group Any GTAW FCAW Manual MachineDocument2 pagesWPS P1 Group Any To P1 Group Any GTAW FCAW Manual MachinePrasad ChakkrapaniNo ratings yet

- Final Insepection Reports and WPS PQRDocument14 pagesFinal Insepection Reports and WPS PQRVikas Verma100% (1)

- F-02 (Magnetic Particle Test) - (NEW) ..Latest 006Document42 pagesF-02 (Magnetic Particle Test) - (NEW) ..Latest 006Himanshu SinghNo ratings yet

- Ir 5073 Ppa 005Document6 pagesIr 5073 Ppa 005ValiNo ratings yet

- 8D - Bend IssueDocument3 pages8D - Bend Issuemoonlight toolsNo ratings yet

- Format. No: TSSA - IS - IN - FR - 05 Rev 4 Dated. 15.01.2021Document3 pagesFormat. No: TSSA - IS - IN - FR - 05 Rev 4 Dated. 15.01.2021Raja KrsNo ratings yet

- 2005 S003 NBPG Rfi 04957 - R00Document1 page2005 S003 NBPG Rfi 04957 - R00RPDeshNo ratings yet

- PPAP Check SheetDocument13 pagesPPAP Check SheetNinnammanNo ratings yet

- Oil Test-1Document2 pagesOil Test-1ForenTec Engineers RanchiNo ratings yet

- Engineering Service Revenues World Summary: Market Values & Financials by CountryFrom EverandEngineering Service Revenues World Summary: Market Values & Financials by CountryNo ratings yet

- ACS310 Short ManualDocument40 pagesACS310 Short ManualJNo ratings yet

- CBLM Common 3 Perform Industry CalculationDocument23 pagesCBLM Common 3 Perform Industry CalculationAnonymous jGHeIS100% (1)

- Kompass - Aircrete Building Materials EN PrintDocument6 pagesKompass - Aircrete Building Materials EN PrintJacob PriyadharshanNo ratings yet

- Skimmer Pipe Example DrawingDocument1 pageSkimmer Pipe Example Drawingjagannadha varma100% (1)

- Tms500 Parts ManualDocument1,102 pagesTms500 Parts ManualWFT 777No ratings yet

- B 2890Document2 pagesB 2890vespxNo ratings yet

- Alum A Frame Product SheetDocument2 pagesAlum A Frame Product SheetEben EzerNo ratings yet

- Raga-Cece-Colango Engr. Hana Myka Gaton Cost Estimation Bsce 5-1 CPM Part.1 ArchitecturalDocument33 pagesRaga-Cece-Colango Engr. Hana Myka Gaton Cost Estimation Bsce 5-1 CPM Part.1 ArchitecturalLnazerA.CeceNo ratings yet

- Vitosol 100fm sv1fDocument52 pagesVitosol 100fm sv1fGile SimunovicNo ratings yet

- 550 Manual-2008Document37 pages550 Manual-2008MiguelNo ratings yet

- 99929Document20 pages99929Tamer Moustafa100% (2)

- Introduction Letter: Stainless SteelDocument4 pagesIntroduction Letter: Stainless SteelArvind JainNo ratings yet

- Fabrication Method For HSM 2 ProjectDocument14 pagesFabrication Method For HSM 2 ProjectMikiRoniWijayaNo ratings yet

- Haitian Mars Tech SpecificationsDocument8 pagesHaitian Mars Tech Specificationsaakashlakhanpal9830100% (2)

- 014 - 030 Single Reduction Worm IntroductionDocument17 pages014 - 030 Single Reduction Worm IntroductionAlejandro MartinezNo ratings yet

- Standard Groove Specifications PDFDocument5 pagesStandard Groove Specifications PDFDavid Salguero OlveaNo ratings yet

- HRD FTM 2012-09Document24 pagesHRD FTM 2012-09Thang VoNo ratings yet

- Catalog Emko PDFDocument116 pagesCatalog Emko PDFwarung1bensinNo ratings yet

- Ace III Service ManualDocument46 pagesAce III Service Manualosiris israely100% (1)

- TSPG - Engine Tools 2-139 A 2-220 PDFDocument82 pagesTSPG - Engine Tools 2-139 A 2-220 PDFAKshay100% (1)

- Suzuki Liana 2004-2006 1.4 Diesel Service Manual 99501-73J00-01EDocument569 pagesSuzuki Liana 2004-2006 1.4 Diesel Service Manual 99501-73J00-01Evik_md67% (3)

- Class Flanges Bolt Torque Loads PDFDocument2 pagesClass Flanges Bolt Torque Loads PDFHomer SilvaNo ratings yet

- 4H.2209 - Illustrated Spare Parts Manual - KFP4R-UF07 - FM-UL PDFDocument91 pages4H.2209 - Illustrated Spare Parts Manual - KFP4R-UF07 - FM-UL PDFPankaj JainNo ratings yet

- Statoil WR 0235 Safe Use of Lifting and Transporting EquipmentDocument35 pagesStatoil WR 0235 Safe Use of Lifting and Transporting Equipmentadriancovalciuc4863No ratings yet

Quote 5960A

Quote 5960A

Uploaded by

Gyan Ka Data PackOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Quote 5960A

Quote 5960A

Uploaded by

Gyan Ka Data PackCopyright:

Available Formats

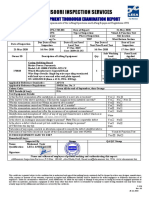

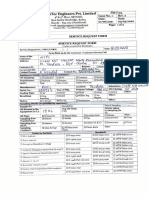

Doc No.

F05(QAD-P-09)

Rev. No. 00

VOICE OF CUSTOMER Rev. Date 15.11.2018

Enquiry No. 5960A06122023 Date: 06/12/2023

Telephonic Mail

Mode Of Enquiry

Others (Please Specify)

Customer STERLING TOOLS LIMITED Mobile Number: 9625143635

M10X1.25X71 BOLT

Part Description

Drawing Availability Available Not Available

If available please attached drawing & mention :

Drawing No. : NA Rev No. / Date:

End Customer /OEM: Honda

Ref. Standard : NA

Not Required + Torquer series

Coating

If your requirement is not mentioned , or if you are unaware please select "OTHERS" . We will assist you .

NA Hrs. No Red Rust

SST Hours

If you are unaware, please mention "Unknown" ; we will assist you.

0.15-0.19

COF

Mention range of COF, Eg 0.10-0.16

Mating part

Gauge/Mating Part

After coating what is your fitment requirement?please note for gauge qualification , trials will be required and may result in higher coating price.

Customer Others

Requirement Appearance

For attaining a smooth and good finish , spray process is recommended.Spray process is expensive as compared to our standard dip spin process.

100% Visual As per Sampling Plan (Ref. St. IS 2500)

Visual Inspection Coating process in general is bound to have some defects (usually 2-5%). Generally for very critical parts, 100% inspection is required. Doing 100%

inspection will result in higher coating price

Standard Packaging

Packaging

By default we give the parts back in customer incoming bin

Others (If Any)

Type of NPD: Prototype Pilot Lot PPAP Lot

Testing Requirement: Aum Dacro (SST, COF etc)

By default, we do COF testing for PPAP lot only and NSST test for regular production items once every 3 months per customer

Third Party (SST, COF etc)

Customer End (SST, COF etc)

Remarks : Annual Volume : 4.3 Lakh

Prepared by: SHIVAM

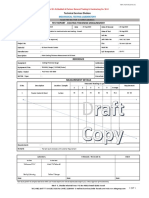

Doc. No. F03(QAD-P-09)

Rev No. 00

FEASIBILITY STUDY REPORT Rev Date : 15.11.2018

Customer : M/s. STERLING TOOLS LIMITED Date : 06/12/2023

Part Name : BOLT Inquiry no.: 5960A06122023

Coating Requirement as per customer :

Part Desc : M10X1.25X71 BOLT Base Coat : Others

Top Coat : Torquer Series

Feasibility Consideration :

Our product quality team has considered the following question , not intended to be all-inclusive in performing a feasibility evaluation. The drawing and/or

specifications provided have been used as a basis for analyzing the ability to meet all specified requirements. All "no" answers (except point 4,6b and 7) are

supported with attached comments identifying our concerns and/or proposed changes to enable us to meet the specified requirements.

Sr. No. Consideration Yes No May be Comments

Is product adequately defined

1 (application requirements, etc). to

enable feasibility evaluation?

Can Engineering Performance

2 APPEARANCE : "GREEN"

Specifications be met as written ?

Can product be manufactured to Incoming plated parts must be free from oil dust and greese.COF offered by our

tolerance specified on drawing ? product 0.15-0.19 as per ISO 16047.

3

Is there adequate capacity to produce

product ?

Does the design of process allow the use

4 of any special material handling

techniques?

Can the product be manufactured

without incurring any unusual :

5 5a. Cost for capital equipment ?

5b. Alternative processing methods ?

6a. Availability of skilled man power

6

6b. Any special Training required

7 Any special packaging required? Coated product to be returned in customer incoming bin

Coating material

suggested as per TORQUER CA-H (GREEN)

requirement.

Process suggested:

DIPSPIN 1C1B

INSPECTION: 100% AS PER SAMPLING PLAN

Conclusion :

Feasible Product can be produced as specified with no revisions.

Feasible Changes recommended ( see attached )/ Need to do some trials

Not Feasible Design revision required to produce product within the specified requirements.

Sign Off Cross Functional Team Members :

Sr. No Team Member Name Department Comments

01 Mr. Jaiyender Shrivastav Marketing

02 Mr. Shivam Sharma Marketing

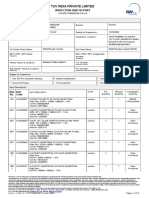

Doc. No. F03(QAD-P-09)

Rev No. 00

FEASIBILITY STUDY REPORT Rev Date : 15.11.2018

Process flow considered:

Applicable /

Sr. No. Process / Operation Additional Activity* Remarks

Not Applicable

Sampling Plan IS

01 Incoming Inspection 2500

Applicable NA

02 Degreasing & Drying Applicable NA

03 Shot Blasting Applicable NA

04 Base Coat 1C1B Not Applicable NA

05 Base Coat 1C1B Not Applicable NA

06 Base Coat 1C1B Not Applicable

07 Visual Inspection Not Applicable

08 Top Coat 1C1B Dip & Spin Applicable

09 Top Coat 1C1B Not Applicable

10 Final Inspection 100% Applicable NA

11 Packing & Dispatch Applicable Normal

Additional activities* if selected may include:

Degreasing Oven burning , re-drying etc

Shot Blasting Sand blasting , manual parts seperation etc.

Base Coat Brushing, Finishing , Seperating etc.

Top Coat Brushing, Finishing , Seperating etc.

Packaging Special packaging

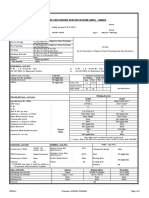

QUOTATION Address : Plot No. 04, Sector-6, IMT Manesar, Gurugram, Haryana - 122050

Phone : (0124) 482764, Mobile : 9311313802

E-mail : marketing1@aumdacro.co.in

GST No. : 06ACRPC7168E1ZH

Quotation For

Customer Name : Mr. RAHUL NEGI Date : 06/12/2023

Company Name : STERLING TOOLS LIMITED Inquiry No. : 5960A06122023

Address : 5-A DLF Ind. Estate Valid Until : 06/03/2024

Faridabad-121 003 (Haryana)

Contact No. : 9625143635 Prepared By : SHIVAM

Surface Price

Weight NSST

Sr. Area

DESCRIPTION (Gram/ INSPECTION COATING (RED QTY Remarks

No. (mm²/ Per Pc

Pc) RUST)

Pc)

Torquer CA- 4.3 Lakh

1 M10X1.25X71 BOLT 4240 57 Rs2.94 100% NA -

H Green Annually

Terms and Conditions:

1 Quotation is valid for the specified surface area / weight of the part. In case of significant change in surface area / weight of actual part, above quoted rate will not be applicable.

2 Above quoted rate is applicable for a minimum commitment as per above. Price may change if committed quantity/volume is not met for consecutive 3 months.

3 Packing and forwarding of finished products will be through the containers in which we receive the material. In case of special packaging requirements, Packing material has to be provided by the customer.

4 Parts with heavy rust/grease/damages will not be processed.

5 Due to process limitation, 0.25% of total lot or parts equivalent to 0.06 square meter area (whichever is more) will be rejected and must be accepted by the customer on chargeable basis.

6 No other process will be entertained other than coating job work as specified in the quotation

7 Material pick and drop in the scope of the customer.

8 Lead time to process the material is minimum 3 working days.

9 SST testing requirements should be intimidated in advance as parts that are needed to be tested for salt spray should be in “AS COATED” condition (reference ISO 10683)

10 Dip-Spin process has limitation to some scratches/belt marks; however, this will not have any impact on the performance of the coating.

11 Any third-party lab testing will be in the scope of the customer.

12 Coating output is as per remarks(if mentioned). This is due to inspection limitation, requiring more output than mentioned will result in increased coating prices.

General Terms and Conditions:

1 Payment Terms – 45 days. In-case of failure, interest of 18% will be charged.

2 Aum Dacro Coatings is registered under MSME (Ref: UDYAM - HR- 05-0003132)

3 GST extra as applicable.

If you have any questions concerning this quotation, please contact:

Name : SHIVAM

Contact No. : 9311313802

Email : marketing6@aumdacro.com

Thank you for your Business!

06/12/2023 16:56:37 1

You might also like

- NJP 1200 Series Automatic Capsule Filling Machine PDFDocument53 pagesNJP 1200 Series Automatic Capsule Filling Machine PDFtrungvu80% (5)

- Weider CrossbowDocument24 pagesWeider CrossbowAmish PatelNo ratings yet

- ROTALIGN PRO Manual Part 2 PDFDocument86 pagesROTALIGN PRO Manual Part 2 PDFTheerayoot Poomchai67% (3)

- Group 3 - Gearbox Daf-CfDocument504 pagesGroup 3 - Gearbox Daf-Cfюрий ерёменко100% (1)

- Visual Inspection ReportDocument5 pagesVisual Inspection ReportOmar WardehNo ratings yet

- SC100V ManualDocument22 pagesSC100V ManualPeter OberauerNo ratings yet

- MRO Stop Industrial Fastener CatalogDocument53 pagesMRO Stop Industrial Fastener CatalogMROstop.comNo ratings yet

- Inspection Report: Page 1 of 2 Vendor P.O. NODocument4 pagesInspection Report: Page 1 of 2 Vendor P.O. NOsudipta dasNo ratings yet

- TATA PIGMENT Vendor Registration & Assessment Form For Manufacturer - TPLDocument15 pagesTATA PIGMENT Vendor Registration & Assessment Form For Manufacturer - TPLVikrant SinghNo ratings yet

- Irn 20.09.2019 Fl-Smidth VoltampDocument2 pagesIrn 20.09.2019 Fl-Smidth VoltampHARI PRASATHNo ratings yet

- Inspection Report: Page 1 of 2 Vendor P.O. NODocument3 pagesInspection Report: Page 1 of 2 Vendor P.O. NOsudipta dasNo ratings yet

- nITP For Suspenion Hanger Pin Alt 2Document4 pagesnITP For Suspenion Hanger Pin Alt 2ABHISHEK KUMARNo ratings yet

- Casing Stabbing BoardDocument1 pageCasing Stabbing BoardRanjithNo ratings yet

- LAB 115 Services IndDocument2 pagesLAB 115 Services IndUsama JavedNo ratings yet

- Sub Supplier Declaration For Raw Material Source: Dated: 14.05.2016Document5 pagesSub Supplier Declaration For Raw Material Source: Dated: 14.05.2016AjayNo ratings yet

- Chemical Analysis Report (Pmi / Spectro - Oes) : Naser M. AL-Baddah & Partner General Trading & Contracting Co. W.L.LDocument1 pageChemical Analysis Report (Pmi / Spectro - Oes) : Naser M. AL-Baddah & Partner General Trading & Contracting Co. W.L.Lm.aliNo ratings yet

- Inspection Report: Page 1 of 3 Vendor P.O. NODocument3 pagesInspection Report: Page 1 of 3 Vendor P.O. NOsudipta dasNo ratings yet

- D7057 - NOI - 033 Rev.7 - MechDocument1 pageD7057 - NOI - 033 Rev.7 - Mechnisha_khanNo ratings yet

- Ir 0703Document3 pagesIr 0703sheikmoinNo ratings yet

- MATL PFAB DR Preparation 0060Document18 pagesMATL PFAB DR Preparation 0060Sakshi SinghNo ratings yet

- Packaging Details: Vendor Name & AddressDocument4 pagesPackaging Details: Vendor Name & AddressPk NimiwalNo ratings yet

- Technical Services Division: Mechanical Testing LaboratoryDocument1 pageTechnical Services Division: Mechanical Testing Laboratorym.aliNo ratings yet

- 1046A Sraf No.Document1 page1046A Sraf No.Imran KhanNo ratings yet

- 3x5 BP Part1Document12 pages3x5 BP Part1siva dhamotharanNo ratings yet

- Visit Report: TUV Control No.: TUV SAP No: 8115236437 (Branch: Report NoDocument4 pagesVisit Report: TUV Control No.: TUV SAP No: 8115236437 (Branch: Report NoVinay YadavNo ratings yet

- 12-12-19 IR#10193372207 (W203.2, W979 - Walmart) - Pass - Self PDFDocument13 pages12-12-19 IR#10193372207 (W203.2, W979 - Walmart) - Pass - Self PDFrubel sabiNo ratings yet

- WPQ Process As Per ISO-9606-1 2013Document4 pagesWPQ Process As Per ISO-9606-1 2013Md Anamul Hoque0% (1)

- Technip - IVR - 8116970849 - Sr. No.01 - R00 - 077015C002-PO-1310-0012-02-O9833 PDFDocument18 pagesTechnip - IVR - 8116970849 - Sr. No.01 - R00 - 077015C002-PO-1310-0012-02-O9833 PDFAbhay KarandeNo ratings yet

- Datasheet, Drawings & QAP For Pressure Relief Valve DN400 PN16-LBC - 180920 PDFDocument4 pagesDatasheet, Drawings & QAP For Pressure Relief Valve DN400 PN16-LBC - 180920 PDFYogesh GawadeNo ratings yet

- Datasheet, Drawings & QAP For Pressure Relief Valve DN400 PN16-LBC - 180920 PDFDocument4 pagesDatasheet, Drawings & QAP For Pressure Relief Valve DN400 PN16-LBC - 180920 PDFYogesh GawadeNo ratings yet

- Ho SơDocument47 pagesHo SơHuy BầuNo ratings yet

- Part Submission Warrant (PSW)Document8 pagesPart Submission Warrant (PSW)api-980604No ratings yet

- FA ReportDocument4 pagesFA ReportBudi ArtantoNo ratings yet

- Pgca MR D06 005 - C1 - 2Document90 pagesPgca MR D06 005 - C1 - 2Ami PutraNo ratings yet

- Welder Qualification Test Certificate BS EN ISO 9606-1: 2013Document2 pagesWelder Qualification Test Certificate BS EN ISO 9606-1: 2013LeonNo ratings yet

- Failure Analysis Report: Information - 01Document4 pagesFailure Analysis Report: Information - 01Budi ArtantoNo ratings yet

- Welding Procedure qualificationsQW483 PDFDocument2 pagesWelding Procedure qualificationsQW483 PDFTC Chick WilliamNo ratings yet

- Wire PDFDocument3 pagesWire PDFm.aliNo ratings yet

- Cp5-Itp CWC RomanuDocument22 pagesCp5-Itp CWC RomanuherdiansyahNo ratings yet

- Inspection Report: 150 MW Dhamangaon Solar Project, MaharashtraDocument6 pagesInspection Report: 150 MW Dhamangaon Solar Project, Maharashtrakaushik21185No ratings yet

- Release Note N°: RN210607060EDocument3 pagesRelease Note N°: RN210607060ESantosh Iim LucknowNo ratings yet

- Vinfast PIDDocument16 pagesVinfast PIDGalva decoNo ratings yet

- IVR 050112009522 - 95 2 Rev.0Document6 pagesIVR 050112009522 - 95 2 Rev.0Vinay YadavNo ratings yet

- Inspection Report: IR No.: QETO/IR/SUD/110Document2 pagesInspection Report: IR No.: QETO/IR/SUD/110sudipta dasNo ratings yet

- 4845 PDFDocument1 page4845 PDFRavi patelNo ratings yet

- Bis-Dk-Rt-1049 - Ip2022-CeDocument2 pagesBis-Dk-Rt-1049 - Ip2022-CeTomasPavlovicNo ratings yet

- Marking Guidelines - PM-PU-6.022Document14 pagesMarking Guidelines - PM-PU-6.022PINNACLE ENGINEERINGNo ratings yet

- Bis-Dk-Rt-1047 - Ip2022-CeDocument2 pagesBis-Dk-Rt-1047 - Ip2022-CeTomasPavlovicNo ratings yet

- 1SV10110-110C08-BEC-MAT-AR-0068-C0 - Material Submittal For Porcelain Tile RT02 (900x400x20mm) at ROOF (Maintenance Walkway) From ALFANARDocument176 pages1SV10110-110C08-BEC-MAT-AR-0068-C0 - Material Submittal For Porcelain Tile RT02 (900x400x20mm) at ROOF (Maintenance Walkway) From ALFANAROmar TarekNo ratings yet

- IVR-8117994011-01 - Rev.00Document6 pagesIVR-8117994011-01 - Rev.00Abhay KarandeNo ratings yet

- Cpri Section II - Technical Specification Tender Enquery No: PUR/UHVRL-04/14-15Document3 pagesCpri Section II - Technical Specification Tender Enquery No: PUR/UHVRL-04/14-15Gaurav KumarNo ratings yet

- Orifice Cal. Rev.2Document75 pagesOrifice Cal. Rev.2waheed2286No ratings yet

- Muhammad WaqasDocument1 pageMuhammad WaqasthehitechmultanNo ratings yet

- Ibo Pm9s Exe I19 99 Qac RPT 0006 - Rev. B (Amended)Document6 pagesIbo Pm9s Exe I19 99 Qac RPT 0006 - Rev. B (Amended)Gokhula KannanNo ratings yet

- Purchase Request (PR) : AttachmentsDocument6 pagesPurchase Request (PR) : AttachmentsDILNo ratings yet

- FeasibilityDocument8 pagesFeasibilityTarun MarskoleNo ratings yet

- WPS P1 Group Any To P1 Group Any GTAW FCAW Manual MachineDocument2 pagesWPS P1 Group Any To P1 Group Any GTAW FCAW Manual MachinePrasad ChakkrapaniNo ratings yet

- Final Insepection Reports and WPS PQRDocument14 pagesFinal Insepection Reports and WPS PQRVikas Verma100% (1)

- F-02 (Magnetic Particle Test) - (NEW) ..Latest 006Document42 pagesF-02 (Magnetic Particle Test) - (NEW) ..Latest 006Himanshu SinghNo ratings yet

- Ir 5073 Ppa 005Document6 pagesIr 5073 Ppa 005ValiNo ratings yet

- 8D - Bend IssueDocument3 pages8D - Bend Issuemoonlight toolsNo ratings yet

- Format. No: TSSA - IS - IN - FR - 05 Rev 4 Dated. 15.01.2021Document3 pagesFormat. No: TSSA - IS - IN - FR - 05 Rev 4 Dated. 15.01.2021Raja KrsNo ratings yet

- 2005 S003 NBPG Rfi 04957 - R00Document1 page2005 S003 NBPG Rfi 04957 - R00RPDeshNo ratings yet

- PPAP Check SheetDocument13 pagesPPAP Check SheetNinnammanNo ratings yet

- Oil Test-1Document2 pagesOil Test-1ForenTec Engineers RanchiNo ratings yet

- Engineering Service Revenues World Summary: Market Values & Financials by CountryFrom EverandEngineering Service Revenues World Summary: Market Values & Financials by CountryNo ratings yet

- ACS310 Short ManualDocument40 pagesACS310 Short ManualJNo ratings yet

- CBLM Common 3 Perform Industry CalculationDocument23 pagesCBLM Common 3 Perform Industry CalculationAnonymous jGHeIS100% (1)

- Kompass - Aircrete Building Materials EN PrintDocument6 pagesKompass - Aircrete Building Materials EN PrintJacob PriyadharshanNo ratings yet

- Skimmer Pipe Example DrawingDocument1 pageSkimmer Pipe Example Drawingjagannadha varma100% (1)

- Tms500 Parts ManualDocument1,102 pagesTms500 Parts ManualWFT 777No ratings yet

- B 2890Document2 pagesB 2890vespxNo ratings yet

- Alum A Frame Product SheetDocument2 pagesAlum A Frame Product SheetEben EzerNo ratings yet

- Raga-Cece-Colango Engr. Hana Myka Gaton Cost Estimation Bsce 5-1 CPM Part.1 ArchitecturalDocument33 pagesRaga-Cece-Colango Engr. Hana Myka Gaton Cost Estimation Bsce 5-1 CPM Part.1 ArchitecturalLnazerA.CeceNo ratings yet

- Vitosol 100fm sv1fDocument52 pagesVitosol 100fm sv1fGile SimunovicNo ratings yet

- 550 Manual-2008Document37 pages550 Manual-2008MiguelNo ratings yet

- 99929Document20 pages99929Tamer Moustafa100% (2)

- Introduction Letter: Stainless SteelDocument4 pagesIntroduction Letter: Stainless SteelArvind JainNo ratings yet

- Fabrication Method For HSM 2 ProjectDocument14 pagesFabrication Method For HSM 2 ProjectMikiRoniWijayaNo ratings yet

- Haitian Mars Tech SpecificationsDocument8 pagesHaitian Mars Tech Specificationsaakashlakhanpal9830100% (2)

- 014 - 030 Single Reduction Worm IntroductionDocument17 pages014 - 030 Single Reduction Worm IntroductionAlejandro MartinezNo ratings yet

- Standard Groove Specifications PDFDocument5 pagesStandard Groove Specifications PDFDavid Salguero OlveaNo ratings yet

- HRD FTM 2012-09Document24 pagesHRD FTM 2012-09Thang VoNo ratings yet

- Catalog Emko PDFDocument116 pagesCatalog Emko PDFwarung1bensinNo ratings yet

- Ace III Service ManualDocument46 pagesAce III Service Manualosiris israely100% (1)

- TSPG - Engine Tools 2-139 A 2-220 PDFDocument82 pagesTSPG - Engine Tools 2-139 A 2-220 PDFAKshay100% (1)

- Suzuki Liana 2004-2006 1.4 Diesel Service Manual 99501-73J00-01EDocument569 pagesSuzuki Liana 2004-2006 1.4 Diesel Service Manual 99501-73J00-01Evik_md67% (3)

- Class Flanges Bolt Torque Loads PDFDocument2 pagesClass Flanges Bolt Torque Loads PDFHomer SilvaNo ratings yet

- 4H.2209 - Illustrated Spare Parts Manual - KFP4R-UF07 - FM-UL PDFDocument91 pages4H.2209 - Illustrated Spare Parts Manual - KFP4R-UF07 - FM-UL PDFPankaj JainNo ratings yet

- Statoil WR 0235 Safe Use of Lifting and Transporting EquipmentDocument35 pagesStatoil WR 0235 Safe Use of Lifting and Transporting Equipmentadriancovalciuc4863No ratings yet