Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

4 viewsSpecifications For Tuff Care

Specifications For Tuff Care

Uploaded by

Kushagri JoshiThis document specifies the properties and quality standards for Tuff Care 1 ply paper. It lists 15 key properties including substance, thickness, dry tensile strength, wet tensile strength, and brightness. The paper comes in various substance weights between 28-42 g/m2 and meets defined specifications for each property depending on the substance weight. It also specifies furnish, core size, and reel packaging details.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You might also like

- Complete First Certificate WB AnswersDocument20 pagesComplete First Certificate WB Answersdamasil278% (18)

- Product pdf106 PDFDocument10 pagesProduct pdf106 PDFMcFlyNo ratings yet

- Mix Design As Per BSDocument10 pagesMix Design As Per BSChetan SohalNo ratings yet

- KUKA Programming NotesDocument13 pagesKUKA Programming Notes92dalliNo ratings yet

- Specifications For Kitchen Towel IVDocument2 pagesSpecifications For Kitchen Towel IVKushagri JoshiNo ratings yet

- Kitchen Towel III - Specification SheetDocument2 pagesKitchen Towel III - Specification SheetKushagri JoshiNo ratings yet

- Kitchen Towel I - Specification SheetDocument2 pagesKitchen Towel I - Specification SheetKushagri JoshiNo ratings yet

- Napkin II - Specification SheetDocument2 pagesNapkin II - Specification SheetKushagri JoshiNo ratings yet

- Facial - Specification SheetDocument2 pagesFacial - Specification SheetKushagri JoshiNo ratings yet

- Napkin I - Specification SheetDocument2 pagesNapkin I - Specification SheetKushagri JoshiNo ratings yet

- Specifications For Toilet IDocument2 pagesSpecifications For Toilet IKushagri JoshiNo ratings yet

- Specifications For Toilet IIDocument2 pagesSpecifications For Toilet IIKushagri JoshiNo ratings yet

- Diamondline SpecsDocument1 pageDiamondline SpecsEng Burhaanudiin CumarNo ratings yet

- Specification For Base PaperDocument3 pagesSpecification For Base PapervenkNo ratings yet

- Ganesha Ecosphere - Pet Recycle ProductsDocument17 pagesGanesha Ecosphere - Pet Recycle ProductsSanjay Kumar ShahiNo ratings yet

- SGL Datasheet SIGRAFINE Materials For Mechanical Applications ENDocument2 pagesSGL Datasheet SIGRAFINE Materials For Mechanical Applications ENMayur PattanshettiNo ratings yet

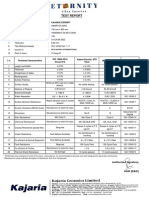

- Testing ReportDocument1 pageTesting ReportfaizNo ratings yet

- ADSS-80M Cable Specifications-2018.11.2. FibrastorepdfDocument6 pagesADSS-80M Cable Specifications-2018.11.2. FibrastorepdfDANIEL LEADNo ratings yet

- 8.ningbofold - EuropapierDocument1 page8.ningbofold - EuropapierMark Sebastian MitranNo ratings yet

- Constellation SnowDocument2 pagesConstellation SnowNadia GNo ratings yet

- Green ABSOLUTE BWP16mm (1) - 1Document1 pageGreen ABSOLUTE BWP16mm (1) - 1linkwithankit2No ratings yet

- Specification 710 HDMRDocument1 pageSpecification 710 HDMRDharm veerNo ratings yet

- Comparison PPC Eye Care (Paper Prop) - 1Document1 pageComparison PPC Eye Care (Paper Prop) - 1FarhanNo ratings yet

- Arena Smooth EngDocument8 pagesArena Smooth Engevi saragihNo ratings yet

- Capacitor HF B41858 TDKDocument33 pagesCapacitor HF B41858 TDKb_dupNo ratings yet

- Specification - Containers R R PolypackDocument1 pageSpecification - Containers R R PolypackBM HướngNo ratings yet

- Technical Data Sheet: SpecificationsDocument1 pageTechnical Data Sheet: SpecificationsNurettin TERZİOĞLUNo ratings yet

- Jx260ho TdsDocument1 pageJx260ho TdsNurettin TERZİOĞLUNo ratings yet

- Johnson Elite Wall Collection 30 X45 Rajasthan Feb 21Document36 pagesJohnson Elite Wall Collection 30 X45 Rajasthan Feb 21ABCNo ratings yet

- 富特士80 Series silicone rubberDocument4 pages富特士80 Series silicone rubberzhang kiraNo ratings yet

- Spec SheetDocument6 pagesSpec SheettristanNo ratings yet

- Jelf243c 0031-1569892Document11 pagesJelf243c 0031-1569892PIER ANGEL SUAREZ GUTIERREZNo ratings yet

- (35631) F. Cabo 12 Fibras Autosust As80m-Gyfty 12B1 G652DDocument3 pages(35631) F. Cabo 12 Fibras Autosust As80m-Gyfty 12B1 G652DAbelMouraNo ratings yet

- Specification For Approval: Shenzhen CND-TEK Industrial Co.,LtdDocument4 pagesSpecification For Approval: Shenzhen CND-TEK Industrial Co.,LtdLeonardo Armando RomeroNo ratings yet

- Brief Introduction of UHMWPEDocument3 pagesBrief Introduction of UHMWPEFatima NusserNo ratings yet

- B41858 PDFDocument32 pagesB41858 PDFNéstor MeizosoNo ratings yet

- PolyLite PETG TDS V5.3-20240309Document6 pagesPolyLite PETG TDS V5.3-20240309Freddy ArribasplataNo ratings yet

- Volumic FT en Pla UltraDocument2 pagesVolumic FT en Pla UltrakaleniaNo ratings yet

- (3564) F. Cabo 08 Fibras Autosust Gyfty-8b1 G652D SMDocument5 pages(3564) F. Cabo 08 Fibras Autosust Gyfty-8b1 G652D SMAbelMouraNo ratings yet

- En Breathinghoseen14593Document2 pagesEn Breathinghoseen14593razvan.prosalvNo ratings yet

- FOC - CAT 1 CableDocument2 pagesFOC - CAT 1 CablesuchpewNo ratings yet

- MTC Luna NestleDocument1 pageMTC Luna Nestlekamleshsingh28533No ratings yet

- DatasheetDocument16 pagesDatasheetErick MauricioNo ratings yet

- Multilayer Chip Capacitors X7R/B Characteristic: FeaturesDocument17 pagesMultilayer Chip Capacitors X7R/B Characteristic: FeaturesLupita Motta TobíasNo ratings yet

- MTC Amazon NestleDocument1 pageMTC Amazon Nestlekamleshsingh28533No ratings yet

- Fibra FTTH SolutionsDocument26 pagesFibra FTTH SolutionsIjam AsNo ratings yet

- CD54 Surface Mount Power InductorDocument4 pagesCD54 Surface Mount Power InductorIvo MatosNo ratings yet

- MTC Kotagreen NestleDocument1 pageMTC Kotagreen Nestlekamleshsingh28533No ratings yet

- (35621) F. Cabo 12 Fibras Autosust As120m-12f G652D SMDocument5 pages(35621) F. Cabo 12 Fibras Autosust As120m-12f G652D SMAbelMouraNo ratings yet

- 3320Document2 pages3320victorNo ratings yet

- (5789) F. Cabo 24 Fibras Autosust As80m Gyfty24b1 G652DDocument3 pages(5789) F. Cabo 24 Fibras Autosust As80m Gyfty24b1 G652DAbelMouraNo ratings yet

- 20 Microns Coated Calcium Carbonate 1t VDocument1 page20 Microns Coated Calcium Carbonate 1t VChandrakantNo ratings yet

- Poplar Puls FBB GC2 - Shandong MillDocument1 pagePoplar Puls FBB GC2 - Shandong MillBill KingNo ratings yet

- Johnson Tiles Floor 60x60cm (New Collection) Catalogue VJWD Mar 23Document12 pagesJohnson Tiles Floor 60x60cm (New Collection) Catalogue VJWD Mar 23sudhakarvenkatesan31No ratings yet

- B1300 SM Ver1Document73 pagesB1300 SM Ver1Abd Elh AdiNo ratings yet

- Basalt RovingDocument2 pagesBasalt Rovingdmitry kudryashovNo ratings yet

- Ashoka International - 20220801 - 122153Document2 pagesAshoka International - 20220801 - 122153Pritpal SinghNo ratings yet

- Data Sheet-H140A (1) (1) - WAZAMDocument2 pagesData Sheet-H140A (1) (1) - WAZAMdaniel.rabahdunordNo ratings yet

- MDI Catalogue.Document18 pagesMDI Catalogue.N ThulasiramanNo ratings yet

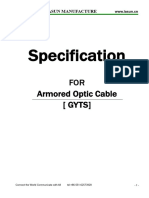

- GYTS-Cable Specifications G655DDocument7 pagesGYTS-Cable Specifications G655DcxhernanNo ratings yet

- Elite (Radial Thru-Hole) LM SeriesDocument2 pagesElite (Radial Thru-Hole) LM Serieszuigh899gNo ratings yet

- Specifications For Toilet IIDocument2 pagesSpecifications For Toilet IIKushagri JoshiNo ratings yet

- Napkin I - Specification SheetDocument2 pagesNapkin I - Specification SheetKushagri JoshiNo ratings yet

- Specifications For Toilet IDocument2 pagesSpecifications For Toilet IKushagri JoshiNo ratings yet

- Kitchen Towel I - Specification SheetDocument2 pagesKitchen Towel I - Specification SheetKushagri JoshiNo ratings yet

- January NewsletterDocument2 pagesJanuary NewsletterKushagri JoshiNo ratings yet

- October NewsletterDocument2 pagesOctober NewsletterKushagri JoshiNo ratings yet

- CS F342-11 PDFDocument24 pagesCS F342-11 PDFsky_davisNo ratings yet

- What Is AgilityDocument8 pagesWhat Is AgilityJustinNepomuceno100% (1)

- Tiss Sample Test PaperDocument53 pagesTiss Sample Test PaperLight ZoomNo ratings yet

- Study On Vibration Analysis For Printed Circuit Board of An Electronic ApparatusDocument6 pagesStudy On Vibration Analysis For Printed Circuit Board of An Electronic ApparatusAnand Ras100% (1)

- Da 1998Document17 pagesDa 1998Paul DumitruNo ratings yet

- Mif Brochure PDFDocument28 pagesMif Brochure PDFcommerce.academy.bamNo ratings yet

- Advertisement AnalysisDocument4 pagesAdvertisement AnalysisbhavaniNo ratings yet

- Teacher S Feedback Sutanaree and Saehara 417 311 Argumentative Essay Exercise G 1Document3 pagesTeacher S Feedback Sutanaree and Saehara 417 311 Argumentative Essay Exercise G 1Saimee AbuNo ratings yet

- 2Nd Generation Cpted: An Antidote To The Social Y2K Virus of Urban DesignDocument19 pages2Nd Generation Cpted: An Antidote To The Social Y2K Virus of Urban DesignFábio SalvadorNo ratings yet

- Producing Clinical Laboratory Shift Tables From Adam Data: Rao Bingi, Octagon Research Solutions, Wayne, PADocument12 pagesProducing Clinical Laboratory Shift Tables From Adam Data: Rao Bingi, Octagon Research Solutions, Wayne, PAlenithNo ratings yet

- US20190295733A1 - Pasma Compression Fusion DeviceDocument8 pagesUS20190295733A1 - Pasma Compression Fusion DevicedaveklodavekloNo ratings yet

- CIE 2010 Handbook For Centres - IGCSE - O-Levels - A-LevelsDocument124 pagesCIE 2010 Handbook For Centres - IGCSE - O-Levels - A-Levelssafwan120% (1)

- Kent 1997 Milling ModellingDocument7 pagesKent 1997 Milling Modellinggustool7No ratings yet

- For Front End Point Protection 2012 R 2Document29 pagesFor Front End Point Protection 2012 R 2Karim MessoussiNo ratings yet

- The Engine Oil BibleDocument28 pagesThe Engine Oil BibleJacques SwartNo ratings yet

- Iasp Finalpreview - PHP Absnum 107579Document2 pagesIasp Finalpreview - PHP Absnum 107579eswar110582No ratings yet

- Turbidity Sensor SKU SEN0189-DFRobotDocument4 pagesTurbidity Sensor SKU SEN0189-DFRobotBlak Dia MondNo ratings yet

- Practical Research 2.4Document7 pagesPractical Research 2.4Michael GabertanNo ratings yet

- Manish Kumar Jadaun: Personal Info Current Work ProfileDocument1 pageManish Kumar Jadaun: Personal Info Current Work ProfileEr Manish JadaunNo ratings yet

- Nadig Press Newspaper Chicago June 26 2013 EditionDocument22 pagesNadig Press Newspaper Chicago June 26 2013 EditionchicagokenjiNo ratings yet

- DFA Interpretation HelpDocument36 pagesDFA Interpretation Helpanupam99276No ratings yet

- Sekolah Menengah Kebangsaansura 23000 Dungun, TerengganuDocument14 pagesSekolah Menengah Kebangsaansura 23000 Dungun, TerengganuSUHAINA BINTI SAMSUDIN -No ratings yet

- Annotation - Objective 12Document1 pageAnnotation - Objective 12ROGER RAYMUND MALESIDONo ratings yet

- Activities For Oral ComDocument3 pagesActivities For Oral ComHanna Vin JuezanNo ratings yet

- SWDD TemplateDocument6 pagesSWDD TemplateSulthonul MubarokNo ratings yet

- New Welding Technologies in The ShipbuildingDocument2 pagesNew Welding Technologies in The ShipbuildingTahsinul Haque TasifNo ratings yet

- Sydsaeter Instructor ManualDocument11 pagesSydsaeter Instructor ManualPreetinder Kaur100% (1)

Specifications For Tuff Care

Specifications For Tuff Care

Uploaded by

Kushagri Joshi0 ratings0% found this document useful (0 votes)

4 views2 pagesThis document specifies the properties and quality standards for Tuff Care 1 ply paper. It lists 15 key properties including substance, thickness, dry tensile strength, wet tensile strength, and brightness. The paper comes in various substance weights between 28-42 g/m2 and meets defined specifications for each property depending on the substance weight. It also specifies furnish, core size, and reel packaging details.

Original Description:

Tuff Care

Original Title

Specifications for Tuff Care

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document specifies the properties and quality standards for Tuff Care 1 ply paper. It lists 15 key properties including substance, thickness, dry tensile strength, wet tensile strength, and brightness. The paper comes in various substance weights between 28-42 g/m2 and meets defined specifications for each property depending on the substance weight. It also specifies furnish, core size, and reel packaging details.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

Download as xlsx, pdf, or txt

0 ratings0% found this document useful (0 votes)

4 views2 pagesSpecifications For Tuff Care

Specifications For Tuff Care

Uploaded by

Kushagri JoshiThis document specifies the properties and quality standards for Tuff Care 1 ply paper. It lists 15 key properties including substance, thickness, dry tensile strength, wet tensile strength, and brightness. The paper comes in various substance weights between 28-42 g/m2 and meets defined specifications for each property depending on the substance weight. It also specifies furnish, core size, and reel packaging details.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

Download as xlsx, pdf, or txt

You are on page 1of 2

Product Specification

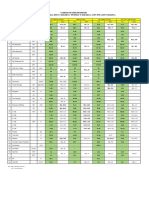

S.No. Properties UOM Product Quality : Tuff C

l No of Ply 1 Ply

2 Substance ( l Ply) g/m2 28 ± 0.8 30 ± 0.8 32 ± 0.8 35 ± 0.9

3 Thickness ( l Ply) Micron 106 ± 10 114 ± 10 122 ± 10 133 ± 10

4 Bulk cc/gm 3.8 ± 0.5 3.8 ± 0.5 3.8 ± 0.5 3.8 ± 0.5

Dry Tensile Strength MD gf/25mm 1100 ± 100 1200 ± 100 1300 ± 100 1800 ± 100

5

Dry Tensile Strength CD gf/25mm 650 ± 50 710 ± 50 750 ± 50 1050 ± 50

6 MDT/CDT RATIO 1.7 ± 0.2 1.7 ± 0.2 1.7 ± 0.2 1.7 ± 0.2

7 Stretch MD % 12.0 ± 2.0 12.0 ± 2.0 12.0 ± 2.0 12.0 ± 2.0

8 Wet Tensile Strength MD gf/50mm 462 ±42 504 ± 42 546 ± 42 756 ± 42

9 Wet/ Dry Tensile % 42 ± 2 42 ± 2 42 ± 2 42 ± 2

10 ISO Brightness(Frank, PTI ) % ISO 87 ± 2 87 ± 2 87 ± 2 87 ± 2

11 Shade - Natural

12 Furnish - ·Virgin pulp

13 Core (ID) mm 76

14 Number of joints - 70% ZERO JOINT, 20% ONE JOINT 10%

15 Reel Diameter mm ± 10 % of Actual ordered reel d

*Note : If goes beyond higher side tolerance, Quality is OK.

Test Conditions : Temperature 23 ± l °C & Relative Humidity 50± 2 % ( Toppi 402)

All properties are as per CPP Lalkua measurements

Tolerance are based upon 95 % confidence limits of single mill measurement on conditioned Random samples.

An ISO 9001,ISO 14001 & OHSAS 18001 Company.

on

Product Quality : Tuff Care

1 Ply

36 ± 0.9 37 ± 0.9 38 ± 0.9 40 ± l 42 ± l

137 ± 10 140 ± 10 145 ± 10 150 ± 10 158 ±10

3.8 ± 0.5 3.8 ± 0.5 3.8 ±0.5 3.8 ±0.5 3.8 ± 0.5

1900 ± l 00 2000 ± 100 2100 ± 100 2200 ± 100 2300 ± 100

1100±50 1175 ± 50 1225 ± 50 1300 ± 50 1350 ± 50

1.7 ± 0.2 1.7 ± 0.2 1.7 ± 0.2 1.7 ± 0.2 1.7 ± 0.2

12.0 ± 2.0 12.0 ± 2.0 12.0 ± 2.0 12.0 ± 2.0 12.0 ± 2.0

800 ± 42 850 ± 42 885 ± 42 925 ± 42 975 ± 42

42 ± 2 42 ± 2 42 ± 2 42 ± 2 42 ± 2

87 ± 2 87 ± 2 87 ± 2 87 ± 2 87 ± 2

Natural

·Virgin pulp

76

O JOINT, 20% ONE JOINT 10% TWO JOINTS

± 10 % of Actual ordered reel dia.

You might also like

- Complete First Certificate WB AnswersDocument20 pagesComplete First Certificate WB Answersdamasil278% (18)

- Product pdf106 PDFDocument10 pagesProduct pdf106 PDFMcFlyNo ratings yet

- Mix Design As Per BSDocument10 pagesMix Design As Per BSChetan SohalNo ratings yet

- KUKA Programming NotesDocument13 pagesKUKA Programming Notes92dalliNo ratings yet

- Specifications For Kitchen Towel IVDocument2 pagesSpecifications For Kitchen Towel IVKushagri JoshiNo ratings yet

- Kitchen Towel III - Specification SheetDocument2 pagesKitchen Towel III - Specification SheetKushagri JoshiNo ratings yet

- Kitchen Towel I - Specification SheetDocument2 pagesKitchen Towel I - Specification SheetKushagri JoshiNo ratings yet

- Napkin II - Specification SheetDocument2 pagesNapkin II - Specification SheetKushagri JoshiNo ratings yet

- Facial - Specification SheetDocument2 pagesFacial - Specification SheetKushagri JoshiNo ratings yet

- Napkin I - Specification SheetDocument2 pagesNapkin I - Specification SheetKushagri JoshiNo ratings yet

- Specifications For Toilet IDocument2 pagesSpecifications For Toilet IKushagri JoshiNo ratings yet

- Specifications For Toilet IIDocument2 pagesSpecifications For Toilet IIKushagri JoshiNo ratings yet

- Diamondline SpecsDocument1 pageDiamondline SpecsEng Burhaanudiin CumarNo ratings yet

- Specification For Base PaperDocument3 pagesSpecification For Base PapervenkNo ratings yet

- Ganesha Ecosphere - Pet Recycle ProductsDocument17 pagesGanesha Ecosphere - Pet Recycle ProductsSanjay Kumar ShahiNo ratings yet

- SGL Datasheet SIGRAFINE Materials For Mechanical Applications ENDocument2 pagesSGL Datasheet SIGRAFINE Materials For Mechanical Applications ENMayur PattanshettiNo ratings yet

- Testing ReportDocument1 pageTesting ReportfaizNo ratings yet

- ADSS-80M Cable Specifications-2018.11.2. FibrastorepdfDocument6 pagesADSS-80M Cable Specifications-2018.11.2. FibrastorepdfDANIEL LEADNo ratings yet

- 8.ningbofold - EuropapierDocument1 page8.ningbofold - EuropapierMark Sebastian MitranNo ratings yet

- Constellation SnowDocument2 pagesConstellation SnowNadia GNo ratings yet

- Green ABSOLUTE BWP16mm (1) - 1Document1 pageGreen ABSOLUTE BWP16mm (1) - 1linkwithankit2No ratings yet

- Specification 710 HDMRDocument1 pageSpecification 710 HDMRDharm veerNo ratings yet

- Comparison PPC Eye Care (Paper Prop) - 1Document1 pageComparison PPC Eye Care (Paper Prop) - 1FarhanNo ratings yet

- Arena Smooth EngDocument8 pagesArena Smooth Engevi saragihNo ratings yet

- Capacitor HF B41858 TDKDocument33 pagesCapacitor HF B41858 TDKb_dupNo ratings yet

- Specification - Containers R R PolypackDocument1 pageSpecification - Containers R R PolypackBM HướngNo ratings yet

- Technical Data Sheet: SpecificationsDocument1 pageTechnical Data Sheet: SpecificationsNurettin TERZİOĞLUNo ratings yet

- Jx260ho TdsDocument1 pageJx260ho TdsNurettin TERZİOĞLUNo ratings yet

- Johnson Elite Wall Collection 30 X45 Rajasthan Feb 21Document36 pagesJohnson Elite Wall Collection 30 X45 Rajasthan Feb 21ABCNo ratings yet

- 富特士80 Series silicone rubberDocument4 pages富特士80 Series silicone rubberzhang kiraNo ratings yet

- Spec SheetDocument6 pagesSpec SheettristanNo ratings yet

- Jelf243c 0031-1569892Document11 pagesJelf243c 0031-1569892PIER ANGEL SUAREZ GUTIERREZNo ratings yet

- (35631) F. Cabo 12 Fibras Autosust As80m-Gyfty 12B1 G652DDocument3 pages(35631) F. Cabo 12 Fibras Autosust As80m-Gyfty 12B1 G652DAbelMouraNo ratings yet

- Specification For Approval: Shenzhen CND-TEK Industrial Co.,LtdDocument4 pagesSpecification For Approval: Shenzhen CND-TEK Industrial Co.,LtdLeonardo Armando RomeroNo ratings yet

- Brief Introduction of UHMWPEDocument3 pagesBrief Introduction of UHMWPEFatima NusserNo ratings yet

- B41858 PDFDocument32 pagesB41858 PDFNéstor MeizosoNo ratings yet

- PolyLite PETG TDS V5.3-20240309Document6 pagesPolyLite PETG TDS V5.3-20240309Freddy ArribasplataNo ratings yet

- Volumic FT en Pla UltraDocument2 pagesVolumic FT en Pla UltrakaleniaNo ratings yet

- (3564) F. Cabo 08 Fibras Autosust Gyfty-8b1 G652D SMDocument5 pages(3564) F. Cabo 08 Fibras Autosust Gyfty-8b1 G652D SMAbelMouraNo ratings yet

- En Breathinghoseen14593Document2 pagesEn Breathinghoseen14593razvan.prosalvNo ratings yet

- FOC - CAT 1 CableDocument2 pagesFOC - CAT 1 CablesuchpewNo ratings yet

- MTC Luna NestleDocument1 pageMTC Luna Nestlekamleshsingh28533No ratings yet

- DatasheetDocument16 pagesDatasheetErick MauricioNo ratings yet

- Multilayer Chip Capacitors X7R/B Characteristic: FeaturesDocument17 pagesMultilayer Chip Capacitors X7R/B Characteristic: FeaturesLupita Motta TobíasNo ratings yet

- MTC Amazon NestleDocument1 pageMTC Amazon Nestlekamleshsingh28533No ratings yet

- Fibra FTTH SolutionsDocument26 pagesFibra FTTH SolutionsIjam AsNo ratings yet

- CD54 Surface Mount Power InductorDocument4 pagesCD54 Surface Mount Power InductorIvo MatosNo ratings yet

- MTC Kotagreen NestleDocument1 pageMTC Kotagreen Nestlekamleshsingh28533No ratings yet

- (35621) F. Cabo 12 Fibras Autosust As120m-12f G652D SMDocument5 pages(35621) F. Cabo 12 Fibras Autosust As120m-12f G652D SMAbelMouraNo ratings yet

- 3320Document2 pages3320victorNo ratings yet

- (5789) F. Cabo 24 Fibras Autosust As80m Gyfty24b1 G652DDocument3 pages(5789) F. Cabo 24 Fibras Autosust As80m Gyfty24b1 G652DAbelMouraNo ratings yet

- 20 Microns Coated Calcium Carbonate 1t VDocument1 page20 Microns Coated Calcium Carbonate 1t VChandrakantNo ratings yet

- Poplar Puls FBB GC2 - Shandong MillDocument1 pagePoplar Puls FBB GC2 - Shandong MillBill KingNo ratings yet

- Johnson Tiles Floor 60x60cm (New Collection) Catalogue VJWD Mar 23Document12 pagesJohnson Tiles Floor 60x60cm (New Collection) Catalogue VJWD Mar 23sudhakarvenkatesan31No ratings yet

- B1300 SM Ver1Document73 pagesB1300 SM Ver1Abd Elh AdiNo ratings yet

- Basalt RovingDocument2 pagesBasalt Rovingdmitry kudryashovNo ratings yet

- Ashoka International - 20220801 - 122153Document2 pagesAshoka International - 20220801 - 122153Pritpal SinghNo ratings yet

- Data Sheet-H140A (1) (1) - WAZAMDocument2 pagesData Sheet-H140A (1) (1) - WAZAMdaniel.rabahdunordNo ratings yet

- MDI Catalogue.Document18 pagesMDI Catalogue.N ThulasiramanNo ratings yet

- GYTS-Cable Specifications G655DDocument7 pagesGYTS-Cable Specifications G655DcxhernanNo ratings yet

- Elite (Radial Thru-Hole) LM SeriesDocument2 pagesElite (Radial Thru-Hole) LM Serieszuigh899gNo ratings yet

- Specifications For Toilet IIDocument2 pagesSpecifications For Toilet IIKushagri JoshiNo ratings yet

- Napkin I - Specification SheetDocument2 pagesNapkin I - Specification SheetKushagri JoshiNo ratings yet

- Specifications For Toilet IDocument2 pagesSpecifications For Toilet IKushagri JoshiNo ratings yet

- Kitchen Towel I - Specification SheetDocument2 pagesKitchen Towel I - Specification SheetKushagri JoshiNo ratings yet

- January NewsletterDocument2 pagesJanuary NewsletterKushagri JoshiNo ratings yet

- October NewsletterDocument2 pagesOctober NewsletterKushagri JoshiNo ratings yet

- CS F342-11 PDFDocument24 pagesCS F342-11 PDFsky_davisNo ratings yet

- What Is AgilityDocument8 pagesWhat Is AgilityJustinNepomuceno100% (1)

- Tiss Sample Test PaperDocument53 pagesTiss Sample Test PaperLight ZoomNo ratings yet

- Study On Vibration Analysis For Printed Circuit Board of An Electronic ApparatusDocument6 pagesStudy On Vibration Analysis For Printed Circuit Board of An Electronic ApparatusAnand Ras100% (1)

- Da 1998Document17 pagesDa 1998Paul DumitruNo ratings yet

- Mif Brochure PDFDocument28 pagesMif Brochure PDFcommerce.academy.bamNo ratings yet

- Advertisement AnalysisDocument4 pagesAdvertisement AnalysisbhavaniNo ratings yet

- Teacher S Feedback Sutanaree and Saehara 417 311 Argumentative Essay Exercise G 1Document3 pagesTeacher S Feedback Sutanaree and Saehara 417 311 Argumentative Essay Exercise G 1Saimee AbuNo ratings yet

- 2Nd Generation Cpted: An Antidote To The Social Y2K Virus of Urban DesignDocument19 pages2Nd Generation Cpted: An Antidote To The Social Y2K Virus of Urban DesignFábio SalvadorNo ratings yet

- Producing Clinical Laboratory Shift Tables From Adam Data: Rao Bingi, Octagon Research Solutions, Wayne, PADocument12 pagesProducing Clinical Laboratory Shift Tables From Adam Data: Rao Bingi, Octagon Research Solutions, Wayne, PAlenithNo ratings yet

- US20190295733A1 - Pasma Compression Fusion DeviceDocument8 pagesUS20190295733A1 - Pasma Compression Fusion DevicedaveklodavekloNo ratings yet

- CIE 2010 Handbook For Centres - IGCSE - O-Levels - A-LevelsDocument124 pagesCIE 2010 Handbook For Centres - IGCSE - O-Levels - A-Levelssafwan120% (1)

- Kent 1997 Milling ModellingDocument7 pagesKent 1997 Milling Modellinggustool7No ratings yet

- For Front End Point Protection 2012 R 2Document29 pagesFor Front End Point Protection 2012 R 2Karim MessoussiNo ratings yet

- The Engine Oil BibleDocument28 pagesThe Engine Oil BibleJacques SwartNo ratings yet

- Iasp Finalpreview - PHP Absnum 107579Document2 pagesIasp Finalpreview - PHP Absnum 107579eswar110582No ratings yet

- Turbidity Sensor SKU SEN0189-DFRobotDocument4 pagesTurbidity Sensor SKU SEN0189-DFRobotBlak Dia MondNo ratings yet

- Practical Research 2.4Document7 pagesPractical Research 2.4Michael GabertanNo ratings yet

- Manish Kumar Jadaun: Personal Info Current Work ProfileDocument1 pageManish Kumar Jadaun: Personal Info Current Work ProfileEr Manish JadaunNo ratings yet

- Nadig Press Newspaper Chicago June 26 2013 EditionDocument22 pagesNadig Press Newspaper Chicago June 26 2013 EditionchicagokenjiNo ratings yet

- DFA Interpretation HelpDocument36 pagesDFA Interpretation Helpanupam99276No ratings yet

- Sekolah Menengah Kebangsaansura 23000 Dungun, TerengganuDocument14 pagesSekolah Menengah Kebangsaansura 23000 Dungun, TerengganuSUHAINA BINTI SAMSUDIN -No ratings yet

- Annotation - Objective 12Document1 pageAnnotation - Objective 12ROGER RAYMUND MALESIDONo ratings yet

- Activities For Oral ComDocument3 pagesActivities For Oral ComHanna Vin JuezanNo ratings yet

- SWDD TemplateDocument6 pagesSWDD TemplateSulthonul MubarokNo ratings yet

- New Welding Technologies in The ShipbuildingDocument2 pagesNew Welding Technologies in The ShipbuildingTahsinul Haque TasifNo ratings yet

- Sydsaeter Instructor ManualDocument11 pagesSydsaeter Instructor ManualPreetinder Kaur100% (1)