Professional Documents

Culture Documents

T-50 PakFa 60%

T-50 PakFa 60%

Uploaded by

dominunsevera0Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

T-50 PakFa 60%

T-50 PakFa 60%

Uploaded by

dominunsevera0Copyright:

Available Formats

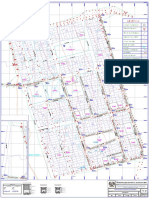

58 18 21

191 37 191

39

196

196

196

120

Wing center core.

x2

Wing top and bottom forward KF3 parts.

6 mm Depron.

96

x4

6 mm Depron.

59

30

6

141 87 75 116 52 7 32

4

4

141

1

9

12

2

18

38 16 14

9

14

11

7

12

4

R4

39

196

4

KF4 tapered wing spar.

x4 Hard balsa or pine.

10 mm wide. 25

68

0

29

44

53

36

Main Wing Optional 9

KF3 Type 154 109 45

9

116 D-D

15 3 11

E-E

30

20 28 10 58

2 26 28

R30

22

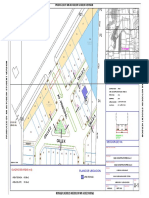

Part of fuselage above intake mounted to bulkhead location E-E.

32

70

76

3

R5

1

3

Part of wing that is connected to the vortex stabilisator

20 10 18 38 30

R29

Tail cone R2 A-A

5

7

60

2

27 73 17

6mm Balsa x1.

3mm Depron x2.

Laminate with Depron on each side.

5

1

90 11

72

91

B-B

55

57 34

7

7

3

26

69

42 10

18

Ø2

Ø1

190 13 41 14 37 Moving canard (vortex stabiliser)

25

26

27

A-A

47

12

20

19

3

51

C-C

60

25

60

60 Nose cone

34

F-F

67

15

44

208

3 45°

51

View of how the hinge can be made.

44

1

113

33

32

24

C-C D-D

B-B A-A

While cutting the wing move the hotwire at the wingtip rapidly back and forth about 5-10 mm while the

18 31 root part is moved as quick as possible. This dispurses the heat better.

16

17

18

17

17

147

D-D

83

32 46

134 Intake inner side

Intake

8

7°

45°

15

bottom

4

5

36

15

Ø1

17

Intake outer side

28

27

6

18 G1-G1

13 250 21 24 18

66°

4

45

15

10

49

9

37

37

76 119

4

271 Schematic View

203 E-E

87 E-E

12

12

NACA 2408

18

12

115 E1-E1

Shown without balsa cover.

Ø3 Vertical stabiliser root

2 parts.

15

7

Main Wing

Inner templates cut from carboard about 300-400 gr/m².

Cheaper than anything else and works perfectly. Vertical stabilisator root Air intake from E to G1

119 Bluecore cut type 138 56 E not shown

34

F-F

15

K

H I J

F G1,G

The reason for the part having a bit that needs to cut away is for one, it's easier to make the cut with the hot wire

E1, E

60 saw if it has more or less the same distance to cut. And it's easier to align the template prior the cut.

F-F If one for some reason don't want to make that part then the fuselage center bottom part has nothing to be

bonded to and that part of the section has to be made separately from Depron.

51

Ø58

76 5°

2

8

95

°

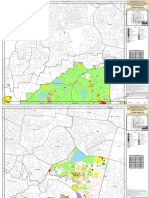

Side View

18

58

Ø2

2

5 49

85

°

28

28

95

C °

198 G-G G1-G1

B 42 29

A 90 6

15

15

R3

0°

9

11

G-G

12

R27 Ø55

R21 Elevon.

2 pcs. 6 mm Depron Exhaust

7

°

60

CG Ø3 82

72

sandwiched.

98

15

°

90

7 Top View

Ø4

115

180

A

88 Canopy

°

°

92

B

60

143

C 3

2

130

D

29

23

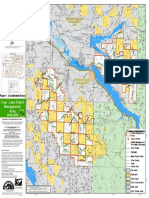

Ø2 H-H

20

+0.1

14

Ø2 0

60

27

4

34

H-H

64

8 1.5 61

16

45°

R1.5 57

54

K Elevon 99 12

E1, E 169 1.5

F G1,G

H I J

1

Ø2

Ø2

10

4

72 66

2

20

I-I

Ø2 12

14

Pitot tube

2

114 6

104 ° I-I

°

Center line

12

106

40 Vertical stabilizator.

28

2

2 pcs. 6 mm Depron

sandwiched.

6

7

11

43°

25

29

19

R4

5

13

J-J

29

R4

14

7

1 27

0°

24

79

11

71 65

24

J-J

C

D

11

11 2

83

E1, E

76

F 29

B

59

I J

2

G1,G K

A H Top

3

Ø3

0°

11

12

9

67 12 28 11 7 109

21

48

7 K-K

13

25

40°

+0.1

Front Ø2 0 K-K

Ø2

A B C R72 D E1, E CG

Sections:

· A-B: 50 mm K

F

Canards and part of wing if not

59

J

R72

· B-C: 150 mm I

· C-D: 100 mm G1,G

H

using movable ones Cross sections of the fuselage where the parts are glued together Templates for the fuselage sections

Vertical stabilisator

39

· D-E1: 180 mm

· E-F: 70 mm

· F-G1: 100 mm

· G-H: 100 mm

· H-I: 100 mm

· I-J: 200 mm Ø28 15 Ø48

· J-K: 150 mm 27

90 30 90 60 108 42 60 60 60 120 90 53

Vyplacering Skala johan.fasth@

1:1 telia.com

Beskrivning 2015-03-27

Sukhoi T-50 Pak Fa

(60% version for DF)

You might also like

- ME201 CourseworksDocument10 pagesME201 CourseworksOctavianLarsNo ratings yet

- G650 Amtm 09 AhrsDocument23 pagesG650 Amtm 09 Ahrsstive100% (1)

- Polaris - Boku No Hero Academia Season 4fd OPDocument3 pagesPolaris - Boku No Hero Academia Season 4fd OPAlcaNo ratings yet

- Ce 208 MMEL EU RevOriginalDocument68 pagesCe 208 MMEL EU RevOriginalGourav DasNo ratings yet

- Hinterland Dress Sizes0-24 - 2xa0Document2 pagesHinterland Dress Sizes0-24 - 2xa0Taryn BarryNo ratings yet

- Before Start After Start: Part B1 Flight Training Adelaide Fcom Da40Cs/Da40Xls Operations ManualDocument2 pagesBefore Start After Start: Part B1 Flight Training Adelaide Fcom Da40Cs/Da40Xls Operations ManualSam Rogers100% (1)

- EIAC B737-437 Freighter Specs Sheet PDFDocument7 pagesEIAC B737-437 Freighter Specs Sheet PDFMartín MéndezNo ratings yet

- An Apg 66Document3 pagesAn Apg 66sorin birouNo ratings yet

- Embraer E145 MEL Technical SummeryDocument57 pagesEmbraer E145 MEL Technical SummeryGourav DasNo ratings yet

- Understanding MIL-F-8785C PDFDocument20 pagesUnderstanding MIL-F-8785C PDFFlorence KwokNo ratings yet

- MOH 407A Adults Register - MOH 407A Adults - RegisterDocument1 pageMOH 407A Adults Register - MOH 407A Adults - Registeremmanuel nyongesaNo ratings yet

- Guia - Clinicas - Pediatria - v2 - Nueva (2) ADocument7 pagesGuia - Clinicas - Pediatria - v2 - Nueva (2) AWilber MaravillaNo ratings yet

- L'Arlesienne Suite No.2: IV. FarandoleDocument1 pageL'Arlesienne Suite No.2: IV. FarandoleOscar WeiNo ratings yet

- Acteon A3Document1 pageActeon A3Eurico MesquitaNo ratings yet

- Existing Land Use Map Planning District:32Document3 pagesExisting Land Use Map Planning District:32Shashidhar HattiNo ratings yet

- ANi MA2Document12 pagesANi MA2raziel0871No ratings yet

- 4.00 Plano Ubicacion de Conexiones-Plano Clave Agua Potable A1Document1 page4.00 Plano Ubicacion de Conexiones-Plano Clave Agua Potable A1Yossmel Raymundo SanchezNo ratings yet

- PLANO CLAVE - III ETAPA FINAL-Plano Clave A1Document1 pagePLANO CLAVE - III ETAPA FINAL-Plano Clave A1Yossmel Raymundo SanchezNo ratings yet

- Proposed 60 M Wide Sector RoadDocument1 pageProposed 60 M Wide Sector RoadAashu SharmaNo ratings yet

- CornwallDocument2 pagesCornwallhenry.mcbride555No ratings yet

- Black ForestDocument5 pagesBlack Forest林立No ratings yet

- Мовчати1Document2 pagesМовчати1марияNo ratings yet

- Yahood W Nisara Sa Mukhalfat Islamic Urdu BookDocument128 pagesYahood W Nisara Sa Mukhalfat Islamic Urdu Bookapi-3782112No ratings yet

- Plano de Ubicación A-08Document1 pagePlano de Ubicación A-08Kevim Dharen Hernandez CastilloNo ratings yet

- Belmont Mountain Bike Tracks Map For WebDocument1 pageBelmont Mountain Bike Tracks Map For Webrahmat.sadikNo ratings yet

- Ecopark FinalDocument1 pageEcopark FinalKhoi TranNo ratings yet

- U2 S6 A2 CompressedDocument1 pageU2 S6 A2 CompressedcodrutanegrulescuNo ratings yet

- Designed by Sitra Hassen: Dilla University Department of ArchitectureDocument7 pagesDesigned by Sitra Hassen: Dilla University Department of ArchitectureSitra HassenNo ratings yet

- Bengaluru Bda RMP 2031 Elu PD 28Document4 pagesBengaluru Bda RMP 2031 Elu PD 28hxjzoqaimeqlzgkfgoNo ratings yet

- Autumn MemoriesDocument7 pagesAutumn MemoriesHarry AddisonNo ratings yet

- Cueca Cantarina Willy Claure 6a44c9c4Document3 pagesCueca Cantarina Willy Claure 6a44c9c4YaskoFujiiNo ratings yet

- Ba 1Document3 pagesBa 1Sucrose BoyNo ratings yet

- Zapateado, Op. 23, No. 2 - Pablo Sarasate (Arranged For Solo Piano)Document11 pagesZapateado, Op. 23, No. 2 - Pablo Sarasate (Arranged For Solo Piano)juicedspy66554No ratings yet

- Tendernotice 2Document37 pagesTendernotice 2AmulyaRajbharNo ratings yet

- Macque - RuggieroDocument3 pagesMacque - Ruggierosnow93No ratings yet

- Selvi Boylum Al Yazmalım: Film MüziğiDocument3 pagesSelvi Boylum Al Yazmalım: Film Müziğiper zeyt50% (2)

- SAMPAI JUMPA - Piano - 2022-05-10 0226Document2 pagesSAMPAI JUMPA - Piano - 2022-05-10 0226Seta DewaNo ratings yet

- AragamiDocument6 pagesAragamiC WNo ratings yet

- Señalizacion de NomenclaturaDocument1 pageSeñalizacion de NomenclaturaGherson Galvez SánchezNo ratings yet

- 01 - Full Score - Challan 211Document1 page01 - Full Score - Challan 211rferrohNo ratings yet

- The Witchs BreathDocument2 pagesThe Witchs BreathIrene Ceba AycartNo ratings yet

- NYC Soil MapDocument1 pageNYC Soil Mapagr5063No ratings yet

- Breakthrough PoppinPartyDocument8 pagesBreakthrough PoppinPartyh7vdtsqgf8No ratings yet

- BORDOGNI Solfeggio Nº 1Document2 pagesBORDOGNI Solfeggio Nº 1AmtNo ratings yet

- Amwod Awd FawdfDocument6 pagesAmwod Awd FawdfHipidyHopidyNo ratings yet

- Like Stars On Earth Ishann's ThemeDocument3 pagesLike Stars On Earth Ishann's ThemeSimiMMNo ratings yet

- I Ask The Lord FinalDocument8 pagesI Ask The Lord FinalRujean Romy Porteza GuisandoNo ratings yet

- Sibelius Piano Sonatina: in F MajorDocument4 pagesSibelius Piano Sonatina: in F MajorFabiÁnNo ratings yet

- ZimmerHans RingThe EndCreditsDocument2 pagesZimmerHans RingThe EndCreditsmmrocker1No ratings yet

- Andre Popp - Song For AnnaDocument2 pagesAndre Popp - Song For AnnabardlancerNo ratings yet

- Yeeun Ahn Night Flower Yeeun Ahn Night FlowerDocument5 pagesYeeun Ahn Night Flower Yeeun Ahn Night FlowerXian HaebomNo ratings yet

- T-50 PakFaDocument1 pageT-50 PakFadominunsevera0No ratings yet

- Pizza TimeDocument2 pagesPizza Timelukedelacruz525No ratings yet

- East Lane MapDocument1 pageEast Lane MapSinclair Broadcast Group - EugeneNo ratings yet

- (Free Scores - Com) Rimbault Edward Francis Happy Day 165324Document2 pages(Free Scores - Com) Rimbault Edward Francis Happy Day 165324JORGINA GIRONESNo ratings yet

- Super Mario - PianoDocument2 pagesSuper Mario - PianogudzalovNo ratings yet

- EX3G HMI PLC All-In-One User ManualDocument2 pagesEX3G HMI PLC All-In-One User ManualFahadNo ratings yet

- Benzinarie Chiajna - PTH - Rev 2-R01Document1 pageBenzinarie Chiajna - PTH - Rev 2-R01sephoraengNo ratings yet

- Confesion Pasillo Galo TeranDocument1 pageConfesion Pasillo Galo TeranJuan Carlos Orozco NoboaNo ratings yet

- Butter - BTSDocument4 pagesButter - BTSKhuyen Mai PhuocNo ratings yet

- Glimpse of Us JojiDocument3 pagesGlimpse of Us JojiagentqlfNo ratings yet

- Missa Brevissima Agnus DeiDocument1 pageMissa Brevissima Agnus Deichabar20007842No ratings yet

- La Cortesía - Clarinete 3Document1 pageLa Cortesía - Clarinete 3Jonatan LpNo ratings yet

- Con Fior Di FrumentoDocument1 pageCon Fior Di FrumentoCristian Del CoreNo ratings yet

- 9 Mt. Wide Road: Type DDocument1 page9 Mt. Wide Road: Type DjitendraNo ratings yet

- Missa Brevissima KyrieDocument2 pagesMissa Brevissima Kyriechabar20007842No ratings yet

- Societymap PDFDocument1 pageSocietymap PDFNouman EnterprisesNo ratings yet

- Weight and BalanceDocument10 pagesWeight and BalanceMarcus SantosNo ratings yet

- Boeing 737 Airconditioning System Arcilla Johnmark P Bsaet3b Amta329Document17 pagesBoeing 737 Airconditioning System Arcilla Johnmark P Bsaet3b Amta329BENoNo ratings yet

- 549-00-0058 J Weight and Balance AddendumDocument8 pages549-00-0058 J Weight and Balance AddendumWong BennyNo ratings yet

- Jeppesen May 20Document201 pagesJeppesen May 20RomerNo ratings yet

- Department of Transportation Federal Aviation AdministrationDocument32 pagesDepartment of Transportation Federal Aviation Administrationnabawi24No ratings yet

- KAP-150 Pilot GuideDocument117 pagesKAP-150 Pilot GuideMarcus DragoNo ratings yet

- Drone NotesDocument6 pagesDrone NotesheypartygirlNo ratings yet

- Etops Lrops EdtoDocument7 pagesEtops Lrops EdtoRao NirupamaNo ratings yet

- Asf ActDocument3 pagesAsf Actwaqar100% (2)

- Team 13 (Adp 2 Presentation)Document15 pagesTeam 13 (Adp 2 Presentation)BAYANAGARI VENKATA BALA SAI ESWAR STUDENT - AERONo ratings yet

- CHAPTER 3 Turbine EnginesDocument43 pagesCHAPTER 3 Turbine EnginesJP DavidNo ratings yet

- Airships 101Document57 pagesAirships 101Jim CognitoNo ratings yet

- Sil 34 084 006Document14 pagesSil 34 084 006ErichCastrejónRodriguezNo ratings yet

- How To Live and Die in The Virtual Sky V0.2Document25 pagesHow To Live and Die in The Virtual Sky V0.2apexbangNo ratings yet

- Attach 6271067 1 PDFDocument3 pagesAttach 6271067 1 PDFMahrukh IlyasNo ratings yet

- Airline CodesDocument26 pagesAirline CodesSavita PooniaNo ratings yet

- San Juan Cartagena and Back: Making Travel Better 1 4 1 0 7 5 8 2 5Document6 pagesSan Juan Cartagena and Back: Making Travel Better 1 4 1 0 7 5 8 2 5Ginna Buitrago CeballosNo ratings yet

- Present and Future of Air Navigation PBN Operations and Supporting TechnologiesDocument18 pagesPresent and Future of Air Navigation PBN Operations and Supporting TechnologiesFelipe VillamilNo ratings yet

- DEL YYZ: TICKET - ConfirmedDocument3 pagesDEL YYZ: TICKET - ConfirmedFateh MaanNo ratings yet

- Jet Airways Web Booking ETicket (CRTBTB) - PeterDocument3 pagesJet Airways Web Booking ETicket (CRTBTB) - PeterLeon Peter0% (1)

- Finkerens Spotting Guide - Edit 1Document6 pagesFinkerens Spotting Guide - Edit 1Paul VortexNo ratings yet

- 行程單 2Document2 pages行程單 2wbxrhvrbvgNo ratings yet