Professional Documents

Culture Documents

Methane Leakage Article

Methane Leakage Article

Uploaded by

smrahman17323Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Methane Leakage Article

Methane Leakage Article

Uploaded by

smrahman17323Copyright:

Available Formats

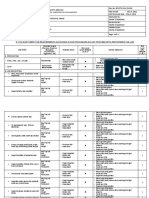

Basic familiarization of Dual Fuel Engine concept.

(© Moshiur Rahman)

Methane Loss in Dual Fuel Engine:

Impact on MARPOL ANNEX-VI Regulation:13-NOx Emission

Methane Slip: Methane Leaks:

Unburn methane trapped in the dead space of Methane Leakage in the annular

combustion chamber space of Double wall LNG fuel pipe.

Cause Cause

Dead space in Gas Quenching in cool Mechanical failure

combustion chamber area of combustion of the pipe system

chamber due to corrosion,

fatigue, crack and

rupture.

Dead space: Gas Quenching:

Gaps between cylinder head and liner, Incomplete combustion of methane in

Remedy to reduce

Between piston top side wall and cylinder form of Quenching (cold gas molecule)

Methane Leakage

liner, Behind anti-polishing ring & piston ring at the coldest part of the combustion

chamber which is normally liner

Methane slip mechanism: surface close to scavenging area. -Double wall non-

corrosive SS piping

1. During the compression stroke the gas Methane slip mechanism:

system with flexible

mixture is compressed and trapped into

Quenching occur when the mixture is joint to be used in

these gaps and hide away from the

too lean (Less CH4 + More Air) and design

combustion.

cool- down along the cylinder liner.

2. The Methane molecule is very stable and This mainly happen during low load - well secured

need high temperature to ignite (above operation. clamping system to

600-degree C depending on air fuel be maintained

Remedy to reduce Methane Slip:

ratio). This hidden area temperature against vibration

remains below this ignition point. So, 1. Quenching can be significantly damage.

methane molecules remain unburn in reduced by enriching the “Gas-Air”

this area. -Sufficient safety

mixture. But richer mixture with

device (Pressure

3. During expansion stroke this hidden gas higher CH4 will create more NOx.

relief vv, pressure

flows out from the gaps area it cools So dynamic balancing of the

mixture is essential with effective sensor, Isolation vv

down further and comes out in the

control system between unburned etc) to be used

exhaust flow.

methane and NOx. against over

Remedy to reduce Methane Slip in DFE: pressure of the

2. Fine Optimization of Gas- fuel ratio piping system

1. This dead volume can be reduced to a for each load with the control

minimum by design system can minimize methane Gas -Regular inspection

Quenching.

2. High pressure direct LNG injection can

-Use GCU to burn

also minimize this gas trapping.

leakage methane

Basic familiarization of Dual Fuel Engine concept. (© Moshiur Rahman)

Methane slip is an important environmental concern for the modern dual fuel

engine. This causes great harm to our environment by affecting Ozone layer. It

has also high global warming potential (GWP). This also impact the MARPOL

Annex-VI regulation 12 (Ozone depleting substance). Many of our industry

practitioners and Marine engineers and Marine Engineering students do not

have the clear idea about this methane Slip. They are also not sure about how

this methane slip occurs in the Marine dual fuel engine. Many of them are

confused between Methane leakage and methane slip in the dual fuel engine.

To provide a basic picture to them about this methane slip and menthe leakage

in a brief frame, I develop this “Graphical model of Methane Leakage” from

the dual fuel engine. Hope this will be helpful to my industry people and

academics who are working with dual fuel engine.

You might also like

- Isuzu 3ld1Document127 pagesIsuzu 3ld1jvega_53412093% (43)

- Mitsubishi FD20CN, FD20N, FD25N, FD30N, FD35AN, FGE15N, FGE18N, FGE20CN, FGE20N, FGE20ZN Service ManualDocument22 pagesMitsubishi FD20CN, FD20N, FD25N, FD30N, FD35AN, FGE15N, FGE18N, FGE20CN, FGE20N, FGE20ZN Service ManualLeotubeNo ratings yet

- Bosch MW ManualDocument59 pagesBosch MW Manualsteynhen100% (7)

- CDM PDFDocument3 pagesCDM PDFferas_elnggarNo ratings yet

- M2M CMM Tech DatabaseDocument14 pagesM2M CMM Tech Databasebrian.watling4223No ratings yet

- GT2013 94680Document9 pagesGT2013 94680luca.bozzi74No ratings yet

- Heat Transfer Enhancement in Heat Recovery Steam Generator Using Dry Ice Co Blasting Cleaning MethodDocument2 pagesHeat Transfer Enhancement in Heat Recovery Steam Generator Using Dry Ice Co Blasting Cleaning MethodDimas PalgunadiNo ratings yet

- Latest Rotary Kiln Burner TechnologyDocument9 pagesLatest Rotary Kiln Burner TechnologyKristínaNo ratings yet

- Specialized Coal and Pet Coke Firing Pipe DesignDocument6 pagesSpecialized Coal and Pet Coke Firing Pipe Designary.engenharia1244No ratings yet

- LINTEC Burner En13Document4 pagesLINTEC Burner En1328g8stj2cjNo ratings yet

- Parallel-Flow Drum-Mix Plants: SectionDocument33 pagesParallel-Flow Drum-Mix Plants: SectionTayyabah ZafarNo ratings yet

- Soot Formation: Institut Ffir Physikalische Chemic Der Universiti T Gi Ttinoen, 3400 Gbttingen, West German)Document45 pagesSoot Formation: Institut Ffir Physikalische Chemic Der Universiti T Gi Ttinoen, 3400 Gbttingen, West German)MahmoudKamalElshazlyNo ratings yet

- Kempster 1995Document6 pagesKempster 1995Hiwa KhalediNo ratings yet

- Ammonia Destruction in The Reaction Furnace - Optimized Gas TreatingDocument9 pagesAmmonia Destruction in The Reaction Furnace - Optimized Gas TreatingAlejandro PedezertNo ratings yet

- pp74-78 MSI10Document5 pagespp74-78 MSI10Mohamed ShabanNo ratings yet

- Low Nox Pyro-SystemDocument9 pagesLow Nox Pyro-SystemKristínaNo ratings yet

- Motoring (Non Firing) : Chapter in A NutshellDocument21 pagesMotoring (Non Firing) : Chapter in A Nutshellhemant sainiNo ratings yet

- Oil and Gas Generation - Supplementary SlidesDocument6 pagesOil and Gas Generation - Supplementary SlidesgorkemerkanliNo ratings yet

- 17chap18 PDFDocument9 pages17chap18 PDFmick.pride81No ratings yet

- Pet RocheDocument2 pagesPet RochejuniorNo ratings yet

- Effect of Burning Rate Modifiers On Subatmospheric Flame Temperatures of Ap/Htpb Composite Solid PropellantsDocument7 pagesEffect of Burning Rate Modifiers On Subatmospheric Flame Temperatures of Ap/Htpb Composite Solid PropellantsMohamed MohamedNo ratings yet

- 402 Fuch2016Document9 pages402 Fuch2016FurqanNo ratings yet

- WP - Insight Into Heat Treatment and Quenching Gears - EN - GLDocument13 pagesWP - Insight Into Heat Treatment and Quenching Gears - EN - GLida fariyantiNo ratings yet

- GTP041501Document8 pagesGTP041501tpmachinethermiqueNo ratings yet

- AGMA Technical PaperDocument16 pagesAGMA Technical Paperdwimukh360No ratings yet

- Gas Engine - Detonation & Pre-IgnitionDocument16 pagesGas Engine - Detonation & Pre-IgnitionMauro DiazNo ratings yet

- CaterpillarDocument13 pagesCaterpillarAlfredoNo ratings yet

- A Method of Reducing The Thermal Stresses in The Lining of The Tuyere Belt in A Nonferrous Metallurgy ConverterDocument3 pagesA Method of Reducing The Thermal Stresses in The Lining of The Tuyere Belt in A Nonferrous Metallurgy ConverterVictorNo ratings yet

- Densification During Hot Pressing of Carbon Nanotube Metal Magnesium Aluminate Spinel Nanocomposites 2007 Journal of The European Ceramic SocietyDocument11 pagesDensification During Hot Pressing of Carbon Nanotube Metal Magnesium Aluminate Spinel Nanocomposites 2007 Journal of The European Ceramic SocietyIon ZabetNo ratings yet

- Selectionof Oil QuenchantsDocument8 pagesSelectionof Oil QuenchantsalmasNo ratings yet

- Characterisation of Non-Premixed, Swirl-Stabilised, Wet Hydrogenair FlameDocument14 pagesCharacterisation of Non-Premixed, Swirl-Stabilised, Wet Hydrogenair Flamejiangtianzhou0409No ratings yet

- PowerDocument62 pagesPowerjuniorNo ratings yet

- Hermal Spray: Current Status and Future Trends: Herbert Herman, Sanjay Sampath, and Robert MccuneDocument9 pagesHermal Spray: Current Status and Future Trends: Herbert Herman, Sanjay Sampath, and Robert MccuneDivyam RaiNo ratings yet

- Full Length Article: SciencedirectDocument9 pagesFull Length Article: SciencedirecthelenNo ratings yet

- Fea Analysis and Experimental Investigation of Ceramic Coating On Aluminium Piston Material by Plasma Spray CoatingDocument10 pagesFea Analysis and Experimental Investigation of Ceramic Coating On Aluminium Piston Material by Plasma Spray Coatingvikky coolNo ratings yet

- Lecture8 PDFDocument9 pagesLecture8 PDFRomesh RajputNo ratings yet

- Fuel Oil Firing System Write Up - BaraDocument32 pagesFuel Oil Firing System Write Up - BaraJAYKUMAR SINGHNo ratings yet

- Development of The "Micro Combustor"Document6 pagesDevelopment of The "Micro Combustor"HERDI SUTANTONo ratings yet

- Seminar ReportDocument19 pagesSeminar ReportmujeebNo ratings yet

- 2 - SeggianiDocument11 pages2 - Seggianimohammadjm2008No ratings yet

- RobinsonDocument25 pagesRobinsonbarakalami94hudahaiderNo ratings yet

- 1.10 Mine Gases - Methane IVDocument9 pages1.10 Mine Gases - Methane IVDeepakKattimaniNo ratings yet

- Report 63 Chemical & Thermochemical 5 2014Document24 pagesReport 63 Chemical & Thermochemical 5 2014Rikshita Agarwal100% (1)

- Rocket PropulsionDocument7 pagesRocket PropulsionHARSHEEN KOURNo ratings yet

- Evaluating Hydrogen Rich Fuel Gas FiringDocument4 pagesEvaluating Hydrogen Rich Fuel Gas FiringVenkatesh Kumar RamanujamNo ratings yet

- GDHKDocument28 pagesGDHKNassim Ben AbdeddayemNo ratings yet

- AMMONIA Syn Gas Drying With Z4-01Document4 pagesAMMONIA Syn Gas Drying With Z4-01raghu4594No ratings yet

- Cardoix: ChemetronDocument19 pagesCardoix: Chemetrondon timoNo ratings yet

- Biomass Gasification On A New Really Tar Free DownDocument5 pagesBiomass Gasification On A New Really Tar Free DownJoseph OtengNo ratings yet

- Efficient Gas UtilizationDocument27 pagesEfficient Gas Utilizationhasan waqarNo ratings yet

- Fores Presentation Zero Flare 2016 - Rev.01Document14 pagesFores Presentation Zero Flare 2016 - Rev.01Nechikhe LimaneNo ratings yet

- Combustion in Spark Ignition EngineDocument9 pagesCombustion in Spark Ignition EngineJimmy ValeNo ratings yet

- Power System Operation and ControlDocument10 pagesPower System Operation and ControlnajmuulislaamNo ratings yet

- Air Pool Protection From Emissions Of The Power Industry: 1.1.2.1.3. Burners Out оf Service - BOOSDocument1 pageAir Pool Protection From Emissions Of The Power Industry: 1.1.2.1.3. Burners Out оf Service - BOOSJagdeep ArryNo ratings yet

- EIL Fired Heater Article - PTQ Q1Document4 pagesEIL Fired Heater Article - PTQ Q1aminwahiNo ratings yet

- Fundamentals of Vacuum Technologies Part 2Document100 pagesFundamentals of Vacuum Technologies Part 2napoleonmNo ratings yet

- Numerical and Experimental Investigation of A Mild Combustion BurnerDocument16 pagesNumerical and Experimental Investigation of A Mild Combustion BurnerMahendra ReddyNo ratings yet

- Simulation of Heat Transfer and Fluid Flow in A Porous Bed of Iron Ore Pellets During Up-Draught DryingDocument6 pagesSimulation of Heat Transfer and Fluid Flow in A Porous Bed of Iron Ore Pellets During Up-Draught DryingaliNo ratings yet

- CombustionOne WhitePaper v1Document20 pagesCombustionOne WhitePaper v1Khan ZaheerNo ratings yet

- Patent Application Publication (10) Pub. No.: US 2009/0030201 A1Document6 pagesPatent Application Publication (10) Pub. No.: US 2009/0030201 A1Aquae Tyo WijiantoNo ratings yet

- Casale Chemicals Pure Oxygen Autothermal Reformer BurnersDocument12 pagesCasale Chemicals Pure Oxygen Autothermal Reformer BurnersGaurav GuptaNo ratings yet

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- Engine Special Tool (S) / General Equipment: 303-01A Engine - 1.5L Ecoboost (118Kw/160Ps) 2013 - 2014 Fusion RemovalDocument41 pagesEngine Special Tool (S) / General Equipment: 303-01A Engine - 1.5L Ecoboost (118Kw/160Ps) 2013 - 2014 Fusion RemovalildefonsoNo ratings yet

- Marine Generator Set Quiet Diesel Series 7/9 QD Model MDKBL: Features and BenefitsDocument4 pagesMarine Generator Set Quiet Diesel Series 7/9 QD Model MDKBL: Features and BenefitsAngel Segura100% (1)

- Jsa 3 Yearly PM Kerisi CPP South - May 2021Document5 pagesJsa 3 Yearly PM Kerisi CPP South - May 2021Wiratma HadiNo ratings yet

- Lead The Change With: High Altitude PackageDocument9 pagesLead The Change With: High Altitude PackageGiri ShankarNo ratings yet

- ZX15 Manual 2 PDFDocument22 pagesZX15 Manual 2 PDFpgmyjqwsrfNo ratings yet

- Course Dacourse Titcourse Coresults Delivery History U Recognitiopre Test S Post Test ScoreDocument1 pageCourse Dacourse Titcourse Coresults Delivery History U Recognitiopre Test S Post Test ScoreSteyn VisserNo ratings yet

- Encyclopedia of Ship TechnologyDocument663 pagesEncyclopedia of Ship TechnologyNAUTASNo ratings yet

- Caterpillar C32Document10 pagesCaterpillar C32Carlos BarbosaNo ratings yet

- Fire Pump Model JU4HUF50Document12 pagesFire Pump Model JU4HUF50Đoàn Trung HậuNo ratings yet

- Conf Ssy116Document4 pagesConf Ssy116ivan oliverosNo ratings yet

- Product CatalogueDocument138 pagesProduct CatalogueMini Fatullaeva GafurNo ratings yet

- V 3307 Dite 2 BDocument149 pagesV 3307 Dite 2 BJeisson Eduardo Ortiz100% (6)

- Engine 12V140E-3 Series: 50 Disassembly and AssemblyDocument19 pagesEngine 12V140E-3 Series: 50 Disassembly and AssemblyЕгорNo ratings yet

- 3.0 Gas Turbine (For Printing)Document42 pages3.0 Gas Turbine (For Printing)yam3thebnyNo ratings yet

- FTR TEST REPORT OF MAHINDRA 605 DI I Aug 2020Document57 pagesFTR TEST REPORT OF MAHINDRA 605 DI I Aug 2020Mekh MitraNo ratings yet

- Back PrintDocument4 pagesBack PrintHewa PCNo ratings yet

- Zexel Nozzle of NISSAN Product InformationDocument2 pagesZexel Nozzle of NISSAN Product InformationSydneyKasongoNo ratings yet

- Revised Draft SCH of 1400HP DEMU - MP-MISC-157 - Rev-05 - July-2021 - DT 14-7-2021Document58 pagesRevised Draft SCH of 1400HP DEMU - MP-MISC-157 - Rev-05 - July-2021 - DT 14-7-2021Pradnyesh PrabhuNo ratings yet

- Hsmy17fm2628-0921 WebDocument4 pagesHsmy17fm2628-0921 WebAhmed BalajNo ratings yet

- 2019-2020 Resource Guide and Parts CatalogDocument140 pages2019-2020 Resource Guide and Parts CatalogRafael RafaelNo ratings yet

- Royal Enfield Bullet Workshop Manual PDFDocument110 pagesRoyal Enfield Bullet Workshop Manual PDFdyna1450hotmail.frNo ratings yet

- MLT845 120Document2 pagesMLT845 120ricky.nurdiansyah.310893No ratings yet

- Introducing The: Specification Xr400/206Document14 pagesIntroducing The: Specification Xr400/206Sergio RazoNo ratings yet

- Coleman BarbecueDocument14 pagesColeman BarbecueVeronika Pandža BuzatovićNo ratings yet

- Technical Results With Driving Power: Drive Systems For DecantersDocument6 pagesTechnical Results With Driving Power: Drive Systems For DecantershaggNo ratings yet

- Cummins 4BTAA3.9 C125Document10 pagesCummins 4BTAA3.9 C125Anky IsmasNo ratings yet

- Data Book: Automotive TechnicalDocument1 pageData Book: Automotive TechnicalDima DovgheiNo ratings yet