Professional Documents

Culture Documents

Edesander INP Ver300L

Edesander INP Ver300L

Uploaded by

LuisAngelCordovadeSanchezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Edesander INP Ver300L

Edesander INP Ver300L

Uploaded by

LuisAngelCordovadeSanchezCopyright:

Available Formats

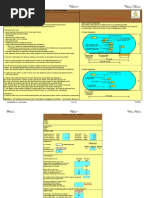

PRODUCED WATER DESANDER

(SOLID-LIQUID HYDROCYCLONE)

SIMULATION INPUT DATA

www.eprocess-tech.com

sales@eprocess-tech.com

PROJECT INFORMATION

Client Name: ESPECIALIDADES EN TURBOMAQUINARÍA

Project Name: RABASA FASE II

Reference Datasheet: HD-BSR-FII-H-202_1

Equip. Tag No. FD-102

EQUIPMENT LOCATION

Produced Water Desander - Located on Water Outlet of Separator Vessel (provide a PFD or PID)

Installation Description: FRESH WATER FROM WELLS, LOCATED IN DEEP WELL PUMP DISCHARGE.

Note: Process data below must match equipment location

PROCESS DESIGN CONDITIONS

Case Title: Units Case 1 Case 2 Case 3

Water Flow Rate: BPD 6000 30000 66000

Inlet Pressure (gauge): kg/cm² 6.4 6.4 6.4

Design Pressure: kg/cm² 10 10 10

Inlet Temperature: °C 30 30 30

Design Temperature: °C 50 50 50

Inlet Solids Concentration: mg/l 2 3 5

Required Outlet Performance: micron 15 15 20

Mechanical Design Rating: 150# 150# 150#

FLUIDS/SOLID PROPERTIES DATA

Oil Density: API NA NA NA

Oil Viscosity: cP NA NA 5

Water Density: s.g. 1.05 1.05 1.05

Water Viscosity: cP 0.8 0.8 0.8

Solids Density: s.g. 2.67 2.67 2.67

SOLIDS PARTICLE SIZE DISTRIBUTION

Distribution Input Type: Computer Computer Computer

Median Particle Size (micron): 20 100 150

Manual Input Particle Size Distribution: Case 1 Case 2 Case 3

Size (µ) Ind. Wt. % Size (µ) Ind. Wt. % Size (µ) Ind. Wt. %

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Total (Must = 100%) 0.00 0.00 0.00

Version 3.00, © 2023 eProcess Technologies

You might also like

- BLDC COMPRESSOR TCC DA HORIZONTAL r1.0Document18 pagesBLDC COMPRESSOR TCC DA HORIZONTAL r1.0Bruno Souza100% (2)

- 3 Research Proposal - Jimenez, Mary Grace P.Document13 pages3 Research Proposal - Jimenez, Mary Grace P.Mary Grace Jimenez100% (3)

- Optimization Improvement - CQIDocument2 pagesOptimization Improvement - CQISyafrialdi MasriNo ratings yet

- Lab Report of Fundamentals of Polymer Engineering LabDocument40 pagesLab Report of Fundamentals of Polymer Engineering LabHafiz Tanveer86% (14)

- Flow AssignmentDocument5 pagesFlow AssignmentUsman MuhammadNo ratings yet

- API 12j SizingDocument8 pagesAPI 12j SizingsegunoyesNo ratings yet

- Wellhead Desander (Multiphase Hydrocyclone) Input Data: Project InformationDocument1 pageWellhead Desander (Multiphase Hydrocyclone) Input Data: Project InformationveronicaNo ratings yet

- Dwnload Full Miller and Freunds Probability and Statistics For Engineers 9th Edition Johnson Solutions Manual PDFDocument36 pagesDwnload Full Miller and Freunds Probability and Statistics For Engineers 9th Edition Johnson Solutions Manual PDFblackinghemmeldsu0100% (13)

- Detailed Performance Summary: Input DataDocument3 pagesDetailed Performance Summary: Input DataSebastian Muñoz GonzalezNo ratings yet

- I-Flow SystemDocument21 pagesI-Flow SystemShigeru AkiseNo ratings yet

- Assignment No.4 - PEP Elective - Spring 2017Document2 pagesAssignment No.4 - PEP Elective - Spring 2017Dr-Adel SalemNo ratings yet

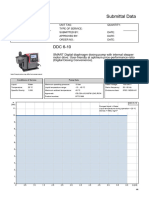

- Submittal Data: CM10-2 A-R-A-E-AQQEDocument9 pagesSubmittal Data: CM10-2 A-R-A-E-AQQEocta aldyNo ratings yet

- 125 PV 4714Document1 page125 PV 4714Pratik SangamNo ratings yet

- Tower FoundationDocument27 pagesTower Foundationmhazarath murariNo ratings yet

- 7.AppNote 3.2 CementDocument4 pages7.AppNote 3.2 CementlehuylapNo ratings yet

- Zone 9 ResultDocument12 pagesZone 9 Resultamnaakram996No ratings yet

- Zone 8 InputDocument4 pagesZone 8 Inputamnaakram996No ratings yet

- Zone 9 CustomerDocument8 pagesZone 9 Customeramnaakram996No ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument3 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- Hydratec Incorporated 64 Haverhill Road Route 111 Windham, NH 03087 603-434-0502Document5 pagesHydratec Incorporated 64 Haverhill Road Route 111 Windham, NH 03087 603-434-0502Sergio HZNo ratings yet

- Zone 9 InputDocument4 pagesZone 9 Inputamnaakram996No ratings yet

- 019-02 - 50 KL Mee Feed Storage Tank 21ST-017 & 21ST-018Document26 pages019-02 - 50 KL Mee Feed Storage Tank 21ST-017 & 21ST-018Bhaumik BhuvaNo ratings yet

- Vessel Calculation Sheet: Internal Pressure DesignDocument7 pagesVessel Calculation Sheet: Internal Pressure DesignAgustín DomínguezNo ratings yet

- PPL NPL FOSL EGB PWIS INS DSH 006 - C02 - DatasheDocument7 pagesPPL NPL FOSL EGB PWIS INS DSH 006 - C02 - DatashesegunNo ratings yet

- Index: Particulars Pages From To Sl. NoDocument40 pagesIndex: Particulars Pages From To Sl. NoTechnowisdom Consultants100% (1)

- 220 M0C 0370 10025Document13 pages220 M0C 0370 10025pca97No ratings yet

- DDC 610Document6 pagesDDC 610Francisco SantanaNo ratings yet

- Ultrahigh-Speed Switching Applications: Package Dimensions FeaturesDocument5 pagesUltrahigh-Speed Switching Applications: Package Dimensions FeaturesCarlosOlivierNo ratings yet

- API 12j SizingDocument1 pageAPI 12j SizingAdewunmi OlufemiNo ratings yet

- Datasheet, Drawings & QAP For Pressure Relief Valve DN400 PN16-LBC - 180920 PDFDocument4 pagesDatasheet, Drawings & QAP For Pressure Relief Valve DN400 PN16-LBC - 180920 PDFYogesh GawadeNo ratings yet

- 15-501-EP-DS-001 (Metering Skid Data Sheet), Rev.1Document2 pages15-501-EP-DS-001 (Metering Skid Data Sheet), Rev.1Umair A. KhanNo ratings yet

- Datasheet, Drawings & QAP For Pressure Relief Valve DN400 PN16-LBC - 180920 PDFDocument4 pagesDatasheet, Drawings & QAP For Pressure Relief Valve DN400 PN16-LBC - 180920 PDFYogesh GawadeNo ratings yet

- STAD PN25 EN LowDocument8 pagesSTAD PN25 EN LowMariusMNo ratings yet

- 20G12-MF-0010 - RA Heat & Mass Balance Diagram-2 PDFDocument7 pages20G12-MF-0010 - RA Heat & Mass Balance Diagram-2 PDFahmedNo ratings yet

- Capture 100% of The Production Stream: Flare LessDocument2 pagesCapture 100% of The Production Stream: Flare LessadrianioantomaNo ratings yet

- 220 M0C 0000 00025Document17 pages220 M0C 0000 00025pca97No ratings yet

- NPT10111-PE-V-DS-621101-030 - Instrument Datasheet - Level Gauge F & B Rev-00Document6 pagesNPT10111-PE-V-DS-621101-030 - Instrument Datasheet - Level Gauge F & B Rev-00kkumar_717405No ratings yet

- Manual Da Bomba Grundfos Crie 3-7Document9 pagesManual Da Bomba Grundfos Crie 3-7Felipe MachadoNo ratings yet

- Technical Manual EVOPICVDocument20 pagesTechnical Manual EVOPICVzoltanNo ratings yet

- Abb-02-Ics-Das-Enf-000-00001-00 Z-03Document2 pagesAbb-02-Ics-Das-Enf-000-00001-00 Z-03mvdeole7056No ratings yet

- Tall Tubular Gal Battery Platinum NewDocument4 pagesTall Tubular Gal Battery Platinum NewchamilsilvaNo ratings yet

- Vane Pump FailureDocument62 pagesVane Pump Failurebatuhan kılıçNo ratings yet

- CT-22-12000.GB: Specifications Turbo CompressorDocument2 pagesCT-22-12000.GB: Specifications Turbo CompressorkaydoNo ratings yet

- DHT Question Answer BankDocument41 pagesDHT Question Answer BankBikas Saha100% (3)

- Control Valves Data Sheet: K9 S.P.A. - ItalyDocument11 pagesControl Valves Data Sheet: K9 S.P.A. - ItalyAhmadNo ratings yet

- Specification Datasheet Pumps and Motors: Fuel Oil 820 - 870 1.5 - 40Document2 pagesSpecification Datasheet Pumps and Motors: Fuel Oil 820 - 870 1.5 - 40HordiNo ratings yet

- PDF SANYO 883252Document5 pagesPDF SANYO 883252JeysonGarzonNo ratings yet

- 2 Phase Separator Sizing: Vertical Horizontal OrientationDocument2 pages2 Phase Separator Sizing: Vertical Horizontal Orientationmohideenaliyarjafeer.shanawazNo ratings yet

- V04 - C03 - Andina Ball Mill Op Manual - 3BHS235454 - EN - Rev - CertDocument115 pagesV04 - C03 - Andina Ball Mill Op Manual - 3BHS235454 - EN - Rev - CertJuan100% (1)

- Compressive Strength of Concrete Core BS EN 12504-1: Project InformationDocument2 pagesCompressive Strength of Concrete Core BS EN 12504-1: Project Informationraja qammar100% (1)

- PPL NPL FOSL EGB PWIS INS DSH 007 - C01 - DatasheDocument4 pagesPPL NPL FOSL EGB PWIS INS DSH 007 - C01 - DatashesegunNo ratings yet

- Stationary Compressors: Principal Data: LE 2-20/ 10 Bar/ 50 HZDocument5 pagesStationary Compressors: Principal Data: LE 2-20/ 10 Bar/ 50 HZAljamali AlhofashiNo ratings yet

- Full Port 2 Piece Ball Valve DN200 - Valve Performance ReportDocument27 pagesFull Port 2 Piece Ball Valve DN200 - Valve Performance ReportSneha ShettyNo ratings yet

- R0 Daikin VRF System Service CommissioningDocument7 pagesR0 Daikin VRF System Service Commissioningta9569922No ratings yet

- Fatigue Design CalculationDocument3 pagesFatigue Design CalculationinnovativekarthiNo ratings yet

- SMD Type Ceramic Multilayer Chip Inductor: FeaturesDocument10 pagesSMD Type Ceramic Multilayer Chip Inductor: FeaturesDanilo PoquiniNo ratings yet

- Tank Design FormDocument26 pagesTank Design FormBhaumik BhuvaNo ratings yet

- KG-TOWER® Software V 5.3 Customer's Copy. Property of Koch-Glitsch. Strictly ConfidentialDocument1 pageKG-TOWER® Software V 5.3 Customer's Copy. Property of Koch-Glitsch. Strictly ConfidentialIlham MacawNo ratings yet

- Miller and Freunds Probability and Statistics For Engineers 9th Edition Johnson Solutions ManualDocument36 pagesMiller and Freunds Probability and Statistics For Engineers 9th Edition Johnson Solutions Manualamoeboid.amvis.uiem100% (28)

- Level Switch Etm Data SheetDocument1 pageLevel Switch Etm Data SheetLuisAngelCordovadeSanchezNo ratings yet

- 57-106 Eclipse Model 706 High Performance Guided Wave Radar Level TransmitterDocument40 pages57-106 Eclipse Model 706 High Performance Guided Wave Radar Level TransmitterLuisAngelCordovadeSanchezNo ratings yet

- Hydrocarbon Dew Point - Critical Considerations For Natural Gas Turbine InstallationsDocument6 pagesHydrocarbon Dew Point - Critical Considerations For Natural Gas Turbine InstallationsLuisAngelCordovadeSanchezNo ratings yet

- Liqui-Cel EXF-10x28 Data Sheet LC-1031Document2 pagesLiqui-Cel EXF-10x28 Data Sheet LC-1031LuisAngelCordovadeSanchezNo ratings yet

- DS FSV430 450 en FDocument44 pagesDS FSV430 450 en FLuisAngelCordovadeSanchezNo ratings yet

- Metric English: TDS-TM8817-03-CS-PET-8278185 © 2019 Caterpillar All Rights Reserved Page 1 of 2Document2 pagesMetric English: TDS-TM8817-03-CS-PET-8278185 © 2019 Caterpillar All Rights Reserved Page 1 of 2LuisAngelCordovadeSanchezNo ratings yet

- Image Shown May Not Reflect Actual Configuration: Metric EnglishDocument2 pagesImage Shown May Not Reflect Actual Configuration: Metric EnglishLuisAngelCordovadeSanchezNo ratings yet

- Disclosure To Promote The Right To InformationDocument180 pagesDisclosure To Promote The Right To InformationLuisAngelCordovadeSanchezNo ratings yet

- GPSADocument21 pagesGPSALuisAngelCordovadeSanchezNo ratings yet

- Handbook of Thermodynamic Diagrams VOLUME2 PDFDocument409 pagesHandbook of Thermodynamic Diagrams VOLUME2 PDFcarlitaGJNo ratings yet

- E17 Fluid Flow and Piping GPSA2Document28 pagesE17 Fluid Flow and Piping GPSA2LuisAngelCordovadeSanchez100% (2)

- Levenspiel 1999 - Chemical Reaction EngineeringDocument4 pagesLevenspiel 1999 - Chemical Reaction EngineeringDrudervenNo ratings yet

- Ncjescoa 10Document61 pagesNcjescoa 10ODDENSIGN 2007No ratings yet

- Robotics Final ReportDocument44 pagesRobotics Final ReportSushma MurthyNo ratings yet

- Task 2 Writing Task Yasneidy ContrerasDocument3 pagesTask 2 Writing Task Yasneidy ContrerasDaniela santanderNo ratings yet

- IBITA Assumptions enDocument12 pagesIBITA Assumptions enPedro FonsecaNo ratings yet

- Social Theory As Habitus (OCR)Document10 pagesSocial Theory As Habitus (OCR)vcvc vcvcNo ratings yet

- Final GEUDP Waesano ESIA Document - Bahasa PDFDocument317 pagesFinal GEUDP Waesano ESIA Document - Bahasa PDFVenan HaryantoNo ratings yet

- Architecture Thesis Topics Ideas PhilippinesDocument4 pagesArchitecture Thesis Topics Ideas Philippinesmichellealexanderminneapolis100% (2)

- RBSS wt10 enDocument3 pagesRBSS wt10 enNguyen Van TruongNo ratings yet

- 27-07-2020 - SR - ICON ALL<-Prog-I&II, All - INDIA - e-TEST - SERIES - Jee-ADV (2018-P1&P2) - AFT-09 - FINAL KEYDocument1 page27-07-2020 - SR - ICON ALL<-Prog-I&II, All - INDIA - e-TEST - SERIES - Jee-ADV (2018-P1&P2) - AFT-09 - FINAL KEYSai GokulNo ratings yet

- PDF 1Document302 pagesPDF 1LuckyNo ratings yet

- Product AI845Document4 pagesProduct AI845Hernan Humberto Castañeda MendozaNo ratings yet

- 2 Teak DeckingDocument25 pages2 Teak DeckingJoshua Swee100% (1)

- Technology in The Ancient WorldDocument66 pagesTechnology in The Ancient WorldAngela Danielle Tan100% (1)

- ReferensiDocument4 pagesReferensiyusri polimengoNo ratings yet

- La Escalera de Wittgenstein, David LehmanDocument6 pagesLa Escalera de Wittgenstein, David Lehmanwilbert_tapia_1No ratings yet

- Pengaruh Harga Dan Lokasi Terhadap Keputusan Pembelian Rumah Pada Cv. Interhouse DesignDocument6 pagesPengaruh Harga Dan Lokasi Terhadap Keputusan Pembelian Rumah Pada Cv. Interhouse DesignAbu RijalNo ratings yet

- C-Reactive Protein (CRP)Document9 pagesC-Reactive Protein (CRP)Ibrahim Alturaiki100% (1)

- The Historical Roots of The Visual ExaminationDocument10 pagesThe Historical Roots of The Visual ExaminationrecolenciNo ratings yet

- Manipal University Jaipur: Branch Timetable For The Academic Session - Aug-Dec 2020Document13 pagesManipal University Jaipur: Branch Timetable For The Academic Session - Aug-Dec 2020Somil VishwakarmaNo ratings yet

- Eigen Values of A Matrix by PowerDocument9 pagesEigen Values of A Matrix by PowerVarnika SinghNo ratings yet

- Capitalization Rules LPDocument6 pagesCapitalization Rules LPCarlynArgentinaPaitanCarduzaNo ratings yet

- Flare Pit Cleaning TechnologyDocument27 pagesFlare Pit Cleaning TechnologyAhmed GamaladdinNo ratings yet

- Chapter 1 - SEQUENCEDocument24 pagesChapter 1 - SEQUENCEAirin SamuelNo ratings yet

- 07 - Chapter 1 IntroductionDocument44 pages07 - Chapter 1 Introductionharshitha pNo ratings yet

- Accumulation of Heavy Metals in SpinaciaDocument12 pagesAccumulation of Heavy Metals in SpinaciaSachin SrivastavaNo ratings yet

- Hearing TestingDocument6 pagesHearing TestingMelody RodriguezNo ratings yet

- Ich E2f DsurDocument23 pagesIch E2f Dsurvinay patidarNo ratings yet

- A Practical Method For Documenting Software ArchitDocument11 pagesA Practical Method For Documenting Software Architolwenntaron1707No ratings yet