Professional Documents

Culture Documents

Documentation TT2

Documentation TT2

Uploaded by

roni_arsyahOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Documentation TT2

Documentation TT2

Uploaded by

roni_arsyahCopyright:

Available Formats

DOCUMENTATION SHEET General

The TT mounts are especially developed for the high powered / low weight, close coupled

Propulsion Equipment engine / gearbox combinations. The unique mounting design characteristics enables to trans-

TT-Mount type 2 mit both Thrust and Torque forces whilst ensuring an excellent vibration isolation. The TT

mounts have a linear stiffness over a wide load range varying from compression ( – ) to

extension ( + ) necessary to maintain the optimum isolation properties of the Mass-Spring

TT2

system formed by engine / gearbox and mounts. The close coupled gearbox reduces the en-

gine rpm ’ s and as a consequence, magnifies the engine torque. The reaction torque is being

transferred over the TT mounts to the foundation as additional compression or extension

forces which requires the TT mounts unique linear ( compression / extension ) stiffness to

maintain the same high degree of isolation.

Remark

It is our intention to maintain the excellent standard of our products. Modifications and im-

provements may be made from time to time, therefore we advise to contact us before order-

ing.

DIMENSIONS

1 PEQ / TT2 / AUG 2012

TT2

Specification

The stiffness ration from Vertical ( Z ) to Longitudinal ( X ) is selected such to minimize

displacements of the installation and connected equipment in this direction, which for instance

is beneficial for shaft seals. The thrust capacity per mount, related to the actual mount load

( F Z ) can be taken from the characteristics table below.

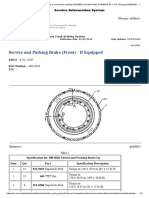

Initial load limit [N] Max. Vertical load [N] Max. Thrust load [N]

at 2mm vertical compression ( - ) ( s tatic load ) Compresion ( - ) Tensile ( + )

45°Sh.A 1000 1750 1250 5000

50°Sh.A 1250 2500 1750 6250

55°Sh.A 1500 3000 2250 7000

60°Sh.A 2000 3750 2750 7000

65°Sh.A 3000 5750 4250 9000

70°Sh.A 3750 7500 5500 10000

75°Sh.A 5250 10500 7750 14250

CHARACTERISTICS

The standard rubber hardness is available from 45° Sh.A up to 75° Sh.A and can be used up

to 90° C continuous and 110° C peak temperature, furthermore it will ensure low creep values.

All TT mounts are marked with the rubber hardness derived from the individual stiffness test

on one side of the top casting.

The TT mounts have an integrated limiter which limits the displacements in the vertical and

horizontal direction.

Direction Vertical up ( + ) Vertical down ( - )

Displacement limiter clearance [mm] 3,3 7,3

Vertical clearance at unloaded condition

CLEARANCE

Direction Fz + Fz - Fy + or - Fx + or -

Max Shockload ( kN ) 25 200 20 50

SHOCKLOADS

Selection

The mount selection for a Thrust and Torque transferring propulsion installation can generally

be made according to the following guidelines and is based solely on mount loads. The selec-

tion made according to these guidelines will prevent overloading of the mountings.

1 ) Calculate the vertical ( Z ) static load per mount position;

2 ) Select mount type rubber hardness, not exceeding initial load limit.

3 ) Calculate the additional torque forces ( +/- ) in the full load situation per mount position.

4 ) Add the load per mount as found under 1 with the torque forces per mount as found

under 3. Check if the calculated maximum and minimum vertical load points are within the

allowed maximal vertical load range.

5 ) Determine the maximum thrust loads from the characteristics table.

6 ) Compare the total horizontal ( X ) thrust load of the installation with the total maximum

thrust load of all mountings together. Select a different rubber hardness if required.

Rubber Design B.V.

The analysis of the disturbing – versus natural frequencies of the mounting system should

confirm the mount selection. Industrieweg 21

2995BE Heerjansdam

The Netherlands

Phone: +31 ( 0 ) 78 677 87 78

Fax: +31 ( 0 ) 78 677 10 38

Email: info@rubberdesign.nl

TYPE APPROVALS Web: www.rubberdesign.nl

2 PEQ / TT2 / AUG 2012

You might also like

- ISO 6330 2021 (E) - Character PDF DocumentDocument7 pagesISO 6330 2021 (E) - Character PDF DocumentNaveedNo ratings yet

- Predmaint UgDocument620 pagesPredmaint UgAhad MunawarNo ratings yet

- Davit Anchor Calculation PDFDocument14 pagesDavit Anchor Calculation PDFRiyas RafiNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Kellner Douglas. Human Nature and Capitalism in Adam Smith and Karl MarxDocument20 pagesKellner Douglas. Human Nature and Capitalism in Adam Smith and Karl MarxIraldoMatias100% (1)

- Chain Conveyors 150508Document16 pagesChain Conveyors 150508MarcNo ratings yet

- Sheet SM RD 35m1Document2 pagesSheet SM RD 35m1Sea Man MktNo ratings yet

- Sheet CM RD 244 ALUDocument2 pagesSheet CM RD 244 ALUSea Man MktNo ratings yet

- Documentation Sheet Conical Mountings GeneralDocument2 pagesDocumentation Sheet Conical Mountings GeneralTayfun SezişNo ratings yet

- Booklet Sandwich MountingsDocument11 pagesBooklet Sandwich MountingsSea Man MktNo ratings yet

- KENR8737 - Service and Parking Brake (Front) - If Equipped - PDF (188-5020)Document3 pagesKENR8737 - Service and Parking Brake (Front) - If Equipped - PDF (188-5020)Anderson Oliveira SilvaNo ratings yet

- TICO Structural BearingsDocument14 pagesTICO Structural BearingsTheoniusNo ratings yet

- Drift Eliminators: Product ProfileDocument2 pagesDrift Eliminators: Product ProfileYohanes Joko TriyantoNo ratings yet

- DXX-790-960/1710-2180-65/65-17.5i/18.5i-M/M-C: Electrical PropertiesDocument2 pagesDXX-790-960/1710-2180-65/65-17.5i/18.5i-M/M-C: Electrical PropertiesЮлия АбоймоваNo ratings yet

- DX-790-960-65-17.5i-M: Electrical PropertiesDocument2 pagesDX-790-960-65-17.5i-M: Electrical PropertiesАлександрNo ratings yet

- TransflexDocument2 pagesTransflexganmosesNo ratings yet

- Shaft AlignmentDocument44 pagesShaft Alignmentrodolfosti100% (1)

- Adjustable Machine Feet From GMTDocument2 pagesAdjustable Machine Feet From GMTGMT Rubber-Metal-TechnicNo ratings yet

- Espec DL310 PDFDocument4 pagesEspec DL310 PDFFranklin LabbeNo ratings yet

- 7-6325-E (DL310-7) PDFDocument4 pages7-6325-E (DL310-7) PDFMax RojasNo ratings yet

- Cordaflex (SMK) (N) ShtoeuDocument4 pagesCordaflex (SMK) (N) ShtoeurachidNo ratings yet

- ANT-A79451702v06-1152-001 DatasheetDocument2 pagesANT-A79451702v06-1152-001 DatasheetАнтонNo ratings yet

- DR-ID 800CL Service Manual: IN: InstallationDocument60 pagesDR-ID 800CL Service Manual: IN: Installationjack danialsNo ratings yet

- SEBF8149 - Specifications For Connecting Rods Used in 3500 Family of EnginesDocument24 pagesSEBF8149 - Specifications For Connecting Rods Used in 3500 Family of Enginesyahmanmahira4No ratings yet

- Entech TPE Resin Datasheet 1Document4 pagesEntech TPE Resin Datasheet 1Ermin CisicNo ratings yet

- TRASCO ES Couplings PDFDocument16 pagesTRASCO ES Couplings PDFAlvaro Felipe CharlinNo ratings yet

- Meltio-Nickel-718 Material Datasheet PDFDocument2 pagesMeltio-Nickel-718 Material Datasheet PDFJakNo ratings yet

- PolyCast TDS V3Document2 pagesPolyCast TDS V3jerome.luganNo ratings yet

- (Solo 5-7C) SANDVIKDocument4 pages(Solo 5-7C) SANDVIKCesar Gabriel Valdez SotoNo ratings yet

- Technical Data Sheet G-10: General DescriptionDocument1 pageTechnical Data Sheet G-10: General Descriptionbahtiar affandyNo ratings yet

- DIN 3015-1 Light Range DIN 3015-2 Heavy Range DIN 3015-3 Twin ClampsDocument28 pagesDIN 3015-1 Light Range DIN 3015-2 Heavy Range DIN 3015-3 Twin ClampsGeovanny Andres Cabezas SandovalNo ratings yet

- Doosan SD200 SpecDocument22 pagesDoosan SD200 SpecAndrea T Filotto100% (1)

- Cable - Datasheet - (En) NSSHCÖU, Prysmian - 2013-06-10 - Screened-Power-CableDocument4 pagesCable - Datasheet - (En) NSSHCÖU, Prysmian - 2013-06-10 - Screened-Power-CableA. Muhsin PamungkasNo ratings yet

- ANT - ADU450900v06-3091 DatasheetDocument2 pagesANT - ADU450900v06-3091 DatasheetfastlinkNo ratings yet

- Zwick: Materials Testing Product Information Servo-Hydraulic Load Frames - HB Series, 2-ColumnDocument3 pagesZwick: Materials Testing Product Information Servo-Hydraulic Load Frames - HB Series, 2-ColumnFrancesco MontagnoliNo ratings yet

- PolyMide CoPA TDS V5.2-20240223Document7 pagesPolyMide CoPA TDS V5.2-20240223Rakan El AtracheNo ratings yet

- High Deflection MountsDocument3 pagesHigh Deflection Mountsandrewnacho22No ratings yet

- Sheet CM RD 215 GGG HRDocument2 pagesSheet CM RD 215 GGG HRSea Man MktNo ratings yet

- Clip LockDocument16 pagesClip LockctaciutNo ratings yet

- Documentation Sheet Steel Spring Isolator GeneralDocument2 pagesDocumentation Sheet Steel Spring Isolator GeneralAhmet HamamcıoğluNo ratings yet

- Direct Drive Servomotor Turrets: SeriesDocument18 pagesDirect Drive Servomotor Turrets: SeriesSHG AUTMEC MANUTENÇÃO E AUTOMAÇÃO MÁQ. INDUSTRIAISNo ratings yet

- TAC-F - v1.1-OmegaAir - EngDocument12 pagesTAC-F - v1.1-OmegaAir - EngMột Lằn QuangNo ratings yet

- 12mm Square (Snap-In Type) : Joint Stem & Flat Stem With Stable Operation FeelingDocument4 pages12mm Square (Snap-In Type) : Joint Stem & Flat Stem With Stable Operation FeelingshyhuNo ratings yet

- Kathrein 80010685V01 (MTC48)Document2 pagesKathrein 80010685V01 (MTC48)iamasimo100% (1)

- Tiavs UdDocument2 pagesTiavs UdgeigerNo ratings yet

- Cordaflex (SMK) (N) ShtoeuDocument3 pagesCordaflex (SMK) (N) Shtoeufikri abu kassimNo ratings yet

- ADU451720Document2 pagesADU451720Raluca Roxana SzaszNo ratings yet

- Disc UsDocument20 pagesDisc Usyeldogan043No ratings yet

- Disc Spring UsesDocument20 pagesDisc Spring Usesharishtoki5430No ratings yet

- HDPE All ThicnkenssDocument2 pagesHDPE All ThicnkenssmikeNo ratings yet

- Documentation Sheet Steel Spring Isolator GeneralDocument2 pagesDocumentation Sheet Steel Spring Isolator GeneralAhmet HamamcıoğluNo ratings yet

- ADU451712 V 01Document2 pagesADU451712 V 01Raluca Roxana Szasz100% (1)

- Tenax-Htt N-Tscgewoeu 6-10 KVDocument2 pagesTenax-Htt N-Tscgewoeu 6-10 KVbeycanNo ratings yet

- Gearbox MountingsDocument2 pagesGearbox Mountingsroni_arsyahNo ratings yet

- DX-790-960-65-17.5i-M: Electrical PropertiesDocument2 pagesDX-790-960-65-17.5i-M: Electrical Propertiesюрий ермошенкоNo ratings yet

- PLANOFLEXDocument3 pagesPLANOFLEXDaniel PerezNo ratings yet

- D/CRCW E3: VishayDocument8 pagesD/CRCW E3: VishayFilipe BrendlerNo ratings yet

- Sheet PEQ MARINE COUPLING TWINDocument2 pagesSheet PEQ MARINE COUPLING TWINroni_arsyahNo ratings yet

- Nbox IoT NodeDocument2 pagesNbox IoT Noderoni_arsyahNo ratings yet

- BLUCHER Marine Cost Comparison GIDocument4 pagesBLUCHER Marine Cost Comparison GIroni_arsyahNo ratings yet

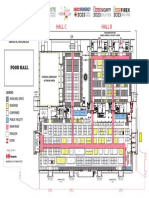

- FloorPlan IDW, IISMEX, ISF 2023 JIEXPO (A 29 Mar 2023)Document1 pageFloorPlan IDW, IISMEX, ISF 2023 JIEXPO (A 29 Mar 2023)roni_arsyahNo ratings yet

- BlueCool S Series - Spec 1Document2 pagesBlueCool S Series - Spec 1roni_arsyahNo ratings yet

- CUMarine References 2020Document63 pagesCUMarine References 2020roni_arsyahNo ratings yet

- Dunn Edwards GuideDocument75 pagesDunn Edwards Guideroni_arsyahNo ratings yet

- FLENDER GB Navy Vessels ReferenceDocument18 pagesFLENDER GB Navy Vessels Referenceroni_arsyahNo ratings yet

- Company Profile PT - CMLDocument12 pagesCompany Profile PT - CMLroni_arsyahNo ratings yet

- Document Title: Technical Proposal For 6500cbm LNG Storage TankDocument4 pagesDocument Title: Technical Proposal For 6500cbm LNG Storage Tankroni_arsyahNo ratings yet

- Implement Spanning Tree Protocols: LAN Switching and Wireless - Chapter 5Document14 pagesImplement Spanning Tree Protocols: LAN Switching and Wireless - Chapter 5Anand WuNo ratings yet

- Chapter 5 Complete Denture Prosthodontics Planning and Decision-Making by Yasemin K. ÖzkanDocument55 pagesChapter 5 Complete Denture Prosthodontics Planning and Decision-Making by Yasemin K. ÖzkanValerio DreiNo ratings yet

- English 7: Part I: Age of InnocenceDocument4 pagesEnglish 7: Part I: Age of InnocenceAngelNicolinE.SuymanNo ratings yet

- CA VD4-31kA (EN) - 1VCP000001 PDFDocument52 pagesCA VD4-31kA (EN) - 1VCP000001 PDFkienNo ratings yet

- FM Transmitter by YewlsewDocument50 pagesFM Transmitter by Yewlsewyewlsewmekonen75% (8)

- BEYOND THE CD: How SACD Won The WarDocument76 pagesBEYOND THE CD: How SACD Won The WarenergiculNo ratings yet

- Chaitanya Bharati Institute of Technology (A) CED Question Bank-HWRE (18CEC25) Unit-1Document12 pagesChaitanya Bharati Institute of Technology (A) CED Question Bank-HWRE (18CEC25) Unit-1AKHILA UMMANAVENANo ratings yet

- 如何分配正式电荷Document6 pages如何分配正式电荷lnqthxmpdNo ratings yet

- Iching 49Document3 pagesIching 49Jhe CreciaNo ratings yet

- ,DanaInfo Blvsapep32, Port 50000+Markem-Imaje 3520 Ribbon Datasheet PDFDocument2 pages,DanaInfo Blvsapep32, Port 50000+Markem-Imaje 3520 Ribbon Datasheet PDFIrpan SusiloNo ratings yet

- Course Outline Jan 2012Document4 pagesCourse Outline Jan 2012Urim ParkNo ratings yet

- ResourcesDocument5 pagesResourcesvarunNo ratings yet

- Junos Release Notes 12.3r11 PDFDocument390 pagesJunos Release Notes 12.3r11 PDFHellman Roman Pinzon GarciaNo ratings yet

- Unit 5 - Assignment 1 - The BlitzkriegDocument1 pageUnit 5 - Assignment 1 - The Blitzkriegapi-267183694No ratings yet

- Gwatkin. Early Church History To A.D. 313. 1912. Volume 1.Document338 pagesGwatkin. Early Church History To A.D. 313. 1912. Volume 1.Patrologia Latina, Graeca et OrientalisNo ratings yet

- Ans Teachers Notes - Reviving Love SPHURTI 2017Document12 pagesAns Teachers Notes - Reviving Love SPHURTI 2017Mathuranath DasNo ratings yet

- Diffusion Coefficient Full Report TiqaDocument19 pagesDiffusion Coefficient Full Report TiqaAtiqah Samad95% (21)

- Alternating Current and Direct Current PDFDocument5 pagesAlternating Current and Direct Current PDFHafiz HamzaNo ratings yet

- Toucan DrawingDocument34 pagesToucan Drawingapi-293137787No ratings yet

- CellStructureSEDocument7 pagesCellStructureSEkumardarsheel65No ratings yet

- Cotton ManagementDocument24 pagesCotton ManagementramNo ratings yet

- How To Repair A ShoeDocument2 pagesHow To Repair A ShoeVictor J TorresNo ratings yet

- Catalogo S20Document25 pagesCatalogo S20Jaime Zzaa100% (1)

- EQ-22080-IOQ Arrowsmith and Grant Refrigerator For Asset No: 4.2 Equipment ControlsDocument1 pageEQ-22080-IOQ Arrowsmith and Grant Refrigerator For Asset No: 4.2 Equipment ControlstonyNo ratings yet

- HTGD 90117 - Aa - Instruction For Lube OilDocument22 pagesHTGD 90117 - Aa - Instruction For Lube Oilabdikariev.aybekNo ratings yet

- P-3 - A Tiger in The Zoo - Ques.-Ans.Document1 pageP-3 - A Tiger in The Zoo - Ques.-Ans.bindragunroopNo ratings yet