Professional Documents

Culture Documents

Jarring Operation by Weatherford

Jarring Operation by Weatherford

Uploaded by

GordonOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Jarring Operation by Weatherford

Jarring Operation by Weatherford

Uploaded by

GordonCopyright:

Available Formats

Fishing Best Practices Manual

Jarring Operations

REV. # DATE REVISIONS PREPARED CHECKED APPROVED

2001 Weatherford. All Rights Reserved.

October 18, 2000 Page 8-1

Contents

Introduction........................................................................................................................8-3

Bumper Jars (Mechanical and Lubricated) ...........................................................................8-3

Bumper Sub Operation....................................................................................................8-4

Hydraulic Up Stoke Jars .....................................................................................................8-4

Hydraulic Up Jar Operation.............................................................................................8-5

Mechanical Up Jar Operation..............................................................................................8-6

Accelerator Jars.................................................................................................................8-6

Hydro-Mechanical Dual Acting Jars ....................................................................................8-7

Additional Jarring Procedures..............................................................................................8-8

Jar Failure..........................................................................................................................8-9

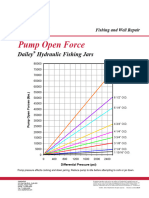

Pump Open Force...........................................................................................................8-9

Notes:..............................................................................................................................8-10

List of Figures

Figure 8-1: Hydraulic Jar Operation, 1 of 2 ................................................................................8-5

Figure 8-2: Hydraulic Jar Operation, 2 of 2 ................................................................................8-5

2001 Weatherford. All Rights Reserved.

Page 8-2 October 18, 2000

Introduction

Jars are used to release most stuck tool strings. They are available in a wide range of

sizes. Jars are normally full opening allowing fluid circulation and wireline tools such

as a free point tool or back off string shot to pass through them. Jars are run above

any tool that may stick or any tools that may require a bump down on to effect

release of a grappling device. They are capable of delivering an immediate high

impact blow in either direction, which enhances the chances of release. Jars work by

delaying the tripping action until the fishing string has stretched storing energy. The

energy is released when the jar trips or fires. The force of the jarring blow is

influenced by many of the following factors:

• Length of the jar stroke

• Hole friction

• Number of weight members above the jar [the hammer]

• The amount of stretch in the drill string

• The amount of overpull exerted prior to the jar tripping

• The upward movement speed of the hammer

CAUTION: Always get permission from the Company Man before any jarring operation is

started if there is a top drive on the rig. Jarring can damage the top drive.

• Jar Accelerator/Intensifier

• Jarring work string

Bumper Jars (Mechanical and Lubricated)

Bumper jars deliver a sharp downward blow to free a fish whenever needed. There

are two types of bumper jars the mechanical bumper sub, which is nothing more

than a slack joint, and the lubricated bumper sub. If pump pressure greater then

500 psi is expected, the lubricated bumper jar should be used because it is in a

closed housing protected by seal rings. When very high temperatures are expected,

the mechanical bumper sub should be used. High temperatures may destroy the

seals in the lubricated bumper jar. Splines built into the jar prevent internal rotation,

therefore high torque can be transmitted through the jar to effect release. Uses for

bumper subs include the following:

• Aid in the release of grappling tools (overshot or spears)

• Jar down on a fish to free it

2001 Weatherford. All Rights Reserved.

October 18, 2000 Page 8-3

• To provide a means to move the work string approximately 18 inches if the

string is attached to a stuck fish.

• Help to get over the top of a fish.

• Apply a predetermined amount of weight to tools such as internal mechanical

cutters.

• To swage out collapsed casing.

• To run above a marine swivel to compensate for rig movement on floating rigs.

Some uses for lubricated bumper subs are as follows:

• Use a lubricated bumper sub instead of a mechanical bumper sub.

• More sealing elements, not as likely to wash out.

• In hot holes, a mechanical bumper sub is used, the heat will damage the packing

in lubricated ones.

Bumper Sub Operation

To operate a mechanical or lubricated bumper sub perform the following steps:

1. Close the jar mandrel and mark the pipe for reference.

2. Pick up on the string until the mandrel is fully extended. This is determined when

the weight indicator shows the free travel as the bumper sub is opening and then

a rapid gain is noted on the weight indicator when the mandrel is fully extended.

3. Drop the string as fast as possible and stop abruptly a few inches above the

referenced mark. The elasticity of the string, plus the law of inertia, will cause

the bumper sub to move downward rapidly, delivering a sharp blow to the fish.

Note: This procedure requires a little practice and finesse.

Hydraulic Up Stoke Jars

There are two basic types of jars, mechanical and hydraulic.The terms mechanical

and hydraulic refer to the method of tripping the jar. Hydraulic jars use hydraulic fluid

to delay tripping the jar.

Tripping is delayed until a sufficient pull-load (stretch) is applied overcoming the

trapped oil in the jar. The jar then trips applying a high impact blow to the fish. When

overpull is applied to the jar, the time delay is provided by hydraulic fluid being forced

through a series of small jets (Figure 8-1). As the hydraulic oil is metered through the

jets, the piston is slowly moving upward until it reaches an enlarged fluid bypass. This

allows a rapid release of the fluid and the jar fires (Figure 8-2). The jar firing delay is

2001 Weatherford. All Rights Reserved.

Page 8-4 October 18, 2000

determined by a combination of load applied and time. Do not exceed the

manufacturers recommended maximum jarring load and do not exceed the tensile

strength of the fishing tools or work string.

Note: A computer program is required to precisely determine optimum jar

placement in deviated holes.

Large Bore Area Pressure Housing

Hydraulic

Fluid Pressure

Piston

Inner

Mandrel

Figure 8-1: Hydraulic Jar Operation, 1 of 2

Large Bore Area Pressure Housing

Pressure

Piston

Inner

Mandrel

Figure 8-2: Hydraulic Jar Operation, 2 of 2

Hydraulic Up Jar Operation

To operate a hydraulic up stoke jar perform the following steps:

1. Close the jar mandrel and mark the pipe for reference.

2. Pick up 20,000 lbs. over pull and let the jars bleed open.

2001 Weatherford. All Rights Reserved.

October 18, 2000 Page 8-5

3. Take a significant over pull and mark the pipe for reference.

4. Close the jar mandrel again (the previous mark should be at the rotary).

5. Pull up approximately 1/2 of the jar manufacturers maximum jarring load and wait

for the jar to fire.

6. Slack off slowly (this saves the seal integrity) to cock the jars.

7. Check to see if any progress has been made by the position of the referenced

mark on the pipe.

8. Continue jarring, while raising the overpull in 10,000 lb. increments every 15-

minutes until the maximum jarring load is reached.

9. Continue jarring at the maximum jar capacity until the fish is freed, the jars wear

or a decision is made to do something else because of a lack of progress.

Mechanical Up Jar Operation

Mechanical jars have a preset load setting that causes the jar to trip. They are

sensitive to load only and not time. One must pull the preset load before the

mechanical jar will trip. Since hole friction can account for up to a 50% loss in the

pull, mechanical jars are not recommended in holes with an angle greater than 30

degrees. In cases where two jars are run, the mechanical jar would be the upper jar.

To operate a mechanical up stroke jar perform the following steps:

1. Close the jar mandrel and mark the pipe for reference.

2. Pick up on the string until the predetermined load is achieved. The jar will then

fire.

3. Remember, the mechanical jar is fired only by pulling the correct over pull.

4. Time has nothing to do with it.

Note: Jarring should start in the opposite direction to that which got the string

stuck.

Accelerator Jars

Accelerator jars are know as accelerator, intensifier, booster and slinger jars. This

manual uses the term accelerator jars. The accelerator consists of an outer barrel

and an inner mandrel. The inner mandrel slides in and out of the outer barrel. The

two are connected by an interference fit between a piston chamber on the outer

barrel and a piston in the inner mandrel. The piston chamber contains a solid, a fluid

or a gas that acts as a spring. When a force is applied to the accelerator, the tool

opens. The extension is dependent upon the applied force. When the extended force

2001 Weatherford. All Rights Reserved.

Page 8-6 October 18, 2000

is released (the hydraulic jar fires) the tool closes under the spring force of the

substance inside the piston chamber. The following are some of the uses for the

accelerator jar:

• Intensify the jar blow

• Compensate for the lack of stretch in a short workstring

• Compensate for slow contraction of the drill string caused by high side-wall

friction.

• Act as a reflector to the shock wave traveling up the workstring protecting the

surface equipment and work string.

Hydro-Mechanical Dual Acting Jars

The Bowen hydro-mechanical drilling jar is a dual acting combination tool. The

hydraulic mechanism is used only during up jar operation. The down jar is a friction

mechanical system. The metering action of the hydraulic mechanism is controlled by

ports on an insert within a piston. This configuration differs from other types, such as

the Dailey Jars.

The Dailey hydraulic jar consists of an inner mandrel and an outer mandrel. The

inner mandrel has two pistons that seal on the outer mandrel. Between the two

2001 Weatherford. All Rights Reserved.

October 18, 2000 Page 8-7

Additional Jarring Procedures

The correct use of jars and the correct application of jarring is critical to freeing stuck

pipe.

the natural instinct of a driller is to jar up if the string becomes stuck when pulling out

of the hole. If the string is packed off above a stabilizer, jarring up may make the

situation worse by compacting the pack-off.

One reason for the jars not firing is miscalculating the required pull at the surface to

fire the jars. All jars have a firing force window for each direction that they fire in.

A dual acting jar (one that can fire up or down) will have an up jar force and a down

jar force envelope. The firing force envelope consists of two forces, one to cock the

jar and one to fire the jar. A dual acting jar will therefor have two force envelopes,

one for up jarring and one for down jarring. The jar envelope forces must be

considered at the jar and at the surface. The jar firing force at the jar is known. It is

the drillers job to determine the required firing force at the surface.

For example, a compression force of 5,000 pounds is required to cock the jar

in order to fire up. This is to overcome internal friction. Once cocked, the jar

will fire when the force at the jar reaches the predetermined firing load, lets say

90,000 pounds. This is for a mechanical jar. To fire down at a predetermined

load of 20,000 pounds, 5,000 pounds must be applied to overcome internal

friction, plus another 20,000 to fire the jar. The fixed limits of 90,000 and

20,000 are typical of mechanical jars.

A hydraulic jar will fire as long as the jar's internal friction is exceeded. The time

required to fire is inversely proportional to the force applied; the greater the force, the

shorter the waiting time. We have only considered the forces at the jar so far. Only

the driller knows the force at the surface and must estimate the force at the jar.

It is usually easy to see on the weight indicator when the jars are opening or closing.

The measured weight indicator needle will stop moving for a few seconds while the

string is still being moved up or down. This is a good indicator that the axial neutral

point at the jar has been reached. This is often observed while drilling vertical wells,

but can be difficult to observe in highly deviated, extended reach or horizontal wells.

If this neutral weight is observed on the weight indicator, it is easy to determine

surface jarring forces. The measured weight at which the neutral point is observed is

recorded. The up trip force (mechanical only) is added to this value along with any up

drag.

When stuck, any pull on the string results in an increase in drag over and above the

normal up drag. The full amount of overpull at the surface will not reach the jar. In

deviated wells this must be compensated for by additional overpull. If the pumps are

running, then the pump open force must also be subtracted from the firing force if

jarring up, and added to the set down weight to cock the jars. The pump open force

2001 Weatherford. All Rights Reserved.

Page 8-8 October 18, 2000

charts are found in the manual for the jar being used. The down trip force

(mechanical only), the down drag, and the pump open force are subtracted from the

neutral point reading.

Jar Failure

Jars thought to have failed in the field frequently test successfully in the shop. The

reason for this appears to be the inability to fire the jars, often in the down direction.

An estimation of the force required to fire the jars is not always performed correctly.

This section explains why jars fail and how to use the correct surface pull to fire the

jars. Common reasons for jar failure include the following:

• Incorrect weight applied to fire the jar, assumptions in calculations incorrect.

• Pump open force exceeds compression force at the jar (no down jar action)].

• The string is stuck above the jar

• The jar mechanism failed

• The jar was not cocked

• Hole drag is high enough to prevent sufficient force to be applied at the jar to fire

it (usually mechanical jars).

• The well path prevents compression being applied to the jar (no down jar action).

• The jar is firing but cannot be felt at the surface.

• Right hand torque is trapped in torque set mechanical jars.

• Not waiting long enough for the jar to fire.

Pump Open Force

The jar pump open force (also called the jar extension force) is the effect of the

difference in surface areas of the jar exposed to pressures on the outside and inside

of the jar. When a differential pressure exists, it causes a force that opens the jar.

The effect on jarring can be considerable, if for example 2,000 psi is trapped inside

the jar when the string is packed off below the jar the pump open force acts to:

• Assist in firing the jar up.

• Assist cocking the jar after firing down.

• Oppose firing the jar down.

• Oppose cocking the jar after firing up.

2001 Weatherford. All Rights Reserved.

October 18, 2000 Page 8-9

Notes:

2001 Weatherford. All Rights Reserved.

Page 8-10 October 18, 2000

You might also like

- Drilling Operations Manual Combined - V5Feb2015' PDFDocument498 pagesDrilling Operations Manual Combined - V5Feb2015' PDFBadinescu Sergiu-Cristian100% (3)

- DrillScan Catalog TrainingDocument10 pagesDrillScan Catalog TrainingMehdi Mehdi0% (1)

- Stuckpipe Course by IPM Schlumberger PDFDocument23 pagesStuckpipe Course by IPM Schlumberger PDFddiazveNo ratings yet

- Milling in Drilling Operations Guidelines For Oil &Document7 pagesMilling in Drilling Operations Guidelines For Oil &AboZaidNo ratings yet

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Bowen External CuttersDocument12 pagesBowen External Cuttersdedy H50% (2)

- Circulation Junk Baskets ManualDocument22 pagesCirculation Junk Baskets ManualAnonymous R4VU5fxINo ratings yet

- Petro Bowl Example QuestionsDocument6 pagesPetro Bowl Example QuestionsAndre Atanova100% (4)

- Drilling Jar Manual PDFDocument33 pagesDrilling Jar Manual PDFsmithyry2014No ratings yet

- D430 Z Type Hydraulic Fishing Jars ManualDocument38 pagesD430 Z Type Hydraulic Fishing Jars Manualnjava1978No ratings yet

- Section 5 - Milling Tools & Washover EquipDocument22 pagesSection 5 - Milling Tools & Washover EquipMichèle SpiteriNo ratings yet

- Casing Cutting Procedure - WFDDocument5 pagesCasing Cutting Procedure - WFDprateek132106No ratings yet

- RTTS Packer: Technical Data SheetDocument5 pagesRTTS Packer: Technical Data SheetHamid Reza Babaei100% (1)

- PeroforacionDocument35 pagesPeroforacionDaniel DelgadoNo ratings yet

- 08 Well Control in Cased HoleDocument42 pages08 Well Control in Cased HoleYoucef LiasNo ratings yet

- Plug Setting Tool and Junk Basket: Purpose of The ServiceDocument15 pagesPlug Setting Tool and Junk Basket: Purpose of The Servicerobin2806No ratings yet

- Fishing ToolsDocument10 pagesFishing Toolsdanarkurniadi123No ratings yet

- BOP TrainingDocument83 pagesBOP TrainingMiguel Angel Marenco MonteroNo ratings yet

- Fishing Tools: Tubular, Drilling and Worover ToolsDocument16 pagesFishing Tools: Tubular, Drilling and Worover ToolsAchraf Ben DhifallahNo ratings yet

- Fishing ToolDocument17 pagesFishing ToolKaleem UllahNo ratings yet

- Open Hole FishingDocument89 pagesOpen Hole FishingShiela O100% (1)

- Itcoloy and Milling Tools: Instruction Manual 5100Document12 pagesItcoloy and Milling Tools: Instruction Manual 5100Foros IscNo ratings yet

- Barrier (Well Control) 1Document13 pagesBarrier (Well Control) 1Zahraa AliNo ratings yet

- Bridge Plug-Cement RetainerDocument7 pagesBridge Plug-Cement RetainerhabibimarioNo ratings yet

- Off-Bottom Drilling PracticesDocument3 pagesOff-Bottom Drilling PracticesAdel Ahmed AlkhaligyNo ratings yet

- Liner Procedure 5.5 ExamDocument3 pagesLiner Procedure 5.5 ExamOmar Eduardo Sanchez GodinezNo ratings yet

- Casing Running and Drilling ToolsDocument33 pagesCasing Running and Drilling Toolsfffggg777No ratings yet

- Reverse Circulating Junk BasketDocument7 pagesReverse Circulating Junk BasketLove KumarNo ratings yet

- Lubricate and BleedDocument18 pagesLubricate and BleedRoby Rido100% (2)

- Fishing Tools For 17 and Half Inch HoleDocument2 pagesFishing Tools For 17 and Half Inch Holehamid0% (1)

- LinerhangersystemsDocument33 pagesLinerhangersystemsBrahim LetaiefNo ratings yet

- Bha# 4 Fishing With Spear Assy 1227 Grapple 3032Document1 pageBha# 4 Fishing With Spear Assy 1227 Grapple 3032Ivan Dario Benavides BonillaNo ratings yet

- 00 - Downhole Hydraulic II - UTC VersionDocument44 pages00 - Downhole Hydraulic II - UTC VersionaungwinnaingNo ratings yet

- Fishing: - What Is There? - Recovery - Free Point and Back-OffDocument139 pagesFishing: - What Is There? - Recovery - Free Point and Back-OffandrewNo ratings yet

- Kicks IndicatorsDocument17 pagesKicks IndicatorsGhavban DavidNo ratings yet

- Wireline Operations Techniques: Approach Into Slick, Braided & Electrical Line Equipment, Tools & ApplicationsDocument4 pagesWireline Operations Techniques: Approach Into Slick, Braided & Electrical Line Equipment, Tools & ApplicationsJerome LIKIBINo ratings yet

- Taper Taps: Engaging The FishDocument2 pagesTaper Taps: Engaging The Fishderick davidNo ratings yet

- External Cutter PDFDocument16 pagesExternal Cutter PDFnasr yassinNo ratings yet

- Fishing Techniques For Drilling Operations2Document14 pagesFishing Techniques For Drilling Operations2Rosalie EdwardsNo ratings yet

- 03 OJT SlicklineDocument57 pages03 OJT SlicklineIbnu KostNo ratings yet

- RemedialTDH PDFDocument297 pagesRemedialTDH PDFAnonymous UrqcGy3No ratings yet

- 30575.fishing Services CatalogDocument180 pages30575.fishing Services CatalogACD100% (1)

- A120 Series 70 150 Overshot ManualDocument48 pagesA120 Series 70 150 Overshot ManualHamdi SaidNo ratings yet

- FR ToolsSrvs CTLG WIS-BR-MKT-002 r3 Web PDFDocument40 pagesFR ToolsSrvs CTLG WIS-BR-MKT-002 r3 Web PDFIvan Dario Benavides BonillaNo ratings yet

- Hydraulics Theory PDFDocument23 pagesHydraulics Theory PDFAhmed Ali Alsubaih100% (1)

- OKC Millhead ModificationDocument22 pagesOKC Millhead ModificationRazvan RaduNo ratings yet

- PDC Drilling ProceduresDocument8 pagesPDC Drilling ProceduresJosue FishNo ratings yet

- Pressure Rating For SSII Float EquipmentDocument2 pagesPressure Rating For SSII Float EquipmentMahmoud Ahmed Ali AbdelrazikNo ratings yet

- Drilltech Services (USA) Inc: Spiro-TorqDocument10 pagesDrilltech Services (USA) Inc: Spiro-TorqDante Cabrera GuzmanNo ratings yet

- Fishing Tools ListDocument6 pagesFishing Tools Listกัญญารัตน์ พูลทองNo ratings yet

- DrawingsDocument8 pagesDrawingsjesus77777777777No ratings yet

- Releasing & Circulating OvershotDocument16 pagesReleasing & Circulating OvershotPrime Energy Warehouse-YemenNo ratings yet

- Fishing Techniques For Drilling OperationsDocument14 pagesFishing Techniques For Drilling OperationsJuan Lozano ArevaloNo ratings yet

- Drilling Day 3 Valve Wireline Bop Manual Hydraulic Slick Line and Multi StrandDocument132 pagesDrilling Day 3 Valve Wireline Bop Manual Hydraulic Slick Line and Multi Strandhosam aliNo ratings yet

- BHA Tally: Customer: Well Name: Job Number: Drillstring IADC Rig BHA# 0100 Run# 100Document2 pagesBHA Tally: Customer: Well Name: Job Number: Drillstring IADC Rig BHA# 0100 Run# 100Animesh ChoudharyNo ratings yet

- Fishing Tools For 8 and Half HoleDocument1 pageFishing Tools For 8 and Half HolehamidNo ratings yet

- Posiset Ds PDFDocument2 pagesPosiset Ds PDFariosabzNo ratings yet

- Drilling LineDocument41 pagesDrilling LineAboZaidNo ratings yet

- Completion Fluid 2Document45 pagesCompletion Fluid 2Waled Fekry100% (2)

- Measurement While Drilling: Signal Analysis, Optimization and DesignFrom EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignNo ratings yet

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsFrom EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsNo ratings yet

- Azimuthal Resisitivity ImagerDocument1 pageAzimuthal Resisitivity ImagerGordonNo ratings yet

- JaringDocument7 pagesJaringGordonNo ratings yet

- GriffithForce Jar Technical SummaryDocument1 pageGriffithForce Jar Technical SummaryGordonNo ratings yet

- Resisitivity of NaCL Water SolutionsDocument1 pageResisitivity of NaCL Water SolutionsGordonNo ratings yet

- Resisitivity of NaCL Water SolutionsDocument1 pageResisitivity of NaCL Water SolutionsGordonNo ratings yet

- Gas Effect On Compressional SlownessDocument1 pageGas Effect On Compressional SlownessGordonNo ratings yet

- Weatherford Dailey Hydraulic Fishing Jars Pump Open ForceDocument1 pageWeatherford Dailey Hydraulic Fishing Jars Pump Open ForceGordonNo ratings yet

- CGE416 - Chap6 - Drilling Engineering and Well CompletionDocument109 pagesCGE416 - Chap6 - Drilling Engineering and Well CompletionHumaira Mirza50% (2)

- 5A - Horizontal Well Application N PlanningDocument203 pages5A - Horizontal Well Application N PlanningAlex CadareNo ratings yet

- EP046 - Jar Operational Manual - 6Document8 pagesEP046 - Jar Operational Manual - 6bigpimpinmo80100% (1)

- Bottom Hole Assembly (BHA) Design For Directional Control-1Document7 pagesBottom Hole Assembly (BHA) Design For Directional Control-1Freddy EtapaNo ratings yet

- Jet LubeDocument20 pagesJet LubeAkimBiNo ratings yet

- 9852 1319 44 COP 44 Instructions and Part ListDocument72 pages9852 1319 44 COP 44 Instructions and Part ListCesar GutierrezNo ratings yet

- JarsDocument36 pagesJarsRajat Khanna100% (4)

- Drilling Products and Solutions CatalogDocument141 pagesDrilling Products and Solutions CatalogAlex Boz100% (1)

- Performance Comparison Analysis Between RSS and Conventional Mud Motor in Mavvar FieldDocument5 pagesPerformance Comparison Analysis Between RSS and Conventional Mud Motor in Mavvar FieldM. Fadhli Cesar KNo ratings yet

- Soft Torque-ZDocument2 pagesSoft Torque-ZGuilherme FerrariNo ratings yet

- Analysis of An Annular Pressure Buildup Failure During Drill AheadDocument6 pagesAnalysis of An Annular Pressure Buildup Failure During Drill AheadJulian OlarteNo ratings yet

- Hydraulics - Summary: Including Cutting Weight & Tool JointDocument17 pagesHydraulics - Summary: Including Cutting Weight & Tool Jointmsu6383No ratings yet

- Top DriveDocument6 pagesTop DriveRenny Gracezifa BandasoNo ratings yet

- DrillingDocument37 pagesDrillingDiana La CruzNo ratings yet

- SLBSmith Services JarpresentationxDocument88 pagesSLBSmith Services JarpresentationxShiela ONo ratings yet

- Hydra Jar ManualDocument43 pagesHydra Jar ManualKarim IsmailNo ratings yet

- 6-Drill String Components PDFDocument29 pages6-Drill String Components PDFYè Paing OoNo ratings yet

- Stuck PipeDocument42 pagesStuck PipeDaniel Anzola Camargo100% (1)

- IADC/SPE 101795 Theory and Application of Buoyancy in Wells: F PzdxdyDocument10 pagesIADC/SPE 101795 Theory and Application of Buoyancy in Wells: F PzdxdyVíctor CarvallidoNo ratings yet

- QY Full Hydraulic Drilling JarDocument7 pagesQY Full Hydraulic Drilling Jarsaeed65No ratings yet

- Oxy Limiters Ryan Davis 10K Forum PresentationDocument25 pagesOxy Limiters Ryan Davis 10K Forum PresentationJorgito AriasNo ratings yet

- Drillstring Hardbanding: Arcraft Plasma IndiaDocument10 pagesDrillstring Hardbanding: Arcraft Plasma Indiapavi32No ratings yet

- Tubular Mechanics in Oil-Gas WellsDocument79 pagesTubular Mechanics in Oil-Gas WellsSherif Fathy100% (1)

- Stuck Pipe PDFDocument27 pagesStuck Pipe PDFduncmcleod100% (1)

- NOV - Motores - PDM TrainingDocument50 pagesNOV - Motores - PDM TrainingJuan Camilo Muñoz Carmona100% (1)

- Wellbore Sidetracking GuidelinesDocument4 pagesWellbore Sidetracking Guidelinesmadonnite3781No ratings yet