Professional Documents

Culture Documents

Stahlwille Manoskop 755

Stahlwille Manoskop 755

Uploaded by

marranOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Stahlwille Manoskop 755

Stahlwille Manoskop 755

Uploaded by

marranCopyright:

Available Formats

Friction gauge

1 indicating type 1 certificate in accordance with DIN EN

1 permanently installed square drive for clockwise use ISO 6789-2:2017

1 trailing pointer dial 1 display deviation value ± 4%

1 no "needle wobble" during measurements

1 lighter construction due to use of aluminium

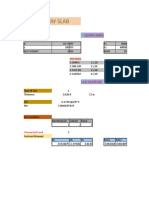

73Nm/15 Friction gauge

LF

h b

D b h L LF R

Code W X " mm mm mm mm g

50 24 00 15 2-15 N·m 0.5 N·m 1/2 72 50 298.5 250 676

Industrial MANOSKOP® 755

For work on production lines or series production. No setting scale; have to be set with testers such

as the STAHLWILLE No 7707 W, SmartCheck tester or the No 7794, No 7706 calibration system.

1 click-type cause damage to it

1 mount for interchangeable insert tools 223- 1 anticlockwise torquing thanks to swap-over insert

229

(755/4-30) tools

1 dual stop signal 1 on request with preset cut-out value (surcharge 10%)

1 particularly light and easy to handle 1 display deviation value ± 4%

1 handle and shank are made of square tubular steel

1 any force applied to the tool after the 'click' or

applied in the opposite direction to the current

function (up to the maximum of the wrench's range)

does not act on the trigger mechanism and cannot

755R/1 Series MANOSKOP® torque wrench with permanently installed ratchet

1 measurements independent of the point of application of force

h b

D b h L R

Code W W " mm mm mm g

50 10 00 01 1.5–12.5 N·m 1.0–9.0 ft·lb 1/4 22 18 173.5 335

755 Series MANOSKOP® torque wrenches with mount for insert tools

LF

b h

SF L

J b h L LF SF R

Code size W W mm mm mm mm mm mm g

50 01 00 04 4 4–40 N·m 4–30 ft·lb ; 22 18 201 172 17.5 500

50 01 00 10 10 20–100 N·m 15–74 ft·lb ; 28 24 318 289 17.5 635

50 01 00 20 20 40–200 N·m 30–147 ft·lb , 28 24 457 435 25 1045

50 01 00 30 30 60–300 N·m 40–220 ft·lb , 28 24 609 587 25 1210

195

KG5 Print ES DE EN 2019-12-18 mTabellen.indd 195 18.12.2019 16:01:15

You might also like

- 2005 2006 2007 2008 Toyota Tacoma Factory Service ManualDocument12 pages2005 2006 2007 2008 Toyota Tacoma Factory Service Manualmarran0% (1)

- 2019 EverdigmRocktools Catalogue (20191011)Document52 pages2019 EverdigmRocktools Catalogue (20191011)Claudio EspinozaNo ratings yet

- Toyota Vitz 2005-2012 (XP90) Fuse DiagramsDocument25 pagesToyota Vitz 2005-2012 (XP90) Fuse Diagramsmarran100% (1)

- Chatbot SynopsisDocument19 pagesChatbot SynopsisDeepanshu Sharma75% (4)

- Std. Test Methods For Metal Powders & PM ProductsDocument12 pagesStd. Test Methods For Metal Powders & PM ProductschandiniNo ratings yet

- Self Healing Concrete - PpsDocument17 pagesSelf Healing Concrete - PpsShubham Agarwal0% (1)

- Electrical Pump PDFDocument28 pagesElectrical Pump PDFSalman SaifuddinNo ratings yet

- Nylon Sleeve CouplingDocument3 pagesNylon Sleeve CouplingHudiNo ratings yet

- FH235 & FH236 Series Diesel Pro FlyerDocument2 pagesFH235 & FH236 Series Diesel Pro FlyercharisNo ratings yet

- F85B.0.22 ONE Policja LublinDocument93 pagesF85B.0.22 ONE Policja LublinPiotr KlodaNo ratings yet

- DL311 7Document4 pagesDL311 7Vanessa Astudillo RNo ratings yet

- Drilling Attachment: - Product RangeDocument3 pagesDrilling Attachment: - Product Rangewaleed talalNo ratings yet

- Multi-Axis Controller: Technical DataDocument11 pagesMulti-Axis Controller: Technical DataAof ThiwakornNo ratings yet

- Ficha Tecnica E - McmiDocument9 pagesFicha Tecnica E - McmiTECNOINDUSTRIASNo ratings yet

- Load-Cell Type Multi-Vickers Hardness TesterDocument6 pagesLoad-Cell Type Multi-Vickers Hardness TesterEwo50 NewNo ratings yet

- Manual Zenner MTKDDocument3 pagesManual Zenner MTKDDanNo ratings yet

- Bom File 12349876Document2 pagesBom File 12349876Daniel BravoNo ratings yet

- Bom File 12349876Document2 pagesBom File 12349876Daniel BravoNo ratings yet

- H 4300 Woltmann Meter M 190 Multi-Jet MeterDocument2 pagesH 4300 Woltmann Meter M 190 Multi-Jet MeterMohammad ZeeshanNo ratings yet

- DB WMZ DFS Imf enDocument4 pagesDB WMZ DFS Imf enZakaria Ait MehdiNo ratings yet

- 5 - Combined Footing Case 2Document2 pages5 - Combined Footing Case 2ABAMELANo ratings yet

- CORONA P 423/424: Multi-Jet Meter - Wet RunnerDocument5 pagesCORONA P 423/424: Multi-Jet Meter - Wet RunnerDhanushka RathnasooriyaNo ratings yet

- CORONA P 423/424: Multi-Jet Meter - Wet RunnerDocument5 pagesCORONA P 423/424: Multi-Jet Meter - Wet RunnerDhanushka RathnasooriyaNo ratings yet

- Flowmeter For Boiler Vzo 25Document16 pagesFlowmeter For Boiler Vzo 25jebisiNo ratings yet

- Espec DL311-7 7 - 6328-EDocument4 pagesEspec DL311-7 7 - 6328-EFranklin LabbeNo ratings yet

- Characteristics Series D1VL, D3DL, D4L, D9L: Directional Control ValvesDocument11 pagesCharacteristics Series D1VL, D3DL, D4L, D9L: Directional Control ValvesBhagwati HydraulicNo ratings yet

- Dayliff Water Meters 378490819Document12 pagesDayliff Water Meters 378490819毛伟勇No ratings yet

- One Way Slab: Given DataDocument2 pagesOne Way Slab: Given DataAli hamzaNo ratings yet

- Gbb322e-18 Flow PetDocument6 pagesGbb322e-18 Flow Petimahoo okNo ratings yet

- Part D-MachiningDocument18 pagesPart D-MachiningSayed qasimNo ratings yet

- Turbine CatalogeDocument4 pagesTurbine Catalogetechhustler2No ratings yet

- C 2900 Supplement Eng - 22.1Document31 pagesC 2900 Supplement Eng - 22.1Laercio JoseNo ratings yet

- RotameterDocument2 pagesRotameterJove MultisystemsNo ratings yet

- Power Pack & Tools-1Document14 pagesPower Pack & Tools-1Dodi Julianto فاصلNo ratings yet

- Manual TYL Gas MeterDocument8 pagesManual TYL Gas MeterNîakâm UshuaiaNo ratings yet

- Crouzet Miniature V3S 83169Document4 pagesCrouzet Miniature V3S 83169wg0532No ratings yet

- Ip200 enDocument2 pagesIp200 ensalawasna92No ratings yet

- Reed Miniature Basic Switch D2RVDocument7 pagesReed Miniature Basic Switch D2RVMuhamad PriyatnaNo ratings yet

- Level Indicator Vertical Float TypeDocument4 pagesLevel Indicator Vertical Float Typeanon_83594873No ratings yet

- AxlesDocument10 pagesAxleshernanNo ratings yet

- O&K Carraro AxlesDocument10 pagesO&K Carraro AxlesMarek WyszatyckiNo ratings yet

- Part Number System: Voltage Capacitance Size Material RemarkDocument1 pagePart Number System: Voltage Capacitance Size Material RemarksanazmeloNo ratings yet

- Wesan WP: Bulk Water Meter - WoltmanDocument5 pagesWesan WP: Bulk Water Meter - WoltmanMohammad ZeeshanNo ratings yet

- DU Series MCCB CatalogueDocument8 pagesDU Series MCCB Cataloguerobinknit2009No ratings yet

- FHP Pressure FiltersDocument10 pagesFHP Pressure Filtersfrancis_15in100% (1)

- RKP Product Info New Gear Pump En-2006-03Document9 pagesRKP Product Info New Gear Pump En-2006-03Arko RoosNo ratings yet

- LS 400 Series: Incremental Linear Encoders With Slimline Scale Housing - For Limited Installation SpaceDocument2 pagesLS 400 Series: Incremental Linear Encoders With Slimline Scale Housing - For Limited Installation SpaceНиколайNo ratings yet

- HYBT Series: Assembling Terminal BlockDocument8 pagesHYBT Series: Assembling Terminal Blockanon_670965762No ratings yet

- 8 5-FX56sDocument4 pages8 5-FX56snappyNo ratings yet

- 2603 - Citizen D010Document3 pages2603 - Citizen D010level48No ratings yet

- Service-Parts Wp2 Catalog 10-21-21Document9 pagesService-Parts Wp2 Catalog 10-21-21dilipNo ratings yet

- Simbologia Elétrica PDFDocument5 pagesSimbologia Elétrica PDFleandro_pescadorNo ratings yet

- Series: Vibratory Single Drum RollerDocument2 pagesSeries: Vibratory Single Drum RollerAlifianMAkmalNo ratings yet

- Sakai Sv900Document2 pagesSakai Sv900Nguyễn ThaoNo ratings yet

- Fivc PN16 Vodrv DN65 600Document9 pagesFivc PN16 Vodrv DN65 600Rabea EzzatNo ratings yet

- Catalogo 2 MicrotechDocument30 pagesCatalogo 2 MicrotechDavid GüdelNo ratings yet

- Familyoverview LFV300 g149993 enDocument7 pagesFamilyoverview LFV300 g149993 enLeo PastinNo ratings yet

- Rotameterw FiltravDocument2 pagesRotameterw FiltravJohn AdewaleNo ratings yet

- Water Meter SeriesDocument15 pagesWater Meter Seriestejo murgiyantoNo ratings yet

- 国际39M混凝土泵车卖点介绍Specification & Advantages of SYG39Document30 pages国际39M混凝土泵车卖点介绍Specification & Advantages of SYG39Alex MazaNo ratings yet

- Types of ValvesDocument14 pagesTypes of ValvesguruNo ratings yet

- Cold Water: Rubin Meistream, Meistream PlusDocument12 pagesCold Water: Rubin Meistream, Meistream PlusAgus SuwardonoNo ratings yet

- 2021-2022 Robonity eDocument35 pages2021-2022 Robonity eJ. S.No ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- Fuzzy Control Systems Design and Analysis: A Linear Matrix Inequality ApproachFrom EverandFuzzy Control Systems Design and Analysis: A Linear Matrix Inequality ApproachNo ratings yet

- Map Sensors1Document72 pagesMap Sensors1marranNo ratings yet

- 99UGS7ADocument95 pages99UGS7AmarranNo ratings yet

- #07-06-04-019: Intermittent MIL/SES, DTC P2138 With Reduced Engine Power (Repair Instrument Panel (IP) To Body Harness Connector) - (Jun 21, 2007)Document2 pages#07-06-04-019: Intermittent MIL/SES, DTC P2138 With Reduced Engine Power (Repair Instrument Panel (IP) To Body Harness Connector) - (Jun 21, 2007)marranNo ratings yet

- Removal: 2Uz-Fe Engine Mechanical - Timing BeltDocument4 pagesRemoval: 2Uz-Fe Engine Mechanical - Timing BeltmarranNo ratings yet

- 2017 ForteDocument12 pages2017 FortemarranNo ratings yet

- NCS Auto Mechanic RevisedDocument56 pagesNCS Auto Mechanic RevisedmarranNo ratings yet

- Section 6 1 G13 General EngineDocument108 pagesSection 6 1 G13 General EnginemarranNo ratings yet

- Removal: 2Uz-Fe Engine Mechanical - CamshaftDocument14 pagesRemoval: 2Uz-Fe Engine Mechanical - Camshaftmarran100% (1)

- B5a 2091 00Document52 pagesB5a 2091 00marranNo ratings yet

- Ect SensorsDocument87 pagesEct SensorsmarranNo ratings yet

- 2008 FusionDocument304 pages2008 FusionmarranNo ratings yet

- Installation InstructionsDocument5 pagesInstallation InstructionsmarranNo ratings yet

- SERIES 9100Q Pumps and Dispensers Installation/Operation ManualDocument51 pagesSERIES 9100Q Pumps and Dispensers Installation/Operation ManualmarranNo ratings yet

- 0901d196807662c1-810-701 CRSeals Handbook Jan 2019 TCM 12-318140Document1 page0901d196807662c1-810-701 CRSeals Handbook Jan 2019 TCM 12-318140marranNo ratings yet

- 2az Engine ToyotaDocument9 pages2az Engine ToyotamarranNo ratings yet

- Remaster Proportioning Valve: Installation Instructions # 6000549Document7 pagesRemaster Proportioning Valve: Installation Instructions # 6000549marranNo ratings yet

- Ds 715Document2 pagesDs 715marranNo ratings yet

- Product Recommendation Toyota (EU) Yaris XP10 Yaris 1.3 16V VVT-i (2003-2005)Document3 pagesProduct Recommendation Toyota (EU) Yaris XP10 Yaris 1.3 16V VVT-i (2003-2005)marranNo ratings yet

- Af64 3042Document1 pageAf64 3042marranNo ratings yet

- BPV 1r1Document1 pageBPV 1r1marranNo ratings yet

- Rus 63 0133 r654000Document1 pageRus 63 0133 r654000marranNo ratings yet

- Installation Instructions: Load Sensing ValveDocument8 pagesInstallation Instructions: Load Sensing ValvemarranNo ratings yet

- Brake Proportioning ValveDocument5 pagesBrake Proportioning ValvemarranNo ratings yet

- PUB-ahc ControllerDocument3 pagesPUB-ahc ControllermarranNo ratings yet

- MPB F200 102Document1 pageMPB F200 102marranNo ratings yet

- Tech Bulletin 09-10Document1 pageTech Bulletin 09-10marranNo ratings yet

- RABS Valves Restricting Fluid Flow To The Rear BrakesDocument2 pagesRABS Valves Restricting Fluid Flow To The Rear BrakesmarranNo ratings yet

- FsdrivingabsDocument1 pageFsdrivingabsmarranNo ratings yet

- ITT HydrogenThyratronTubes 1984Document6 pagesITT HydrogenThyratronTubes 1984zahidurrehman486No ratings yet

- Outillage Fourniture IndustrielleDocument329 pagesOutillage Fourniture IndustrielleFodil ZouziNo ratings yet

- EmaillogDocument60 pagesEmaillogGet JinxedNo ratings yet

- Modern Compressible Flow With Historical Perspective 3rd Edition Anderson Solutions ManualDocument7 pagesModern Compressible Flow With Historical Perspective 3rd Edition Anderson Solutions Manualserenadinhmzi100% (27)

- Ayanaamsa by HariprasadDocument11 pagesAyanaamsa by HariprasadtothekenNo ratings yet

- AMS4016MDocument5 pagesAMS4016M黄当甲No ratings yet

- N-Gram Models For Language DetectionDocument14 pagesN-Gram Models For Language DetectionjeysamNo ratings yet

- 11.mass Storage System and Disc Scheduling Hk3cLRdEXm PDFDocument50 pages11.mass Storage System and Disc Scheduling Hk3cLRdEXm PDFShivam mishraNo ratings yet

- Solution: TET401: Material Engineering & ThermofluidDocument2 pagesSolution: TET401: Material Engineering & Thermofluidantima meena100% (1)

- Jurnal Literatur Review CTMDocument10 pagesJurnal Literatur Review CTMNafFadhillaNo ratings yet

- Course Module 1 Intro NetworkingDocument2 pagesCourse Module 1 Intro NetworkingJonah Jatte MuñezNo ratings yet

- Report - Welding and Types of WeldingDocument13 pagesReport - Welding and Types of WeldingИгорь ПетраковNo ratings yet

- State Space Solutions and Realizations: EE-601: Linear System TheoryDocument29 pagesState Space Solutions and Realizations: EE-601: Linear System TheorysunilsahadevanNo ratings yet

- AOGE Presentation Rev1 FinalDocument24 pagesAOGE Presentation Rev1 FinalBeatriz Velásquez LeónNo ratings yet

- Fictiv 10 DFA RulesDocument1 pageFictiv 10 DFA RulesKevinNo ratings yet

- Math 10 Midterm 2 - Online PDFDocument4 pagesMath 10 Midterm 2 - Online PDFFatemeh YarahmadiNo ratings yet

- Mikrotik FundamentalDocument126 pagesMikrotik Fundamentalkurikulum smk tel sidoarjo100% (1)

- MCQ Engineering Mechanics Part VDocument17 pagesMCQ Engineering Mechanics Part VDominic LanticseNo ratings yet

- RT 7000Document2 pagesRT 7000Majeed AhmedNo ratings yet

- Eva Lobach and Dick J. Bierman - Who's Calling at This Hour? Local Sidereal Time and Telephone TelepathyDocument7 pagesEva Lobach and Dick J. Bierman - Who's Calling at This Hour? Local Sidereal Time and Telephone TelepathySorrenneNo ratings yet

- Online Lab: Resonance of Sound: ObjectiveDocument9 pagesOnline Lab: Resonance of Sound: ObjectiveEsteban Escalante CordobaNo ratings yet

- Numerical Simulation of Ship Motion Due To Waves and ManoeuvringDocument48 pagesNumerical Simulation of Ship Motion Due To Waves and ManoeuvringHung NguyenNo ratings yet

- Assembler DesignDocument40 pagesAssembler DesignAdilyt yttNo ratings yet

- Artikel 2013 03 Period of AdjustmentDocument7 pagesArtikel 2013 03 Period of AdjustmentAdriano AngelicoNo ratings yet

- 5Document39 pages5Abhishek KushwahaNo ratings yet

- Reference Manual Standard Interface Command ... - Mettler Toledo PDFDocument92 pagesReference Manual Standard Interface Command ... - Mettler Toledo PDFRastiNo ratings yet

- DehydrationDocument13 pagesDehydrationSaa D ShamimNo ratings yet