Professional Documents

Culture Documents

21 Series Preventive List 2022 09 01 1

21 Series Preventive List 2022 09 01 1

Uploaded by

Ton marquesCopyright:

Available Formats

You might also like

- MG ZS UK Maintenance Check Sheet V1.03 PDFDocument2 pagesMG ZS UK Maintenance Check Sheet V1.03 PDFyogapost100% (1)

- A Course in Power Plant Engineering - S. C. Arora, S. Domkundwar, A. v. DomkundwarDocument286 pagesA Course in Power Plant Engineering - S. C. Arora, S. Domkundwar, A. v. DomkundwarSyed Majeed38% (13)

- Preventive Maintenance For The CARESTREAM DRX-Evolution/ DRX-Evolution PlusDocument62 pagesPreventive Maintenance For The CARESTREAM DRX-Evolution/ DRX-Evolution PlusIzzeldin ZakiNo ratings yet

- Material Specification and Compatibility ChartDocument2 pagesMaterial Specification and Compatibility ChartmasoodmuhidNo ratings yet

- Belt Scale Maintenance ChecklistDocument2 pagesBelt Scale Maintenance ChecklistJohn Eduard CarinoNo ratings yet

- Typical Detail of Friction Slab With Crash Barrier (1) - LayoutDocument1 pageTypical Detail of Friction Slab With Crash Barrier (1) - LayoutAditya ChauhanNo ratings yet

- Che341 Examples BatchrDocument9 pagesChe341 Examples BatchrAybike TaşdemirNo ratings yet

- AOT-MD-500 gERADOR OZONIO USA PDFDocument8 pagesAOT-MD-500 gERADOR OZONIO USA PDFaninNo ratings yet

- BS en 837-3-98Document26 pagesBS en 837-3-98Pablo DM100% (1)

- Partsbook Lube Truck R60814 PDFDocument93 pagesPartsbook Lube Truck R60814 PDFagn75% (4)

- Maintenance InstructionsDocument3 pagesMaintenance InstructionsNavnath GawasNo ratings yet

- Service Instructions For Vst-Se: 11.3 Inspection & Maintenance ScheduleDocument1 pageService Instructions For Vst-Se: 11.3 Inspection & Maintenance ScheduleAhmadNo ratings yet

- MVPS21CPXT WP en 11 PDFDocument9 pagesMVPS21CPXT WP en 11 PDFOusseni SawadogoNo ratings yet

- Stručni Test Engleskog JezikaDocument3 pagesStručni Test Engleskog JezikadjukalNo ratings yet

- Top Drive Maintenance Plan20210925Document4 pagesTop Drive Maintenance Plan20210925Franklin Silva100% (1)

- Crane Inspection LOG: MaintainerDocument27 pagesCrane Inspection LOG: MaintainerRodolfo CastroNo ratings yet

- K500 Service Manual PDFDocument27 pagesK500 Service Manual PDFMichaelNo ratings yet

- Maintenance Check List of HydraulicDocument7 pagesMaintenance Check List of HydraulicShubham SinghNo ratings yet

- Accessories Preventive Maintenance ChecklistDocument1 pageAccessories Preventive Maintenance ChecklisttmamputsiNo ratings yet

- Operation Check List / Start-Up Report: Axijet High Plume Exhaust SystemDocument2 pagesOperation Check List / Start-Up Report: Axijet High Plume Exhaust SystemZainul Abedin SayedNo ratings yet

- Industrial Safety ChecklistDocument1 pageIndustrial Safety ChecklistluigiNo ratings yet

- Microsoft Word - Tire Handler Owners Manual PDFDocument195 pagesMicrosoft Word - Tire Handler Owners Manual PDFPlanificador MantencionNo ratings yet

- Chemical CleaningDocument3 pagesChemical Cleaningmaxterminator555No ratings yet

- Check List de Brazo ArticuladoDocument6 pagesCheck List de Brazo ArticuladoJaime SuaNo ratings yet

- Maintenance Schedule For Water Distribution Systems: Description Comments Maintenance FrequencyDocument1 pageMaintenance Schedule For Water Distribution Systems: Description Comments Maintenance FrequencyGaurav JhaNo ratings yet

- Overhead Crane Safety and Inspection RequirementsDocument69 pagesOverhead Crane Safety and Inspection RequirementsAhmed ReguiegNo ratings yet

- Snorkel Maintenimiento TB80 TB 86JDocument22 pagesSnorkel Maintenimiento TB80 TB 86Jcesar alejandro scavoNo ratings yet

- Machine Maintenance.: General Workshop ProceduresDocument23 pagesMachine Maintenance.: General Workshop Proceduresvld7rpmNo ratings yet

- Ewp Annual or Third Party Inspection ChecklistDocument5 pagesEwp Annual or Third Party Inspection ChecklistScott BoogemansNo ratings yet

- Manrider Manual MODEL # FA150KGIMR12AIH-CEDocument16 pagesManrider Manual MODEL # FA150KGIMR12AIH-CESamuel Perez0% (1)

- Comprehensive Guide To Hydraulic Hose Inspection TestingDocument21 pagesComprehensive Guide To Hydraulic Hose Inspection TestingasmahemmanuelprincetonNo ratings yet

- Hydraulic System Initial Start-Up and MaintenanceDocument4 pagesHydraulic System Initial Start-Up and MaintenanceLuisNo ratings yet

- HG Hydraulic Valves Cut-Sheet WebDocument2 pagesHG Hydraulic Valves Cut-Sheet WebgrantNo ratings yet

- 1w Mech Mob Crane-Hyd Insp. Maint. 15tonDocument18 pages1w Mech Mob Crane-Hyd Insp. Maint. 15tonebonilla88No ratings yet

- Irrigator Preseason Check ListsDocument10 pagesIrrigator Preseason Check ListsriyazNo ratings yet

- Article Should Crane InspDocument2 pagesArticle Should Crane Inspsenioor2004No ratings yet

- Manual Barredora CONEQTEC LPB1500Document29 pagesManual Barredora CONEQTEC LPB1500El AlemanNo ratings yet

- Bison RHTDocument60 pagesBison RHTLuis Enrique PeñaNo ratings yet

- Interpretation of Sections of ASME B30.9 Standard: Alloy Steel Chain SlingsDocument2 pagesInterpretation of Sections of ASME B30.9 Standard: Alloy Steel Chain SlingsEdson AlvesNo ratings yet

- Pauta de Mantencion RWE 120Document2 pagesPauta de Mantencion RWE 120Fran PobleteNo ratings yet

- Transformer: Power/TractionDocument9 pagesTransformer: Power/Tractionappy sagarNo ratings yet

- Cartilla Mantenimiento Brazo ArtDocument9 pagesCartilla Mantenimiento Brazo ArtFabian Jara RodriguezNo ratings yet

- Maintenance and Inspection of BTH LiftersDocument8 pagesMaintenance and Inspection of BTH Liftersrpatel12No ratings yet

- Inspection of Cargo GearDocument4 pagesInspection of Cargo Gearmohan parthasarathyNo ratings yet

- 50 200 Cylinder Diesel EngineDocument30 pages50 200 Cylinder Diesel EngineFranklin FernandezNo ratings yet

- The Basics of Rebuilding Machine ToolsDocument8 pagesThe Basics of Rebuilding Machine ToolsSundar Kumar Vasantha Govindarajulu100% (1)

- 05 Mechanical MaintenanceDocument30 pages05 Mechanical MaintenancejanetNo ratings yet

- Mechanical Overhaul Procedures For Hydroelectric Units: Facilities Instructions, Standards, and Techniques Volume 2-7Document58 pagesMechanical Overhaul Procedures For Hydroelectric Units: Facilities Instructions, Standards, and Techniques Volume 2-7anshikas_4100% (1)

- Halliburton: S S7 JO/5//3Document4 pagesHalliburton: S S7 JO/5//3Khalfan Al HabsiNo ratings yet

- Control Valve Selection PDFDocument218 pagesControl Valve Selection PDFSyed Ali100% (2)

- Fcu OjtDocument3 pagesFcu OjtHuzairi SulaimanNo ratings yet

- Genset Preventive MaintenanceDocument6 pagesGenset Preventive MaintenanceSatria PinanditaNo ratings yet

- Sample Check ListDocument2 pagesSample Check ListHarsun HarNo ratings yet

- Pre-Commissioning Check List Form Switchgear-General: October 2019Document3 pagesPre-Commissioning Check List Form Switchgear-General: October 2019xchannel28No ratings yet

- Maintenance of Motor PDFDocument4 pagesMaintenance of Motor PDFBilal AslamNo ratings yet

- HVAC Maintenance Checklist Template SafetyCultureDocument18 pagesHVAC Maintenance Checklist Template SafetyCultureOdyssey Bartolome100% (2)

- Chapter 2 Machine Maintenance.: General Workshop ProceduresDocument22 pagesChapter 2 Machine Maintenance.: General Workshop ProcedureswillifenlonNo ratings yet

- 2020 - MU - HTL - 4014 - 4017 - PLATF - 36a-Light - Mif CHECK LISTDocument4 pages2020 - MU - HTL - 4014 - 4017 - PLATF - 36a-Light - Mif CHECK LISTOsscar HerreraNo ratings yet

- FlowLine Level Switch Sensors Switch-Tek LV20 LV35 LH25 LH29 LH35 ManualDocument14 pagesFlowLine Level Switch Sensors Switch-Tek LV20 LV35 LH25 LH29 LH35 ManualPromagEnviro.comNo ratings yet

- Checklist Mobil Crane PT NusakuraDocument6 pagesChecklist Mobil Crane PT NusakuraArisNo ratings yet

- Interpretation of Sections of ASME B30.9 Standard: Alloy Steel Chain SlingsDocument2 pagesInterpretation of Sections of ASME B30.9 Standard: Alloy Steel Chain Slingsscofiel1No ratings yet

- Preparing A Prover For A Water Draw CalibationsDocument3 pagesPreparing A Prover For A Water Draw CalibationsLeonel NavaNo ratings yet

- Grease Gun Procedure - FinalDocument12 pagesGrease Gun Procedure - Finalch420No ratings yet

- ABL-74T Machine MaintenanceDocument1 pageABL-74T Machine MaintenanceChris McNairNo ratings yet

- I.B.9560 Westinghouse RototrolDocument37 pagesI.B.9560 Westinghouse RototrolTon marquesNo ratings yet

- Waterside Plaza Technical Investigation Report (English Version)Document14 pagesWaterside Plaza Technical Investigation Report (English Version)Ton marquesNo ratings yet

- MFDElevator Accident ReportDocument1 pageMFDElevator Accident ReportTon marquesNo ratings yet

- BVL00000011 - Exhibit IL - 2 - Procedure Mech - LIF - Proc - 001 - Inspection or Testing Document Electric Traction Lifts (February 2017)Document19 pagesBVL00000011 - Exhibit IL - 2 - Procedure Mech - LIF - Proc - 001 - Inspection or Testing Document Electric Traction Lifts (February 2017)Ton marquesNo ratings yet

- In-Depth Investigation of Escalator Riding Accidents in Heavy Capacity MRT StationsDocument10 pagesIn-Depth Investigation of Escalator Riding Accidents in Heavy Capacity MRT StationsTon marquesNo ratings yet

- 01CA009Document7 pages01CA009Ton marquesNo ratings yet

- Reporting Escalator Incidents BCADocument2 pagesReporting Escalator Incidents BCATon marquesNo ratings yet

- DINACELL CÉLULA DE CARGA 1262-04 (En - Web)Document33 pagesDINACELL CÉLULA DE CARGA 1262-04 (En - Web)Ton marquesNo ratings yet

- Analysis of VibroacousticDocument9 pagesAnalysis of VibroacousticTon marquesNo ratings yet

- Ed 5622240Document9 pagesEd 5622240Ton marquesNo ratings yet

- BPMG EMED F1 v1 (Jul2016)Document2 pagesBPMG EMED F1 v1 (Jul2016)Ton marquesNo ratings yet

- RideWatcher EngDocument12 pagesRideWatcher EngTon marquesNo ratings yet

- Siti 2018 IOP Conf. Ser. Earth Environ. Sci. 117 012025Document9 pagesSiti 2018 IOP Conf. Ser. Earth Environ. Sci. 117 012025Ton marquesNo ratings yet

- CoP Le Works With Appendices EngDocument218 pagesCoP Le Works With Appendices EngTon marquesNo ratings yet

- Release LiftEscalator Regulations 080716Document11 pagesRelease LiftEscalator Regulations 080716Ton marquesNo ratings yet

- Modelo InformativoDocument1 pageModelo InformativoTon marquesNo ratings yet

- Safety Information Requiring Immediate Action: Code Oi217Document39 pagesSafety Information Requiring Immediate Action: Code Oi217Lidia PopaNo ratings yet

- Screw Jack: B.I.T., Mesra Engg - Mechanics LabDocument5 pagesScrew Jack: B.I.T., Mesra Engg - Mechanics LabSanatan MurmuNo ratings yet

- 7-Slip and CutDocument2 pages7-Slip and CutHosam HamdyNo ratings yet

- Riser DiagramsDocument16 pagesRiser DiagramsSajidNo ratings yet

- Robinson Willey Firegem Visa 2-4Document10 pagesRobinson Willey Firegem Visa 2-4Kevin TraynorNo ratings yet

- TRW Steering Box Service ManualDocument0 pagesTRW Steering Box Service ManualJuanLopez64Ch100% (1)

- Fatima KadhemDocument2 pagesFatima Kadhemapi-663622821No ratings yet

- Carta de Inmitancia de SmithDocument1 pageCarta de Inmitancia de SmithEddy Santiago Neira SisaNo ratings yet

- Quality Control Operator TrainingDocument73 pagesQuality Control Operator TrainingAizaz FarhatNo ratings yet

- No More Secrets - January 2013Document18 pagesNo More Secrets - January 2013IchbinsNo ratings yet

- E SplayDocument10 pagesE SplayNhuVan NguyenNo ratings yet

- 4 File PDFDocument89 pages4 File PDFGifson MuntheNo ratings yet

- Mistral Agrofinal Spare Parts CatalogueDocument87 pagesMistral Agrofinal Spare Parts CatalogueKaloyanNo ratings yet

- WM 15038 EN PRO VW Rotary-Mill 2022-07Document3 pagesWM 15038 EN PRO VW Rotary-Mill 2022-07Castillo Rangel AntonioNo ratings yet

- CNC Mill Programming PDF MDocument35 pagesCNC Mill Programming PDF Mcappo.draganoneNo ratings yet

- Pipe System Pipe System: Price Parts Number Description Price Parts Number DescriptionDocument17 pagesPipe System Pipe System: Price Parts Number Description Price Parts Number DescriptionSiddhi SparesNo ratings yet

- 1200 Series Pressure Regulators1 - CAT1631 PDFDocument34 pages1200 Series Pressure Regulators1 - CAT1631 PDFMiloš StijeljaNo ratings yet

- Front Derailleurs X-Gen 3.0: User ManualDocument2 pagesFront Derailleurs X-Gen 3.0: User ManualAlex JonesNo ratings yet

- FormulaSheet For EM and SHM v1.1.1Document1 pageFormulaSheet For EM and SHM v1.1.1陳輝王No ratings yet

- Machines Important-Qs Important-QuestionsDocument2 pagesMachines Important-Qs Important-QuestionsFathima Az ZahraNo ratings yet

- Sheet 1Document180 pagesSheet 1Kadri HelmiNo ratings yet

- 42crmo4 EnglishDocument3 pages42crmo4 Englisheduardomanar1224No ratings yet

- RoofDek Manual 2016Document43 pagesRoofDek Manual 2016Vasile BudaNo ratings yet

21 Series Preventive List 2022 09 01 1

21 Series Preventive List 2022 09 01 1

Uploaded by

Ton marquesOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

21 Series Preventive List 2022 09 01 1

21 Series Preventive List 2022 09 01 1

Uploaded by

Ton marquesCopyright:

Available Formats

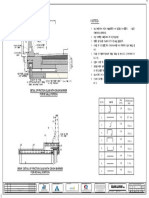

www.pflow.

com

P 414 352 9000

21 Series Preventive Maintenance F 414 352 9002

6720 N. Teutonia Ave.

and Schedule Checklist Milwaukee, WI 53209

The VRC requires minimal attention on a regular basis. Make sure all steps are completed. A record of regular,

properly conducted preventive maintenance provides a running history of any issues the VRC may have. The

reports will identify trends, and helps anticipate expected wear and tear repairs. Sign and return to PFlow

Industries, Inc. Customer Support Department via e-mail to csd@pflow.com

✓ Action How Often

Verify overall operation. monthly

Verify that the carriage deck is flush with the floor level and every level. Adjust as necessary. monthly

Verify that all areas under and around the VRC are clean. monthly

Verify that all electrical components are undamaged. Repair or replace as needed. monthly

Verify that all gates and enclosures are undamaged and properly installed. monthly

Verify that all gate interlocks are functioning properly. monthly

Verify that all push-button stations and e-stops are functioning correctly on each level. monthly

Identify any unsafe condition. Document and report the condition immediately to the customer and monthly

then PFlow Industries, Inc. Customer Support Department. Do not allow the lift to operate when unsafe

conditions arise.

Inspect hoses and fitting for leaks. monthly

Verify that there is sufficient hydraulic fluid for operation. Add as needed. monthly

Inspect all welding, bracing, and anchoring for structural integrity. 3 months

Verify that all nuts and bolts are tight. Adjust as necessary. 3 months

Visually inspect all chains (e.g., lift, drive, tensioner, gate) for wear, rust, bent, cracked, or binding links. 3 months

Lubricate with non-detergent, petroleum-based SAE 30 oil when dry.

Verify that all moving components are functioning properly. 3 months

Inspect all additional options and accessories (e.g., DeckLocks, maintenance pins, limit switches) and 3 months

operation. Adjust as necessary

Visually inspect the wheelblock guide rollers for rotation interference and wear. 3 months

Verify that all electrical connections are tight. 3 months

Inspect the drivebase chain sprocket for alignment and wear. Adjust as necessary. 6 months

Inspect the set collars for alignment. Apply blue Loctite #242 to the setscrews and tighten. 6 months

Apply lithium axle grease to the pillow block bearings on the drivebase. 6 months

Verify that the carriage is level. Adjust as necessary. 6 months

Inspect the hydraulic pump and motor operation, pressure switch setting, relief valve, and velocity fuses. 12 months

Replace the hydraulic oil and oil filter. 12 months

Remove the wheelblocks. Inspect the wheelblocks and safety cam for deterioration. 12 months

Replace all hoses and fittings. 5 years

Additional Notes or Follow-up Requirements

Customer signature: Date work completed:

Name/Phone: Authorized Technician(s):

Title: Name:

E-mail: Name:

PSD-0020 | Rev A | 2022-09-01 | e-mail csd@pflow.com 21 Series Preventive Maintenance and Schedule | 1

You might also like

- MG ZS UK Maintenance Check Sheet V1.03 PDFDocument2 pagesMG ZS UK Maintenance Check Sheet V1.03 PDFyogapost100% (1)

- A Course in Power Plant Engineering - S. C. Arora, S. Domkundwar, A. v. DomkundwarDocument286 pagesA Course in Power Plant Engineering - S. C. Arora, S. Domkundwar, A. v. DomkundwarSyed Majeed38% (13)

- Preventive Maintenance For The CARESTREAM DRX-Evolution/ DRX-Evolution PlusDocument62 pagesPreventive Maintenance For The CARESTREAM DRX-Evolution/ DRX-Evolution PlusIzzeldin ZakiNo ratings yet

- Material Specification and Compatibility ChartDocument2 pagesMaterial Specification and Compatibility ChartmasoodmuhidNo ratings yet

- Belt Scale Maintenance ChecklistDocument2 pagesBelt Scale Maintenance ChecklistJohn Eduard CarinoNo ratings yet

- Typical Detail of Friction Slab With Crash Barrier (1) - LayoutDocument1 pageTypical Detail of Friction Slab With Crash Barrier (1) - LayoutAditya ChauhanNo ratings yet

- Che341 Examples BatchrDocument9 pagesChe341 Examples BatchrAybike TaşdemirNo ratings yet

- AOT-MD-500 gERADOR OZONIO USA PDFDocument8 pagesAOT-MD-500 gERADOR OZONIO USA PDFaninNo ratings yet

- BS en 837-3-98Document26 pagesBS en 837-3-98Pablo DM100% (1)

- Partsbook Lube Truck R60814 PDFDocument93 pagesPartsbook Lube Truck R60814 PDFagn75% (4)

- Maintenance InstructionsDocument3 pagesMaintenance InstructionsNavnath GawasNo ratings yet

- Service Instructions For Vst-Se: 11.3 Inspection & Maintenance ScheduleDocument1 pageService Instructions For Vst-Se: 11.3 Inspection & Maintenance ScheduleAhmadNo ratings yet

- MVPS21CPXT WP en 11 PDFDocument9 pagesMVPS21CPXT WP en 11 PDFOusseni SawadogoNo ratings yet

- Stručni Test Engleskog JezikaDocument3 pagesStručni Test Engleskog JezikadjukalNo ratings yet

- Top Drive Maintenance Plan20210925Document4 pagesTop Drive Maintenance Plan20210925Franklin Silva100% (1)

- Crane Inspection LOG: MaintainerDocument27 pagesCrane Inspection LOG: MaintainerRodolfo CastroNo ratings yet

- K500 Service Manual PDFDocument27 pagesK500 Service Manual PDFMichaelNo ratings yet

- Maintenance Check List of HydraulicDocument7 pagesMaintenance Check List of HydraulicShubham SinghNo ratings yet

- Accessories Preventive Maintenance ChecklistDocument1 pageAccessories Preventive Maintenance ChecklisttmamputsiNo ratings yet

- Operation Check List / Start-Up Report: Axijet High Plume Exhaust SystemDocument2 pagesOperation Check List / Start-Up Report: Axijet High Plume Exhaust SystemZainul Abedin SayedNo ratings yet

- Industrial Safety ChecklistDocument1 pageIndustrial Safety ChecklistluigiNo ratings yet

- Microsoft Word - Tire Handler Owners Manual PDFDocument195 pagesMicrosoft Word - Tire Handler Owners Manual PDFPlanificador MantencionNo ratings yet

- Chemical CleaningDocument3 pagesChemical Cleaningmaxterminator555No ratings yet

- Check List de Brazo ArticuladoDocument6 pagesCheck List de Brazo ArticuladoJaime SuaNo ratings yet

- Maintenance Schedule For Water Distribution Systems: Description Comments Maintenance FrequencyDocument1 pageMaintenance Schedule For Water Distribution Systems: Description Comments Maintenance FrequencyGaurav JhaNo ratings yet

- Overhead Crane Safety and Inspection RequirementsDocument69 pagesOverhead Crane Safety and Inspection RequirementsAhmed ReguiegNo ratings yet

- Snorkel Maintenimiento TB80 TB 86JDocument22 pagesSnorkel Maintenimiento TB80 TB 86Jcesar alejandro scavoNo ratings yet

- Machine Maintenance.: General Workshop ProceduresDocument23 pagesMachine Maintenance.: General Workshop Proceduresvld7rpmNo ratings yet

- Ewp Annual or Third Party Inspection ChecklistDocument5 pagesEwp Annual or Third Party Inspection ChecklistScott BoogemansNo ratings yet

- Manrider Manual MODEL # FA150KGIMR12AIH-CEDocument16 pagesManrider Manual MODEL # FA150KGIMR12AIH-CESamuel Perez0% (1)

- Comprehensive Guide To Hydraulic Hose Inspection TestingDocument21 pagesComprehensive Guide To Hydraulic Hose Inspection TestingasmahemmanuelprincetonNo ratings yet

- Hydraulic System Initial Start-Up and MaintenanceDocument4 pagesHydraulic System Initial Start-Up and MaintenanceLuisNo ratings yet

- HG Hydraulic Valves Cut-Sheet WebDocument2 pagesHG Hydraulic Valves Cut-Sheet WebgrantNo ratings yet

- 1w Mech Mob Crane-Hyd Insp. Maint. 15tonDocument18 pages1w Mech Mob Crane-Hyd Insp. Maint. 15tonebonilla88No ratings yet

- Irrigator Preseason Check ListsDocument10 pagesIrrigator Preseason Check ListsriyazNo ratings yet

- Article Should Crane InspDocument2 pagesArticle Should Crane Inspsenioor2004No ratings yet

- Manual Barredora CONEQTEC LPB1500Document29 pagesManual Barredora CONEQTEC LPB1500El AlemanNo ratings yet

- Bison RHTDocument60 pagesBison RHTLuis Enrique PeñaNo ratings yet

- Interpretation of Sections of ASME B30.9 Standard: Alloy Steel Chain SlingsDocument2 pagesInterpretation of Sections of ASME B30.9 Standard: Alloy Steel Chain SlingsEdson AlvesNo ratings yet

- Pauta de Mantencion RWE 120Document2 pagesPauta de Mantencion RWE 120Fran PobleteNo ratings yet

- Transformer: Power/TractionDocument9 pagesTransformer: Power/Tractionappy sagarNo ratings yet

- Cartilla Mantenimiento Brazo ArtDocument9 pagesCartilla Mantenimiento Brazo ArtFabian Jara RodriguezNo ratings yet

- Maintenance and Inspection of BTH LiftersDocument8 pagesMaintenance and Inspection of BTH Liftersrpatel12No ratings yet

- Inspection of Cargo GearDocument4 pagesInspection of Cargo Gearmohan parthasarathyNo ratings yet

- 50 200 Cylinder Diesel EngineDocument30 pages50 200 Cylinder Diesel EngineFranklin FernandezNo ratings yet

- The Basics of Rebuilding Machine ToolsDocument8 pagesThe Basics of Rebuilding Machine ToolsSundar Kumar Vasantha Govindarajulu100% (1)

- 05 Mechanical MaintenanceDocument30 pages05 Mechanical MaintenancejanetNo ratings yet

- Mechanical Overhaul Procedures For Hydroelectric Units: Facilities Instructions, Standards, and Techniques Volume 2-7Document58 pagesMechanical Overhaul Procedures For Hydroelectric Units: Facilities Instructions, Standards, and Techniques Volume 2-7anshikas_4100% (1)

- Halliburton: S S7 JO/5//3Document4 pagesHalliburton: S S7 JO/5//3Khalfan Al HabsiNo ratings yet

- Control Valve Selection PDFDocument218 pagesControl Valve Selection PDFSyed Ali100% (2)

- Fcu OjtDocument3 pagesFcu OjtHuzairi SulaimanNo ratings yet

- Genset Preventive MaintenanceDocument6 pagesGenset Preventive MaintenanceSatria PinanditaNo ratings yet

- Sample Check ListDocument2 pagesSample Check ListHarsun HarNo ratings yet

- Pre-Commissioning Check List Form Switchgear-General: October 2019Document3 pagesPre-Commissioning Check List Form Switchgear-General: October 2019xchannel28No ratings yet

- Maintenance of Motor PDFDocument4 pagesMaintenance of Motor PDFBilal AslamNo ratings yet

- HVAC Maintenance Checklist Template SafetyCultureDocument18 pagesHVAC Maintenance Checklist Template SafetyCultureOdyssey Bartolome100% (2)

- Chapter 2 Machine Maintenance.: General Workshop ProceduresDocument22 pagesChapter 2 Machine Maintenance.: General Workshop ProcedureswillifenlonNo ratings yet

- 2020 - MU - HTL - 4014 - 4017 - PLATF - 36a-Light - Mif CHECK LISTDocument4 pages2020 - MU - HTL - 4014 - 4017 - PLATF - 36a-Light - Mif CHECK LISTOsscar HerreraNo ratings yet

- FlowLine Level Switch Sensors Switch-Tek LV20 LV35 LH25 LH29 LH35 ManualDocument14 pagesFlowLine Level Switch Sensors Switch-Tek LV20 LV35 LH25 LH29 LH35 ManualPromagEnviro.comNo ratings yet

- Checklist Mobil Crane PT NusakuraDocument6 pagesChecklist Mobil Crane PT NusakuraArisNo ratings yet

- Interpretation of Sections of ASME B30.9 Standard: Alloy Steel Chain SlingsDocument2 pagesInterpretation of Sections of ASME B30.9 Standard: Alloy Steel Chain Slingsscofiel1No ratings yet

- Preparing A Prover For A Water Draw CalibationsDocument3 pagesPreparing A Prover For A Water Draw CalibationsLeonel NavaNo ratings yet

- Grease Gun Procedure - FinalDocument12 pagesGrease Gun Procedure - Finalch420No ratings yet

- ABL-74T Machine MaintenanceDocument1 pageABL-74T Machine MaintenanceChris McNairNo ratings yet

- I.B.9560 Westinghouse RototrolDocument37 pagesI.B.9560 Westinghouse RototrolTon marquesNo ratings yet

- Waterside Plaza Technical Investigation Report (English Version)Document14 pagesWaterside Plaza Technical Investigation Report (English Version)Ton marquesNo ratings yet

- MFDElevator Accident ReportDocument1 pageMFDElevator Accident ReportTon marquesNo ratings yet

- BVL00000011 - Exhibit IL - 2 - Procedure Mech - LIF - Proc - 001 - Inspection or Testing Document Electric Traction Lifts (February 2017)Document19 pagesBVL00000011 - Exhibit IL - 2 - Procedure Mech - LIF - Proc - 001 - Inspection or Testing Document Electric Traction Lifts (February 2017)Ton marquesNo ratings yet

- In-Depth Investigation of Escalator Riding Accidents in Heavy Capacity MRT StationsDocument10 pagesIn-Depth Investigation of Escalator Riding Accidents in Heavy Capacity MRT StationsTon marquesNo ratings yet

- 01CA009Document7 pages01CA009Ton marquesNo ratings yet

- Reporting Escalator Incidents BCADocument2 pagesReporting Escalator Incidents BCATon marquesNo ratings yet

- DINACELL CÉLULA DE CARGA 1262-04 (En - Web)Document33 pagesDINACELL CÉLULA DE CARGA 1262-04 (En - Web)Ton marquesNo ratings yet

- Analysis of VibroacousticDocument9 pagesAnalysis of VibroacousticTon marquesNo ratings yet

- Ed 5622240Document9 pagesEd 5622240Ton marquesNo ratings yet

- BPMG EMED F1 v1 (Jul2016)Document2 pagesBPMG EMED F1 v1 (Jul2016)Ton marquesNo ratings yet

- RideWatcher EngDocument12 pagesRideWatcher EngTon marquesNo ratings yet

- Siti 2018 IOP Conf. Ser. Earth Environ. Sci. 117 012025Document9 pagesSiti 2018 IOP Conf. Ser. Earth Environ. Sci. 117 012025Ton marquesNo ratings yet

- CoP Le Works With Appendices EngDocument218 pagesCoP Le Works With Appendices EngTon marquesNo ratings yet

- Release LiftEscalator Regulations 080716Document11 pagesRelease LiftEscalator Regulations 080716Ton marquesNo ratings yet

- Modelo InformativoDocument1 pageModelo InformativoTon marquesNo ratings yet

- Safety Information Requiring Immediate Action: Code Oi217Document39 pagesSafety Information Requiring Immediate Action: Code Oi217Lidia PopaNo ratings yet

- Screw Jack: B.I.T., Mesra Engg - Mechanics LabDocument5 pagesScrew Jack: B.I.T., Mesra Engg - Mechanics LabSanatan MurmuNo ratings yet

- 7-Slip and CutDocument2 pages7-Slip and CutHosam HamdyNo ratings yet

- Riser DiagramsDocument16 pagesRiser DiagramsSajidNo ratings yet

- Robinson Willey Firegem Visa 2-4Document10 pagesRobinson Willey Firegem Visa 2-4Kevin TraynorNo ratings yet

- TRW Steering Box Service ManualDocument0 pagesTRW Steering Box Service ManualJuanLopez64Ch100% (1)

- Fatima KadhemDocument2 pagesFatima Kadhemapi-663622821No ratings yet

- Carta de Inmitancia de SmithDocument1 pageCarta de Inmitancia de SmithEddy Santiago Neira SisaNo ratings yet

- Quality Control Operator TrainingDocument73 pagesQuality Control Operator TrainingAizaz FarhatNo ratings yet

- No More Secrets - January 2013Document18 pagesNo More Secrets - January 2013IchbinsNo ratings yet

- E SplayDocument10 pagesE SplayNhuVan NguyenNo ratings yet

- 4 File PDFDocument89 pages4 File PDFGifson MuntheNo ratings yet

- Mistral Agrofinal Spare Parts CatalogueDocument87 pagesMistral Agrofinal Spare Parts CatalogueKaloyanNo ratings yet

- WM 15038 EN PRO VW Rotary-Mill 2022-07Document3 pagesWM 15038 EN PRO VW Rotary-Mill 2022-07Castillo Rangel AntonioNo ratings yet

- CNC Mill Programming PDF MDocument35 pagesCNC Mill Programming PDF Mcappo.draganoneNo ratings yet

- Pipe System Pipe System: Price Parts Number Description Price Parts Number DescriptionDocument17 pagesPipe System Pipe System: Price Parts Number Description Price Parts Number DescriptionSiddhi SparesNo ratings yet

- 1200 Series Pressure Regulators1 - CAT1631 PDFDocument34 pages1200 Series Pressure Regulators1 - CAT1631 PDFMiloš StijeljaNo ratings yet

- Front Derailleurs X-Gen 3.0: User ManualDocument2 pagesFront Derailleurs X-Gen 3.0: User ManualAlex JonesNo ratings yet

- FormulaSheet For EM and SHM v1.1.1Document1 pageFormulaSheet For EM and SHM v1.1.1陳輝王No ratings yet

- Machines Important-Qs Important-QuestionsDocument2 pagesMachines Important-Qs Important-QuestionsFathima Az ZahraNo ratings yet

- Sheet 1Document180 pagesSheet 1Kadri HelmiNo ratings yet

- 42crmo4 EnglishDocument3 pages42crmo4 Englisheduardomanar1224No ratings yet

- RoofDek Manual 2016Document43 pagesRoofDek Manual 2016Vasile BudaNo ratings yet