Professional Documents

Culture Documents

Wiac - Info PDF Jsa For Using Jack Hammer PR

Wiac - Info PDF Jsa For Using Jack Hammer PR

Uploaded by

maiman.mzakiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wiac - Info PDF Jsa For Using Jack Hammer PR

Wiac - Info PDF Jsa For Using Jack Hammer PR

Uploaded by

maiman.mzakiCopyright:

Available Formats

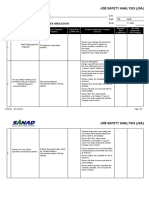

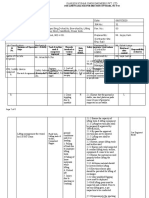

Job Safety Analysis (JSA)

VDU Revamp Project

COMPANY: SENDAN/ RIYAN GULF DATE: JSA NO:

(SUB-CON’)

EQUIPMENT/ TOOLS USED:.

WORK: Removing of Concrete by using Jackhammer

J ackhammer Air Compressor, Jackhammer

PREPARED BY: NAME POSITION SIGNATURE

CONSTRUCTION Furqan Ahmad Project Engineer

REVIEW BY: HSE Nazir Ahmad HSE Supervisor

Risk Risk

Activity Order Potential Hazards Hazard Control Proactive Measures

Rating Rating

List the steps required to perform Against each step list the potential hazards

For each hazard identified list the control measures required

the task in the sequence they are that could cause injury when the task is L/M/H L/M/H

to eliminate or minimise the risk of injury.

carried out. performed

Equipment damage or failure Complete Daily Equipment Checklist.

Maintain equipment M L

Personal injury Familiarize yourself with Operators Manual

Familiarize

compressor yourself with instructions on

All personnel in this area must have on

hearing protection

Check overall condition of compressor and

Equipment damage jackhammer

Set up Equipment M L

Slips, trips, falls Check oil and fuel levels.

Check all fittings and hose connections, if

hose is worn or connections and/or bands on

hoses appear suspect-remove and replace

immediately, when not in use store hoses off

of the ground

Sul-123. REV-0 VDU Revamp SPC 2845 Page 1 of 3

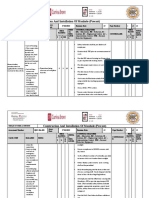

Job Safety Analysis (JSA)

Choose level area to set up compressor, chock

wheels.

Ensure that hose whiplash arrestor are on both

the compressor end and the jackhammer end,

tighten loops to avoid slippage, use cotter pins

or tie wire at Chicago fittings to positively

lock connections

Make sure hose is out of the walking/working

area minimizing trip hazards.

Inspect and barricade area with warning

signage around compressor for any

tools/objects that may pose a tripping hazard

Check the fuel level in compressor

Equipment damage Set compressor to appropriate pressure for

Fire hazard use.

Slips, trips, falls Be aware of anything that may get hot or burn

Running compressor Improper clothing M around compressor. L

Personnel burn while Have proper size and type of fire extinguisher

refuelling compressor within 15 feet of work area with trained fire

Dust or organic vapours watchman.

Remove any flammable items from work area.

Allow compressor time to cool down before

fuelling, at least 5 minutes

When stopping, some compressors may need

Fire hazard to go through ccooling

ooling cycle

cycle.. Read

Fuelling compressor Spill M instructions on side of compressor to L

Eye injury from splash determine if it requires cooling cycle, release

any stored air in compressor when done for

the day and before disconnecting hoses, keep

valve closed when connecting/disconnecting

Sul-123. REV-0 VDU Revamp SPC 2845 Page 2 of 3

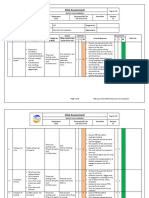

Job Safety Analysis (JSA)

hoses

Fire extinguisher within 15 feet of refuelling.

Use spill rag to catch any overspill of diesel or

kerosene.

Maintain clear travel paths

Slips, trips, falls Pick up all tools, materials, and debris.

End of task Traffic hazards M Ensure work area is secure L

Pinch points Return all tools to proper location.

Dispose of all debris in proper container.

ADDITIONAL HAZARDS IDENTIFIED CONTROL MEASURES

Workers unaware of job hazards Toolbox talk must be conducted prior to start task.

No Proper supervision Construction supervisor & HSE inspector shall be available

Working without Permit at site.

Valid Work permit must be obtain prior to start job.

SULZER DATE: APPROVED SENT FOR REVIEW

CONSTRUCTION NAME POSITION SIGNATURE

DEPARTMENT

HSE. DEPARTMENT

Sul-123. REV-0 VDU Revamp SPC 2845 Page 3 of 3

You might also like

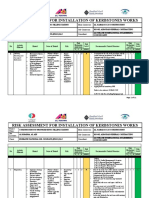

- Risk Assessment For Kerb Stones, Wheel Stopper and Paving InterlocksDocument4 pagesRisk Assessment For Kerb Stones, Wheel Stopper and Paving Interlockspete chiz91% (23)

- Risk Assessment For Curtain Wall & Glazing InstallationDocument4 pagesRisk Assessment For Curtain Wall & Glazing InstallationChristos Loutrakis75% (4)

- Risk Assessment For Anti Termite TreatmentDocument3 pagesRisk Assessment For Anti Termite TreatmentVictor81% (26)

- JSA - Electrical Testing - Circuit Breaker Field TestDocument4 pagesJSA - Electrical Testing - Circuit Breaker Field TestTawfik Mohamed Abu Zaid0% (1)

- Risk Assessment HVAC DuctingDocument5 pagesRisk Assessment HVAC DuctingAsad Zakria100% (6)

- Jsa Tank CleaningDocument5 pagesJsa Tank CleaningASLAM MULANINo ratings yet

- 34.HIRA CompressorDocument2 pages34.HIRA CompressorMMRDACA07 SAFETYNo ratings yet

- Risk Assessment For BridgeDocument31 pagesRisk Assessment For BridgeMariam Mousa100% (2)

- Job Hazard Analysis (JHA) Worksheet: Sungchang & Al-Shaikh Contracting Co.,LtdDocument3 pagesJob Hazard Analysis (JHA) Worksheet: Sungchang & Al-Shaikh Contracting Co.,LtdTeodoro Esquillo100% (1)

- Risk Assessment For Installation of Automatic Revolving Door InstallationDocument7 pagesRisk Assessment For Installation of Automatic Revolving Door InstallationTECHCOM100% (1)

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- Colorado Insurance HandbookDocument36 pagesColorado Insurance Handbookbomama01No ratings yet

- Pdfslide - Us Jsa For Using Jack HammerDocument3 pagesPdfslide - Us Jsa For Using Jack HammerWidya BungaNo ratings yet

- Pipe Nitrogen Testing in Non Confined SpaceDocument4 pagesPipe Nitrogen Testing in Non Confined SpaceKannan KamalNo ratings yet

- JSA HEMP Well Services Pg25-30Document5 pagesJSA HEMP Well Services Pg25-30Ashok SureshNo ratings yet

- General Man Rider OperationsDocument4 pagesGeneral Man Rider OperationsPaulNo ratings yet

- JSA For Station PipingDocument4 pagesJSA For Station PipingR Sahadeo ReddyNo ratings yet

- NEW Form JHA-Assembling & Dismatling of Crawler Crane-FinalDocument15 pagesNEW Form JHA-Assembling & Dismatling of Crawler Crane-FinalKarthik babuNo ratings yet

- Risk Assessment For Concrete Repair WorkDocument11 pagesRisk Assessment For Concrete Repair WorkSaeed AhmadNo ratings yet

- Hydrotest & Pneumatic Test - TRADocument6 pagesHydrotest & Pneumatic Test - TRAOws Anish75% (4)

- Gangway InstallationDocument3 pagesGangway Installationazrul100% (1)

- QRC-RA-001-Construction and Installation of Manhole (Precast)Document10 pagesQRC-RA-001-Construction and Installation of Manhole (Precast)Kallem RajashekarNo ratings yet

- Risk Assessment SheetDocument4 pagesRisk Assessment Sheetfuturecolor7No ratings yet

- CycloneDocument22 pagesCycloneqcath001No ratings yet

- TTEC Fencing RADocument7 pagesTTEC Fencing RAGeml TrinidadNo ratings yet

- JSA CTU Sand Clean Out BPPDocument8 pagesJSA CTU Sand Clean Out BPPLismi LismiNo ratings yet

- Job Safety Analysis (JSA) : Electronics (Cleaning + Servicing)Document2 pagesJob Safety Analysis (JSA) : Electronics (Cleaning + Servicing)Nishad MuhammedNo ratings yet

- 31.HIRA - Boom Placer OperationDocument3 pages31.HIRA - Boom Placer OperationMMRDACA07 SAFETYNo ratings yet

- RA-Installation of GRP Pipe CulvertsDocument6 pagesRA-Installation of GRP Pipe CulvertsArsh NazarNo ratings yet

- Ra ChsDocument12 pagesRa ChsResearcherNo ratings yet

- RA - For Precast ChambersDocument5 pagesRA - For Precast ChambersKallem RajashekarNo ratings yet

- HVAC Risk AssessmentDocument6 pagesHVAC Risk AssessmentpragyaadanaNo ratings yet

- Risk Assesment For GRP Pipe LayingDocument3 pagesRisk Assesment For GRP Pipe LayingSasi Kumar60% (5)

- ExcavationDocument73 pagesExcavationZien Mahmoud Ahmad0% (1)

- Qrc-Ra-001-00-Road and Footpath Modification WorksDocument27 pagesQrc-Ra-001-00-Road and Footpath Modification WorksKallem RajashekarNo ratings yet

- Hira For DemolitionDocument3 pagesHira For DemolitionMokka SamaiyalNo ratings yet

- SFSDFSDDocument8 pagesSFSDFSDali shahNo ratings yet

- JSA Format NEW Equipment ErectionDocument5 pagesJSA Format NEW Equipment Erectionsakthi venkatNo ratings yet

- Core Drilling Saw Cutting Concrete or Asphalt (Wet Method)Document2 pagesCore Drilling Saw Cutting Concrete or Asphalt (Wet Method)rajesh kumar100% (2)

- Risk Assesment For KerbstonesDocument11 pagesRisk Assesment For KerbstonesZain butt67% (3)

- Risk Assessment For Installation of A New AC UnitDocument9 pagesRisk Assessment For Installation of A New AC Unitservice.amepNo ratings yet

- JSA 03 Gate Entrance Traffic ProposalDocument10 pagesJSA 03 Gate Entrance Traffic Proposalrahul tkNo ratings yet

- JSA - Anti Termite Treatment WorkDocument5 pagesJSA - Anti Termite Treatment WorkRaju Khalifa67% (3)

- Risk Assesment For Connecting The Existing Pipe To Pump StationDocument4 pagesRisk Assesment For Connecting The Existing Pipe To Pump StationSasi Kumar100% (2)

- TRA of Ladder & PlatformDocument2 pagesTRA of Ladder & PlatformASIF MUZAFFARNo ratings yet

- HSE-F-NEOM-014 - General Risk AssessmentDocument32 pagesHSE-F-NEOM-014 - General Risk AssessmentAhmed Mohamed100% (1)

- Job Hazard Analysis (JHA) Worksheet: Jerp # 3, Aromatics Unit CompanyDocument9 pagesJob Hazard Analysis (JHA) Worksheet: Jerp # 3, Aromatics Unit CompanyTeodoro Esquillo100% (1)

- HIRA 013 Working Over Water.Document2 pagesHIRA 013 Working Over Water.srinibas mohapatra100% (1)

- 03 Jha For Cable Laying Cable Glanding and Terminationdocx - CompressDocument16 pages03 Jha For Cable Laying Cable Glanding and Terminationdocx - CompressSavio SunnyNo ratings yet

- RA for Lifting & Installation of Ladder and PlatformDocument2 pagesRA for Lifting & Installation of Ladder and Platformferoz khanNo ratings yet

- Job Safety & Environmental Analysis WorksheetDocument2 pagesJob Safety & Environmental Analysis WorksheetCherry BetonioNo ratings yet

- RA 02 - Earth WorkDocument38 pagesRA 02 - Earth WorkAnonymous kWfNFb100% (2)

- JSA Format Internal ReactorDocument13 pagesJSA Format Internal Reactorsakthi venkatNo ratings yet

- JSA Format Erection of Exchanger 903-E-04Document6 pagesJSA Format Erection of Exchanger 903-E-04sakthi venkatNo ratings yet

- Marafiq Risk Assessment 02Document5 pagesMarafiq Risk Assessment 02Arshad Mahmood50% (2)

- JSA Format Erection of Column 903-C-02,03Document5 pagesJSA Format Erection of Column 903-C-02,03sakthi venkat100% (1)

- HF 4 - Maintenance CraneDocument2 pagesHF 4 - Maintenance CraneJohn MelvinNo ratings yet

- Risk Assessment For 4600002029Document213 pagesRisk Assessment For 4600002029Ows Anish67% (3)

- Risk Assessment For Installation of Diesel Generator111111Document8 pagesRisk Assessment For Installation of Diesel Generator111111Baher Mohamed100% (1)

- Risk Assessement For AAES ProductsDocument4 pagesRisk Assessement For AAES ProductsAzhar Shaikh100% (1)

- 12.hse - Risk AssessmentDocument9 pages12.hse - Risk Assessmentsandeep reshmaNo ratings yet

- Brosur Paloma 2022Document46 pagesBrosur Paloma 2022Asri Eka PutraNo ratings yet

- Organic Termite Killer As Replacement To Chemical InsecticidesDocument13 pagesOrganic Termite Killer As Replacement To Chemical InsecticidesROSELYN RAMOSNo ratings yet

- (Download PDF) The Monstrous Feminine in Contemporary Japanese Popular Culture Raechel Dumas Online Ebook All Chapter PDFDocument42 pages(Download PDF) The Monstrous Feminine in Contemporary Japanese Popular Culture Raechel Dumas Online Ebook All Chapter PDFdavid.messer693100% (15)

- Membrane Based SeparationDocument2 pagesMembrane Based SeparationRitika RawatNo ratings yet

- LCS-HAS-09 Halal Risk Management PlanDocument1 pageLCS-HAS-09 Halal Risk Management Planwaihong93No ratings yet

- Pelaporan IKP Puskesmas Arjaty Daud 2022Document16 pagesPelaporan IKP Puskesmas Arjaty Daud 2022Fajar Slalu CeriaNo ratings yet

- Epojet 270Document4 pagesEpojet 270Yudi KurniawanNo ratings yet

- Choosing The Right Surgical Glove An Overview and UpdateDocument5 pagesChoosing The Right Surgical Glove An Overview and UpdateAdel AdielaNo ratings yet

- Liquid FormsDocument29 pagesLiquid Formsaman jainNo ratings yet

- Oxygenation: Nursing Fundamentals Focus ViiiDocument72 pagesOxygenation: Nursing Fundamentals Focus Viiiጀኔራል አሳምነው ፅጌ100% (1)

- Rish Split Current TransformerDocument6 pagesRish Split Current TransformerluisNo ratings yet

- Satip-A-000-01 Rev 8 Soil Improvement (Vibro Replacement - Vibro Compaction FinalDocument2 pagesSatip-A-000-01 Rev 8 Soil Improvement (Vibro Replacement - Vibro Compaction FinalTarek YehiaNo ratings yet

- 5-x Exam 5-Study Guide-Urinary SystemDocument9 pages5-x Exam 5-Study Guide-Urinary SystemAllison GajadharNo ratings yet

- 1.1 Conveyor PulleysDocument34 pages1.1 Conveyor Pulleysrrobles011No ratings yet

- Terapi Keluarga StrategikDocument18 pagesTerapi Keluarga StrategikNurulArifahNo ratings yet

- Starcraft - (2000) Revelations - Michy Neilson PDFDocument12 pagesStarcraft - (2000) Revelations - Michy Neilson PDFHawk RangerNo ratings yet

- Garments Workers in BangladeshDocument4 pagesGarments Workers in BangladeshtasnianasirNo ratings yet

- ToxicologyDocument197 pagesToxicologyRichelle Dianne Ramos-Giang100% (6)

- P-Channel 30-V (D-S) MOSFET: Features Product SummaryDocument9 pagesP-Channel 30-V (D-S) MOSFET: Features Product SummarySantiago Luis GomezNo ratings yet

- Kiln Inlet Analyzer.: CalibrationDocument3 pagesKiln Inlet Analyzer.: CalibrationZakariya ChoudharyNo ratings yet

- Chemistry ProjectDocument22 pagesChemistry ProjectkishoreNo ratings yet

- Susan Sugarman - Freud's Interpretation of Dreams - A Reappraisal-Cambridge University Press (2022)Document195 pagesSusan Sugarman - Freud's Interpretation of Dreams - A Reappraisal-Cambridge University Press (2022)Rodolfo Ferronatto De SouzaNo ratings yet

- TR1 G-Build Technical Data SheetDocument2 pagesTR1 G-Build Technical Data SheetHernan B.No ratings yet

- Call For Applications For PHD in Midwifery September 2023 Intake 6.6.23Document3 pagesCall For Applications For PHD in Midwifery September 2023 Intake 6.6.23EvansNo ratings yet

- Tahun 2021Document7 pagesTahun 2021Dina Pratya NiayNo ratings yet

- Emergency Preparedness For Severe WeatherDocument2 pagesEmergency Preparedness For Severe WeatherRandy PedrozaNo ratings yet

- Moonbase Blues BW v1Document2 pagesMoonbase Blues BW v1Станіслав Польськой100% (3)

- Interpretation of The Maha Dasha of KetuDocument25 pagesInterpretation of The Maha Dasha of Ketuktpadmanabhan9202100% (1)